What is Low Carbon Steel/Mild Steel?

Mild steel is steel with a carbon content of 0.05% to 0.25%. Typical grades include SAE 1010 (U.S.), Q195 (China), and S10C (Japan). As a base material, it can be processed through the hot and cold rolling process, and can be made into steel with different strengths and surface qualities for different purposes.

Characteristics

| Carbon Content | Tensile Strength | Elongation | Hardness |

|---|---|---|---|

| 0.05% – 0.25% | 300 – 500 MPa | 15% – 30% | HB: 100 – 150 |

Global Standard Systems and Grades

| Standard | Grade | Carbon content(%) |

| SAE/AISI | 1008 | 0.06–0.13 |

| 1010 | 0.08–0.13 | |

| 1018 | 0.15–0.20 | |

| DIN | C15 (1.0401) | 0.12–0.18 |

| JIS | S10C | 0.08–0.13 |

| SPCC(Cold rolled sheet) | ≤0.12 | |

| GB | Q195 | ≤0.12 |

| 20#(High quality carbon steel) | 0.17–0.24 | |

| ISO | C10E | 0.07–0.13 |

Comparison of International Standards and Parameters

| Standard | Tensile Strength | Elongation | Typical Use |

|---|---|---|---|

| ASTM A36 | ≥ 400 MPa | ≥ 20% | Building structure, bridge frame |

| EN 10025 | ≥ 360 MPa | General structural parts, mechanical parts | |

| JIS G3101 SS330 | ≥ 330 MPa | ≥ 28% | Light structure, hardware products |

| GB/T 700 Q195 | ≥ 315 MPa | ≥ 33% | General rivets, welded pipes |

What are the Main Types of Low Carbon Steel?

Depending on the carbon content, they can be categorized into ordinary mild steel for structural manufacturing, deep-drawn mild steel for stamping, deep-drawing, etc., and cast mild steel for foundry production.

Ordinary Carbon Steel (Mild Steel)

- Carbon content: 0.05% – 0.25%

- Characteristics: low cost, easy to process, for non-precision structural parts (such as bolts, rivets, brackets).

- Representative grades: SAE 1008, SAE 1010, Q195 (China), S10C (Japan).

Quality Carbon Structural Steel (Quality Carbon Structural Steel)

- Carbon content: 0.10% – 0.25%

- Characteristics: Stricter composition control, used for mechanical parts (gears, shafts).

- Representative grades: SAE 1018, SAE 1020, 45 (China), S20C (Japan).

Cold Heading Steel (Cold Heading Steel)

- Carbon Content: 0.08%-0.15%

- Characteristics: High ductility, suitable for cold heading molding (such as screws, nuts).

- Representative grades: SWRCH10K (Japan), ML08 (China).

Deep Drawing Steel

- Carbon content: ≤0.12%

- Characteristics: ultra-low carbon, used for complex stamping parts (car body, appliance shell).

- Representative grades: DC01 (European standard), SPCC (Japan), 08Al (China).

Why Choose Low Carbon Steel?

Good plasticity: low carbon steel has high plasticity, suitable for cold bending, stamping and other plastic processing, suitable for cold and hot processing.

Superior welding performance: lower carbon content, good weldability, suitable for welding works.

Lower strength: mild steel has lower tensile strength and hardness, good plasticity and ductility.

Poor corrosion resistance: Mild steel has poor abrasion resistance and is prone to rusting, but corrosion resistance can be enhanced by surface treatments such as painting and galvanizing.

What is Low Carbon Steel Used for?

Machinery Manufacturing and Components

- Standard parts: bolts, nuts, rivets, spacers.

- Shaft parts: low load drive shafts, pins.

- Cold heading parts: screws, spring washers.

Building and Structural Engineering

- Light structures: steel frames, supports, guardrails.

- Pipes and vessels: welded steel pipes, storage tanks.

- Reinforcing steel and steel plates: non-load-bearing concrete reinforcement, roof panels.

Automotive & Transportation

- Body Covering Parts: Doors, Hoods.

- Chassis parts: braces, brackets.

- Interior parts: seat frames, storage boxes.

Home Appliances and Consumer Products

- Appliance housings: refrigerator panels, washing machine inner tubes.

- Hardware tools: pliers, wrench handles.

- Furniture: table and chair frames, metal decorative parts.

Energy and Industrial Equipment

- Thermal components: heat sinks for electronic equipment.

- Conveyor systems: conveyor supports, rollers.

- Chemical containers: low-pressure storage tanks.

Daily necessities and light industry

- Kitchenware: pots and pans, knives.

- Stationery: staples, metal parts for folders.

- Packaging materials: cans, metal cans.

Low Carbon Steel: Cold Rolled Mild Steel, Hot Rolled Mild Steel

Cold rolled mild steel coil and hot rolled mild steel coil, with their different processes, surfaces and characteristics, cover a wide range of needs from everyday objects to large-scale projects, and are indispensable metals for building structures, infrastructure construction and industrial production.

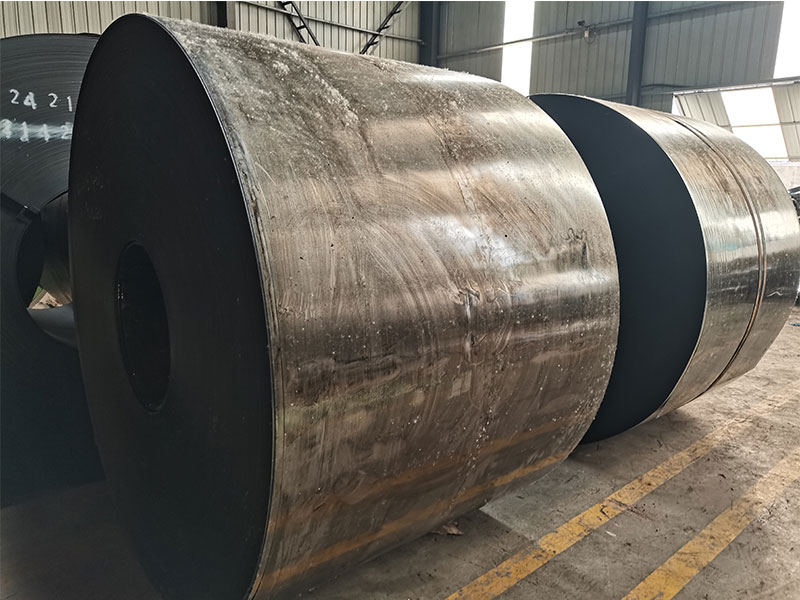

Hot Rolled Mild Steel

Steel made from billets heated to 1100°C-1300°C, continuously rolled in a mill and naturally cooled to a rough surface with oxidized skin.

Material Characteristics

- Coarse grain size: high temperature rolling results in loose grain structure and slightly lower strength than cold rolled steel.

- Low residual stress: sufficient stress release during cooling, good dimensional stability.

- Wide range of thicknesses: typically 1.5 mm-200 mm (plates, profiles).

- Retention of ductility: coarse grain size, suitable for subsequent welding or hot working.

- Low cost: suitable for mass production of thick plates or profiles.

Typical applications

- Building structures: H-beams, I-beams, reinforcing bars (e.g. Q235, ASTM A36).

- Pipelines and vessels: welded steel pipes, storage tanks (API 5L Grade B).

- Heavy machinery: racks, bases (S235JR).

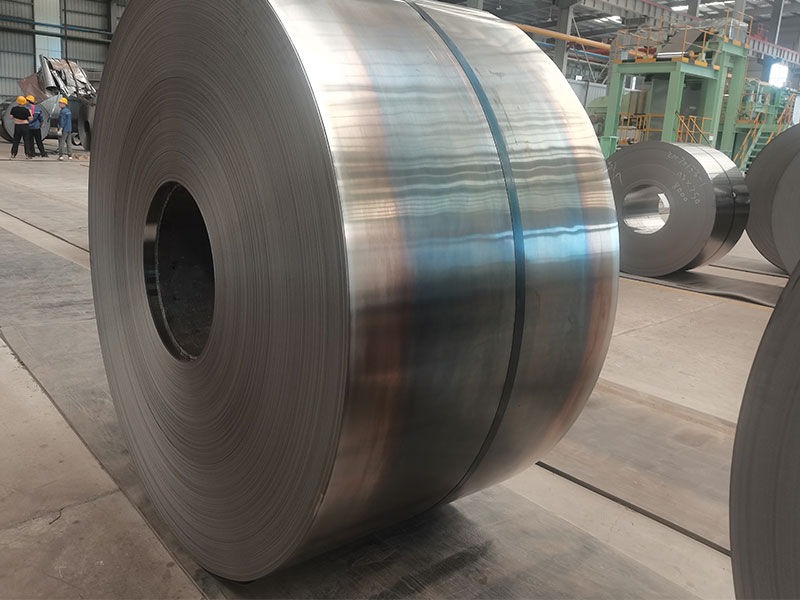

Cold Rolled Mild Steel

Steel made from hot rolled steel coils that have been pickled to remove oxidized skin and then rolled in multiple passes at room temperature, with the possibility of subsequent annealing, with a smooth and flat surface and high dimensional accuracy (tolerance ±0.1 mm).

Performance Characteristics

- Fine grain size: high strength (tensile strength 400-600 MPa).

- Higher hardness: Brinell hardness up to 150-200 HB, but slightly lower ductility.

- Narrow thickness range: usually 0.2 mm-3 mm (sheet, strip).

- High precision: thickness tolerance is controlled within ±0.1 mm.

- Excellent surface quality: can be directly plated, painted or printed.

Typical applications

- Automobile manufacturing: body panels, fuel tanks (DC04, SPCC).

- Appliance housings: refrigerators, washing machines (SPCE).

- Precision parts: spring plates, electronic component holders (08Al).

Hot Rolled vs Cold Rolled Mild Steel

| Property | Hot Rolled Mild Steel | Cold Rolled Mild Steel |

|---|---|---|

| Surface Quality | Rough, with oxide skin | Smooth, without oxide skin |

| Dimensional Accuracy | Lower (tolerance ± 0.5-1 mm) | High (tolerance ± 0.1-0.3 mm) |

| Mechanical Properties | Lower strength, high ductility | High strength, slightly lower ductility |

| Cost | Low (low processing energy) | High (multiple pass rolling + annealing) |

| Typical Thickness | 1.5 mm – 200 mm | 0.2 mm – 3 mm |

| Typical Scenarios | Building structures, heavy machinery | Precision stamped parts, products with high surface requirements |

Low carbon steel is a basic material that can be cold rolled, hot rolled and further processed to produce finished products suitable for different applications. For more product information, price list and case studies, please contact Wanzhi Group.