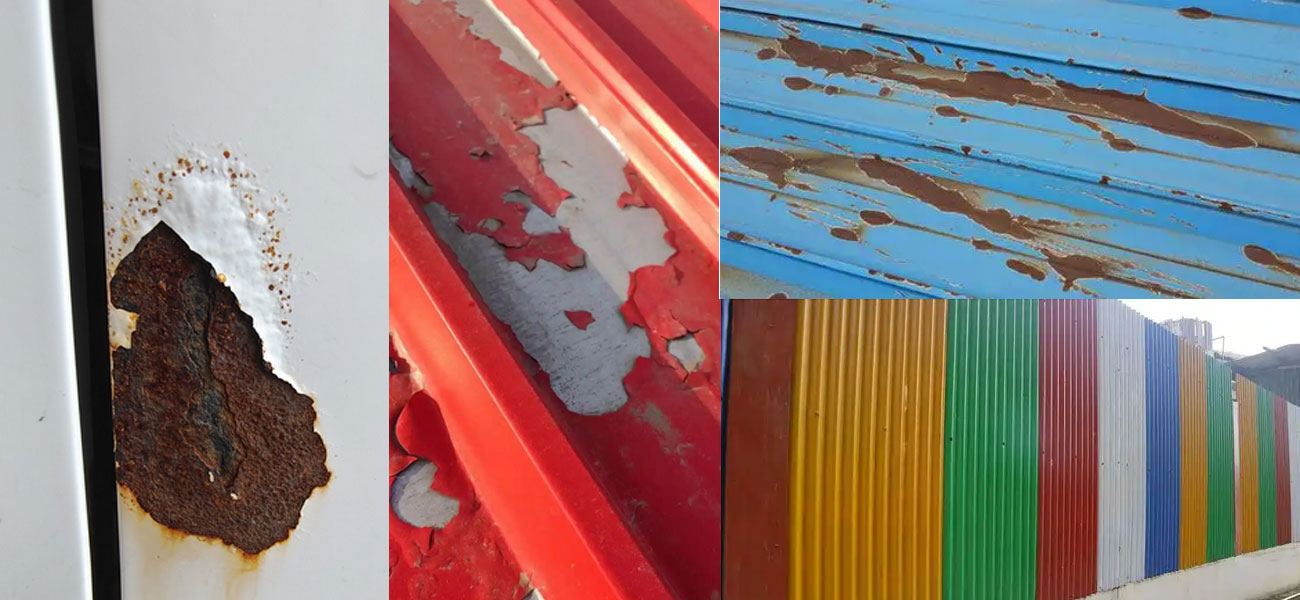

The structure of PPGI steel includes galvanized, chemically converted, and painted layers (primer + topcoat). Premium PPGI has a corrosion resistance of 15-30 years, and the rate of coating peeling is less than 3% in the course of use. If your purchased PPGI has the problem of coating flaking in a short period, you can find out the reasons from the coating technology, product packaging, storage environment, and so on.

Main Reasons for PPGI Coating Flaking

Preventing PPGI Coating Flaking Solution

PPGI Steel Precautions

PPGI coating peeling is one of the reasons affecting the service life of PPGI steel. In addition to improving the production and processing technology, reasonable maintenance should be carried out during installation to ensure the stable performance of PPGI steel.

- Avoid open storage, and control the humidity of PPGI steel storage environment to less than or equal to 70%.

- Use special tools for coating when cutting and punching.

- Avoid welding directly on the coated surface.

- Regularly check the integrity of the coating in highly corrosive environments such as chemical plants.

- Avoid excessive bending and leave expansion joints when producing corrugated boards and roofing sheets with PPGI.

Maintenance of PPGI Steel Coil and Sheet

- Rinse the surface of PPGI products regularly with a neutral detergent.

- Inspect PPGI coatings annually for pinholes and scratches.

- Repair any localised flaking with paint.

- PPGI surface can be sprayed with anti-rust wax to increase corrosion resistance.

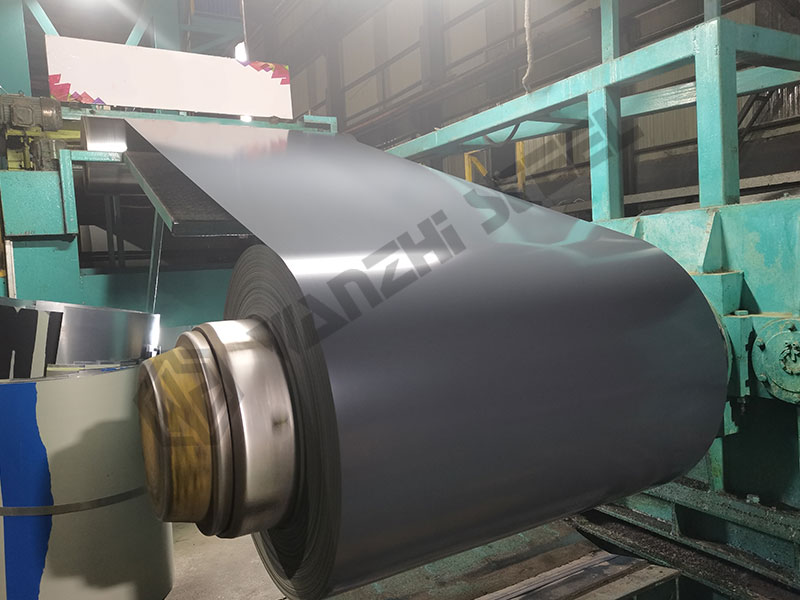

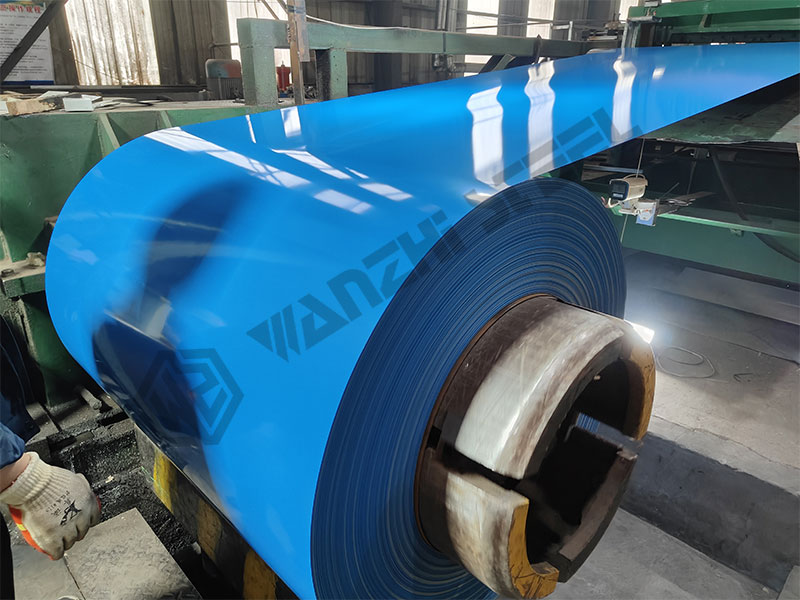

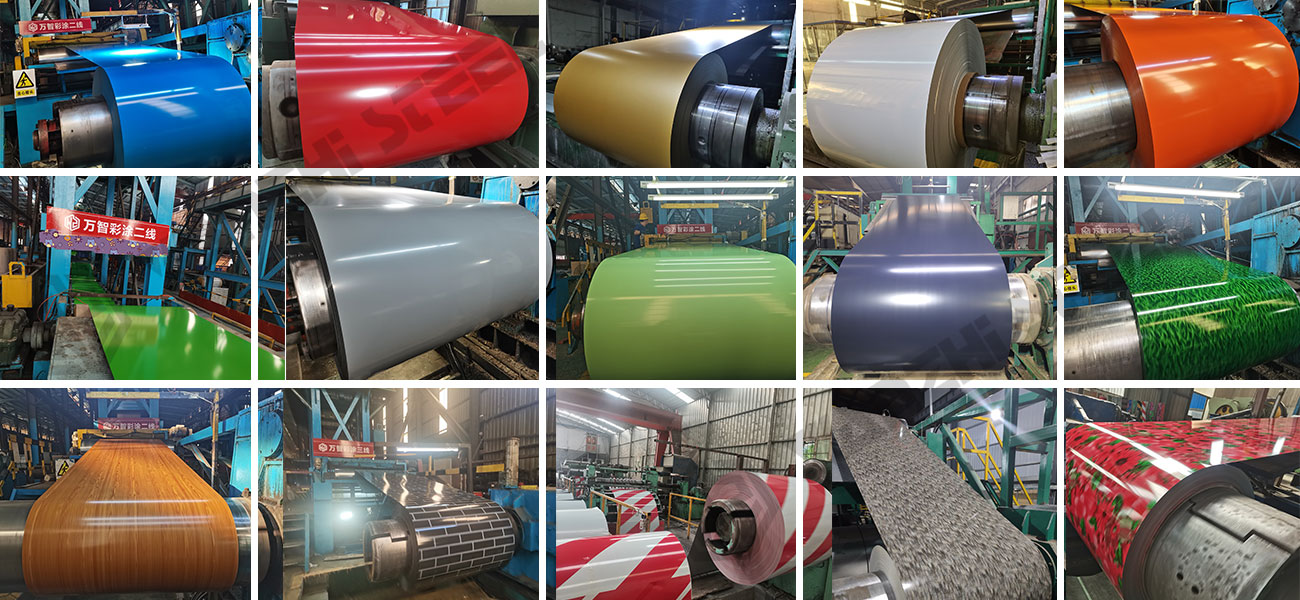

The above are the possible causes and solutions for the flaking of PPGI steel, as well as recommendations for the maintenance and use of PPGI material. If you are planning to purchase a premium PPGI coil sheet with non-peeling coating, welcome to contact Wanzhi Group! Wanzhi has a proven coating technology, our hot-dip galvanizing, roll coating, baking, and curing processes are advanced, and we are experienced in exporting and customizing cost-effective PPGI solutions for a wide range of applications.