What is Galvanized Steel?

Galvanized steel is a composite material that covers ordinary steel with a layer of zinc, the core advantage of which lies in the zinc’s “sacrificial anode” protection mechanism. Zinc is chemically more reactive than iron, so when steel is exposed to corrosive environments, the zinc layer reacts preferentially with oxygen and moisture, slowing down the corrosion of the steel.

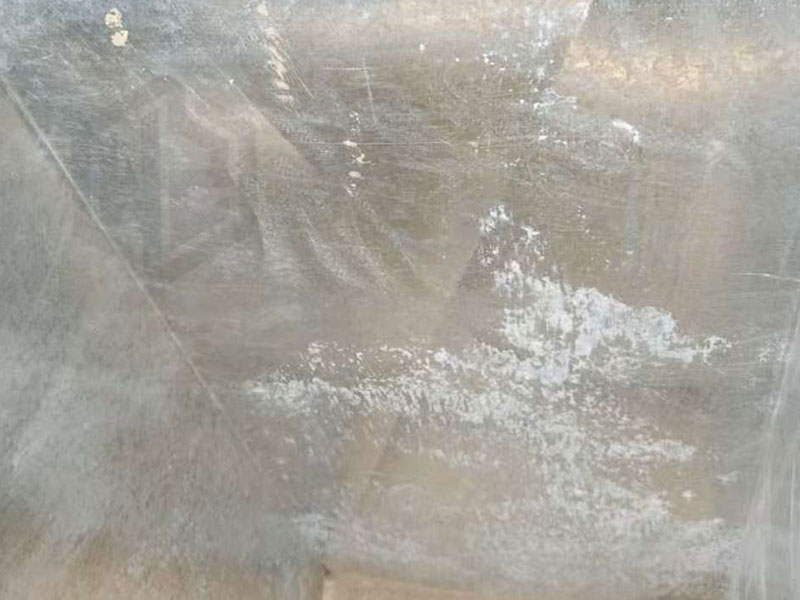

Why Does Galvanized Steel Produce White Rust on its Surface?

When galvanized steel coil is in a humid, high temperature, poor air circulation, corrosive environment, the surface of galvanized steel does not have a free flow of air and can easily form white rust / black spots and other electrochemical corrosion rust on the surface, this phenomenon is often called alkali return phenomenon.

The Chemical Nature of White Rust

White rust is a corrosion product of zinc, mainly composed of zinc hydroxide (Zn(OH)₂) and alkaline zinc carbonate (Zn₅(OH)₆(CO₃)₂), in the form of white or off-white powder. The formation process can be simplified as: Zinc (Zn) + water (H₂O) + carbon dioxide (CO₂) → zinc hydroxide + zinc carbonate.

Trigger conditions for white rust

| Factors | Specific effects |

| High humidity | Corrosion is caused by condensation on the zinc surface when the relative humidity exceeds 60%. |

| Confined environments | poor ventilation leads to accumulation of corrosion products (e.g. inside sea containers) |

| Electrolyte exposure | salt spray, acid rain, industrial pollutants accelerate electrochemical reactions |

| Mechanical damage | scratches or uneven plating increase the exposed area of zinc |

Hazards of white rust

- Reduces aesthetics: White patches affect the appearance of the product.

- Weakens protection: White rust areas deplete the zinc layer faster, eventually leading to rusting of the underlying steel.

- Increased maintenance costs: Severe white rust requires professional restoration, which can cost 30-50% of a new coating.

4 Steps to Remove White Rust from Galvanized Steel

First, assess the surface area of white rust on galvanized steel, and select the cleaning method according to the severity of the white rust, after the white rust is cleaned, passivation treatment can be performed to enhance the corrosion resistance of galvanized steel, and finally regular maintenance.

Step 1: Evaluate the severity of white rust

- Light white rust (<10% of the surface area): only a small amount of white powder on the surface, the zinc layer has not penetrated.

- Moderate white rust (area 10-30%): localized thinning of the zinc layer, with a gray base visible.

- Heavy white rust (area > 30%): the zinc layer is completely detached, and the steel begins to rust red.

Step 2: Choose the right cleaning method

Method ① Mechanical removal method (suitable for light to medium white rust)

Tools: Nylon brush, cleaning cloth, 1200 mesh fine sandpaper

Operation:

- Dry brush to remove loose white rust on the surface.

- Wipe with a sponge moistened with pH-neutral detergent.

- Rinse with clean water and dry immediately with a dry cloth.

- Note: Avoid using steel wool or coarse sandpaper to avoid damaging the zinc layer.

Method ② Chemical dissolution method (suitable for stubborn white rust)

Recipe:

- Household solution: white vinegar (5% acetic acid) mixed with water at 1:3.

- Industrial solution: 5% citric acid solution or special zinc rust remover.

Operation:

- Apply the solution to the rust spot and leave it for 5-10 minutes.

- Brush gently with a soft bristle brush.

- Rinse with plenty of water and dry thoroughly.

- Warning: Strong acids such as hydrochloric acid are prohibited, otherwise the zinc layer will be destroyed!

Method ③ Professional repair (heavy white rust)

- Cold spray zinc repair: Use repair paint containing 96% zinc powder (e.g. ZRC brand), spraying thickness should be more than 80μm.

- Hot dip plating rework: need to send back to the factory to re-galvanize, higher cost but lasting effect.

Step 3: Surface passivation

After removing white rust, spray the surface with a chromate passivator (e.g. SurTec 650) to form a dense oxidized film, which can increase corrosion resistance by 3 times.

Step 4: Preventive Measures

- Control ambient humidity: Use a dehumidifier to maintain humidity <50%.

- Regular Maintenance: Wipe the surface with WD-40 rust inhibitor every 3 months.

- Avoid contact with corrosion sources: Keep away from seawater, snowmelt salt, acid, and alkali chemicals.

Recommended Maintenance Intervals for Galvanized Steel

The maintenance intervals and frequency of inspection of galvanized steel can vary in different environments. The main way to avoid white rust on the surface of galvanized steel is to keep the surface of the steel dry and clean. Regular maintenance of the steel can extend the service life of GI steel to more than 30 years!

- Galvanized steel used indoors in dry environments should be inspected once a year, and if white rust appears it should be wiped down with a neutral detergent.

- Coastal/industrial zones are best inspected quarterly and can be maintained by passivation treatment + rust inhibitor.

- Cold chain/high humidity places need to be checked once a month, real-time monitoring of humidity, and timely rust removal.

Frequently Asked Questions about GI Steel Rust

Q1: What is the difference between white rust and red rust?

- White rust: zinc corrosion products, white powder, can be repaired by cleaning.

- Red rust: Iron oxide (Fe₂O₃), indicating that the zinc layer has failed and the part needs to be replaced immediately.

Q2: Can galvanized steel still be rustproof after white rust?

After treatment of mild white rust, the remaining zinc layer is still protective; if the zinc layer is depleted by more than 50%, zinc replenishment or replacement is required.

Q3: Is it possible to cover white rust with paint?

Not! Unremoved white rust will continue to spread under the paint film and cause blistering and peeling of the coating.

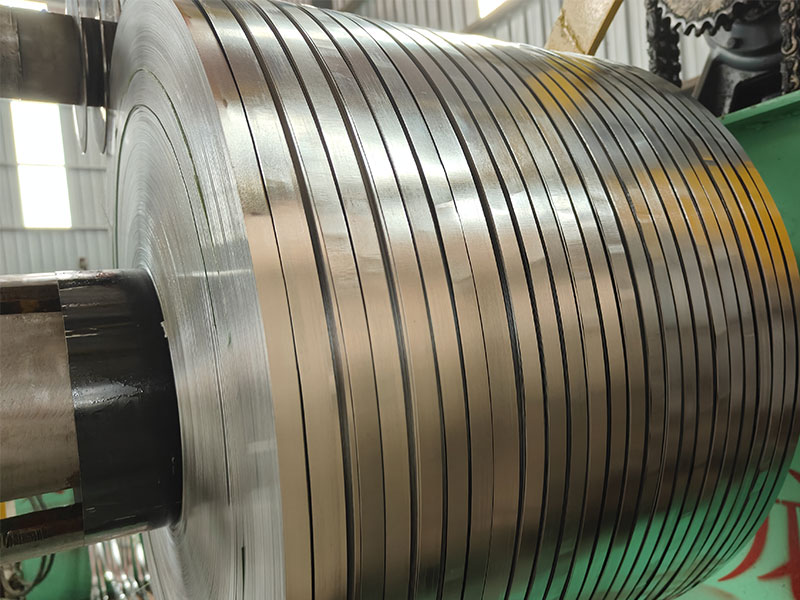

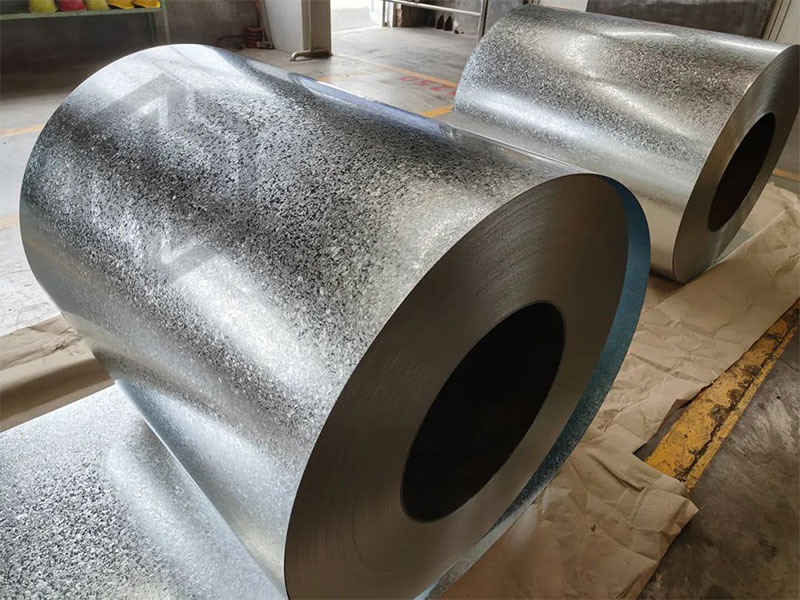

Galvanized Products – Wanzhi

Wanzhi Group is a galvanized steel manufacturer from China, we have a professional galvanized steel production line that has diversified premium galvanized steel products: galvanized steel coil, galvanized steel sheet, galvanized steel strip, galvanized roofing sheet, galvanized steel coil, galvanized steel wire and so on, welcome to contact us for more galvanized related questions!