PPGI is a high-performance material widely used in construction and industry. Its service life can be up to several decades. Wanzhi‘s color coating solutions have been applied to projects in more than 100 countries and regions, creating economic value for customers from all over the world.

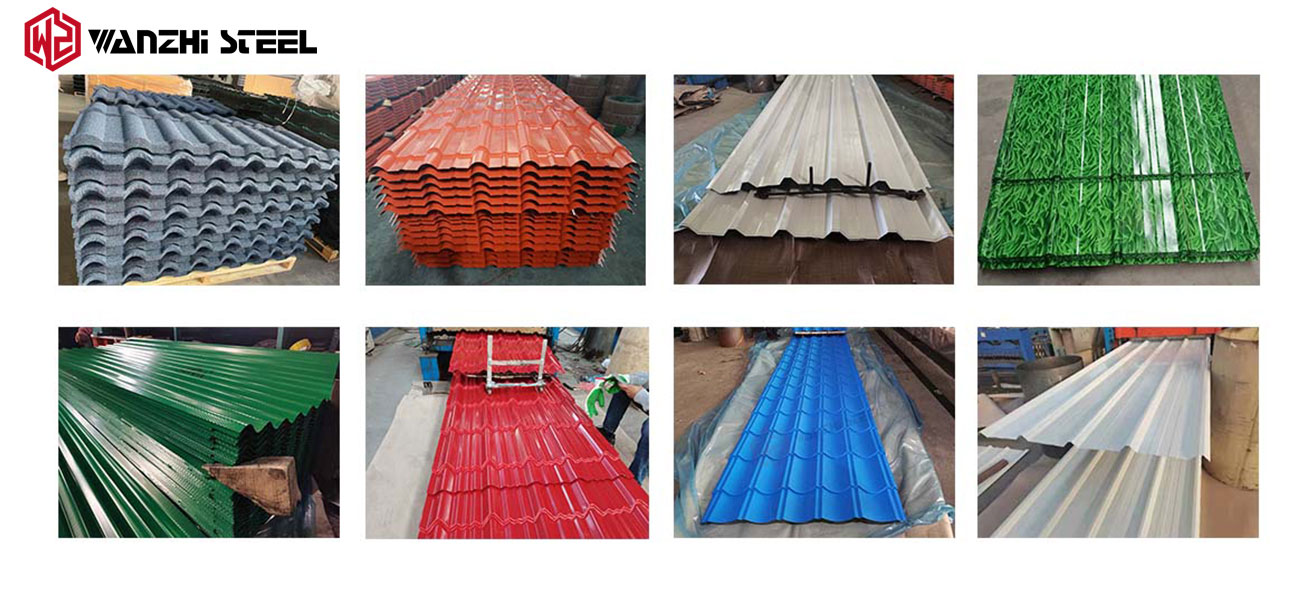

PPGI Steel Products

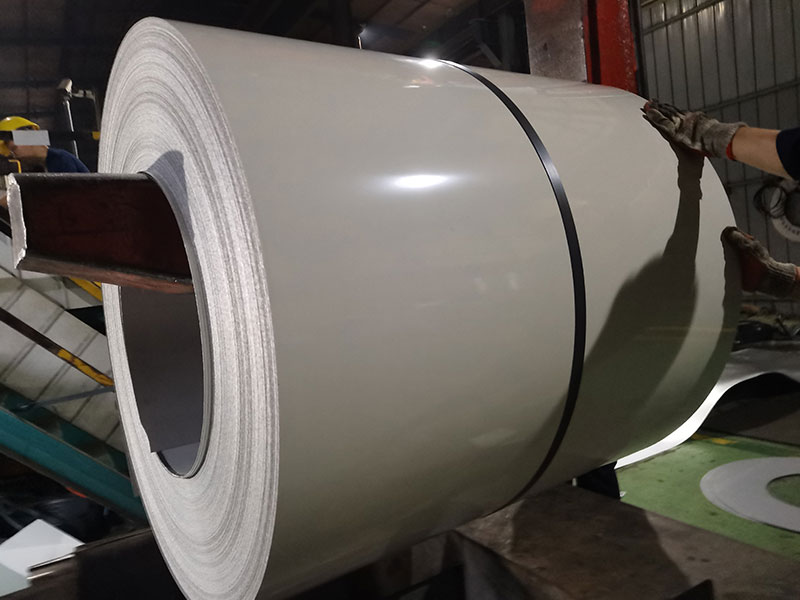

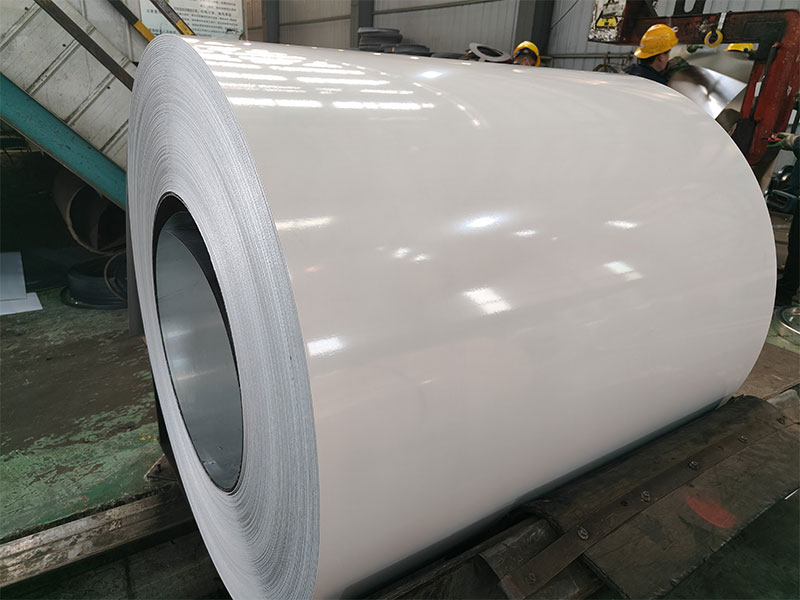

PPGI Steel, also known as pre-painted steel, is produced by applying a coating of paint or polymer coating on galvanized or galvalume steel coils, providing excellent corrosion resistance and an attractive finish. With a wide range of colors, textures, forms, types, and finishes available, color-coated steel is favored for architectural cladding, roofing, and decorative applications.

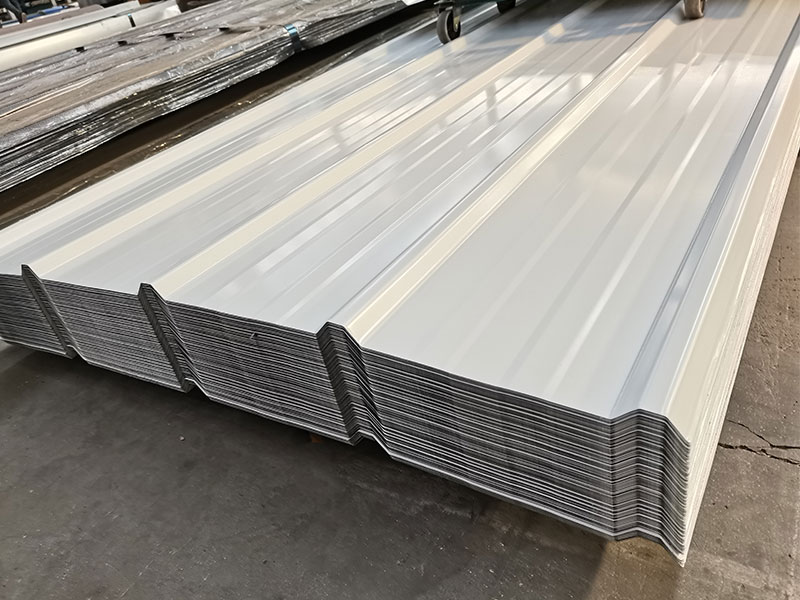

PPGI Sheet: Prepainted Galvanized steel sheet

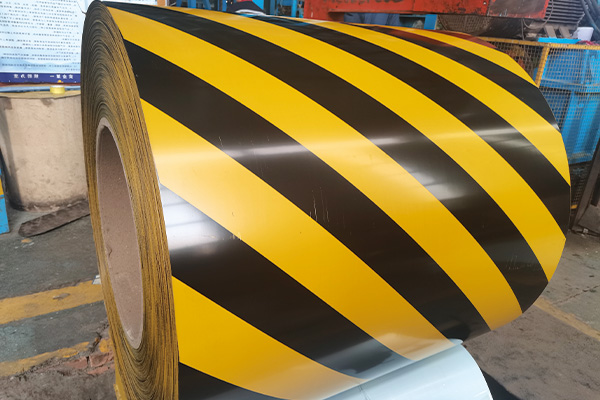

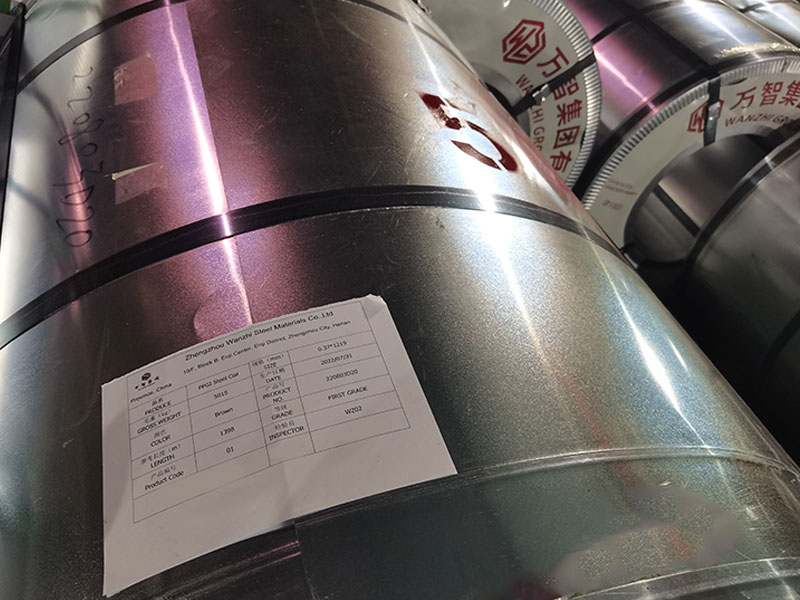

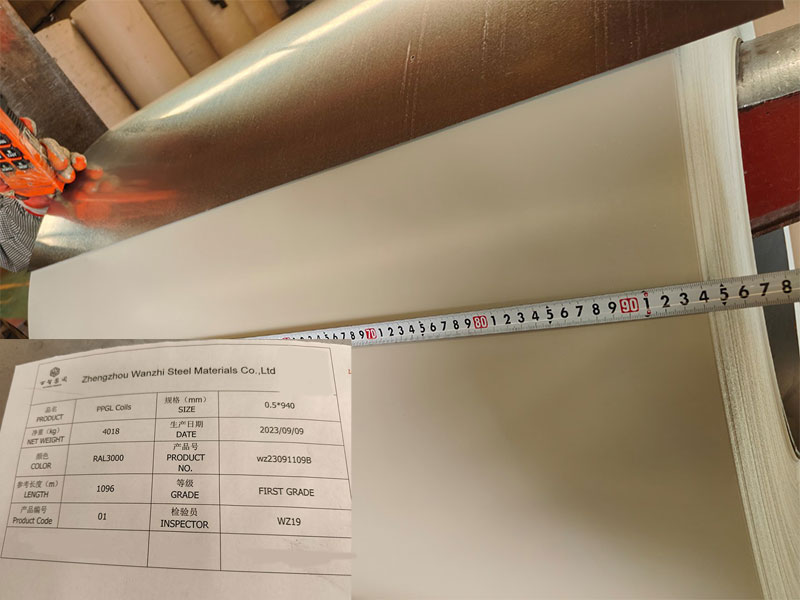

PPGI Coil: Prepainted Galvanized steel coil

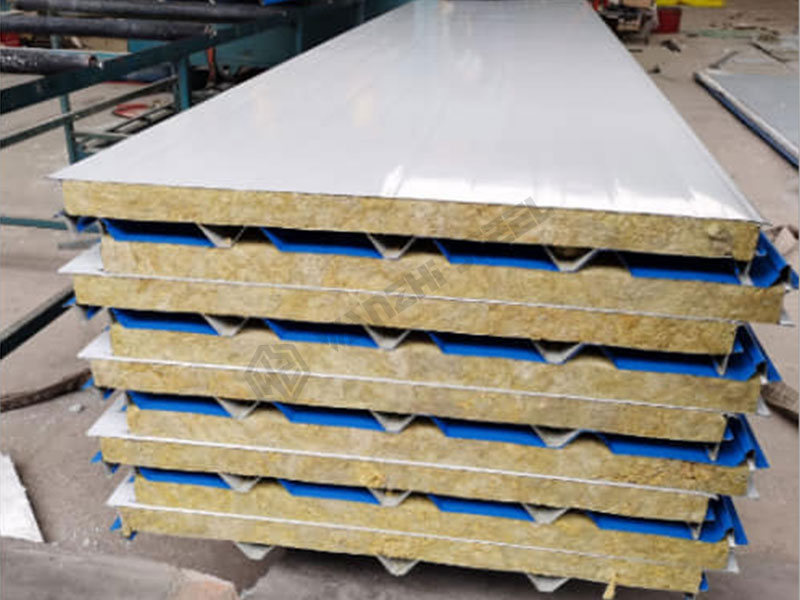

PPGI Panel: Prepainted Galvanized steel Panel

Specification of PPGI Steel

| Grades | GI/GL/SPCC/SPCD/SPCE/DC01-DC07/Q195、Q215、Q235 |

|---|---|

| Colors | Top/Back:RAL,Painted steel,3D Painted steel, etc(can be customized) |

| Thickness | 0.12-1.5 mm |

| Width | 600-1250mm/ customized |

| Coil Weight | 3-6 tons/ customized |

| Substrate Type | Hot dip galvanized, Galvalume, Zinc alloy, Cold rolled steel, Aluminum-zinc plated steel,Zimalium |

| Zinc Coating Thickness | Z30-275g/ ㎡,AZ30-150g/ ㎡ |

| Introduction to Coating | PVDF、HDP、SMP、PE |

| Coating Thickness | Top :10-40 um,Back:5-20 um |

| Inside diameter | 508/610mm |

| Package | Standard export package or as per your requirements |

| Certificates | SGS, ISO 9001,CE |

| Date of Delivery | 5-45 days |

PPGI Steel for Sale – Wanzhi Group

Sells PPGI steel in thicknesses, typically ranging from 0.12 mm to 1.5 mm, depending on the specific application and requirements. The thickness can vary based on the intended use of the steel sheet, such as for roofing, cladding, corrugated, or other structural purposes. Wanzhi Group has various conventional models in stock, and the delivery time for customized products is 5–45 days.

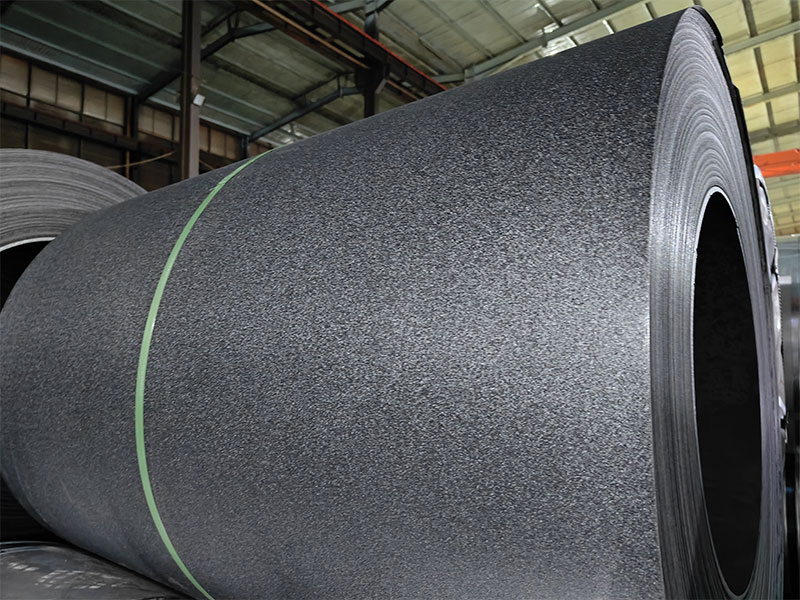

Color Coated Steel with Different Surface

PPGI’s coating is rich in color, it can protect the steel from being corroded by water and other substances in the atmosphere. The anti-corrosion period ranges from 15 to 30 years. Wanzhi PPGI steel color reference RAL, surface: Matt, wrinkle, glossy, etc.

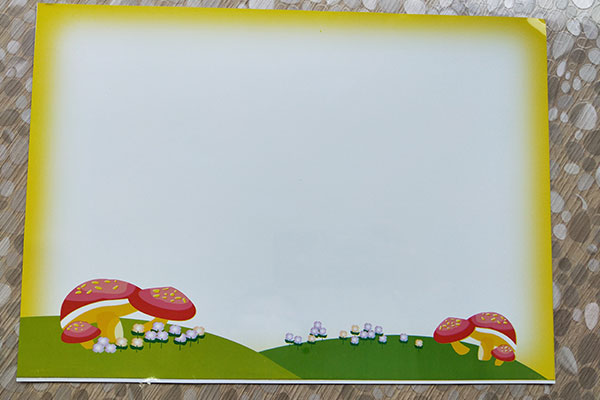

PPGI With Different Pattern Customized

In addition to paint colors and materials, you can customize the steel surface pattern according to your project needs. So far, we have more than 150 kinds of regiment stencils, popular patterns are wooden grain, flower brick pattern, and so on. Leave your desired pattern, we provide customized service.

Coating of PPGI

Application Fields Of Wanzhi PPGI Steel

PPGI (Pre-Painted Galvanized Iron) is used in a wide range of architectural, decorative and façade systems, home appliances and electronics, household appliances, electronic appliance housings, transportation and automotive, shipping and containers, energy and infrastructure, furniture and interior design, power transmission and telecom, industrial and manufacturing applications due to its lightweight and robustness, weatherability, durability, corrosion resistance, aesthetics, and cost-effectiveness.

✔ Architecture ( Roofs, walls, ceilings, partition panels)

✔ Household appliances (refrigerators, air conditioners, ovens, microwave housings)

✔ Automotive (vehicle panels, bus and train interiors, truck bodies)

✔ Industrial (shelving, piping, control cabinets, switchboards, cable bridges.)

✔ Energy (solar racks/solar frames, substation housings, telecom cabinets)

✔ Furniture (cabinets, partitions, office partitions, storage cabinets, display panels)

Pre-painted Galvanized Steel Price

The price of PPGI Steel is determined by the price of color-coated substrates of different specifications, the price of zinc coating, the price of paint film, the price of materials, and the price of paint. The price difference of different specifications of color-coated steel is 50-100 USD per ton. Leave your needs or uses, and Wanzhi will provide a cost-effective quotation.

PPGI Steel Material is Used for

PPGI steel continues the mechanical properties of steel, with good toughness, plasticity, hardness, strength, etc. Through bending, slitting, punching, molding, profiling and other deep processing can be made into PPGI coil, PPGI sheet, PPGI roofing, PPGI board, PPGI strips, etc.

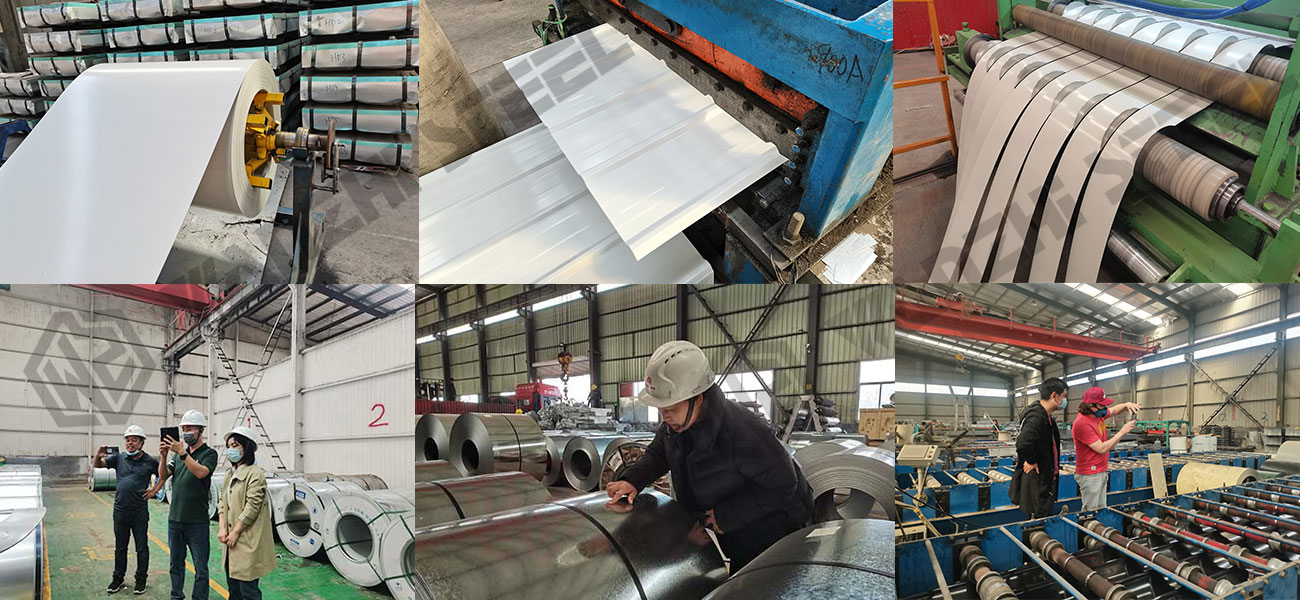

Pre-Painted Galvanized Steel Supplier – Wanzhi Group

Wanzhi Group provides various specifications and customized PPGI steel. We are committed to providing customers with high-quality materials and professional solutions to meet the needs of different projects. So far, Wanzhi has provided various color-coated products to customers engaged in home appliance production, building construction projects, greenhouse production, roof panel production and other industries.

Case Global of PPGI Steel – Wanzhi Group

Wanzhi’s color-coated steel, color-coated coil, color-coated corrugated sheet, etc. have been exported to all over the world. We have many old customers in Turkey, the Philippines, Libya, and Colombia, and we also have teams in different languages to provide service to customers around the world professional, timely service.

Service of Wanzhi Group

In addition to high-quality pre-painted galvanized steel, Wanzhi also provides customers with one-stop services, from pre-sales consultation to after-sales visits, ensuring that customers receive the most cost-effective products and services. In addition, Wanzhi Group has multiple steel production lines, from galvanizing production lines, From color coating production lines, galvanizing production lines, to writing board production lines, we have sufficient inventory and short delivery times.

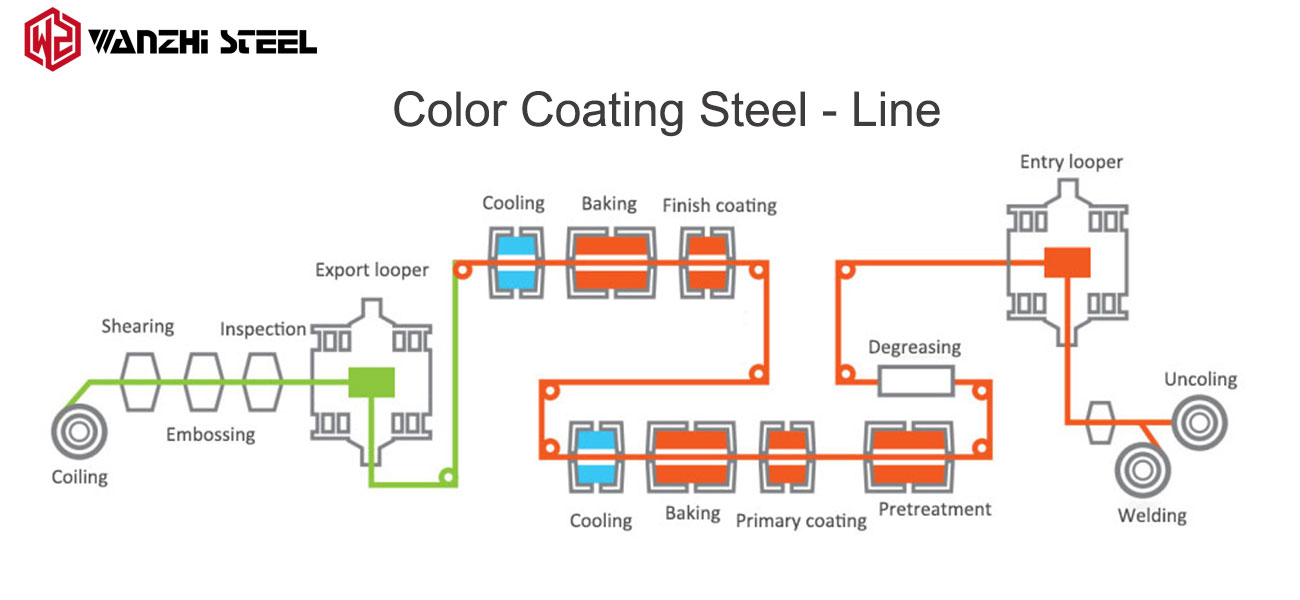

The Process of PPGI Steel

PPGI steel is made by coating the surface of galvanized sheets with organic paint and baking and solidifying it. In addition to galvanized sheets, cold-rolled sheets are also one of the commonly used substrates. Its production process mainly includes pretreatment, initial coating and fine coating. Steel plates have good corrosion resistance and are widely used.

1. Steel substrate preparation: Remove dirt, rust, and other impurities from the steel surface by degreasing and chemically removing it.

2. Surface preparation: Apply a chemical conversion coating.

3. Primer: Apply a coating of primer to the surface of the treated steel.

4. Painting: Apply organic paint to the steel surface after pretreatment and initial coating.

5. Curing: Baking and curing make the paint firmly adhere to the steel surface.

6. Others: Color-coated rolls can be coated on the surface according to the need to add additional protection.

Difference Between PPGI and PPGL

Why Choose PPGI Steel?

Excellent corrosion resistance: galvanized + (PE/SMP/PVDF) coatings are resistant to moisture, UV rays and chemicals for harsh environments.

Longer service life: 7-30 years with different coatings.

Aesthetics, flexibility and customization: Colors, patterns and shades can be customized according to application requirements.

Light weight and high strength: light weight to reduce the structural load, high tensile strength, good rigidity and toughness, high bearing capacity.

Easy processing: cutting, bending, molding, slitting, rolling and welding.

Wide range of applications: Can be used in construction, appliances, transportation, energy, etc.

When to choose PPGI?

Cost-sensitive projects: PPGI steel is more economical and durable than PPGL/stainless steel/aluminum/PPAL.

Harsh Environments: PVDF-coated PPGI has superb weather and corrosion resistance.

Aesthetic Design: PPGI is available in a wide variety of colors/textures and finishes.

Lightweight Requirements: PPGI is lightweight, strong, durable and easy to install.

PPGI steel or PPGL steel is widely used in construction and industrial fields with its excellent anti-corrosion properties and chemical properties. Wanzhi is also designing and producing more styles and models of color-coated rolls according to customer needs. You are welcome to leave your requirements or questions, and we will reply after receipt. Difficulties will be answered within 12 hours after receiving your information.