The zinc coating on the surface of galvanized steel determines the corrosion resistance and service life of the steel. Different galvanizing finishes determine the thickness of the zinc coating, the application, and the cost. The most common types of galvanizing finishes are hot-dip galvanizing, electro-galvanizing, powder, and mechanical galvanizing. Wanzhi Group’s galvanized steel is primarily hot-dip galvanized and electro-galvanized.

What is Galvanized Steel Finish?

Wanzhi Group’s galvanized products are available in both hot-dip galvanized and electro-galvanized finishes. The galvanized steel can be customized according to the product, finish, and application required by the customer.

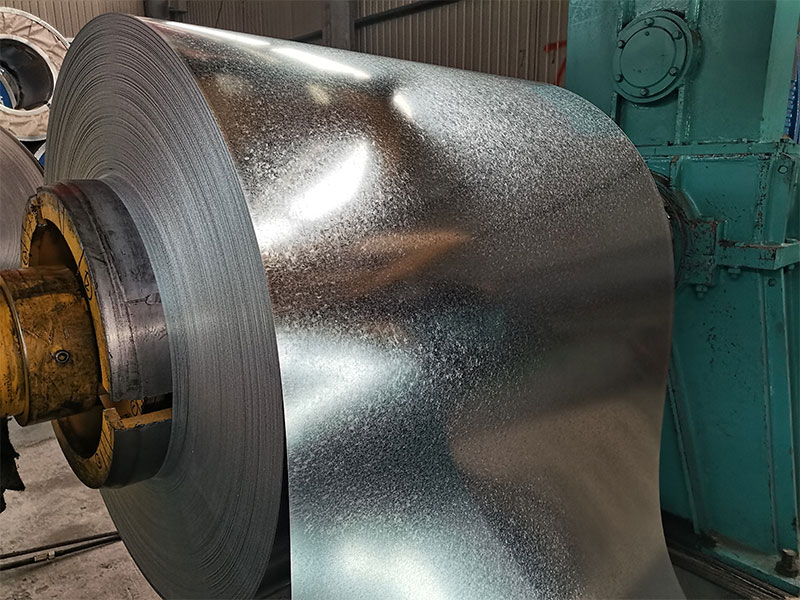

Hot-dip Galvanized Steel

Process: The substrate (cold rolled sheet/hot rolled sheet/strip) is immersed in a high-temperature zinc solution at about 450 degrees Celsius, where the steel and the zinc solution react to form a thick coating of zinc on the surface.

Surface: zero spangle, large spangle, small spangle, regular spangle.

Advantages: low processing cost, high galvanizing efficiency, thick zinc coating, good corrosion resistance.

Application: Suitable for outdoor and harsh environments.

Electro-galvanized Steel

Process: The substrate is passed through an electrolytic solution containing zinc ions and a zinc coating is deposited on the surface of the steel using electrolysis.

Surface: No zinc bloom.

Advantage: Smooth and decorative surface.

Application: Suitable for indoor and dry environments.

What are the post-treatment options for galvanized steel?

To give the steel a better corrosion protection and decorative effect, the surface of galvanized steel can be further treated, e.g. passivated, oiled, lacquered, phosphate treated, etc.

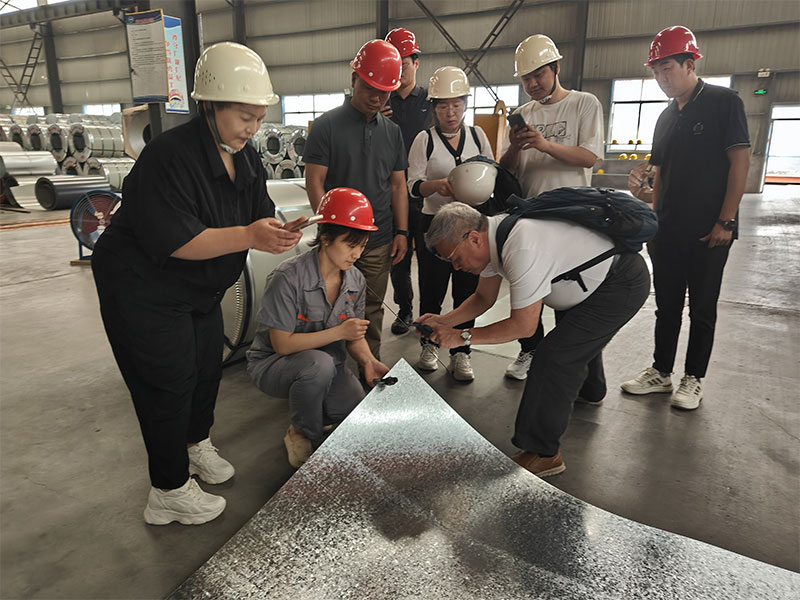

How to Choose Galvanized Steel?

The different galvanized steel surface finishes are designed to maximize the performance of the steel and the coating to extend the life of the steel. Depending on your project budget, application, and other factors, you can choose the steel that best suits your needs. Contact us, we have galvanized steel solutions for all industries.

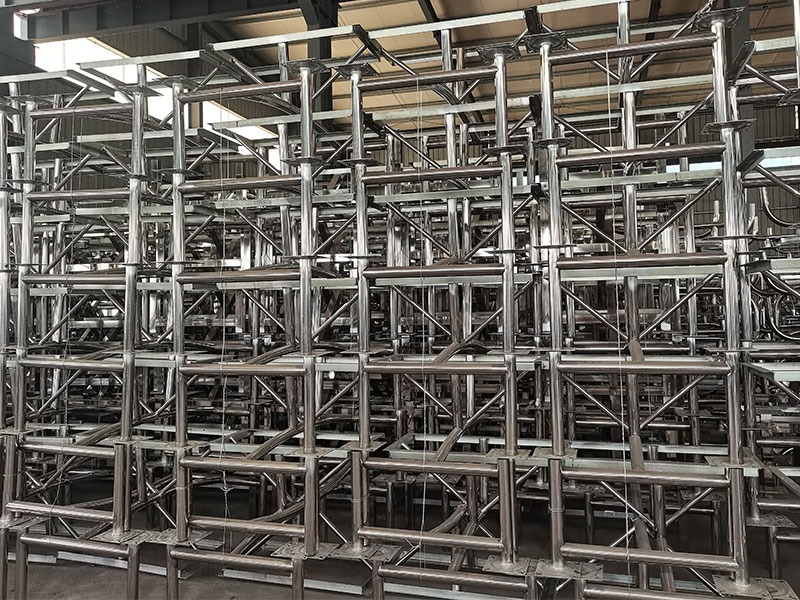

Galvanized Steel Products of Wanzhi Group

Our factory produces Z30-Z350 galvanized products, including galvanized coil, galvanized sheet, galvanized strip and other production materials, as well as galvanized roofing, galvanized pipe, galvanized post, galvanized nails, galvanized planters and other finished products.

Wanzhi Galvanized Product Specifications

| Material | SGCC,S350GD+Z,S550GD+Z,DX51D,DX52D,DX53D, etc |

|---|---|

| Thickness | 0.12mm-6mm |

| Width | The conventional width below 0.5mm is 1000mm, 1200mm, and above is 1000, 1250mm |

| coil weight | 8-10 tons /customized |

| Tolerance | "+/-0.02 mm |

| Substrate Type | Hot rolled coil, Cold rolled coil |

| Surface structure | Zero spangles, Small spangles, Regular spangles, Big spangles |

| Zinc layer thickness | 30g/㎡-275g/㎡ (Z275/G90) |

| Standard | AISI, ASTM, BS, GB, JIS |

| Implementation standards | GB/T2518 GB/T25052, EN10346, JIS G3302, ASTMA653 |

| Certificates | SGS, ISO 9001,CE |

If you have any other questions about galvanized steel surface finishes, feel free to leave a comment and let us know, we’ll answer them for you.