What is Zinc Spangle?

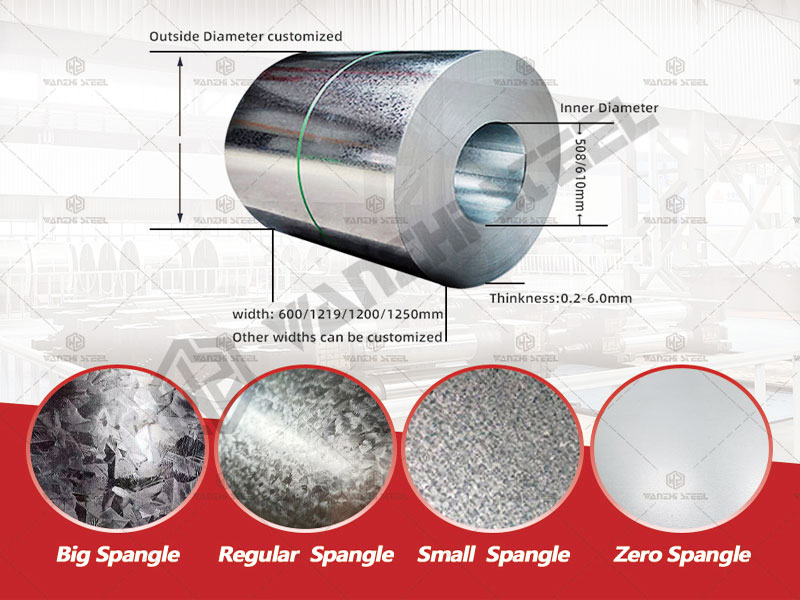

Zinc spangle is mainly found on the surface of HDG hot-dip galvanized steel, it refers to the hot-dip galvanizing process, the zinc liquid cooling in the steel surface formation of irregular zinc crystal pattern, which the size of the pattern, the density, uniformity can be varied with the process, common galvanized steel zinc spangle, large galvanized spangle, regular zinc spangle, small zinc spangle.

Reasons for the Formation of Zinc Flowers on the Surface of GI Steel

During the galvanizing process, the steel is immersed in a zinc solution, which forms a layer of zinc on the surface of the steel. Changes in temperature, cooling rate, and composition of the zinc solution during cooling of the galvanized steel result in the growth of zinc crystals, which in turn form zinc spangles of different shapes and sizes. Therefore, the size of the zinc spangle can be customized according to the project requirements.

Adjusting the Zinc Spangle

The higher the temperature of the zinc solution, the larger the zinc spangle will be, and the opposite is true: the smaller the spangle will be. Electro galvanized steel processed by electrolysis at room temperature has a smooth surface without zinc spangles.

The faster the cooling rate, the smaller the zinc spangle on the steel surface, the slower the rate, the larger the zinc spangle.

The thicker the zinc layer, the more pronounced the zinc spangle, so galvanized steel with a zinc spangle is usually thicker and more resistant to corrosion.

Factors Affecting Zinc Spangle

- Zinc composition: Lead, antimony, and other elements promote zinc spangle.

- Surface treatment: passivation can inhibit zinc spangle.

Types of Zinc Spangle on Galvanized Steel

- Regular zinc spangle: Architectural, industrial applications

- Small zinc spangle: automotive parts/panels, appliance panels

- Zinc free: Electronics, Decoration

The Effect of Spangle on the Properties of Galvanized Steel

Galvanized steel has good corrosion resistance, mechanical properties, adhesion, heat resistance, machinability, and aesthetics. The thicker the zinc layer, the better the corrosion resistance of galvanized steel.

- Corrosion resistance: No direct effect, but a uniform zinc coating means a stable process and better quality steel.

- Appearance: Large zinc spangle is suitable for less demanding applications, and small spangle or zero spangle galvanized steel is suitable for high-end outdoor applications.

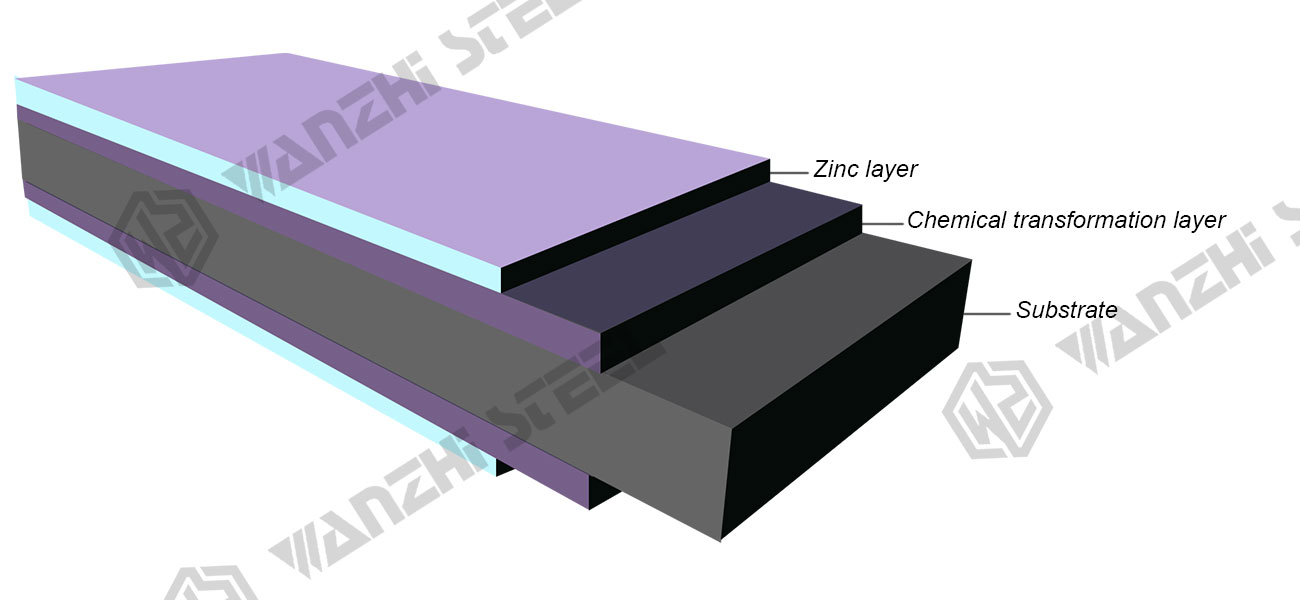

- Adhesion: Zinc spangle reduces the adhesion of the coating, and if further processing such as spraying, passivation, etc. is required, a chemical conversion layer of zinc is applied to the galvanized steel.

How to Choose the Right Spangle Galvanized Steel?

When selecting a galvanized steel, you can refer to ASTM A123 (hot-dip galvanizing requirements), and ISO 1461 (galvanizing thickness and testing), and then choose the right galvanized steel for your application, appearance requirements, environmental conditions, project budget, and surface finish requirements.

Application

Hot-dip galvanized steel with a zinc coating is preferred for applications in highly corrosive environments such as marine and chemical environments.

Appearance

Galvanized steel-free spangle is the preferred choice for special appearance requirements or precision machining.

Environment

Outdoor environments, or environments with high humidity and chemically corrosive substances, choose hot-dip galvanized steels with a thicker zinc coating for greater corrosion resistance. For indoor environments, choose a steel with a thinner zinc coating.

Surface Finish

Electro-galvanized steel has a smooth surface that is not prone to zinc splashes and is relatively easy to weld.

Frequently Asked Questions

Q: Does zinc spangle affect the corrosion resistance of galvanized steel?

A: Corrosion resistance is determined by the thickness and purity of the zinc layer. Zinc splashes are only a surface feature and do not affect the protective properties.

A: Choose zinc: low-cost industrial scenarios (e.g. shelves, fences).

Choosing zinc-free: Scenarios that require painting or high appearance requirements (e.g., automotive, home appliances).

Wanzhi Group – Strengths and Services

Wanzhi Group factory is ISO quality management system certified, with precise zinc spangle control technology and zinc layer thickness gauge, salt spray laboratory, support customized galvanized steel with different surface effects, products comply with international standards such as ASTM/JIS/EN, and support third party inspection such as SGS. If you are looking for galvanized steel with or without zinc coating, welcome to contact us for prices or samples.