AluZinc AZ150 is an alloy coating consisting of 55% aluminum, 43.4% zinc and 1.6% silicon, and is also known as Galvalume steel, GL steel. AZ150 refers to a coating weight of 150 g/m2 (total of both sides, i.e., average of 75 g/m2 on each side), which belongs to the high-coating quantity, super-protective grade of Aluminum-Zinc Alloy Coating. Steel.

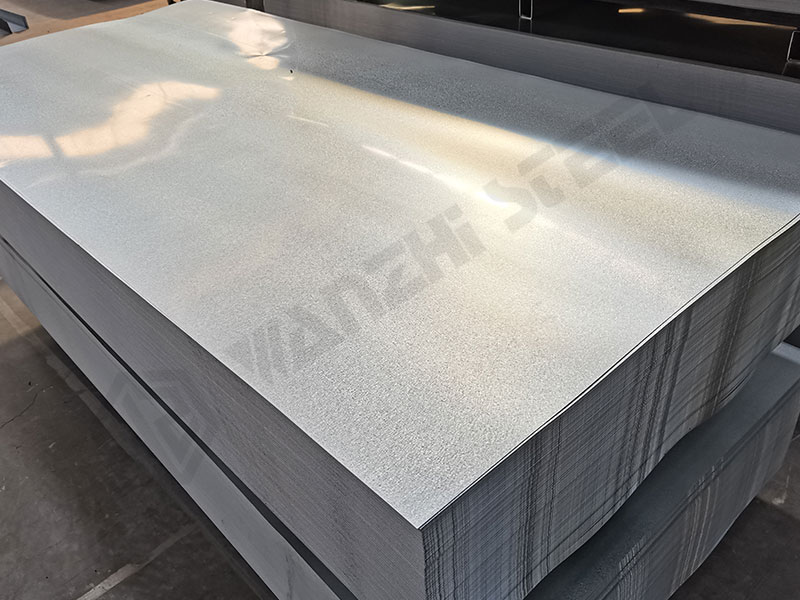

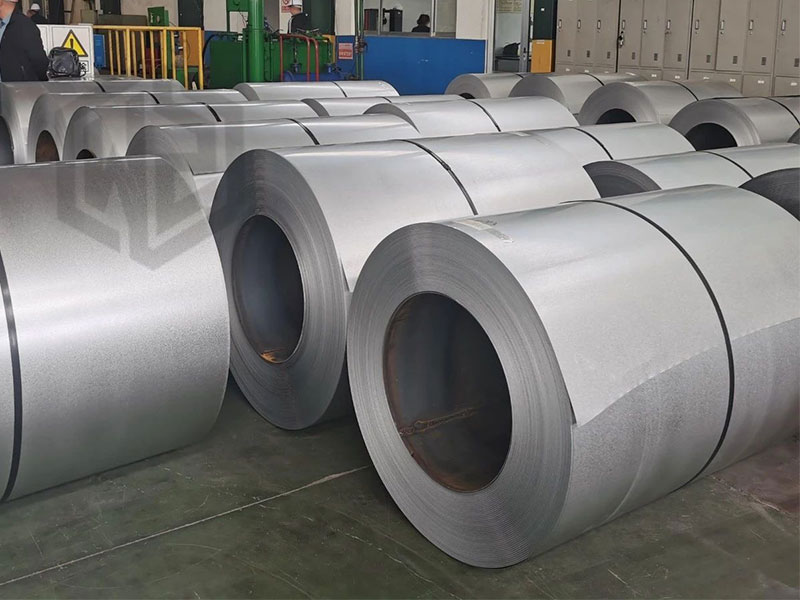

AluZinc AZ150 for Sale

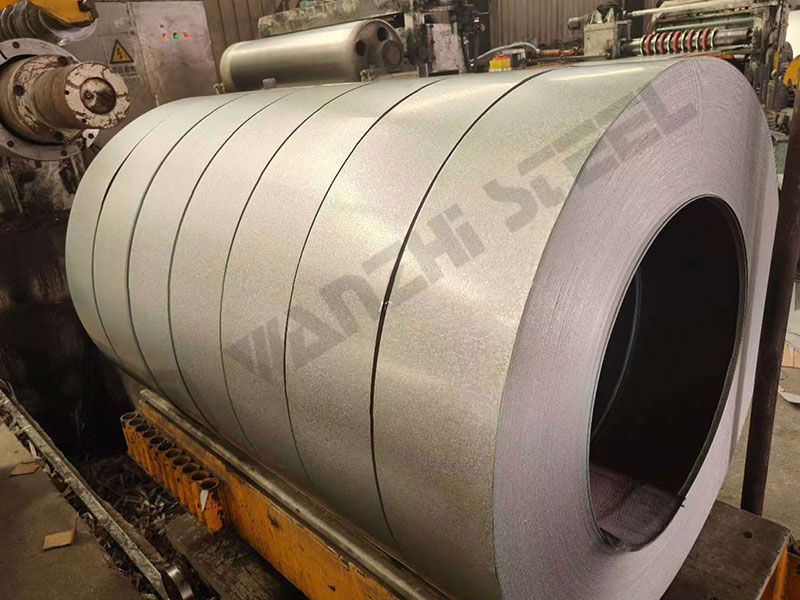

AluZinc AZ150 is made of high quality low carbon cold rolled steel coils such as DX51D, DX52D, DX53D, DX54D, S250GD, S320GD, S350GD, etc. The surface of the steel is coated with zinc-aluminum alloy with a total weight of 150g on both sides and is made of aluminum-zinc-plated steel, which is in accordance with the international standards of EN 10346 / ASTM A792. Wanzhi Group provides alu-zinc steel coil and sheet in accordance with EN 10346 / ASTM A792 and other international standards, and can be customized according to application requirements.

Specification

Standard: Comply with EN 10346:2015, ASTM A792/A792M and other international standards

Coating composition: 55% Al, 43.4% Zn, 1.6% Si.

Coating weight: 150 g/m2 .

| Type | Galvalume Steel |

|---|---|

| Thickness | 0.15-6 mm |

| Width | 600-1250 mm |

| Packing Weight | 5-10t, customize |

| Aluzinc Coating | AZ20-AZ350 g/m2, 40-150 micron. |

| Surface Finish | oiled, chrome plated, anti-fingerprint, lacquered, etc. |

| Quality | SGS, ISO, support third-party organization testing |

AluZinc AZ150 Price

AluZinc AZ150 is a highly coated alloy coated steel, the price per ton is 650-850USD, in addition to the thickness of the zinc layer, the substrate material specifications, width, thickness, surface treatment, the number of purchases will affect the final price, leave a message to tell us the specifications of the product you need, get a free quote!

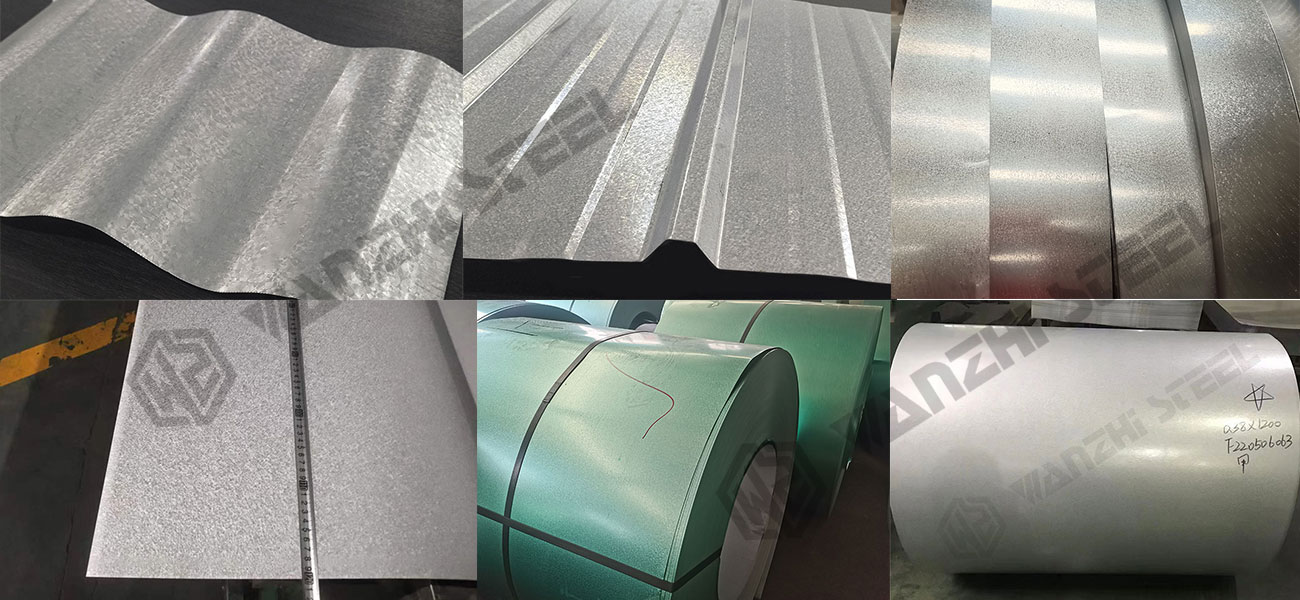

Surface Finish

AluZinc AZ150 has a silver-white matte appearance, because it contains silicon elements that inhibit the formation of zinc crystals, so the surface does not have the “zinc spangle” texture of traditional galvanizing, and presents a uniform and delicate matte effect coating uniformity and good corrosion resistance.

Of course, to improve corrosion resistance, paintability or functionality, surface treatments can be applied to zinc-aluminized steel, including: chemical passivation, fingerprint-resistant treatment, oiling, phosphating, etc.

- Chemical passivation: prevents white rust

- Fingerprint-resistant treatment: keeps the surface clean and aesthetic.

Mechanical Properties

- Mechanical properties of AluZinc steel are determined by the grade of the substrate

- Yield strength ReH: 250-350 MPa

- Tensile strength Rm: 320-450 MPa

- Elongation A80

Performance Certifications

- Corrosion resistance: Evaluated by salt spray test (e.g. ISO 9227 NSS, ASTM B117, ISO 8565).

- Corrosion resistance to cuts: Tested by scratch salt spray test.

- Adhesion / Processability: Verified by bending test, impact test (ISO 6272), T-bend test (after color coating), etc.

- Heat reflectivity: ASTM E903, ASTM C1549.

Further Processing

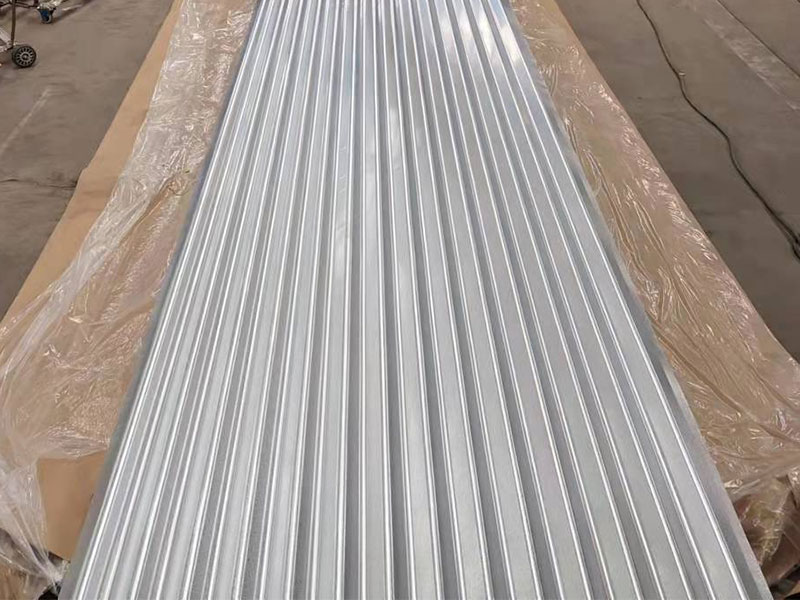

- Raw Material Processing: Aluzinc steel can be curled, flattened, slit, bent, formed, stamped, welded, and the finished products are aluzinc coil, aluzinc sheet, aluzinc roofing, aluzinc embossed sheet, and ect.

- Paint Processing: Aluzinc steel Paint treatment: AZ100-AZ150 as the substrate roller coating PE/SMP/PVDF/HDP/PU and other materials, the finished product has painted aluzinc coil, painted aluzinc sheet, painted aluzinc roofing etc.

Overwhelming Advantages and Applications of AluZinc AZ150

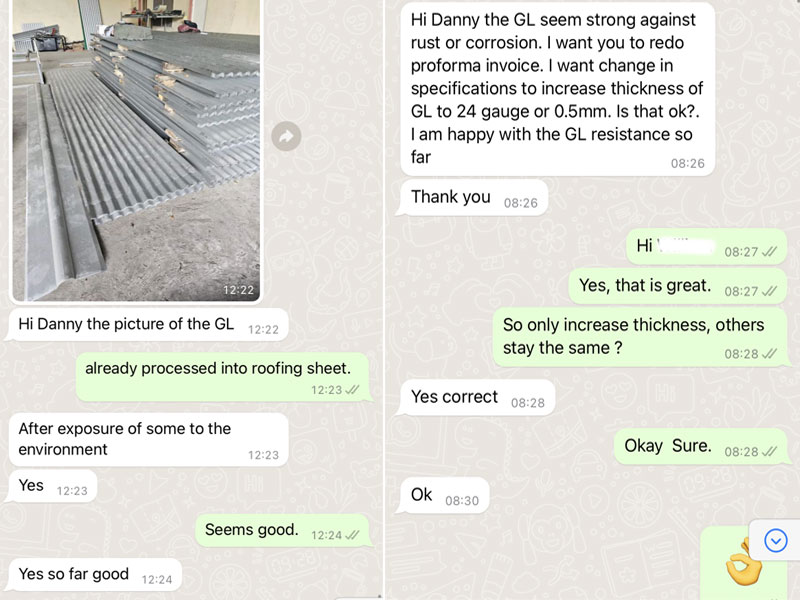

AZ150 has overwhelming advantages in resistance to atmospheric corrosion, notch corrosion, weathering, heat reflectivity, and design life for a wide range of applications in the construction, industrial, appliance manufacturing, and energy sectors that require a long, low-maintenance service life in harsh environments, especially coastal, industrial, and high humidity environments.

Benefits

Exceptional corrosion resistance:

- 3-6 times more galvanized: AZ150 has a much longer corrosion life than pure zinc, even more than twice as long as Z275, for the same plating weight and in harsh environments (e.g. industrial, coastal, high humidity).

Superior weathering:

- The +55% aluminum content of the AZ150 coating gives it excellent UV resistance and color stability, resulting in long term aesthetics and reduced maintenance requirements.

Excellent heat resistance:

- The oxidative stability of the aluminum gives it good protection at higher temperatures (e.g. roofs in direct sunlight) than pure zinc.

Excellent cut edge protection:

- Aluzinc has a unique “self-healing” property. At scratches and cut edges, it forms a dense corrosion product that slows the spread of red rust to the interior of the steel sheet.

Excellent Heat Reflectivity:

- Aluzinc’s bright white surface has a high solar reflectivity. It reflects most of the solar radiation and effectively reduces the internal temperature of the building.

Good processing and molding properties:

- Suitable for a variety of roll forming, stamping, bending and other processing, not easy to appear plating flaking or chalking.

Adaptability to coating:

- Uniform and clean surface is the ideal color coated substrate, which can be perfectly combined with various high-performance coatings (PVDF, SMP, PE/Polyester, etc.) to form a color coated aluzinc steel (PPGL steel).

Excellent resistance to oxidation at high temperatures:

- At higher temperatures, the aluminum-zinc coating’s resistance to oxidative discoloration and peeling is superior to that of pure zinc coatings.

Economical and long-life value:

- has a service life of 25 years or more and is lightweight.

Application Scenarios

- Building Roof and Wall Systems: Large industrial plants, logistics warehouses, commercial complexes, public buildings (airports, stadiums).

- High-end civil roofing: villas, high-grade housing.

- Severe industrial environments: chemical parks, coastal facilities, internal and external components (such as purlins, wall beams, ventilation ducts) of plants with high humidity.

- Agricultural buildings: Livestock farms, greenhouses.

- Photovoltaic racking systems.

- Electrical enclosures and ventilation ducts.

Aluzinc AZ150 VS. Z (GI steel)、ZAM

| Property/Coating Type | AZ150 (AluZinc) | Z (Pure Hot-Dip Galvanized) | ZAM (Zinc-Aluminum-Magnesium) |

| Main Components | 55% Al, 43.4% Zn, 1.6% Si | ≥99% Zn | Zn + 1.5-10% Al + 1-3% Mg (+Si) |

| Coating Amount Represented | 150 g/m² (High) | e.g., Z180 (180 g/m²) | e.g., ZM150 (150 g/m²) |

| Core Advantages | Super high corrosion resistance, excellent notch resistance,excellent weather/heat reflection, long lifespan, high cost-performance ratio | Low cost, mature process, good cathodic protection | Extreme notch/scratch resistance, excellent formability, high corrosion resistance (especially after scratching) |

| Atmospheric Corrosion Resistance | (Extremely high, 3-6 times higher than Z) | Good | Extremely high, comparable to or better than AZ150 |

| Notch/Scratch Protection | Excellent, “self-healing” | Poor | Top-notch, “self-healing” is very strong |

| Weather/Heat Reflection | Optimal | Poor, prone to oxidation and darkening | Medium, depending on specific composition |

| Formability | Excellent | Good | Optimal, reduced friction |

| Typical Applications | High-end roofing/walls, harsh environments, long lifespan requirements, photovoltaic brackets | Cost-sensitive, non-harsh environments, structural parts | Extreme notch/deformation requirements, car chassis, fasteners, high-wear environments |

| Cost | Medium to high, but the best LCC (Life Cycle Cost) | Low | Highest |

AluZinc AZ150 Factory from China

Wanzhi Group is an Aluzinc factory supplier from China, we have provided GI GL PPGI PPGL OEM ODM service to more than 100+ countries and regions worldwide. In addition to manufacturing and processing, we also provide quality inspection, free samples, customized solutions and other services, welcome to contact us for Premium AluZinc steel price.

Certificates

Production Line

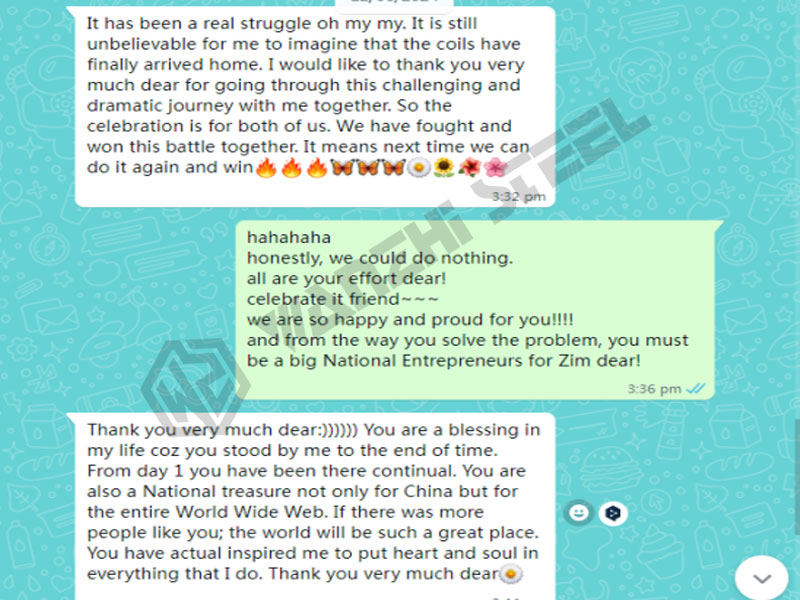

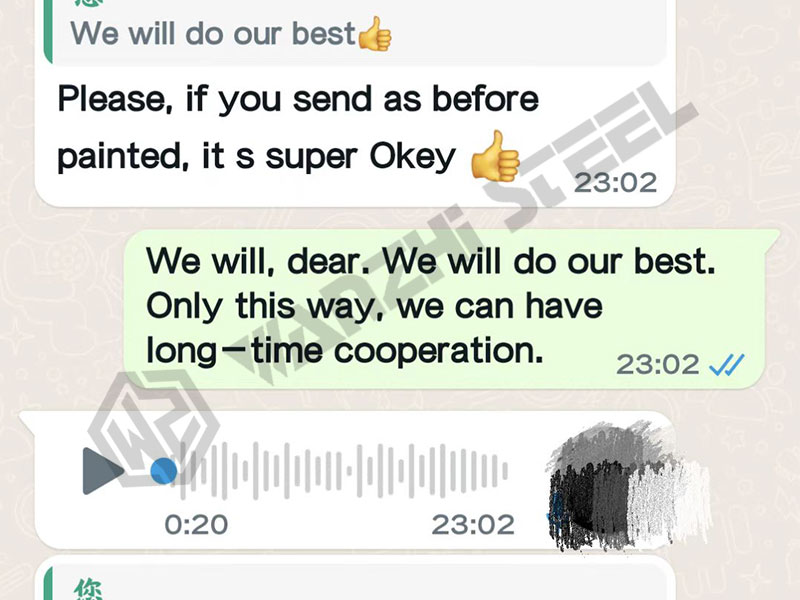

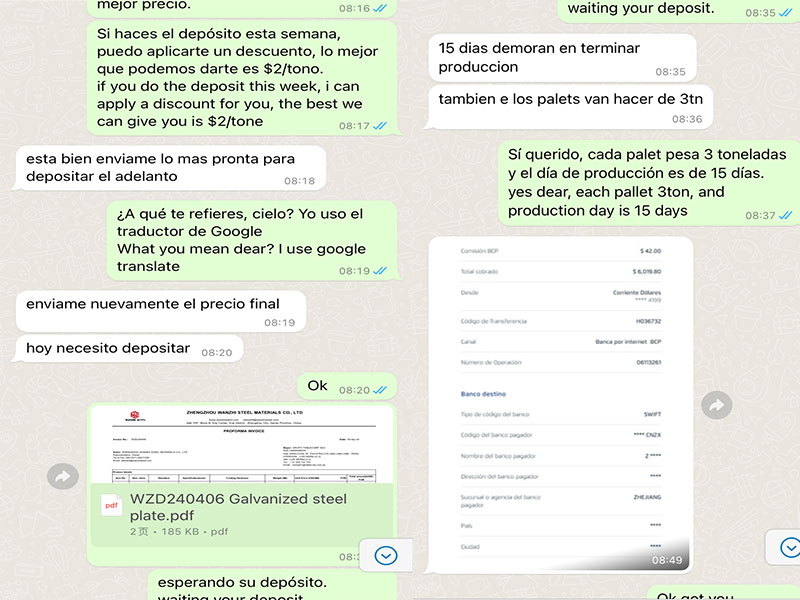

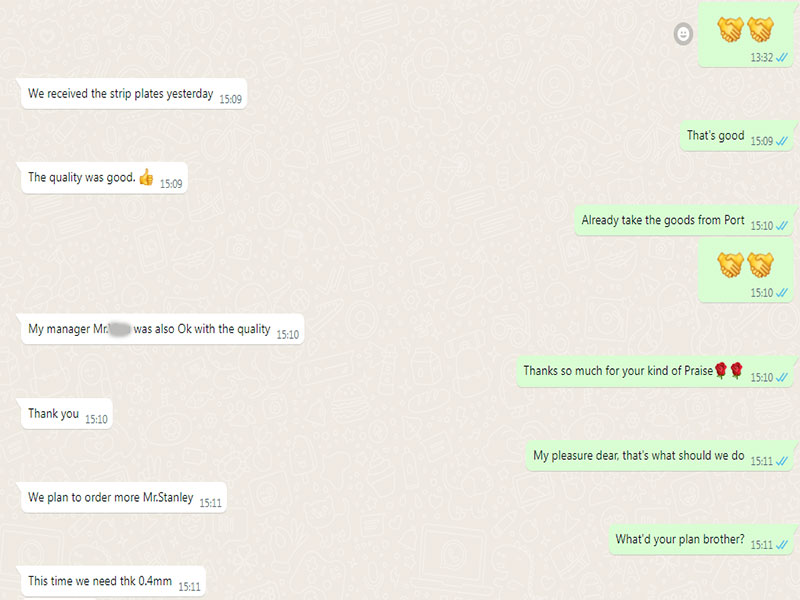

Customer Feedback

AluZinc AZ150 has become the preferred solution for harsh industrial environments due to its unique self-repairing properties, high level of protection, and high return on investment, which plays an important role in metal corrosion protection.