Wanzhi Group Pre-painted galvanized cold-rolled steel coil (PPGI coil), Pre-painted galvanized C.S. COIL, with the double protection of galvanization + organic coating, combines corrosion resistance, weathering resistance, decorative and processability properties, which is an ideal material for the fields of construction, household appliances, industry, automotive, energy, etc.

CONTACT US

Pre-painted Galvanized Cold Rolled Steel Coil PPGI Coil

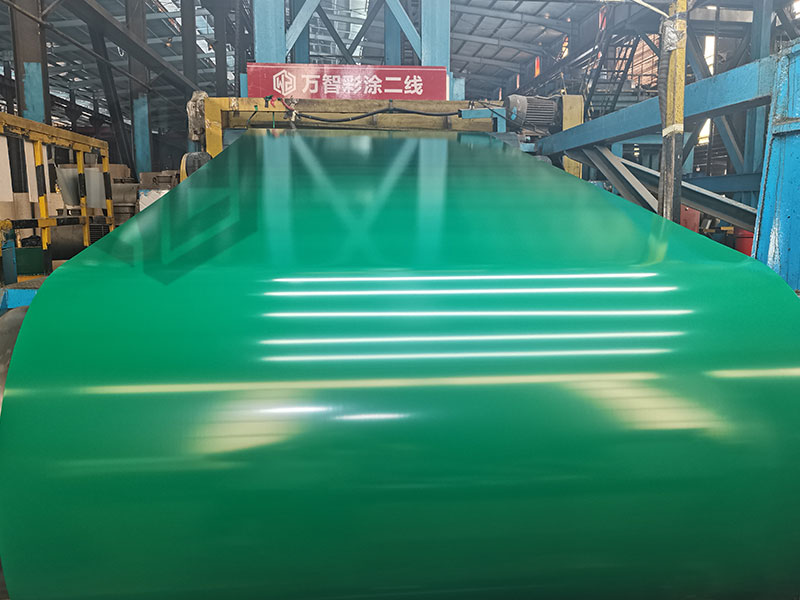

Pre-painted galvanized cold-rolled steel coil is a color-coated steel made from cold rolled steel coils by hot dip galvanizing/electro galvanizing process to form a uniform pure zinc coating on the surface, followed by roll-coating with one or more layers of organic paint.

Structural Components

- Cold Rolled Steel Substrate: Low carbon steel (e.g. SPCC, DC01), formed by cold rolling process, with high surface flatness.

- Galvanized layer: hot dip galvanized (HDG) or electro galvanized (EG), zinc layer weight 30~350g/m² (e.g. Z30-Z350).

- Chemical conversion layer: Chromated or chrome-free passivation (zirconium/titanium) to enhance coating adhesion.

- Organic coating: primer (epoxy resin) + topcoat (polyester PE, silicone-modified polyester SMP, fluorocarbon PVDF, high weather-resistant polyester HDP, etc.), single-side coating thickness of 5~25μm.

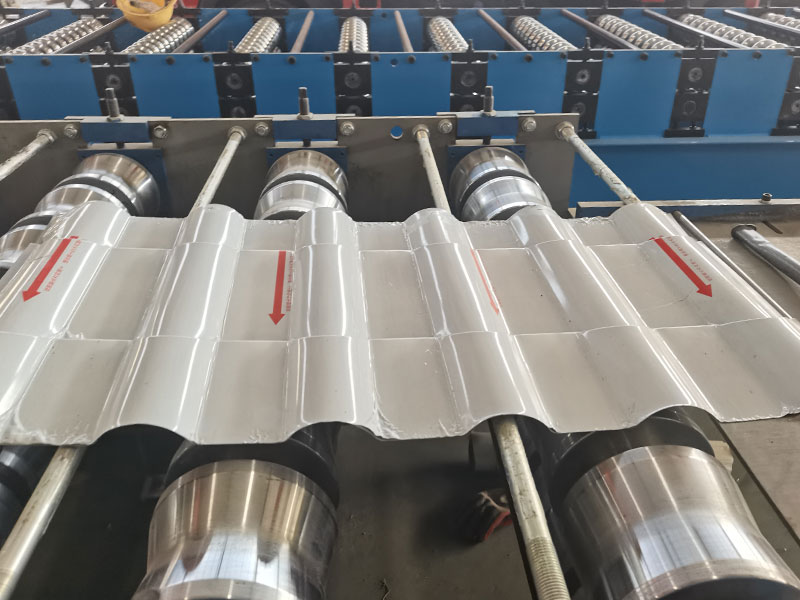

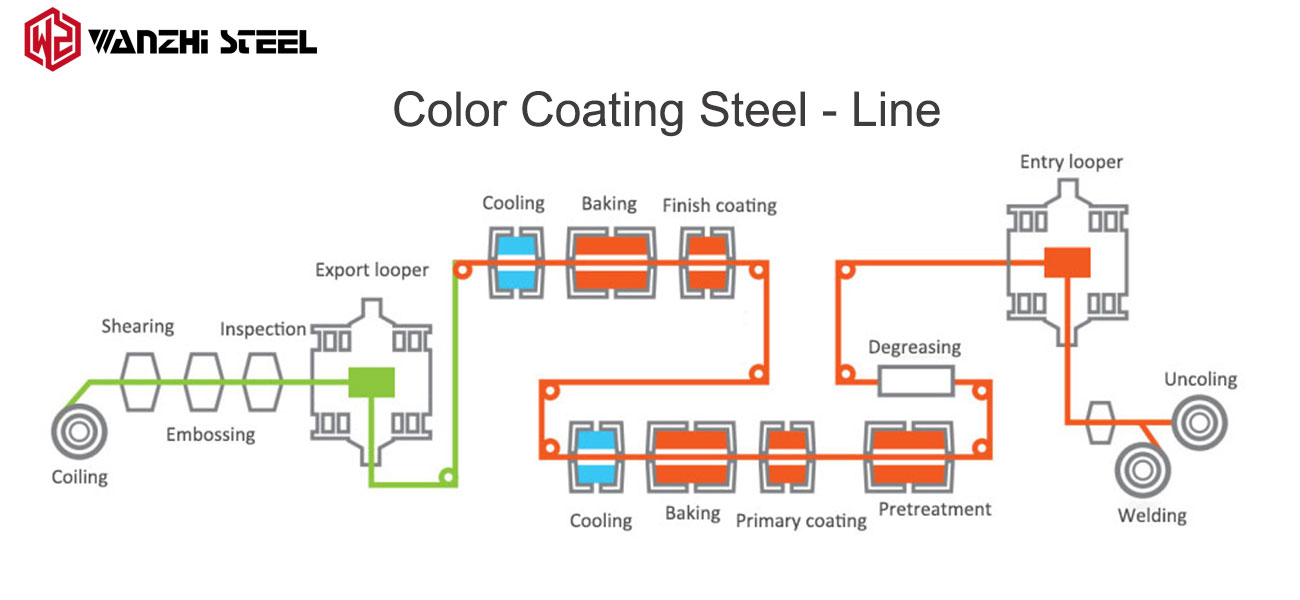

Production Process

Cold rolled substrate preparation

- Cold rolled low carbon steel coil → cleaning and degreasing → annealing → leveling.

Galvanizing treatment

- Hot-dip galvanizing (HDG): immersion in zinc solution at 450~465°C → air knife to control the thickness of zinc layer → cooling → chromating/chrome-free passivation.

- Electro Galvanizing (EG): Electrolytically deposited zinc layer (more uniform thickness, but thinner than hot-dip galvanizing).

Coating Coating

- Roller applying primer → Drying (100~150℃) → Roller applying top coat → Curing at high temperature → Cooling .

Core Performance

| Performance | Typical Values |

|---|---|

| Salt Spray Resistance | Z120+PE coating: ≥500 hours without red rust; Z180+PVDF coating: ≥1000 hours |

| Adhesion | ≥4B level (no peeling of the coating) |

| Bending Performance | 0T~2T (T = plate thickness, for 0.5mm plate, bending radius of 0.5mm without cracking) |

| Weather Resistance | PVDF coating: 2000 hours gloss retention ≥80%, color difference ΔE ≤ 2.0 |

| Hardness | PE coating: ≥2H; PVDF coating: ≥3H |

Specification

| Grades | GI/GL/SPCC/SPCD/SPCE/DC01-DC07/Q195、Q215、Q235 |

|---|---|

| Colors | Top/Back:RAL,Painted steel,3D Painted steel, etc(can be customized) |

| Thickness | 0.12-1.5 mm |

| Width | 600-1250mm/ customized |

| Coil Weight | 3-6 tons/ customized |

| Substrate Type | Hot dip galvanized, Galvalume, Zinc alloy, Cold rolled steel, Aluminum-zinc plated steel,Zimalium |

| Zinc Coating Thickness | Z30-275g/ ㎡,AZ30-150g/ ㎡ |

| Introduction to Coating | PVDF、HDP、SMP、PE |

| Coating Thickness | Top :10-40 um,Back:5-20 um |

| Inside diameter | 508/610mm |

| Package | Standard export package or as per your requirements |

| Certificates | SGS, ISO 9001,CE |

| Date of Delivery | 5-45 days |

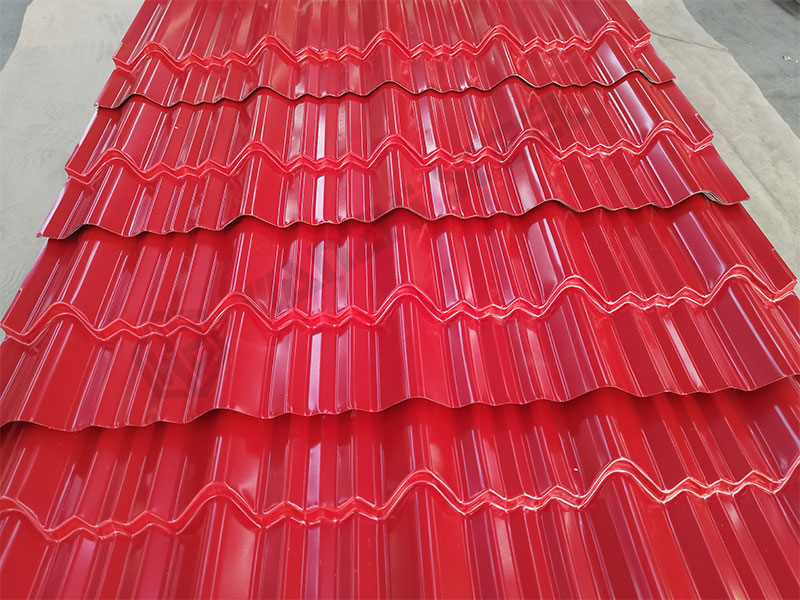

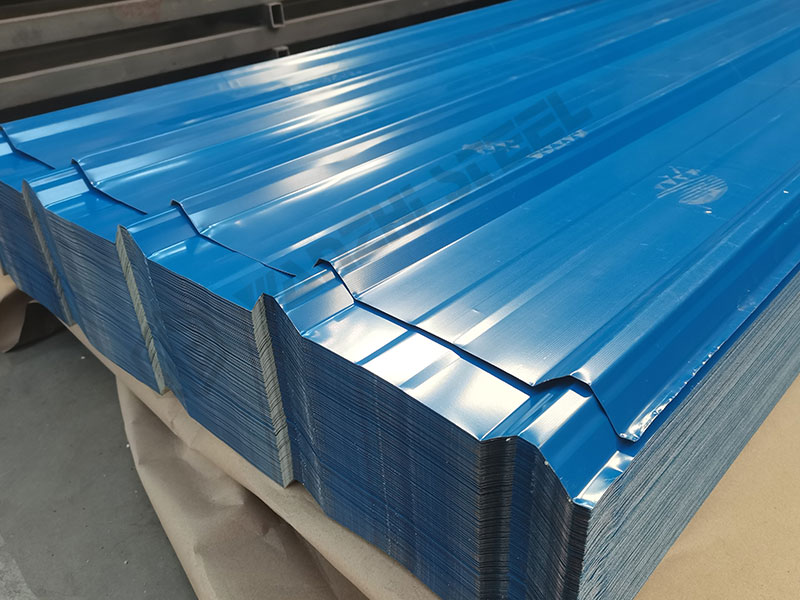

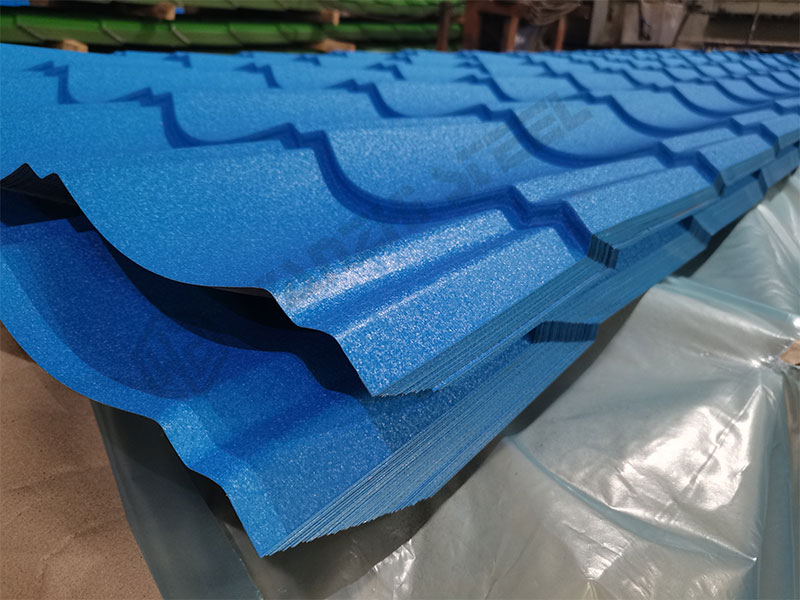

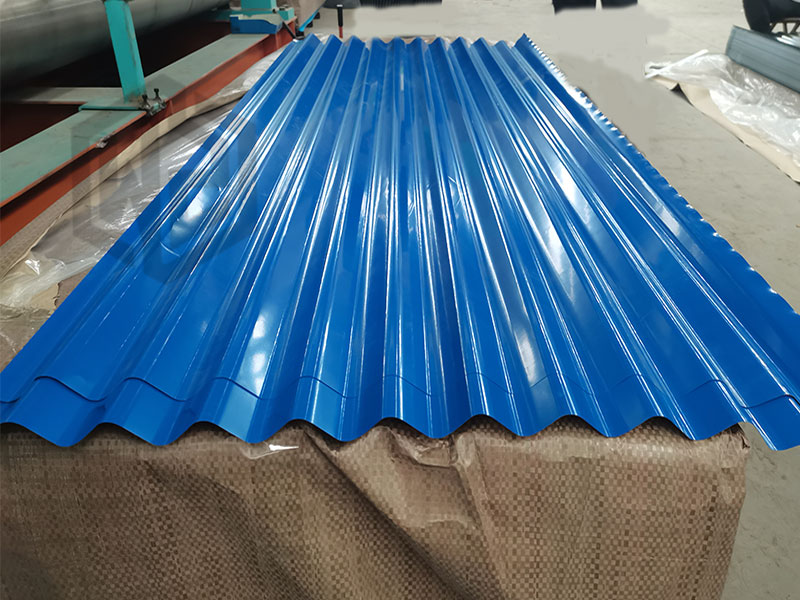

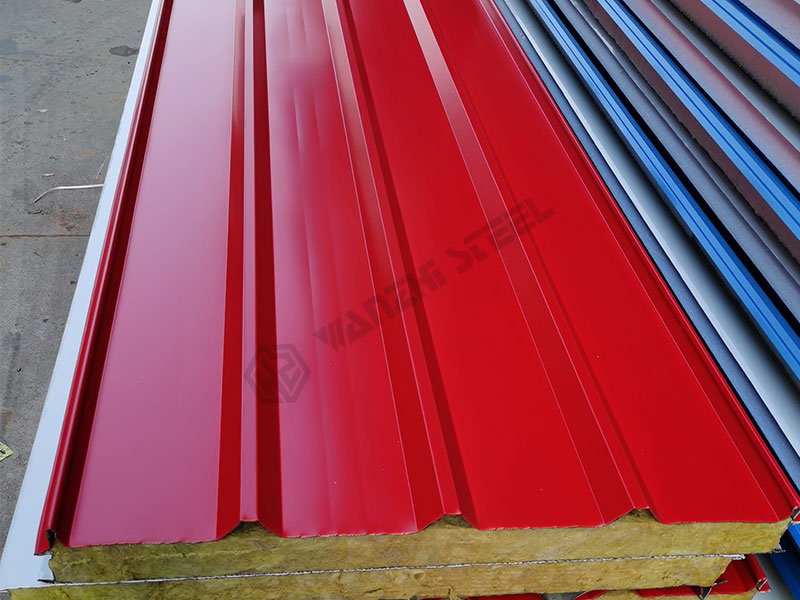

Pre-painted Galvanized Cold-rolled Steel coil Application Scenario

Pre-painted galvanized cold-rolled steel coil can be widely used as color steel tiles, curtain wall panels, noise barriers, refrigerator/air-conditioner shells, washing machine panels, truck panels, container shells, container houses, ventilation ducts, storage shelves and other materials in the fields of construction, home appliance manufacturing, transportation, industrial equipment, agriculture and so on.

Construction and Decoration

PPGI Pre-painted galvanized has the characteristics of lightweight and durable, waterproof and rustproof, colorful and customizable, environmentally friendly and easy to install, weather-resistant, stain-resistant, self-cleaning, etc. It can be used as a substitute for natural materials (e.g., woodgrain, stonegrain) for a wide range of residential, commercial, and industrial buildings and decorations.

- Roofing and walling systems, such as industrial plants, commercial buildings, stadium roofs, etc.

- Interior decoration, e.g., hotel ceilings, shopping mall partitions, office walls, etc.

- Public facilities, e.g. bus stops, highway noise barriers, airport terminals.

Appliance and Electronics Manufacturing

Organic coatings provide a smooth, easy-to-clean, colorful, fingerprint-resistant, electromagnetically shielded, lightweight, and anti-static finish to steel, and play an important role in the appliance and electronics manufacturing industries.

- Structural components for electronic equipment, e.g., refrigerator panels, washing machine housings, microwave oven door panels.

- Appliance housings, e.g., server chassis, 5G base station housings, smart home control panels.

Transportation

PPGI Steel’s lightweight design, salt spray corrosion resistance, fire-retardant, marine environment corrosion resistance and other properties enable it to maintain stable performance in outdoor, high temperature, high humidity and other applications.

- Automobile and truck components, such as truck panels, new energy vehicle battery shells, truck chassis guards.

- Rail transportation and ships, for example, high-speed railroad interior panels, yacht decks, ship bulkheads.

Industrial equipment and storage

The advantages of pre-painted steel (PPGI PPGL), such as resistance to moisture and chemical gases, high hardness, scratch resistance, and high load-bearing capacity, make it play an important role in some industrial fields.

- Ventilation and piping systems, e.g., factory ventilation ducts, laboratory exhaust systems.

- Warehouse shelving and tool cabinets, e.g., warehouse shelves, tool boxes, logistics containers.

Agriculture and other outdoor applications

In addition, coated steels, especially color-coated steels, with their corrosion-resistant, light-transmitting or heat-insulating design and high gloss/print-friendly surfaces, can also be used in agriculture, advertising and education.

- Agricultural facilities, e.g. greenhouses, farm roofs, grain silo roofs.

- Advertising and display, e.g. outdoor billboards, exhibition stands, promotional signage in shopping malls.

- Education, e.g. writing boards, blackboards, etc.

Pre-painted Galvanized cold-rolled Steel Coil Suppliers

If you are looking for pre-painted galvanized cold-rolled steel coil, Wanzhi Group will be your ideal partner, we provide one-stop steel service from raw material, production, processing, transportation to after-sales, we will provide the most cost-effective solution according to your application needs.

Pre-Coated Galvanized Products

We stock cold rolled steel coils, hot rolled steel coils, conventional galvanized and aluminized zinc coils, as well as pre-painted steel coils, pre-painted steel sheets, and other materials, and we can provide cutting, slitting, forming, and punching services according to project requirements.

- Painted Steel Coil (PPGI PPGL)

- Painted Steel Sheet (PPGI PPGL)

- Roof panels

- Wall panels

Steel Factory and Production Line

Our factory shandong wanzhi steel is located in Boxing County, Binzhou City, Shandong Province, China, with carbon steel stock, 3 galvanized production lines, 3 painted production lines, 1 writing board production line, certified to ISO9001, ISO1400 and so on.

Pre-painted galvanized cold-rolled Steel Coil OEM/ODM

OEM: Wanzhi Group has mature production process and technology to produce according to your requirements of size, specification, color, surface effect, coating, etc. and offer the most competitive price of coated steel.

ODM: We also provide full customization service, we can design and produce according to the application scenario and environment, and provide the most cost-effective steel solutions.

Customer Feedback

Our coated steel, including metal coated, alloy coated, color coated steel, has been exported to more than 100 countries and regions. Meanwhile, we show our customers our productivity, factory, samples and quality control room through online and offline. If you are planning to visit pre-painted galvanized steel factory, please feel free to contact us either by site visit or online meeting!

Pre-painted galvanized cold-rolled steel coil combines the mechanical properties of cold rolled steel with the corrosion resistance, weatherability, and aesthetics of zinc and organic coatings to play an important role in the construction of roofs and walls, the production of home appliances, industrial manufacturing, and other areas. What kind of coated steel materials are you looking for? Leave a comment and let us know for a free quote!