Wanzhi Group is a professional supplier of coated metals, improving one-stop service for metal materials, such as pre-painted aluminium sheet, prepainted galvanized/ galvalume sheet OEM, ODM service, our factory has professional prepainted production line, with annual production capacity of 600,000 tons, we can provide the sample and testing.

Pre-painted Aluminium Sheet Introduction

Colour coated aluminum (pre-painted aluminium sheet, PPAL for short) is a kind of decorative sheet made by spraying/roller coating on the surface of aluminum alloy substrate, which has the features of light weight, high strength, corrosion resistance, high heat reflectivity, rich color, high elongation, etc., and is widely used in the fields of construction, home appliances, food, transportation, etc. Structure

Structure

Color Aluminum Sheet is composed of five parts, including base plate, chemical conversion layer, primer layer and top coat, among which the base plate provides strength, chemical conversion layer enhances the adhesion of coating, primer layer improves the adhesion of top coat, and top coat provides decorative and antirust functions.

- Base plate: aluminum alloy (common grades such as 3003, 3004, 5005, etc.).

- Chemical conversion layer: chrome or zirconium treatment.

- Primer layer: Epoxy or polyester primer.

- Top Coat Layer: Polyester (PE), Fluorocarbon (PVDF), Acrylic and other materials paint + monochrome, metallic flash, imitation wood grain, imitation stone grain, imitation brushed metal and other surface effects.

- Back coating (optional): protect the back of the substrate, commonly PE or epoxy coating.

Production Process

The production process of color aluminum alloy plate mainly includes substrate treatment, painting and pressing.

- Substrate: choose aluminum alloy for pre-treatment

- Coating: choose the paint material and roll it evenly on the surface of aluminum alloy substrate.

- Curing: Bake at high temperature to make the coating and the substrate close together.

- Processing: According to the application requirements of the color aluminum coil for cutting, embossing and other processing.

Types of Prepainted Aluminum Sheet

Prepainted aluminum sheet according to the surface structure can be divided into three categories: flat plate, pressing plate, composite plate.

- Flat plate: cut from the color aluminum coil, the surface is smooth, flat plate.

- Pressure plate: through the roll molding for corrugated, diamond and other surface structure of the three-dimensional plate type.

- Composite panels: also known as sandwich panels, composed of two layers of colored aluminum panels + a core material. Common products are aluminum composite panels and aluminum honeycomb panels.

Pre-painted Aluminium Sheet Performance Advantages

pre-painted aluminium sheet metal combines the advantages of aluminum alloy and functional paint, with light weight, high strength, corrosion resistance, weatherability and color durability, good ductility and so on.

Properties

- The density of aluminum is only 2.7g/cm³ (1/3 of steel).

- The tensile strength of commonly used aluminum alloy grades (e.g. 3003, 5052) can reach 150~300MPa.

- Salt spray test: ≥3000 hours without red rust.

- QUV aging test: more than 4000 hours without chalking.

- Color difference ΔE<2.

- Cold bending: the minimum bending radius can be up to 1 times of the thickness of the plate.

- Aluminum melting point: 660°C

- UV reflectivity: light color reflectivity >80%

- 100% recyclable: aluminum recycling energy consumption is only 5% of primary aluminum production.

Advantages

- Reduced energy consumption

- Wind resistant

- Salt spray resistant

- 20 years maintenance free

- Aesthetically pleasing

- Lightweight

- Drainage efficient

- Fine touch

- Scratch resistant

Pre-painted Aluminium Sheet Application

pre-painted aluminium sheet has a wide range of substrates, various coatings/colors/surface effects, and the sheet design can be completed according to the application requirements, which is one of the popular metal materials in the fields of architectural decoration, industry, household appliances, transportation, food packaging, electronic and electrical appliances, printing, advertising and so on.

Building decoration

color aluminum panels are widely used for ceiling, partition and wall decoration of industrial plants, warehouses, gymnasiums and other buildings, providing decoration and protection for the buildings and improving the aesthetics of the buildings at the same time.

- Curtain wall: aluminum panels with high weather resistance, wind pressure resistance, fire resistance, etc., PVDF fluorocarbon coated aluminum panels and aluminum honeycomb composite panels with 3004/H24 substrate are recommended.

- Metal Roofing: panels with UV/acid rain resistance and light weight, PVDF coated colored aluminum panels with 5052 substrate are recommended.

- Interior decoration: aesthetically pleasing, easy-to-clean, anti-bacterial and fire-resistant metal panels, PE-coated bionic aluminum or anti-bacterial coated aluminum panels on 3003 substrate are recommended.

- Ceiling: lightweight and sound-absorbing, perforated sound-absorbing aluminum sheet or matte PE-coated aluminum sheet are recommended.

Industry

The excellent acid and alkali resistance of colored aluminum makes it widely used in the construction of chemical and electroplating factories, grain warehouses and storage spaces in farmers’ markets.

Transportation

Colored aluminum is one of the popular coated steel materials for the interiors or shells of cars, trains, ships, high-speed rail/subway carriages and other means of transportation, as well as signs for transportation facilities, advertising panels, and bags, and it is recommended to use the 5-series high-strength aluminum alloy plate (5052/H34) to improve the impact resistance of the aluminum plate, to reduce the weight and to enhance the aesthetics.

Home Appliances and Electronics

In life, such as refrigerator/air conditioner panels, the shell of electronic products often use color coated aluminum alloy, aluminum surface flatness, good heat dissipation performance, used in home appliances and electronics can enhance the aesthetics and durability of the product, commonly used products are brushed aluminum plate, PE anti-fingerprint coated aluminum, anodic oxidation of aluminum (6061-T6) + color coated and so on.

Other fields

treating construction and technology, in the food, printing field is often used in food cans, can lids, bottle caps, box lids, pull ring, food boxes, all kinds of food packaging sealing bags and manufacturing PS plate, CTP plate and UV – CTP plate production.

Pre-painted Aluminium Sheet Factory Supplier

Wanzhi Group is a steel factory supplier from China, covering carbon steel, coated steel, alloy steel, stainless steel, coils/sheets/strips/tubes and so on. We not only supply steel in various materials, but also provide further processing services such as plating, painting, slitting, profiling, bending, punching and stamping.

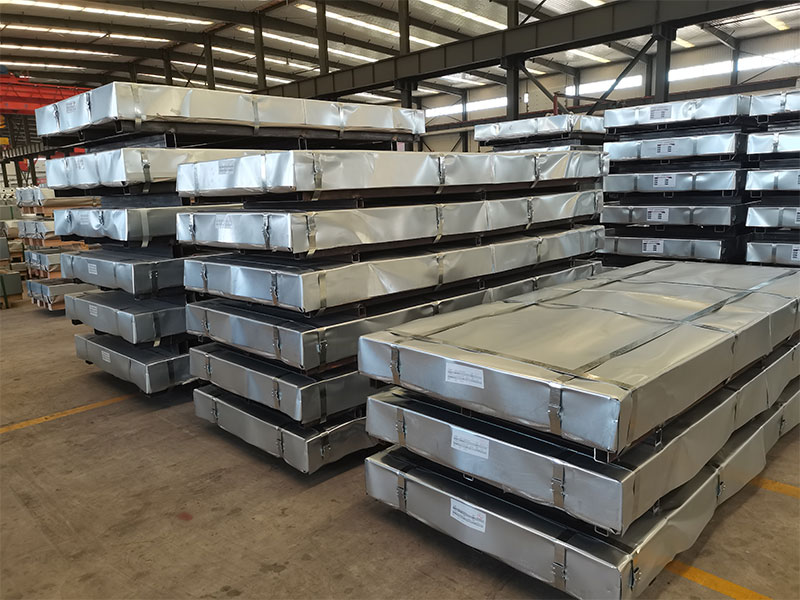

Production Lines

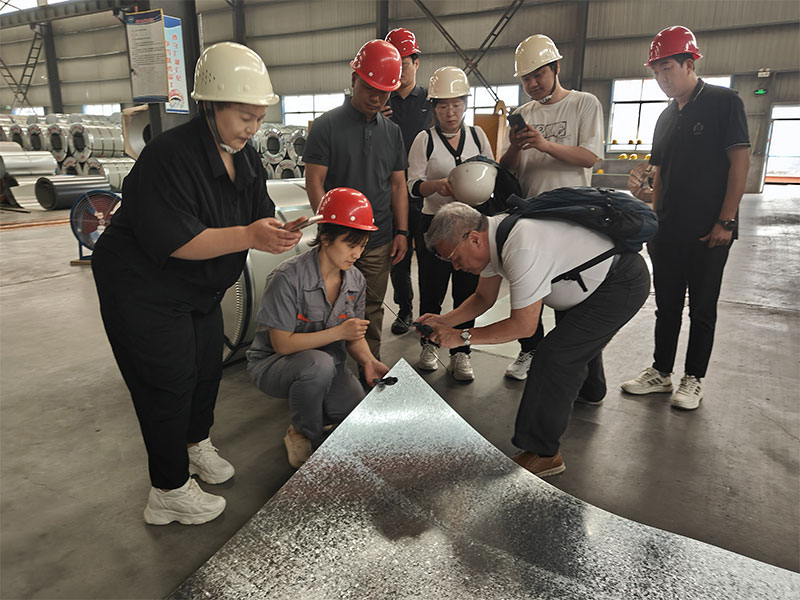

We have 3 painted metal production lines in our factory, with an average monthly production capacity of 30,000 tons and a production cycle of 5-45 days. We have a full process of quality inspection from raw materials to finished products, and our quality inspection room is equipped with coating thickness meter, color difference meter and other equipments, to ensure that the quality of the products is in line with the international standards.

Services and Products

Wanzhi Group improves OEM ODM services for aluminum alloy materials, which can be produced according to the specified specifications or designed for the application environment, with customized scope: material specification, coating material and thickness, surface treatment, surface effect, finished products and so on.

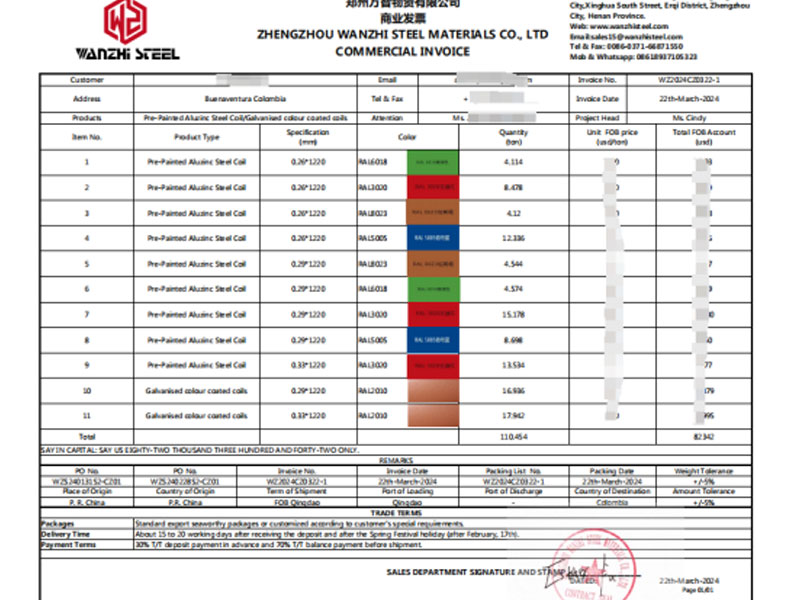

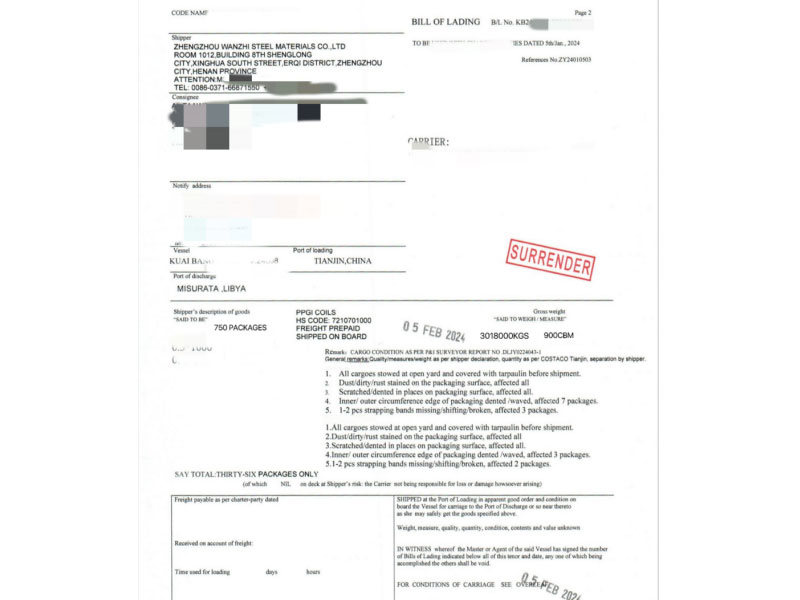

Project and Case

So far, we have supplied premium pre-painted aluminium sheet to building material factories and traders and received feedback from customers all over the world.

Pre-painted Aluminium Sheet vs. Color Steel Sheet

| Feature | PPAL | PPGI/PPGL |

| Substrate | Aluminum Alloy | Galvanized Steel/Aluzinc Steel |

| Weight | Lighter | Heavier |

| Corrosion Resistance | Excellent | Depends on coating and layer |

| Strength | Lower | Higher, better load-bearing capacity |

| Cost | Higher | Lower |

| Applicable Scenarios | Curtain walls, ceilings, decorations, ships | Roofs, walls, structural components |

Pre-painted Aluminium Sheet Suggestions

When purchasing pre-painted aluminium sheet, product performance should be the main decision-making criterion, followed by supplier’s strength, and finally the price.

Substrate Quality

The substrate material for prepainted aluminum sheet requires salt spray test ≥3000 hours and elongation ≥10%.

- Grade: 3003, 5052/3004 (good corrosion resistance), 5083 (marine grade)

- Thickness tolerance: ±0.05mm

Coating Types

Popular coatings include fluorocarbon, polyester, self-cleaning, antimicrobial and anti-fingerprint coatings. PVDF coated aluminum panels are recommended for highly corrosive outdoor environments.

- Thickness: Primer film needs to be >5 microns, topcoat film is recommended to be >20 microns.

Reputation

- Certificates: ISO 9001 (quality management system), ISO 14001 (environmental protection)

- Productivity: production line, annual production, delivery

- After-sales: service, customer feedback

Pre-painted Aluminium Sheet customization process

Define the requirements (outdoor/indoor?). ↓ Selection of substrate (5052)

↓

Select substrate (5052 outdoor, 3003 indoor) + coating (PVDF/PE)

↓

Screening suppliers (check certificates, see cases)

↓

Quotation (including test report + warranty)

↓

Trial inspection (focus on coating thickness, salt spray samples)

↓

Purchase in bulk and sign long-term agreements

pre-painted aluminium sheet is widely used in construction, industry, food and other fields because of strong weather resistance, lightweight and high strength, environmental protection and energy saving, fire retardant, easy to process, etc. If you are interested in this material of painted metal, welcome to contact us!