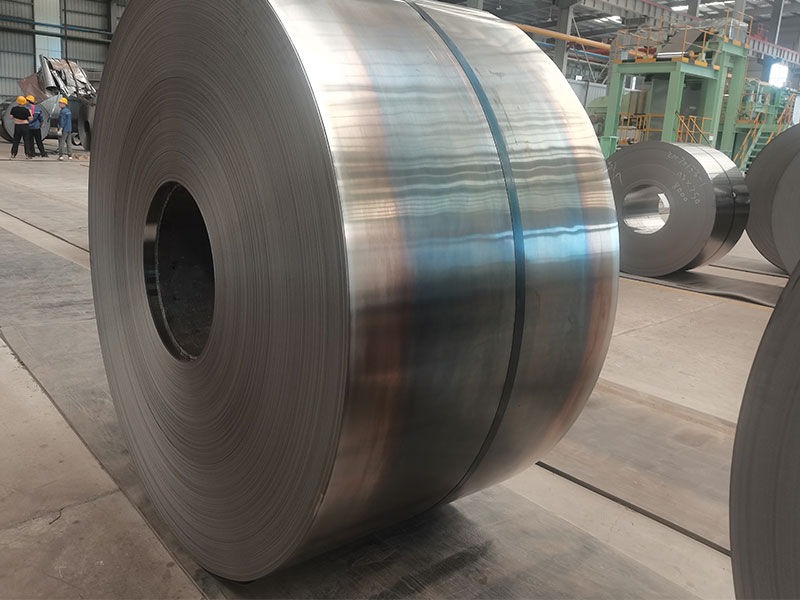

Wanzhi Group supplies all kinds of low carbon steel, including cold rolled coil, hot rolled coil, galvanized substrate, wire rod, welded pipe raw material, etc. We also provide finished products of galvanized, painted, pipe, plate, corrugated sheet, section steel, etc., which are processed by carbon steel as the substrate. If you are looking for a professional steel supplier, please feel free to contact us!

Wanzhi Group Low Carbon Steel Products

Low carbon steel is characterized by high plasticity and excellent weldability, and is widely used in cold forming and welded structures because of its low cost. We have different types of carbon steel products in our plant and can provide further processing services according to the application.

| Product Type | Typical Grade | Specification Range | Core Application |

|---|---|---|---|

| Cold rolled sheet | SPCC (Japanese Standard) | 0.3-3.0mm × 1000-1500mm | Automobile doors, chassis shells |

| Hot Rolled Coil | Q235B (National Standard) | 2.0-25mm × 1500-2500mm | Construction steel structure, shelving |

| Galvanized substrate | DX51D+Z (European standard) | 0.15-6.0mm × 600-1500mm | Roofing panels, ventilation ducts |

| Wire | SWRM6 (JIS) | Φ5.5-20mm | Rivets, wire mesh |

| Welded pipe raw materials | ASTM A53 Gr.A | Φ21.3-610mm | Water and gas pipes, structural pipes |

Low Carbon Steel Composition and Properties

Core Chemical Composition

| Element | Content Range (%) | Function |

|---|---|---|

| Carbon (C) | 0.02-0.25 | Determines strength and hardness; lower content improves plasticity |

| Manganese (Mn) | 0.30-1.65 | Deoxidizer, refines grain structure, increases strength and hardenability |

| Silicon (Si) | 0.10-0.35 | Deoxidizer, enhances strength; excessive amounts can reduce toughness |

| Sulfur (S) | ≤0.050 | Forms sulfide inclusions, reducing ductility (but improves machinability) |

| Phosphorus (P) | ≤0.045 | Increases cold brittleness, reduces weldability |

| Aluminum (Al) | 0.02-0.07 | Refines grain structure, fixes nitrogen (prevents aging brittleness) |

Typical grade chemical composition comparison

| Grades | Standard | C(%) | Mn(%) | Si(%) | S(%) | P(%) |

| Q235B | GB/T 700 | ≤0.22 | 0.30-0.65 | ≤0.35 | ≤0.045 | ≤0.045 |

| A36 | ASTM A36 | ≤0.26 | ≥0.75 | 0.15-0.40 | ≤0.050 | ≤0.040 |

| SPCC | JIS G 3141 | ≤0.15 | ≤0.50 | ≤0.10 | ≤0.030 | ≤0.030 |

| DC01 | EN 10130 | ≤0.12 | ≤0.60 | ≤0.10 | ≤0.035 | ≤0.035 |

| St12 | DIN 1623 | ≤0.10 | 0.30-0.60 | ≤0.10 | ≤0.035 | ≤0.035 |

International standard and grade comparison

low carbon steel is carbon steel with carbon content of 0.02%-0.25%, containing a small amount of manganese (Mn ≤ 1.65%), silicon (Si ≤ 0.35%), sulfur and phosphorus (S / P ≤ 0.05%) and other elements. Common international standards are GB, ASTM, JIS, EN, DIN, ect.

| Standard System | Typical Grade | Carbon Content (%) | Yield Strength (MPa) |

|---|---|---|---|

| China GB | Q195 | ≤0.12 | ≥195 |

| ASTM | A36 | ≤0.26 | ≥250 |

| Japan JIS | SPCC (cold rolled) | ≤0.15 | ≥270 |

| European standard | EN DC01 (EN 10130) | ≤0.12 | N/A |

| Germany DIN | St12 (cold rolled) | ≤0.10 | N/A |

Mechanical Properties

| Performance Parameter | Typical Range | Testing Standard |

|---|---|---|

| Yield Strength (Rp0.2) | 180-300 MPa | ISO 6892-1 (Tensile Test) |

| Tensile Strength (Rm) | 270-500 MPa | ASTM E8/E8M |

| Elongation (A50) | 25-45% | JIS Z 2241 |

| Hardness (HV) | 80-150 HV | ISO 6507-1 |

| Erichsen | ≥9.0 mm (DC04 Deep Drawn Steel) | ISO 20482 |

Low Carbon Steel Classification

Cold Rolled Steel

Cold rolled mild steel is processed at room temperature to produce a smooth surface and a thickness of 0.3-3mm (SPCC, DC01) metal material with smaller tolerances, ideal for precision parts.

Hot Rolled Steel

Hot Rolled Steel is a metallic material made by heating steel to a high temperature and rolling it to a thickness of >3mm (SS400, Q235B) with an oxidized surface. This mild steel is often used to produce large sections and structural parts.

Plated Substrates

Carbon steel is rolled and surface cleaned and then coated with a metal and alloy coating to provide better corrosion protection. Common products: galvanized (DX51D+Z), color coated (TDC51D+Z).

Advantages and Uses of Low Carbon Steel

With its good weldability, easy workability, good ductility, plasticity and workability and relatively low cost, low carbon steel is widely used in building structures, bridges, vehicle manufacturing, machinery parts, pipelines and other fields.

Advantages

| Advantage | Description |

|---|---|

| Cost-effective | Relatively inexpensive to produce compared to high carbon or alloy steels. |

| Versatile | Ideal for structural and non-structural applications like automotive, buildings, piping systems, and wire products. |

| Ease of Fabrication | Excellent formability with a carbon content of ≤0.35% and elongation of ≥25%, making it easier to roll, form, and weld. |

| Corrosion Resistance | Can be protected from corrosion with coatings like paint, galvanizing, or powder coating. |

| Recyclability | Fully recyclable and reusable. |

Uses

| Application | Requirements | Uses | Recommended Grade |

|---|---|---|---|

| Automotive Body Parts | High elongation (≥38%), low yield strength | Vehicle body shells, frames and suspension systems, pipes and exhaust systems | DC04 (EN 10130) |

| Building Structures | Weldability, low cost | Steel structure frames, reinforced concrete structures, reinforcing mesh, prefabricated components | Q235B (GB/T 700) |

| Home Appliance Housings | Surface finish (Ra ≤ 0.8μm) | Home appliance housings, kitchenware, daily metal products | SPCC (JIS G 3141) |

| Galvanized Substrate | Coating adhesion (T-bend test 0T no peeling) | Galvanized steel coils, aluminized zinc-coated steel coils, painted steel, etc. | DX51D+Z (EN 10346) |

Low Carbon Steel Supplier

As a professional steel supplier with more than ten years’ experience in exporting, we have sufficient stock of carbon steel, including cold rolled steel coils, hot rolled steel coils, beams and so on. Wanzhi Group factory is located in Boxing County, Binzhou City, Shandong Province, China, with ISO9001, ISO14001 certificates, we have carbon steel, galvanized steel, aluminum zinc coated steel, painted steel, color steel, stainless steel, alloy steel and so on metal material solutions for construction and industrial use, and we have supplied high quality steel materials to more than 100 countries and regions. If you plan to visit our factory or need samples for testing, please feel free to contact us.

Selection Suggestions

| Industry | Recommended Grades | Core Requirements | Alternative Solutions |

|---|---|---|---|

| Automobile Manufacturing | DC01/DC04 (European Standard) | High elongation (≥38%), surface free of defects | Galvanized steel (DX51D+Z) |

| Home Appliance Housings | SPCC (Japanese Standard) | Cold rolled finish (Ra ≤ 0.8μm) | SECC (Electro galvanized sheet) |

| Building Construction | Q235B/A36 | Low cost, easy to weld | Q345B (Medium carbon steel) |

| Container Manufacturing | SPA-H (Weathering Steel) | Atmospheric corrosion resistance (Cu-P-Cr alloyed) | Ordinary galvanized steel |

| Hardware Stamping Parts | 08Al (National Standard) | Ultra-deep-drawing performance (cupping value ≥ 9.0mm) | SUS304 (Stainless steel) |

low carbon steel, because of its unique economy, strength, processing flexibility and molding, and high sex price, has become an essential material for various industries, such as automotive projects, building structures or the manufacture of daily necessities.