Metal Matrix Engineering Plates

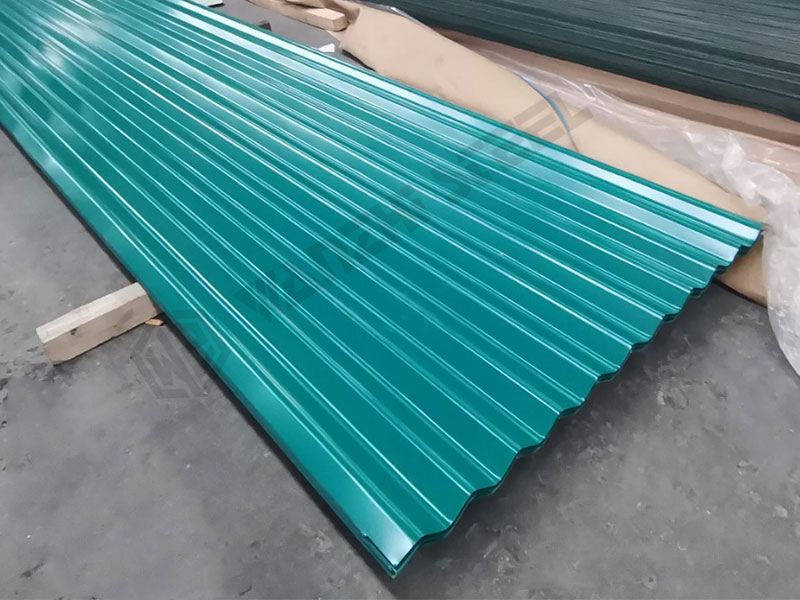

Spray-coated panels are an economical and practical base material manufactured by applying electrostatic spray coating (commonly polyester PE paint) onto galvanized or aluminized steel substrates. Its primary advantages lie in low cost, diverse color options, and excellent processing adaptability. It accommodates varied color requirements and facilitates forming operations like cutting and bending. Due to its relatively average weather resistance, it is primarily used in indoor environments, appliance casings, or as non-exposed backing panels in architectural decoration.

Nano-composite Panel

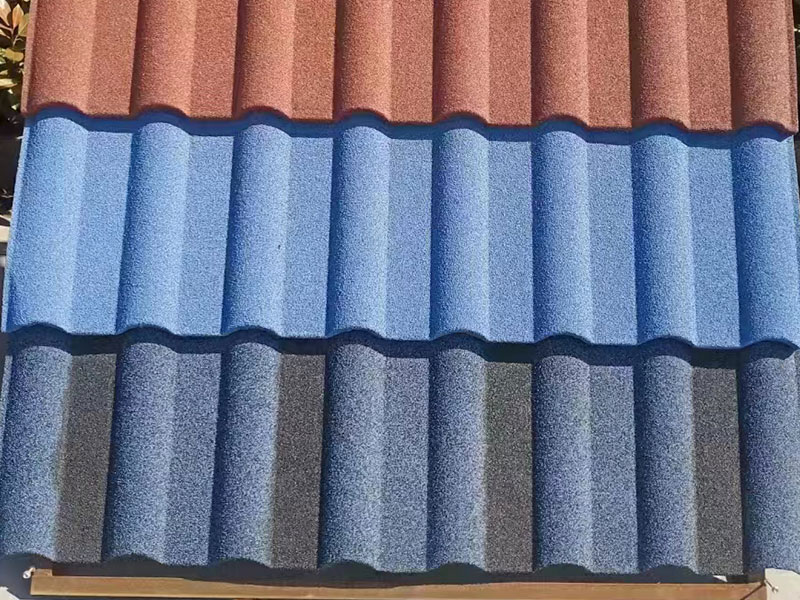

Nano-composite panels represent an upgraded version of traditional coatings. By incorporating nano-materials (such as SiO₂ or TiO₂) into the coating, they achieve self-cleaning and antibacterial properties, effectively reducing stain adhesion and microbial growth. They also offer exceptional weather resistance and UV protection, making them ideal for high-end architectural curtain walls, hospitals, laboratories, and similar spaces.

Tinplate

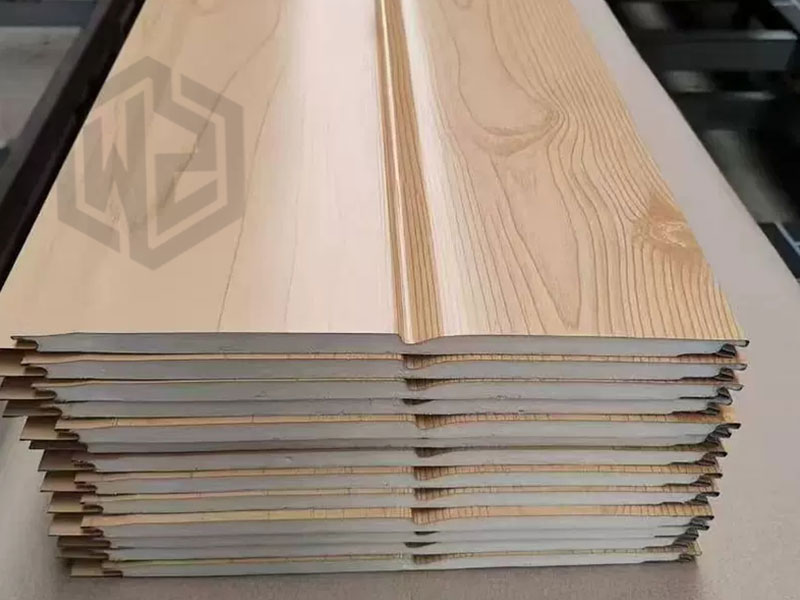

Tinplate, also known as tin-plated steel, is produced by coating low-carbon steel substrates with a layer of tin. The tin coating is non-toxic and odorless, meeting food contact standards; it effectively resists corrosion from various media; and offers excellent weldability and ductility. It is a classic material for food packaging cans, chemical storage tanks, and electromagnetic shielding enclosures for electronic products.