PPGI steel is a kind of color-coated steel with hot-dip galvanized steel as the substrate and organic coating on the surface. It is usually sold in coils and sheets. PPGI coils and sheets, as the raw material, can be made into corrugated sheets, sandwich boards, piping systems, fences, doors, and blackboards as metal materials for construction and industrial after bending, slitting, stamping, punching, profiling, forming, and other further processing.

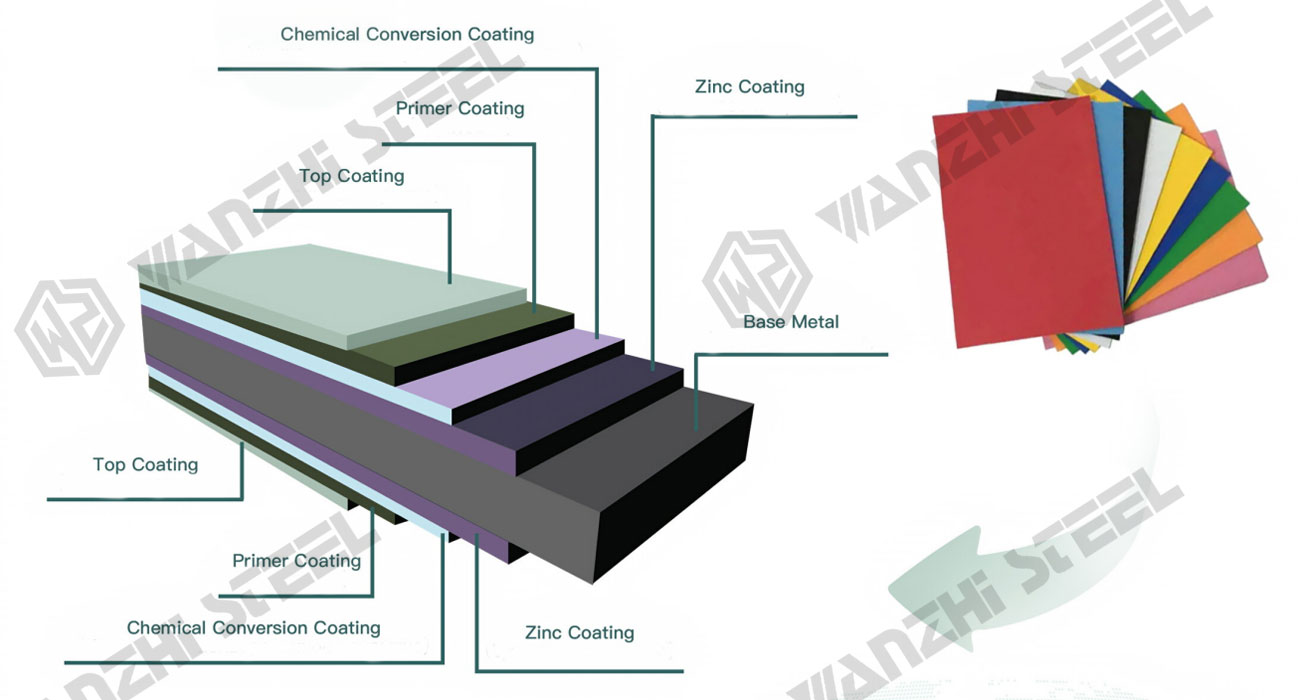

Structure of PPGI Steel

PPGI steel consists of a substrate, a chemical conversion film, a primer, and a topcoat. Substrate material and thickness, paint color, material, and thickness can be made according to requirements, the service life of different PE/SMP/HDP/PVDF PPGI steel is 8–30 years.

Substrate: Hot-dip galvanized steel, zinc coating thickness 30-275g/m².

Chemical conversion layer: Chrome-free passivation

Primer: Thickness 5-20 microns, epoxy or polyester resin coating.

Top coat: Thickness 10-40 microns, coated with polyester (PE), silicone-modified polyester (SMP) or fluorocarbon (PVDF), PU, PVC, etc.

PPGI Steel Production Process

Raw Material Preparation → Galvanizing → Surface Cleaning and Treatment → Coating Process → (Stamping) → Curing and Baking → Surface Inspection → Cutting and Packaging.

Galvanized substrate preparation

Hot dip galvanizing: A steel sheet is immersed in a zinc solution at 450-460°C, with an air knife to control the thickness of the zinc layer.

Passivation: Titanium-Zirconium-based solution to form a nano-protective film.

Coating process

Roller coating technology: synchronized coating of front and back side, speed 100-200m/min, precision ±1μm.

High-temperature curing: Segmented oven (200-270℃) to ensure coating cross-linking.

Post-treatment

Coated with protective film or antirust oil → slitting/coiling → quality inspection.

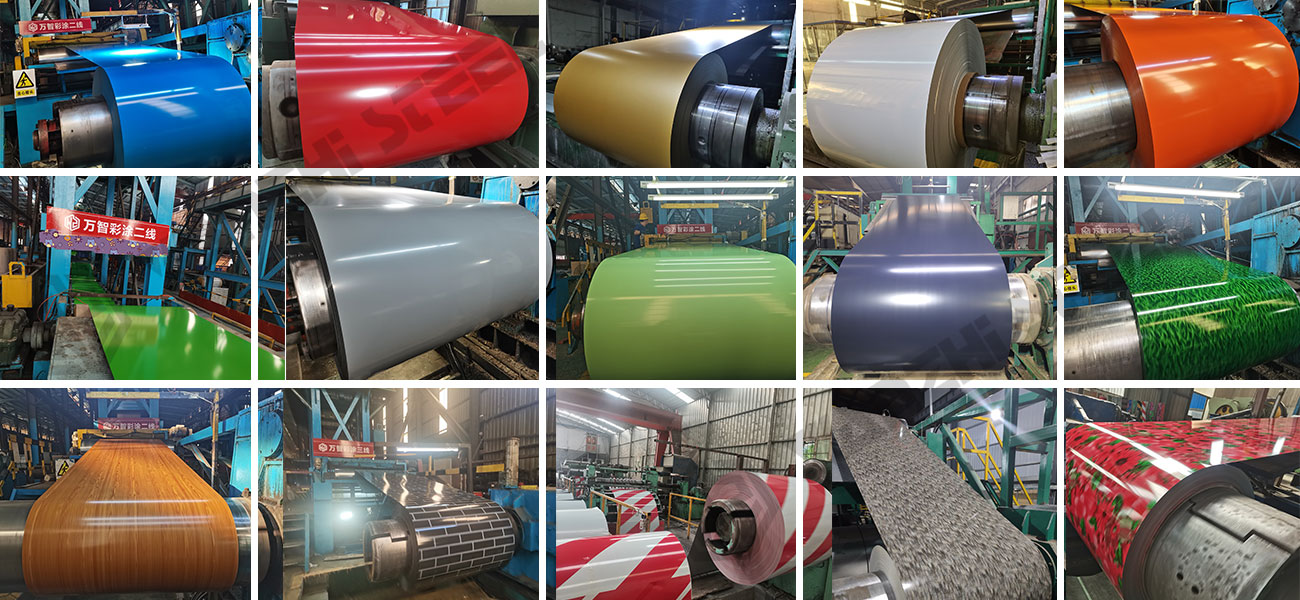

PPGI Steel Surface Effects

During the processing of PPGI Steel, it is possible to change the surface effect of the steel by adjusting the coating process to improve the anti-slip and aesthetic properties of the color-coated steel.

Smooth Surface PPGI

Description: A flat, smooth surface with no visible ripples or irregular surface features. This surface effect is suitable for highly decorative applications such as appliance housings and interior decorative panels.

Matte Finish PPGI

The surface has no luster and presents a matte effect, which is suitable for certain building materials and industrial plates to avoid the interference of reflections. Commonly used in commercial buildings or industrial products to reduce surface reflection.

Glossy Finish PPGI

Surface coating with high gloss, usually with high-quality paint, with a strong reflection effect. Suitable for products that require a high gloss and fine appearance, such as appliances and decorative panels.

Textured Finish PPGI

Creates a unique visual effect by adding texture or pattern to the coating. Common textured effects include wood grain and stone grain. Widely used in building exterior decoration, interior decoration, and some home appliances.

Metallic Finish PPGI

The coating has a metallic texture, such as silver, gold, or other metallic colors. It is used for products with high decorative requirements, such as high-end home appliances, fashionable furniture, automobile parts, etc.

Anti-fingerprint Finish

The surface has been specially treated with an anti-fingerprint function, which can reduce the retention of fingerprints and stains and keep the surface clean. Mainly used in home appliances, cell phone cases, car exterior decoration, and other fields.

PPGI Steel Features and Benefits

PPGI Steel balances corrosion resistance, aesthetics, and functionality by combining a galvanized steel substrate with an organic coating. Its lightweight, ease of processing, and environmentally friendly characteristics make it the material of choice for construction, home appliances, and other fields.

Benefits

Corrosion resistance: Zinc layer + coating double protection.

Decorative: Support for color customization, available in matte, high gloss, or texture (wood grain, stone grain).

Processability: Suitable for stamping, punching, bending, slitting, forming, profiling, welding, etc.

Lightweight: Reduces building loads with a weight of only 4-8 kg/m².

Environmentally friendly: 100% recyclable.

Fields of Application

Construction: Roofing, walling, curtain walling

Home Appliances: Refrigerator, Air Conditioner, Washing Machine Housings

Automotive: interior panels, roofs

Advertising: signage, displays

Education: blackboards, writing boards

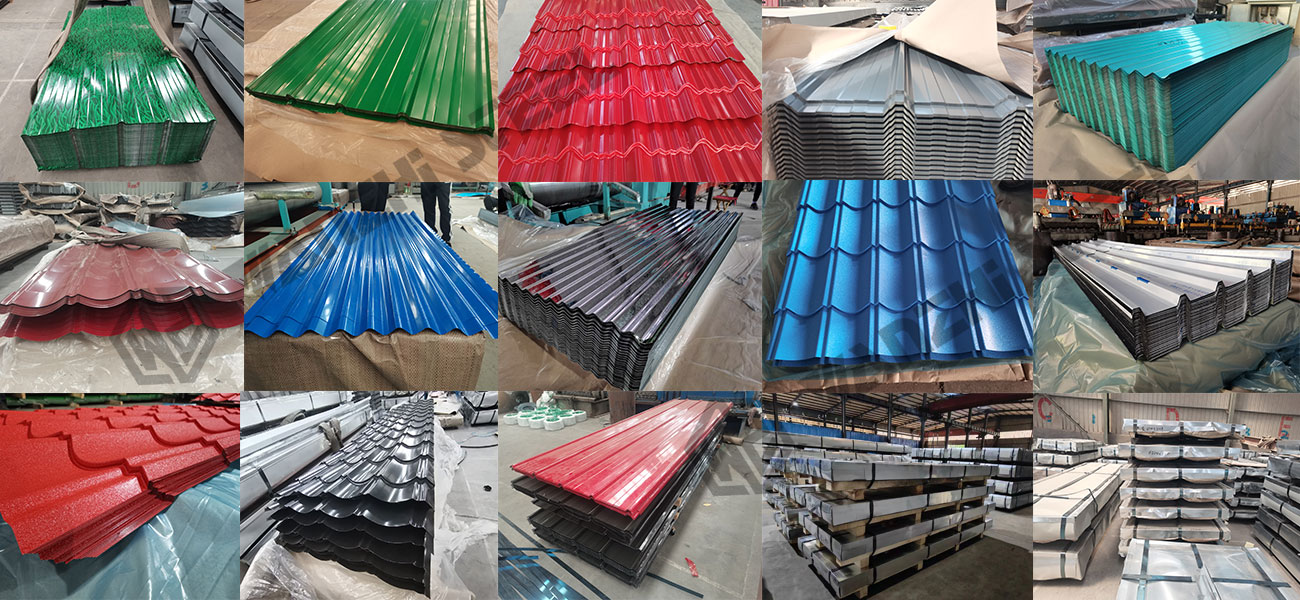

PPGI Steel Finished Products

PPGI steel combines the advantages of steel sheet, zinc, and functional paint, with excellent price performance, through further processing can be applied to different areas of color-coated products.

PPGI Factory

China is the main producer of PPGI steel, China PPGI steel factory has mature PPGI production technology and a flexible supply chain, with strong competitiveness in terms of price and quality. Wanzhi PPGI factory is one of them, we have galvanizing line equipment, coating equipment, curing oven, cooling system, and quality inspection equipment to supply PPGL coils, PPGL sheets, PPGL roofing, wall panels, doors and windows, appliance housings, interior panels, and other raw materials and finished products. finished products. In addition, our PPGI steel factory is ISO9001, and ISO14001 certified and can provide samples for different testing requirements.

PPGI Steel Buyer’s Guide

When purchasing PPGI materials, you can choose the most cost-effective PPGI solution for your application, and then select reliable PPGI suppliers according to your needs, in order to get the most cost-effective premium PPGI products.

Define the Required Parameters

- Substrate specification: thickness (mm), width (mm), steel grade (e.g. DX51D).

- Weight of galvanized coating: Total weight on both sides (g/m²), e.g. Z120, Z180, Z275 Z180 (180 g/m²).

- Coating type: Polyester (PE), Silicon Modified Polyester (SMP), Fluorocarbon (PVDF) PVDF (best weather resistance).

- Coating thickness: Thickness of topcoat on one side (μm).

- Surface treatment: Passivation type (chrome-free/chrome-containing), whether coated (PE protective film).

Supplier Screening

- Certifications: Ask for ISO 9001 (quality management), ISO 14001 (environmental protection), and EN 10169/ ASTM A755 (product standards).

- Production Facilities: Continuous galvanizing line + automatic coating line, support factory inspection.

- Testing Capability: We have a laboratory in the factory for salt spray, adhesion, and color difference testing, and we can provide samples of test reports.

- Case experience: We have export experience and customer feedback.

Customized Service

- PPGI texture: supports color customization (according to the color card or sample customization), and wood grain/stone grain customization (various pattern designs).

- Special performance: PPGI antimicrobial coating (silver ion added), PPGI thermal insulation coating (infrared reflection).

Specification

| Grades | GI/GL/SPCC/SPCD/SPCE/DC01-DC07/Q195、Q215、Q235 |

|---|---|

| Colors | Top/Back:RAL,Painted steel,3D Painted steel, etc(can be customized) |

| Thickness | 0.12-1.5 mm |

| Width | 600-1250mm/ customized |

| Coil Weight | 3-6 tons/ customized |

| Substrate Type | Hot dip galvanized, Galvalume, Zinc alloy, Cold rolled steel, Aluminum-zinc plated steel,Zimalium |

| Zinc Coating Thickness | Z30-275g/ ㎡,AZ30-150g/ ㎡ |

| Introduction to Coating | PVDF、HDP、SMP、PE |

| Coating Thickness | Top :10-40 um,Back:5-20 um |

| Inside diameter | 508/610mm |

| Package | Standard export package or as per your requirements |

| Certificates | SGS, ISO 9001,CE |

| Date of Delivery | 5-45 days |

PPGI, PPGL and PPAL

PPGI (Pre-painted Galvanized Iron), PPGL (Pre-painted Galvalume Steel), and PPAL (Pre-painted Aluminum) are pre-coated steel sheets. The combination of different substrates and organic coatings is what makes PPGI PPGL PPAL steel play an important role in construction, home appliances, automotive housings, high-end architecture, roofing, facade decoration, architectural decoration, aerospace, automotive, and other fields.

| Properties | PPGI | PPGL | PPAL |

| Base material | Galvanized Steel | Galvalume | Aluminum |

| Corrosion resistance | Medium | Superior | Very good |

| Weight | Heavier | Heavier | Lighter |

| Indoor and low corrosive environments | Highly corrosive environments, e.g. coastal areas | Extreme environments, e.g. acidic, alkaline, and corrosive environments | Extreme environments, e.g. alkaline, corrosive environments |

| Cost | Lower | Higher | Higher |

PPGI, PPGL and PPAL Steel QC Process

Pre-Production Inspection (IPC)

Raw material verification:

- Substrate testing: Tensile test, the weight of galvanized coating/aluzinc/aluminum.

- Coating Inspection: Solid content, VOC content.

Process validation:

- Passivation solution composition analysis.

- Coating line calibration records.

In-process inspection (IPQC)

- Coating uniformity

- Coating adhesion

- Color difference control

- Surface defects

Pre-shipment inspection (FQC)

- Salt spray test (ASTM B117): take samples and send them to the third-party laboratory.

- QUV aging: UVB-313 lamp cycle test 2000 hours, light retention rate > 90%.

- Appearance inspection: no rust spots and scratches on the surface, complete protective film. No burrs on the edges, flat plate shape.

- Size verification: thickness caliper measurement (error ± 0.02mm). Width/length (error ±1mm).

- Sampling retest: Randomly select 1-2 rolls to send to the third party for testing (e.g. SGS, BV).

If you have any questions about color-coated steel or plan to purchase premium PPGI PPGL PPAL steel, welcome to contact Wanzhi Group!