ZAM Steel Specification

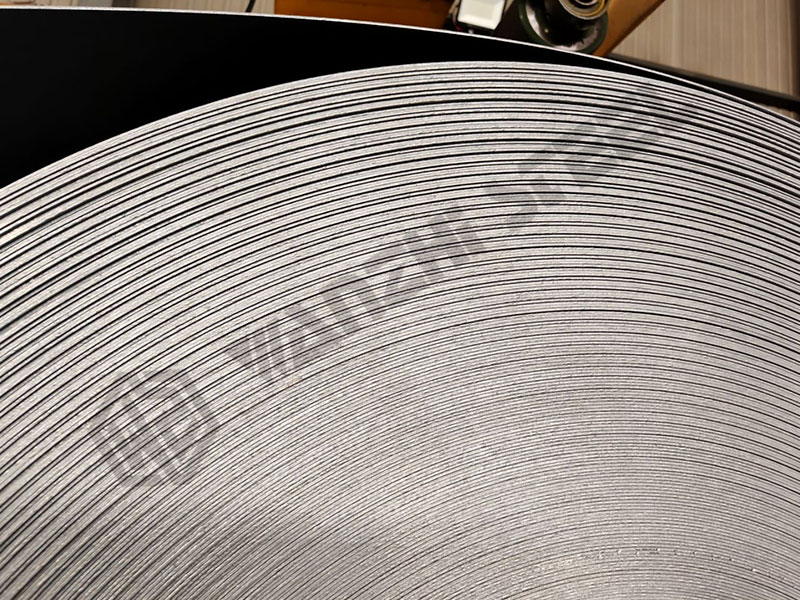

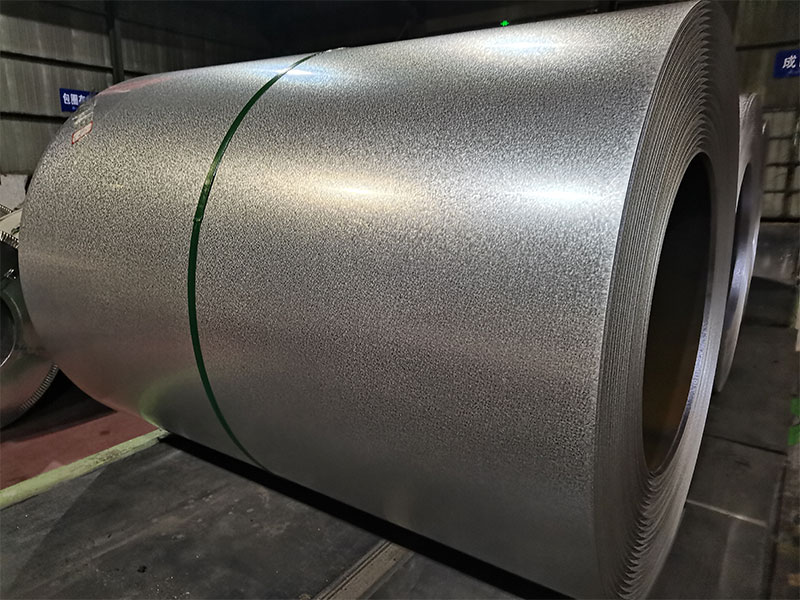

Wanzhi Group has a galvalume and ZAM coating steel production line with an average monthly output of 10,000 tons, producing full-size alloy-coated steel with a delivery time of 5–45 days. If you are interested in coated steel, you can contact us to request a sample!

| ltem | Product Parameter |

|---|---|

| Type | ZAM Steel Coil |

| Based Metal | Cold Rolled Steel |

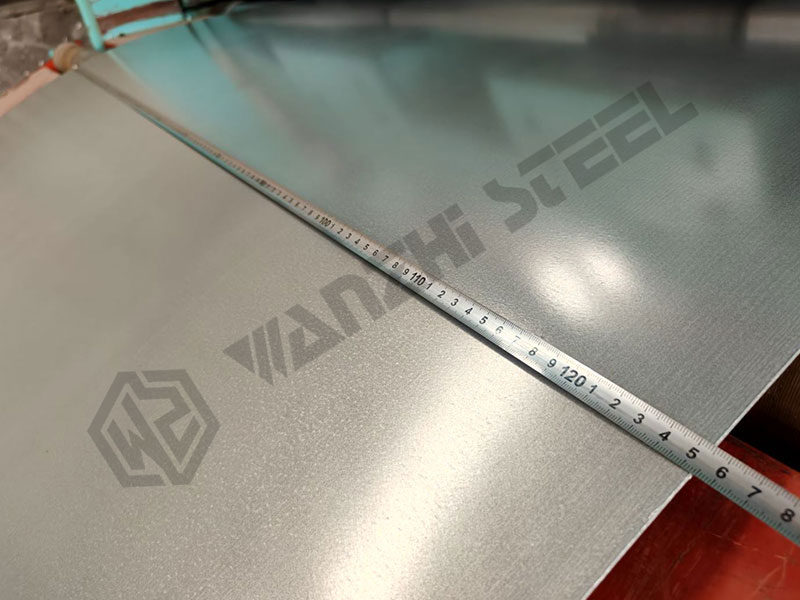

| Thickness | 0.5mm-4.0mm |

| Width | <1500mm |

| CoatingThickness | 80-275 g/㎡ |

| Standard | AISI, ASTM, DIN, GB, JIS, BS |

| SurfaceTreatment | Chromatedskinpassed/oiled/non-oiled /dry/Anti-finger printing |

| Applications | Mainlyused in construction,automobiles, homeappliances,hardware accessories, base metal, etc. |

| Package | Standard exportpackage(waterproof paperinside and steel stripsoutside |

Price of ZAM Steel coil and Sheet

How much does the ZAM steel cost? 650-850 USD per ton. Zinc-aluminum-magnesium (ZAM) coated steel is a ternary alloy coated steel, which is more expensive than other metal-coated steel or alloys. Please send us a message via WhatsApp or Email with your specifications, coating thickness, and weight, and get wholesale prices for ZAM!

ZAM Steel Coating and Applications

ZAM steel is a high-strength steel substrate coated with an alloy layer of three metals, Zn, Al, and Mg. Zn improves the corrosion resistance of the steel, Al provides weathering and oxidation resistance, and Mg enhances the corrosion resistance of the steel. The higher the aluminum and magnesium content, the better the corrosion resistance.

Common Coating Types

- Zn +1.5%Al+1.5%Mg.

- Zn +2%Al+2%Mg.

- Zn +11%Al+3%Mg. (Coating used by Wanzhi ZAM)

Application

- Automobile exterior panels, home appliance exterior panels, etc.

- Color-coated substrates, interior panels for home appliances, etc.

- Soundproof board, photovoltaic support, outdoor screen/fence, etc.

ZAM Coated Steel Benefits

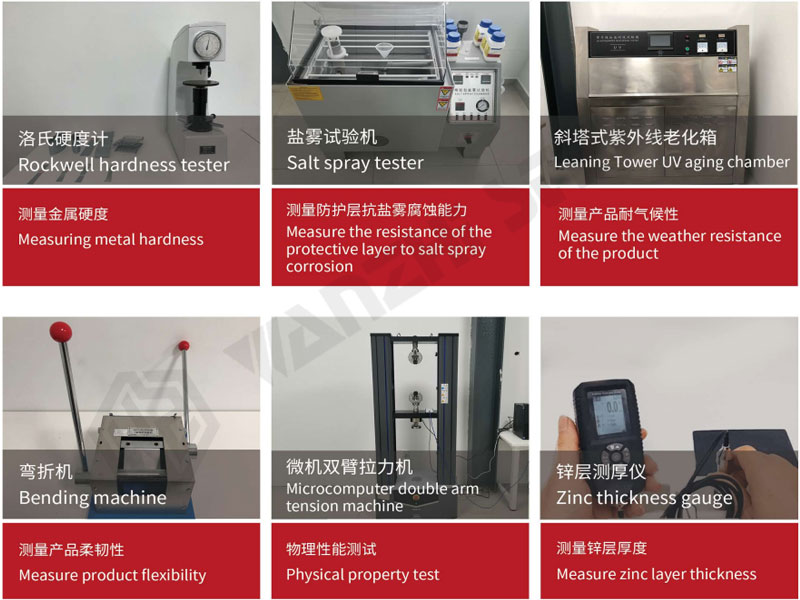

- Corrosion resistance: ZAM coating can make the steel in the humidity, salt spray, and other environments to maintain the performance of stability, and can resist the erosion of harsh weather conditions.

- Self-repairing properties: ZAM-coated steel maintains high corrosion resistance even in scratched or damaged areas.

- Weathering: Keeps steel from deforming in high-temperature environments.

- Durable: Zinc-aluminum-magnesium-coated steel is harder and has good wear resistance.

- Machinability: It can be cold-worked, cut, bent, stamped, and used for other in-depth processing.

Comparison of GI, GL ZAM Steels

GI steel, GL steel, and ZAM steel are three common metal-coated steels and Wanzhi Group’s popular coated steel materials, which are widely used in construction, industry, transportation, and other fields. However, the coating compositions of these three materials are different, so there are differences in price, performance, and application.

- Cost: galvanized has the lowest processing cost, galvalume has a relatively high cost, and Zinc-Aluminum-Magnesium has the highest cost.

- Hardness: GI hardness is 55Hv-65Hv, GL hardness is 100Hv-110Hv, and ZAM hardness is 140Hv-160Hv.

- Corrosion resistance: ZAM is more corrosion resistant than GL and GI steel.

- Uses: galvanized steel is mainly used in general indoor and outdoor environments, Galvalume steel is suitable for use in humid and high-temperature environments, and Zinc-Aluminum-Magnesium steel is suitable for use in marine and chemical environments.

ZAM Coating Factory and Supplier

Wanzhi ZAM steel has been exported to more than 100 countries and regions such as South Africa, UAE, Zambia, Uzbekistan, Singapore, etc. We are an ISO-certified supplier in China, and we can provide professional and customized solutions for different applications in various fields.

We have rich metal material products, besides metal-coated steel, we also have color-coated steel, stainless steel, colored aluminum, and so on products, welcome to contact us for price and service.

ZAM Steel for Sale

Wanzhi Steel ZAM steel factory from China, produces all sizes of ZAM coil, ZAM sheet, ZAM strips, etc. according to various standards (GB, ASTM, GB, EN, etc.).

Products

Wanzhi Coated Steel Factory produces all kinds of metal-coated steel, alloy-coated steel, and color-coated steel products, our products include galvanized steel, aluminum galvanized steel, stainless steel, painted steel, etc. We have been providing high-weathering, fire-resistant, and corrosion-resistant steel materials for construction, industry, home appliance production, transportation facilities, energy, and other fields.

Service

- One-stop service, including solution development, production, transportation, after-sales service, and spare parts procurement.

- Sufficient stock: We have cold rolled coils and hot rolled coils in stock in our warehouses, enabling us to produce and deliver quickly, with a lead time of 5–45 days.

- Stable price: Due to our stock of raw materials and our production line, we can reduce the cost of production in terms of raw materials and production efficiency, and minimize the impact of fluctuating steel prices in the market.

- Free Sample: Our factory can provide samples.

Project

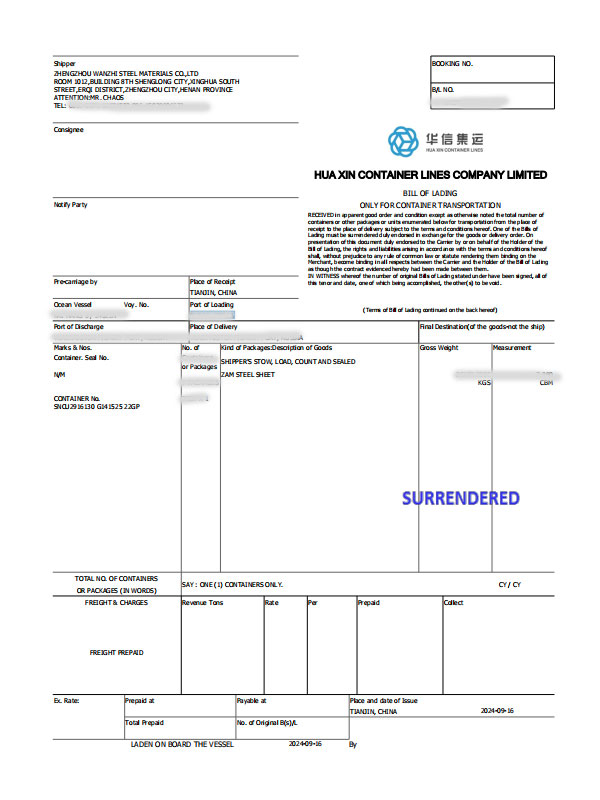

Recently, we exported one container of ZAM sheet to Kazakhstan, the end customer is a local new energy company in Kazakhstan, which purchased ZAM for manufacturing photovoltaic mounts. Wanzhi has a lot of customers for coated steel in Kazakhstan, so our customer trusts us very much, so our first cooperation is very smooth!

ZAM Coated Steel Use and Maintenance

ZAM coated steel sheet is a new type of coated steel sheet with a wide range of uses, excellent performance, and self-repairing ability that can replace stainless steel and aluminum in some areas.

Maintenance

Good maintenance can extend the service life and corrosion resistance of metal-coated steel.

- Routine maintenance: Check whether the zinc aluminum magnesium alloy layer has scratches off, to repair the scratches off the coating.

- Cleaning: Regularly clean the surface of ZAM steel with detergent.

- Anti-corrosion: You can spray paint or other treatments on the surface of ZAM-coated steel.

- Storage: Keep the storage environment dry and away from acids and alkalis.

- Installation: Avoid scratching the alloy coating during use.