Color-Coated Coil Requirements for the Appliance Manufacturing Industry

The appliance manufacturing industry has stringent requirements for the quality of PPGI PPGL coil and sheet materials, including steel coating properties, substrate quality, performance, surface effect, and other aspects.

Substrate Quality Requirements

Good adhesion of the coating, no cracks caused by bending and molding.

High hardness of the coating: it should be scratch and abrasion-resistant

Small color difference: the color difference of the appliance panel should be strict to keep the consistency of the color.

Substrate Quality Requirements

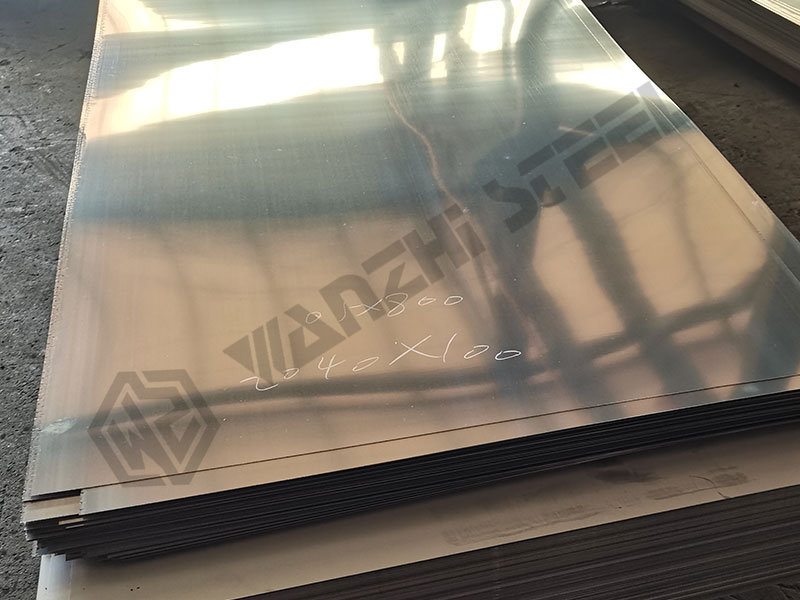

Substrate material: GI steel (galvanized steel), GL steel (galvalume steel).

Substrate thickness: Substrate thickness and tolerance will affect the quality of the appliance board.

Processing Requirements

Stamping and molding: Appliances require bending, cutting, stamping, and molding during the manufacturing process. Weldability: Appliances require localized welding during the manufacturing process.

Why is PPGI PPGL Suitable for the Production of Home Appliances?

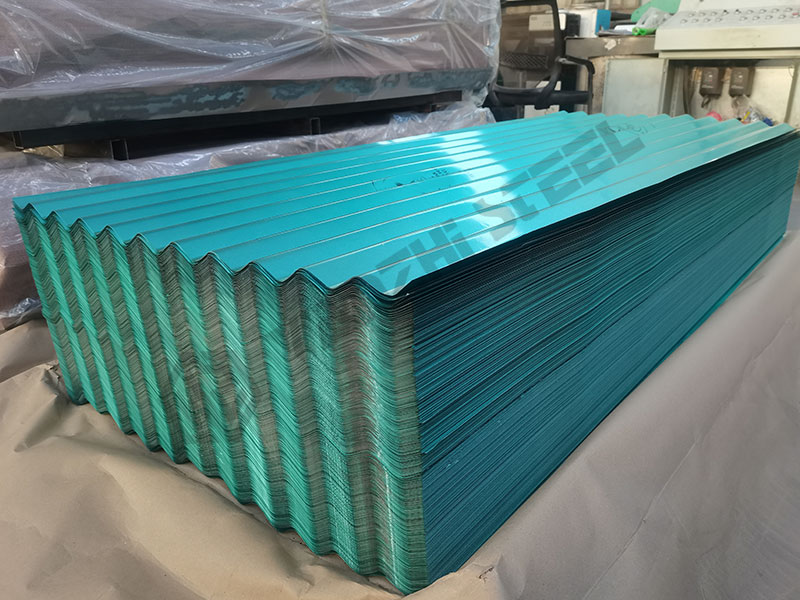

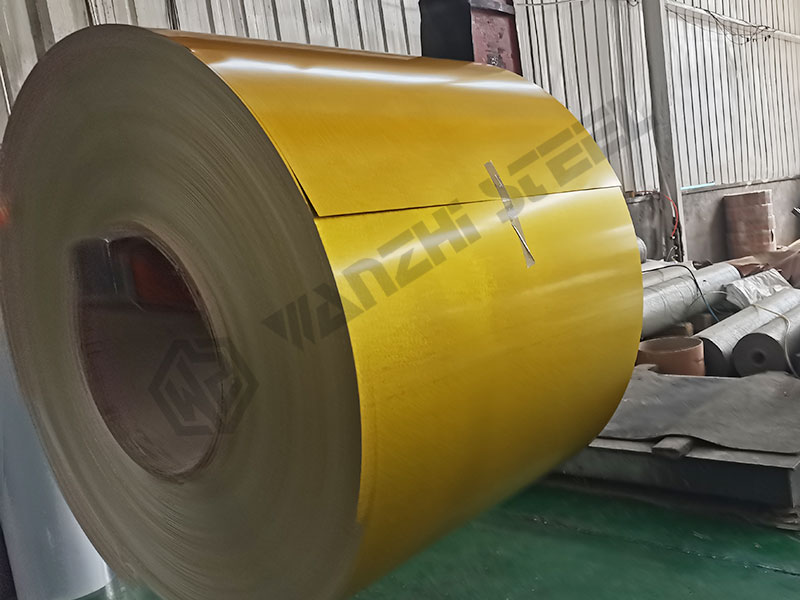

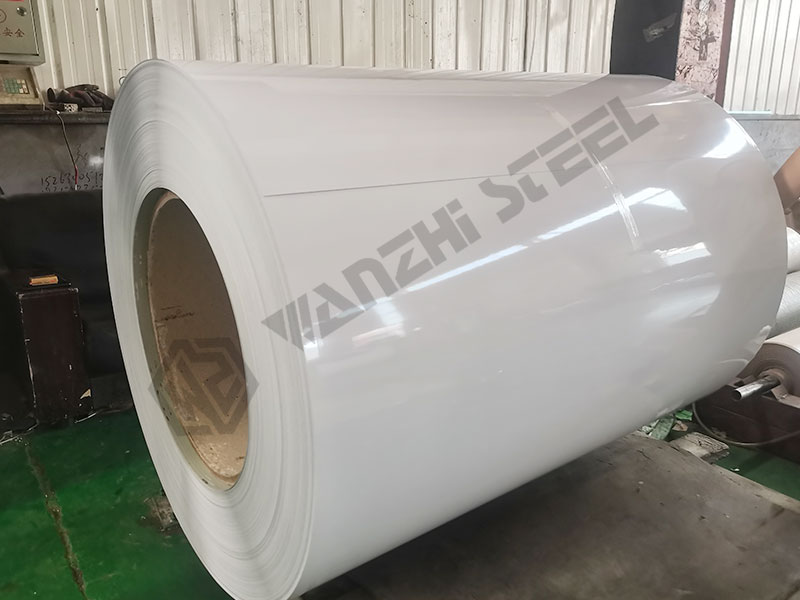

PPGI and PPGL steel are one of the most widely used materials in the appliance industry. PPGI is a galvanized and painted colored sheet metal with a wide range of colorful finishes, corrosion resistance, and durability. PPGL is an aluminized zinc-coated and painted-colored sheet metal with better corrosion and durability, in addition to higher oxidation resistance.

- Corrosion resistance: The corrosion resistance of PPGI PPGL ensures that the appliance will remain stable for a long time in the presence of moisture, heat, and chemicals.

- Durability: PPGI PPGL coating enhances resistance to abrasion and rust, extending the life of the appliance.

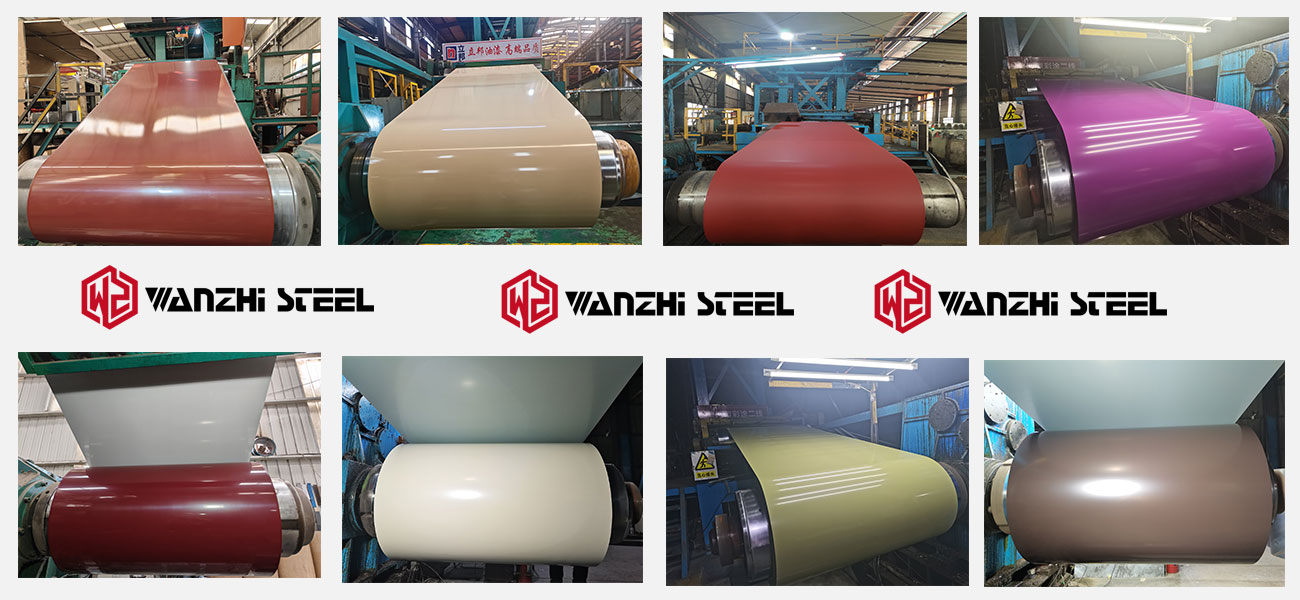

- Aesthetics: PPGI PPGL is available in a wide range of colors and finishes to meet the needs of different appliance manufacturers.

- Ease of processing: PPGI and PPGL inherited the easy molding properties of steel, and can be cut, bent, and formed.

- Economic benefits: Compared with stainless steel, PPGI and PPGL are more cost-effective for the production of home appliances.

What are the Applications of PPGI PPGL in Home Appliances?

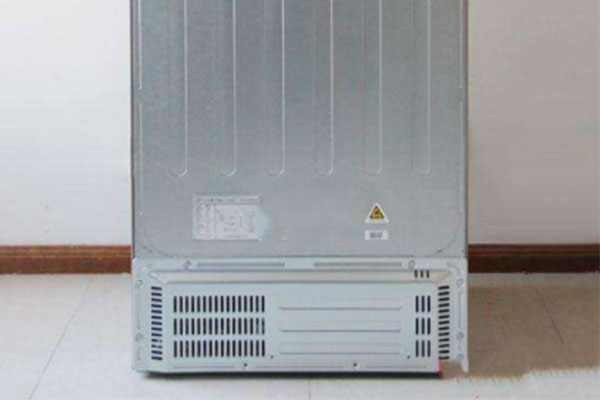

- Refrigerator: PPGI PPGL can keep the corrosion resistance stable for a long time under different temperature and humidity conditions, and can be used for the manufacture of refrigerator shells and panels.

- Washing Machines: PPGI PPGL steel is resistant to water, detergent impact, and corrosion, and can be used to produce washing machine housings and internal components.

- Microwave ovens: PPGI PPGL steel can be used in high-temperature environments and can be used to produce microwave oven housings.

- Dishwashers: PPGI PPGL steel does not rust when in constant contact with water, and can be used to produce dishwasher housings and frames.

- Air Conditioner: As with other household appliances, the use of PPGI PPGL as a raw material can withstand rain, moisture, and other factors.

- Water heaters: PPGI PPGL is a popular material for water heater housings and liners because they can maintain long-lasting stability in humid and high-temperature environments.

Advantages of PPGI PPGL Materials for Home Appliances

Appliance panels are made of a variety of materials, including stainless steel, aluminum, ABS, PC, PP, AS, PA, glass, ceramic, and more. Compared with traditional home appliance panel materials, PPGI PPGL is widely used in the home appliance field because of the advantages of aesthetics, durability, and environmental protection.

- Improve the competitiveness of products: PPGI PPGL sheet can provide aesthetics and durability.

- Lower production cost: PPGI and PPGL sheets are cost-effective and easy to manufacture.

- Environmentally friendly: PPGI and PPGL steel use organic coatings, which have a low impact on the environment.

Differences between PPGI and PPGL in Home Appliances

PPGI and PPGL are two important materials used in the appliance manufacturing industry. Although the two materials are very similar in appearance, there are differences in coatings and properties.

1. Coating

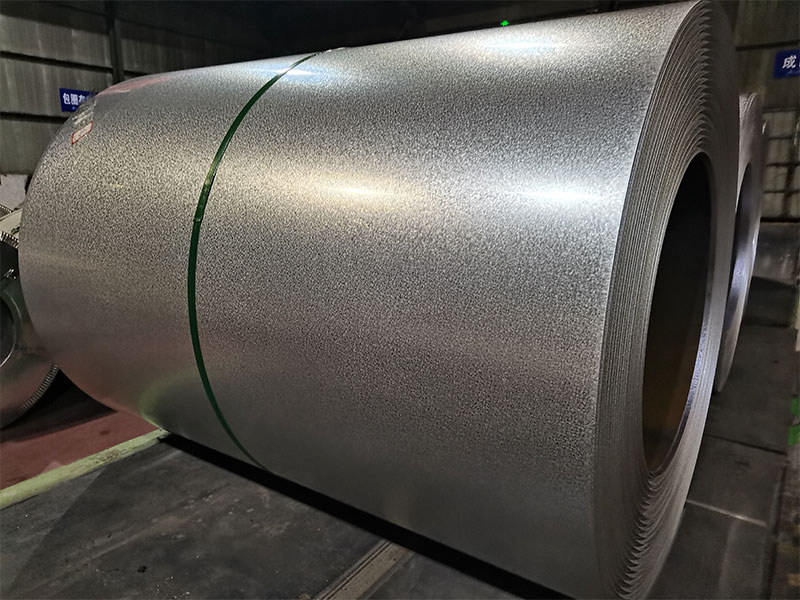

PPGI: A pure zinc metal coating is used to protect the steel from rusting.

PPGL: A zinc-aluminum alloy coating that provides not only corrosion resistance but also good heat reflectivity.

2. Corrosion resistance

PPGI: Corrosion resistance varies with the thickness of the zinc layer, the thicker the zinc layer the better the corrosion resistance, ordinary zinc-coated steel has average corrosion resistance.

PPGL: Higher corrosion resistance than galvanized coatings, especially at high temperatures.

3. High-Temperature Resistance

PPGI: Poor heat resistance, in a high-temperature environment will destroy the protective effect of the zinc layer on the steel, and reduce the corrosion resistance of PPGI.

PPGL: Can be stabilized for a long time in a high-temperature environment.

4. Durability

PPGI: Excellent durability in normal environments, not as good as PPGL steel in harsh environments.

PPGL: Excellent durability, used for appliances that require long-term color and gloss retention.

5. Areas of application

PPGI: Suitable for appliances such as washing machines and refrigerators.

PPGL is suitable for air conditioners, water heaters, dishwashers, and other home appliances.

Buying the Appliance Panel?

Wanzhi Group is a steel supplier from China, our factory Wanzhi Steel Factory is ISO quality management system certified, and we have been providing cost-effective appliance manufacturing solutions for worldwide processors, including PPGI coil, PPGI sheet, PPGL coil, PPGL coil, GI coil sheet, GL coil sheet, stainless steel sheet, and so on. PPGI coil, PPGI sheet, PPGL coil, PPGL coil, GI coil sheet, GL coil sheet, stainless steel sheet, and more. Contact us via WhatsApp for more customized solutions!