Galvalume steel is a type of steel coated with a protective alloy composed of aluminum (55%), zinc (43.4%), and silicon (1.6%), Also known as GL steel, aluzinc steel, etc., it is often sold in the form of coils (GL coil) and plates (GL sheet). It is a popular coated steel materials. This coating provides superior corrosion resistance, heat reflectivity, and durability.

Substrates for Galvalume Steel

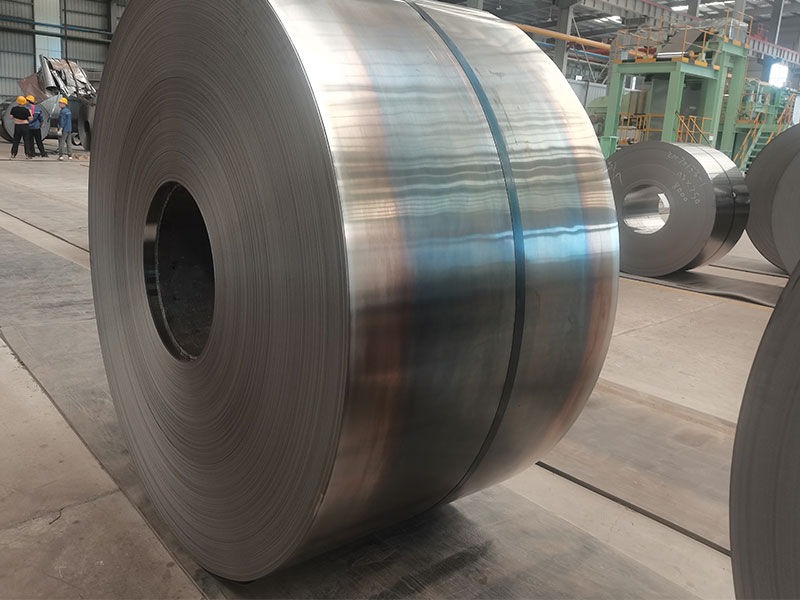

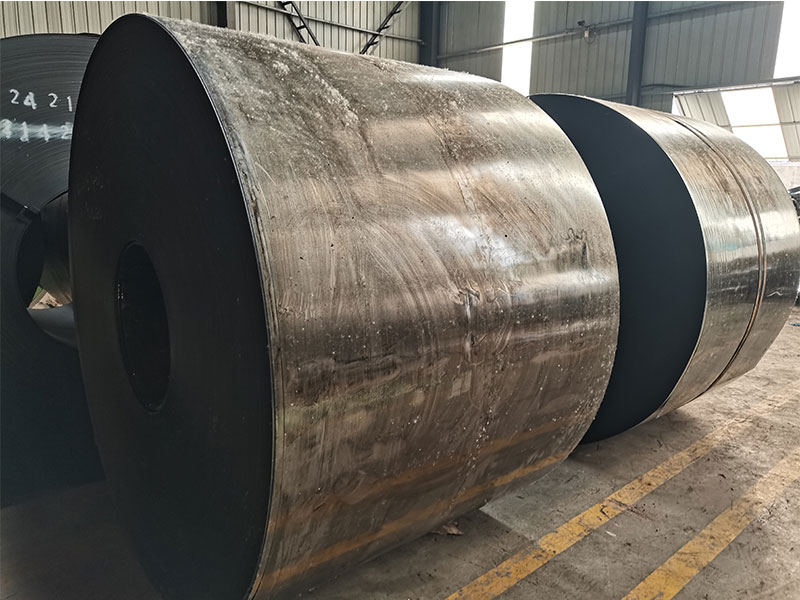

Galvalume steel substrates are typically cold-rolled or hot-rolled to provide good formability, weldability and surface quality.

Grades

Substrates for aluzinc steels are usually cold-rolled low carbon steel. Common types of substrates include:

- CQ (Commercial Quality): for general purpose applications

- HSLA (High Strength Low Alloy): low alloy steel substrate with high strength

- DP (Dual Phase): dual phase steel with good formability and strength. DP (Dual Phase): Dual-phase steel with good formability and strength

- IF (Interstitial Free): Ultra-low-carbon steel/interstitial-free steel

- EGL (Electrogalvanized): Electrogalvanized steel substrates, often used where better weldability and surface finish are required.

Properties

| Property | Typical Value |

|---|---|

| Tensile Strength | 270-550 MPa |

| Yield Strength | 140-350 MPa |

| Elongation, A50mm | 20-40% |

| Hardness (A50mm) | 20-40% |

| Hardness (HRB) | 40-80 HRB |

Chemical Composition

| Element | Content, % |

|---|---|

| C (Carbon) | ≤ 0.10% |

| Mn (Manganese) | 0.20-0.60% |

| P (Phosphorus) | ≤ 0.02% |

| S (Sulphur) | ≤ 0.02% |

| Si (Silicon) | ≤ 0.03% |

| Al (Aluminum) | 0.015-0.060% |

Galvalume Steel Coating

The main components of the aluminized zinc alloy coating are aluminum (Al) and zinc (Zn) with a small amount of silicon (Si). Zinc (Zn) serves as a sacrificial anode to protect the substrate by giving priority to corrosion. Aluminum (Al) serves as a high-temperature and passivation protection to form a dense oxide film that resists high-temperature oxidation and chemical corrosion. Silicon (Si) serves to inhibit brittle layers, improve the bonding of the coating, and prevent the overgrowth of Fe-Al intermetallic compounds (IMCs).

Chemical Composition (Al-Zn-Si Coating)

| Element | Composition |

|---|---|

| Aluminum (Al) | approx. 55% |

| Zinc (Zn) | approx. 43% |

| Silicon (Si) | approx. 1.6% (may be higher than 1.6% in some cases) |

Thickness of coatings

- Light coatings: For normal environments, with a coating thickness of 20g/m² to 40g/m²(Single side weight).

- Medium coatings: for wet or mildly corrosive environments, coating thicknesses from 50g/m² to 150g/m²(Single side weight).

- Heavy: For extreme environments with coating thicknesses of 150g/m² to 350g/m²(Single side weight).

Coating characteristics

Adhesion: the aluminized zinc alloy coating has a strong bond with the base steel and has good mechanical properties.

Corrosion resistance: Due to the alloying effect of aluminum and zinc, galvalume steel has stable performance in corrosive environments such as the atmosphere, the sea and acid rain.

High temperature resistance: Aluminum-zinc alloy has high heat resistance and is suitable for high temperature environments.

Aluminized Zinc Steel Grades and Standards

Wanzhi Group offers coated steel for construction and industrial applications in accordance with international standards such as ASTM, JIS, EN, GB, etc. These include Aluminized Zinc Steel in ASTM DX51D+AZ, EN DC51D+AZ, JIS SGCC and others.

| Standard | Grade | Coating Code |

|---|---|---|

| ASTM A792 | DX51D, DX52D, DX53D | AZ50, AZ55 (50/55 g/m²) |

| EN 10346 | DC51D, DC52D, DC53D | AZ150, AZ200 (150/200 g/m²) |

| JIS | SGCC | 200 g/m² |

| JIS G3321 (Japanese Standard) | SGCC, SGCH | AZ (Al-Zn) |

| GB/T 14978 (Chinese National Standard) | DC51D+AZ, DC52D+AZ | AZ (Aluminum Zinc Plated) |

ASTM DX51D+AZ

ASTM A792 (or ASTM A653), is an American standard that mainly specifies the quality requirements for aluminum zinc plated steel.

DX51D:

- DX indicates that this is a general purpose cold rolled steel.

- 51 indicates that this steel has a minimum yield strength of 51 kilonewtons per square meter (kN/m²).

- D indicates that the applicable grade of this steel is “steel base material”. In general, DX51D is a common steel grade used in the construction, appliance and automotive industries for lightweight materials that require a certain level of strength.

+AZ: Indicates that the steel is coated with an aluminized zinc alloy (55% aluminum and 45% zinc).

EN DC51D+AZ

EN 10346 is a European standard that deals with the technical conditions of delivery of aluminized zinc coated steels.

DC51D:

- DC indicates that the steel is cold-rolled.

- 51 means that the steel has a yield strength of 51 kilonewtons per square meter (kN/m²).

- D means that the steel is suitable for general building and structural use.

+AZ: Indicates an aluminized zinc alloy coating, similar to ASTM DX51D+AZ.

JIS SGCC

JIS G 3316 is a Japanese Industrial Standard that deals with the requirements for galvanized and aluminized zinc coated steel sheets.

SGCC:

- S indicates that the type of steel is plain carbon steel.

- G indicates that the steel is galvanized.

- CC means that the steel is used for general cold-rolled galvanized steel, which is usually used in construction, home appliances, automobiles and other fields.

Comparison of ASTM DX51D+AZ, EN DC51D+AZ, JIS SGCC

| Standard | Designation | Meaning | Application |

|---|---|---|---|

| ASTM | DX51D+AZ | DX51D Ordinary cold-rolled steel, yield strength approx. 51kN/m² | Construction, household appliances, automobiles, etc. |

| EN | DC51D+AZ | DC51D Cold-rolled steel, yield strength approx. 51kN/m² | Construction, household appliances, automobiles, etc. |

| JIS | SGCC | SGCC Galvanized steel, cold rolled steel | Construction, home appliances, automobiles, etc. |

GL Galvalume Steel Production Process

- Substrate pre-treatment: Remove grease and dust on the surface of the carbon steel plate, and remove iron oxide to facilitate plating.

- Annealing: high temperature annealing to eliminate cold rolled steel stresses and improve the formability of the substrate.

- Hot-Dip Coating: 600-620°C high temperature to make the aluminum ingot (55%), zinc ingot (43.4%), silicon additives (1.6%) melt and mix, the substrate is placed into the high temperature solution to complete the plating alloy, through water cooling or air cooling to room temperature to form dense Aluminum-Zinc. The substrate is put into the high temperature solution to complete the plating of the alloy, and then water-cooled or air-cooled to room temperature to form a dense Al-Zn-Si alloy layer.

- Post-Treatment: Chemical passivation/oil coating to enhance the corrosion resistance of Al-Zn steel.

- Slitting: Cutting width (600-1250 mm) according to customer’s requirement.

QC of GL Steel

| Test Items | Methods/Standards | Qualified Range |

|---|---|---|

| Coating Weight | Weighing Method | 30-275g/m² on both sides |

| Adhesion | Bending Test | No Flaking (0T-2T) |

| Surface Quality | Visual/CCD Inspection | No Leakage, Bubbles, Scratches |

| Salt Spray Test | ASTM B117 | Red Rusting Time ≥ 1,000 hrs. |

Galvalume Steel Products

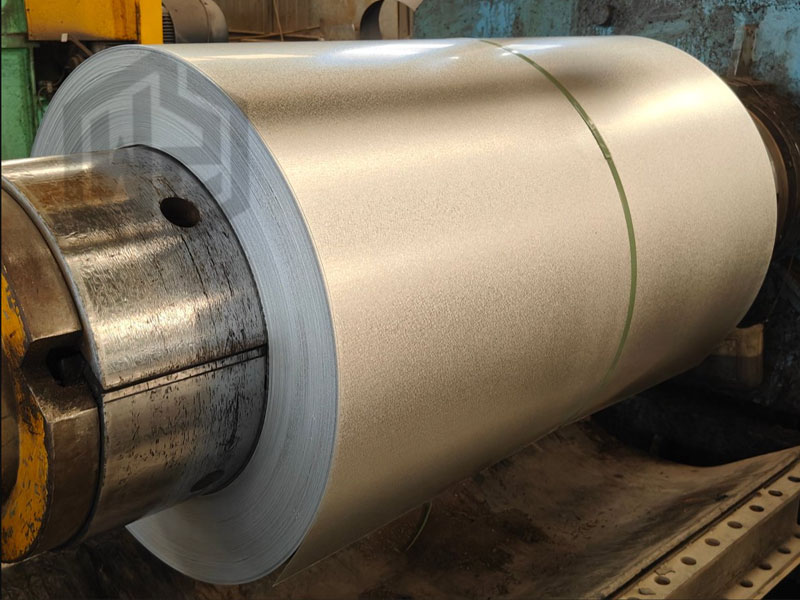

Galvalume products with good toughness and plasticity, it can be slit, cut, bent, formed and painted into coils, plates, strips, tubes, wire mesh, profiles and steel structures for use in construction, home appliances, automobiles, transportation, infrastructure and other fields.

- Galvalume steel sheets

- Galvalume coils

- Galvalume cold rolled steel sheets

- Galvalume steel strips

- Galvalume automotive exterior parts

- Galvalume household appliance housings

- Galvalume roofing sheets

- Galvalume grids

- Galvalume cooling tower materials

- Galvalume electrical fittings

Advantages of Galvalume Steel

Corrosion Resistance: Aluminum in the coating creates a protective barrier against air, moisture and chemicals, enhancing the steel’s ability to resist rust.

Heat Reflective: The aluminum content reflects solar radiation better than galvanized steel, keeping buildings cooler.

Longer life: Typically lasts 2-4 times longer than standard galvanized steel in harsh environments.

Formability and paint adhesion: Can be formed and painted for roofing, siding and automotive applications.

Uses for Galvalume Steel

Roofing and siding (commonly used in agricultural and industrial buildings)

HVAC systems (ductwork and vents)

Automotive components (exhaust systems, fascia boards)

Appliance and appliance housings

Manufacture of color-coated aluminum zinc plated steel

Galvalume vs. Galvanized Steel

| Feature | Galvalume (Al-Zn) | Galvanized (Zn) |

| Coating | 55% Al, 43.4% Zn, 1.6% Si | 100% Zinc |

| Rust Resistance | Better (especially in salty/coastal areas) | Good, but less than Galvalume |

| Heat Resistance | Reflects heat well | Absorbs more heat |

| Lifespan | 2-4x longer than galvanized | Shorter lifespan |

Galvalume steel initial cost is higher than galvanized steel, but the service life is longer, cost-effective, if you want to start a project, welcome to leave a message to consult.