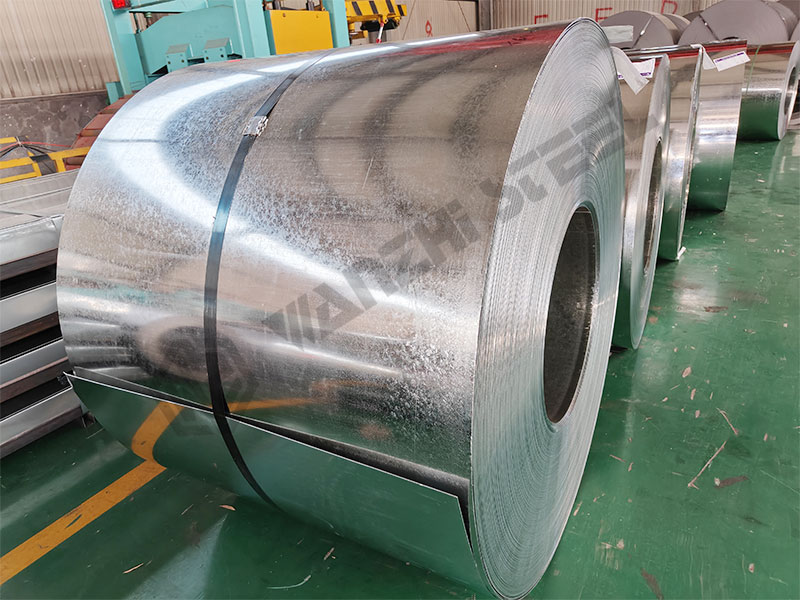

The service life of galvanized steel with different zinc thicknesses in various environments, such as indoor, general outdoor, marine, and chemical environments, ranges from 7 to 50 years, and the corrosion resistance of GI steel can be enhanced by adjusting the thickness of the zinc layer and surface treatment to achieve the purpose of extending the service life of the steel.

Adjustment of the Zinc Coated Thickness

Galvanized steel consists of carbon steel and a zinc layer, which separates the steel from air, moisture, acids, and alkalis and makes the steel less susceptible to rusting. The thickness of the zinc layer and the galvanizing process determine the corrosion resistance of galvanized steel. By optimizing the galvanizing process, the thickness of the zinc layer obtained by hot-dip galvanizing is generally thicker than that of electro-galvanizing, and by adjusting the thickness of the zinc layer, the corrosion resistance of the steel can be enhanced.

DX51D Z140

JIS G3302 SGCC

Q235 Galvanized Steel

z275 Galvanized Steel for Sale

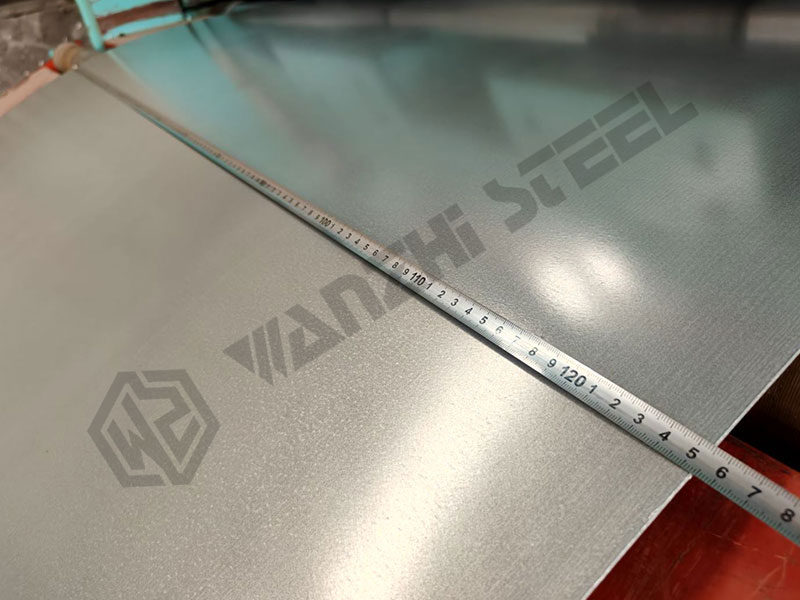

- Zinc thickness: Wanzhi recommends a zinc thickness of Z30-Z275g, 40–150 microns.

- Galvanizing process: Wanzhi galvanizing process is mainly hot-dip galvanizing and electro-galvanizing.

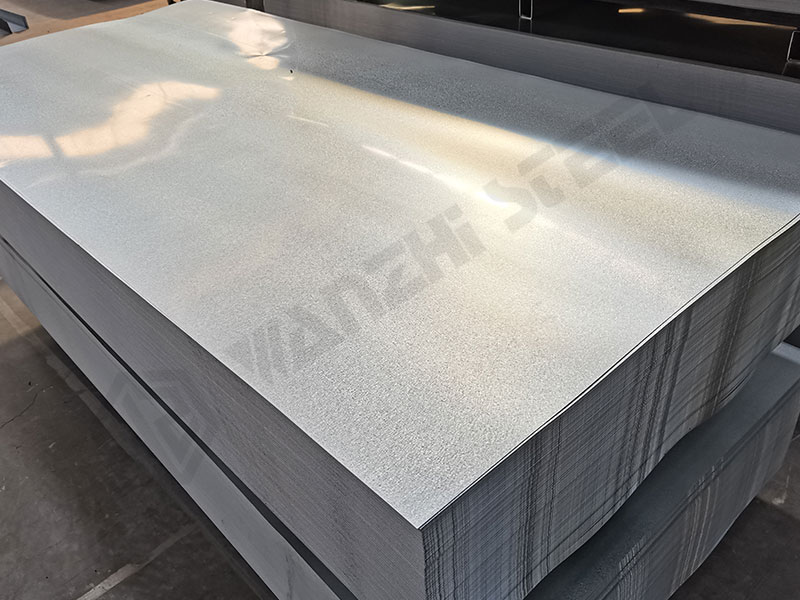

Surface Finish of Galvanized Steel

After galvanizing, a protective film can be formed on the surface of the steel using post-treatments such as passivation, phosphating, etc., which enhances both the adhesion of the zinc layer and the corrosion resistance.

- Passivation: Formation of a dense passivation film to enhance the corrosion resistance of the steel.

- Phosphating: Formation of a phosphating film, which delays the oxidation process of the zinc layer and increases the abrasion and corrosion resistance of galvanized steel.

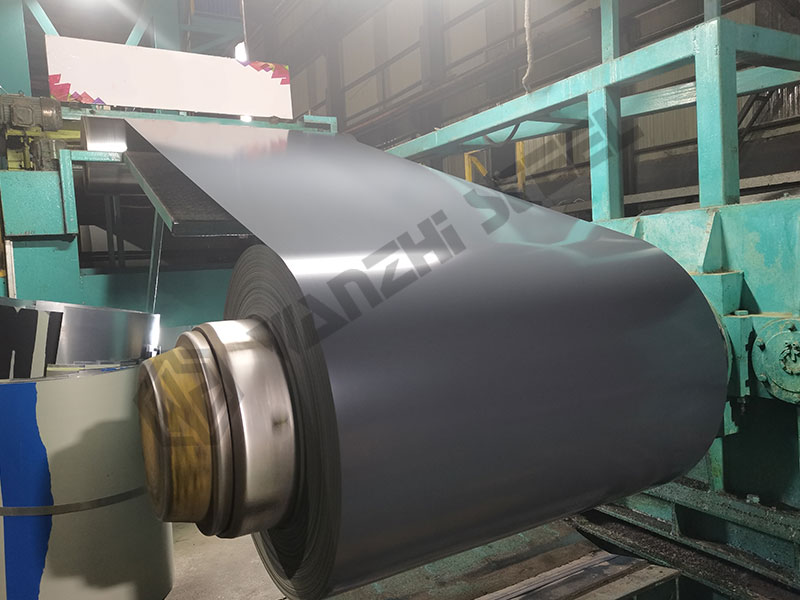

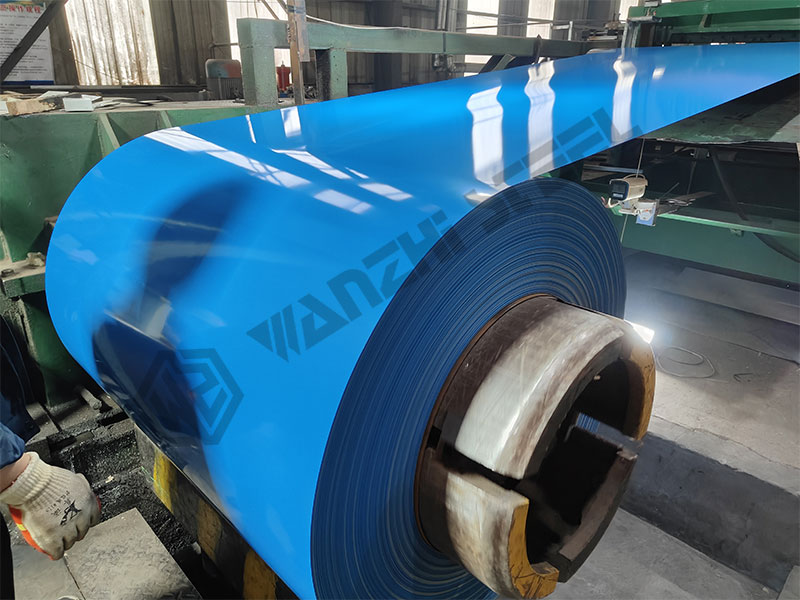

Galvanized Steel Surface Overcoating

The surface of galvanized steel is coated with a layer of corrosion-resistant paint, such as PE, SMP, HDP, PVDF, etc. This type of painted galvanized steel has the corrosion resistance, strength, rigidity, and toughness of galvanized steel as well as the aesthetics and weathering of the coating, which not only provides excellent corrosion protection but also better decorative properties.

PPGI steel, pre-painted galvanized steel consists of galvanized steel, a chemical conversion layer, a primer, and a topcoat.

- Substrate: GI steel

- Primer: epoxy, polyester, acrylic and polyhydrogen ester, film 5–20 microns.

- Top coat: PE, SMP, PVDF, HDP, film 10–40 microns.

- Painting method: roller coating, spraying, etc.

Alloying Galvanized Steel

In addition to the surface treatment of galvanized steel, other alloying elements such as aluminium, silicon, magnesium, tin, etc. can be added to the galvanizing process to improve the corrosion resistance and other properties of galvanized steel.

- GL steel: Galvanized aluminium alloy steel, containing 55% aluminum, 43.4% zinc, and 1.6% silicon, with high corrosion resistance, heat reflectivity, and mechanical strength.

- ZAM steel: Zinc-aluminum-magnesium alloy steel, containing 55% aluminum, 43.4% zinc, and 1.6% magnesium, with superior corrosion, temperature, and heat resistance, can be used as an alternative to stainless steel.

Attention to Use and Storage Environment

In addition to surface treatment, the corrosion resistance of galvanized steel can be improved by controlling the use and storage environment.

- Avoid exposing galvanized steel to moisture, acid, or alkali for a long period as much as possible.

- Avoid contact between the surface of galvanized steel and corrosive substances such as water, salt, acid, etc., and clean up any accumulation of water, dust, leaves, etc., on the surface of galvanized steel.

- Avoid collision and scratching of the zinc layer on the steel surface during transportation, processing, and use.

- Remove rust from the galvanized steel surface on time, and treat and replenish the galvanized steel surface promptly.

Buy Premium Galvanized Steel?

Wanzhi galvanized steel factory, with galvanized, zinc-aluminum, zinc-aluminum-magnesium, painted production lines, from raw material cold rolled steel coils to finished galvanized steel sheets/panels, we can provide professional solutions and customized services for different fields. Please feel free to contact us, visit our factory, or request samples.