PPGI profile sheet, pre-coated galvanized corrugated steel sheet, is a panel with a wavy/trapezoidal cross-section characteristic on its surface, produced by cold-forming pre-coated galvanized coils or pre-coated galvanized flat sheets. The design of profile sheets meets the requirements of residential, commercial, and industrial buildings for large spans, high loads, and rapid construction, while offering a wide range of colors and surface finishes. Classic applications include roof profiled sheets, wall profiled sheets (internal partitions, exterior facades, etc.).

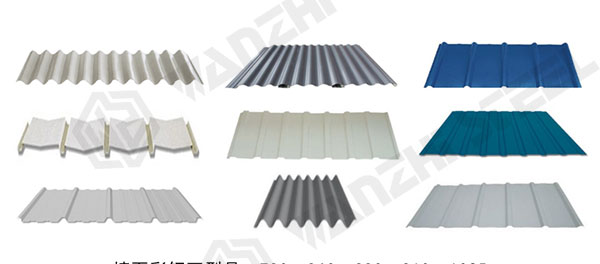

PPGI Profile Sheet Popular Panel Types

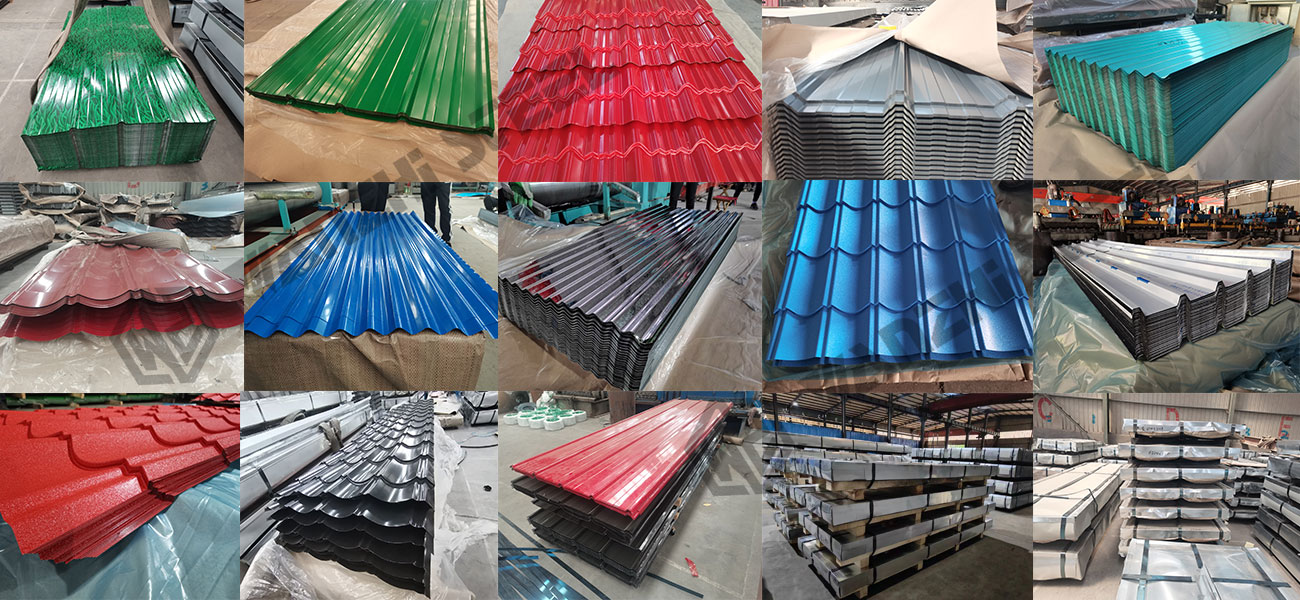

Based on the different requirements of industrial buildings, commercial buildings, residential buildings, agricultural buildings, and other types of buildings, Wanzhi Group provides OEM/ODM PPGI profile sheets and drawings. Let us produce finished pre-coated galvanized steel sheets for you!

PPGI Corrugated Profile

The corrugated design on the surface of PPGI steel sheet offers excellent mechanical properties and drainage performance, while also enhancing the panel’s stiffness. It is the preferred metal panel material for agricultural greenhouses, temporary shelters, sloped roofs, and more. The wave height and wave spacing can be customized according to application requirements.

- Recommendation: The optimal wind resistance is achieved when the wave height/wave spacing ratio is approximately 0.2.

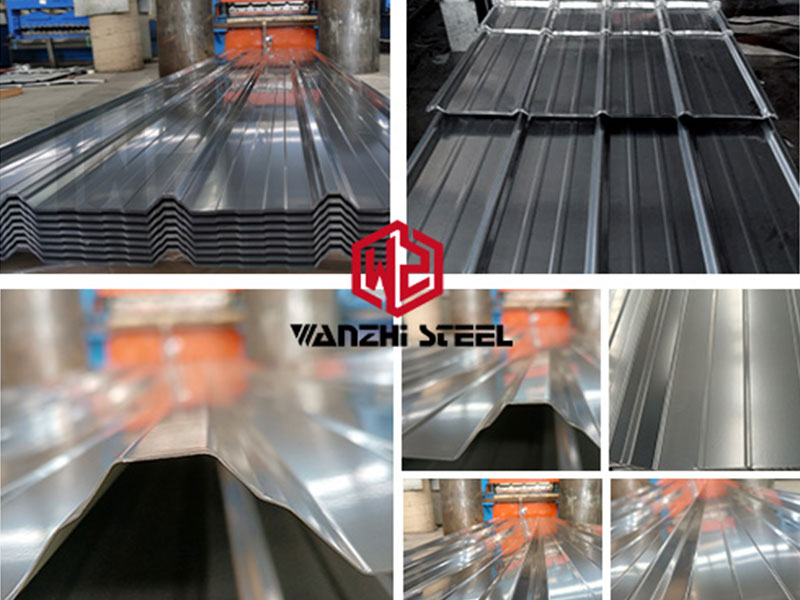

PPGI Trapezoidal Rib Profile

The trapezoidal cross-section, with its higher rib height, offers greater strength and can withstand heavier loads. It is commonly used for wall cladding, interior ceilings, industrial building roofs, and large-span warehouses. The rib height, rib spacing, and width can be customized according to actual application requirements.

PPGI Box Rib Profile

This is a profiled sheet with a closed rectangular cavity cross-section. Its key feature is strong wind uplift resistance, and it can achieve sound insulation by filling the cavity with core material. Rib height and cavity width can also be customized. It is commonly used in commercial applications such as airport terminals, hospital cleanrooms, and high-end commercial complexes.

Special Customized Panel Types

In addition to wave and trapezoidal surfaces, Wanzhi Group also produces removable fan-shaped panels, anti-slip panels, imitation tile panels, and other metal panels with special surface structures to meet different application requirements.

- Fan-fold panels: Foldable design, reusable

- Diamond-embossed panels: Surface features multiple shaped raised patterns to enhance slip resistance.

- Tile-effect panels: Wave height mimics the curved surface of traditional clay tiles, serving as an alternative to conventional clay tiles.

PPGI Profile Sheet Core Characteristics

- Lightweight: The density of PPGI sheets is only 7.85 g/cm³, lighter than concrete slabs/ceramic tiles, reducing building loads.

- Formability: Metal profile sheets are manufactured through cold-forming processes with high precision, supporting custom wave-shaped/trapezoidal/box-ribbed surface structures.

- Weather Resistance: Galvanized substrate + organic coating (PE/HDP/PVDF/HDP/PVDF), with a warranty of 10-25 years.

- Construction Efficiency: Standard sheet length ≤12m, installed on-site via bolt/interlocking connections, offering higher processing efficiency than traditional building materials.

Recommended Application Scenarios for PPGI Profile Sheets

Building roof systems and wall systems are the primary application areas for PPGI profile sheets. Their diverse surface structures, coating materials, colors, and patterns provide excellent waterproofing, drainage performance, weather resistance, aesthetic appeal, thermal insulation, and corrosion resistance, meeting various building requirements for load-bearing capacity, structural support performance, and rapid installation.

| Scene | Recommended Panel Type | Coating Scheme | Advantages |

| Industrial Building Roof | PPGI High Corrugated Profile Rib | PVDF Coating | Wind pressure resistance |

| Commercial Building Walls | PPGI Box Profile / PPGI Plain Panel | HDP Coating | Sound insulation |

| Agricultural Greenhouse Roof | PPGI Corrugated Panel | PE Transparent Coating | Light transmission |

| Warehouse Partition Walls | PPGI Low Wave Panel | PE Back Paint + Single-sided Coating | Fire resistance |

| Temporary Facility Fencing | PPGI Folding Panel | Economy PE Coating | Removable and reusable |

Considerations for Selecting Prepainted Profile Sheets

If you have design drawings, Wanzhi Group can provide processing services tailored to your requirements. Our PPGI steel production line can manufacture a variety of specifications and styles of color-coated steel materials. Of course, if you are selecting PPGI profile sheets for your project and would like some advice, we are also happy to assist you.

Environmental Factors

First and foremost, the application environment is the foundation for steel selection. Based on the climate conditions of the building’s location—such as temperature, humidity, rainfall, and wind speed—select the appropriate coating type and sheet thickness. The zinc coating thickness determines the sheet’s corrosion resistance lifespan; the profile shape determines strength and load-bearing capacity.

Load Requirements

Similarly, roof panels and wall panels have different load-bearing requirements. Based on the building’s functional use and design specifications, select PPGI profiled sheets with sufficient strength and rigidity.

Aesthetic Appeal

Aesthetic factors such as color, waveform, and texture can enhance the building’s visual appeal. These can be selected in consideration of local preferences and market demands.

Quality

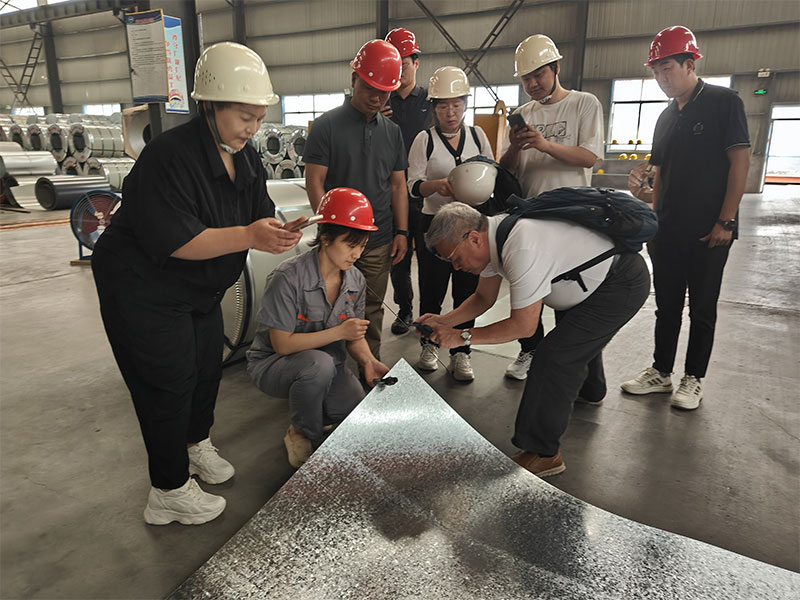

When selecting a PPGI profile sheet supplier, request material certificates and quality inspection reports to understand the coating performance, zinc layer content, and mechanical properties of the panels.

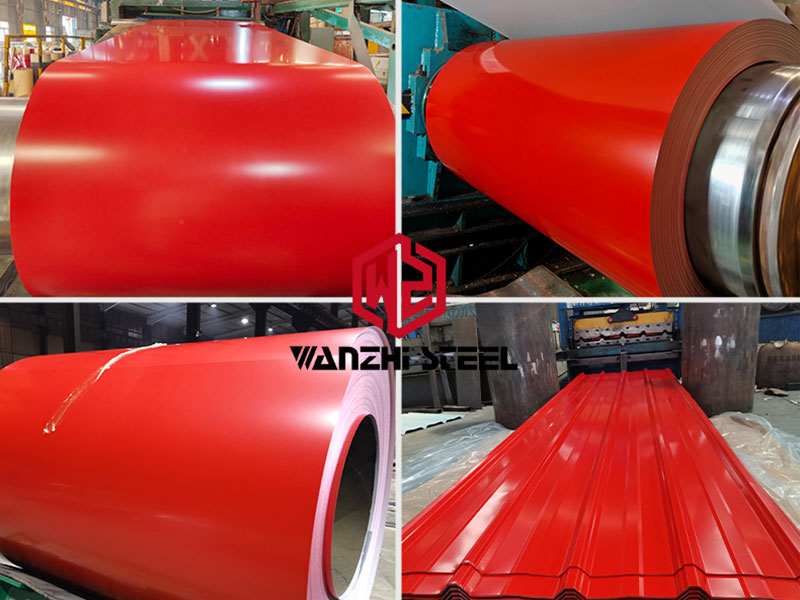

PPGI Profile Sheet Factory in China

Wanzhi Group is a PPGI steel factory supplier from China. We produce PPGI steel in a variety of specifications and forms, and also provide finished product processing services. The factory has obtained ISO9001 and ISO14001 certifications and has been tested by third-party institutions such as SGS and BV.

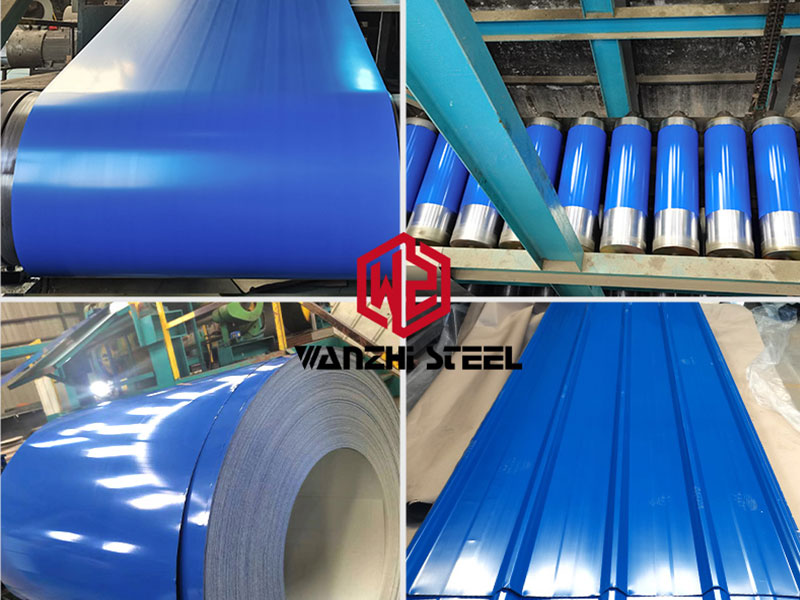

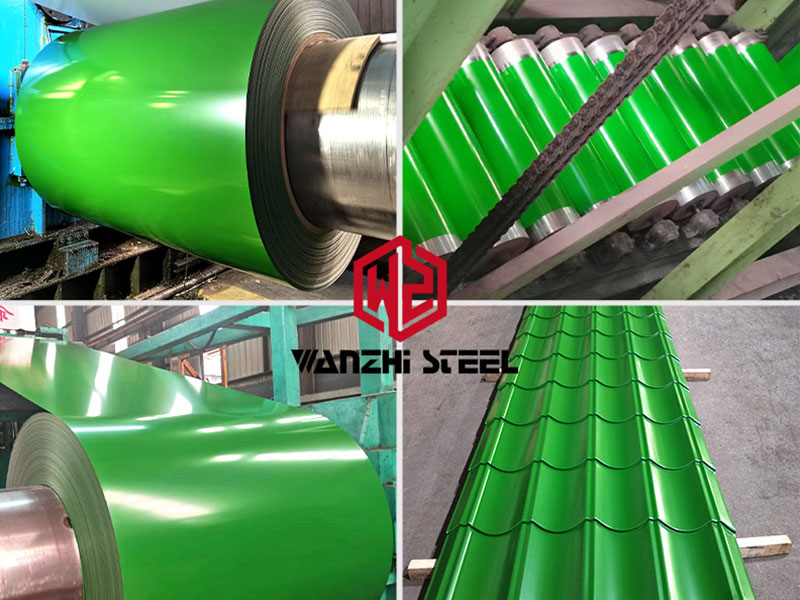

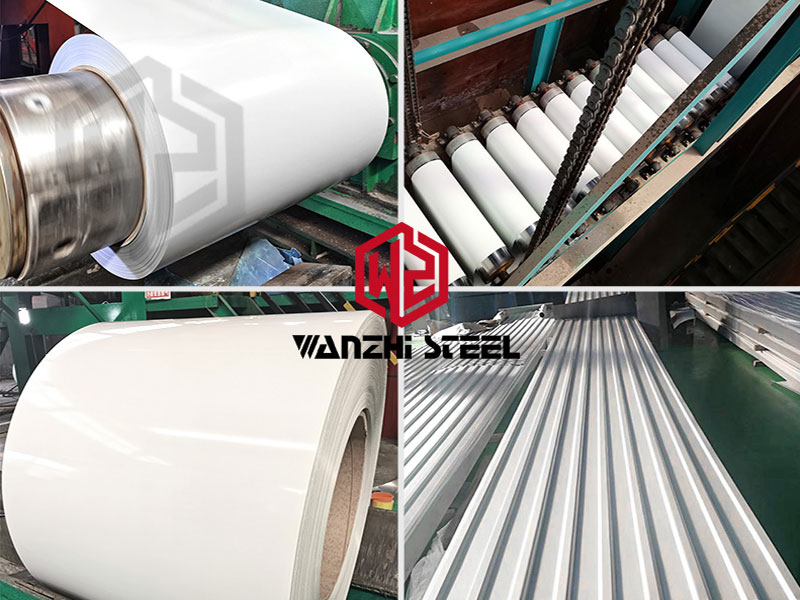

PPGI Coil and Sheet Production

We have three PPGI coil sheet production lines, capable of producing PPGI materials with thicknesses ranging from 0.12 to 1.5 mm, widths from 600 to 1250 mm, topcoat thicknesses from 10 to 40 microns, and primer thicknesses from 5 to 20 microns. We offer standard paint materials such as polyester, high-weatherability polyester, silicone-modified polyester, fluorocarbon, epoxy resin, etc. Special paints like PU and PVC can be customized.

Color-Coated Profiles Sheets Production

In addition to the PPGI production lines, we have slitting machines, sheet processing machines, etc. We can process sheets according to design drawings.

PPGI profile sheets and PPGL profile sheets are among our best-selling color-coated profiled sheets. Leave us a message with your required specifications, materials, and profiles to receive a free quote!