PPGI is a high quality construction and industrial material that is widely used as raw material for roofing, walling, appliances, piping systems, energy facilities, etc. because of its beauty, corrosion resistance, weather resistance, and ease of processing. Wanzhi Group is a steel supplier and manufacturer from China, which produces and sells galvanized, painted and alloy materials in many specifications and styles.

PPGI Introduction

PPGI is the abbreviation of pre-painted galvanized steel, which is a derivative product of galvanized steel. It is a kind of pre-painted steel which is made of hot-dipped galvanized steel or electro-galvanized steel as a base material and roll coated with organic coatings such as PE/SMP/PVDF/PUF/HDP, etc. It is usually sold in the form of coils and sheets.

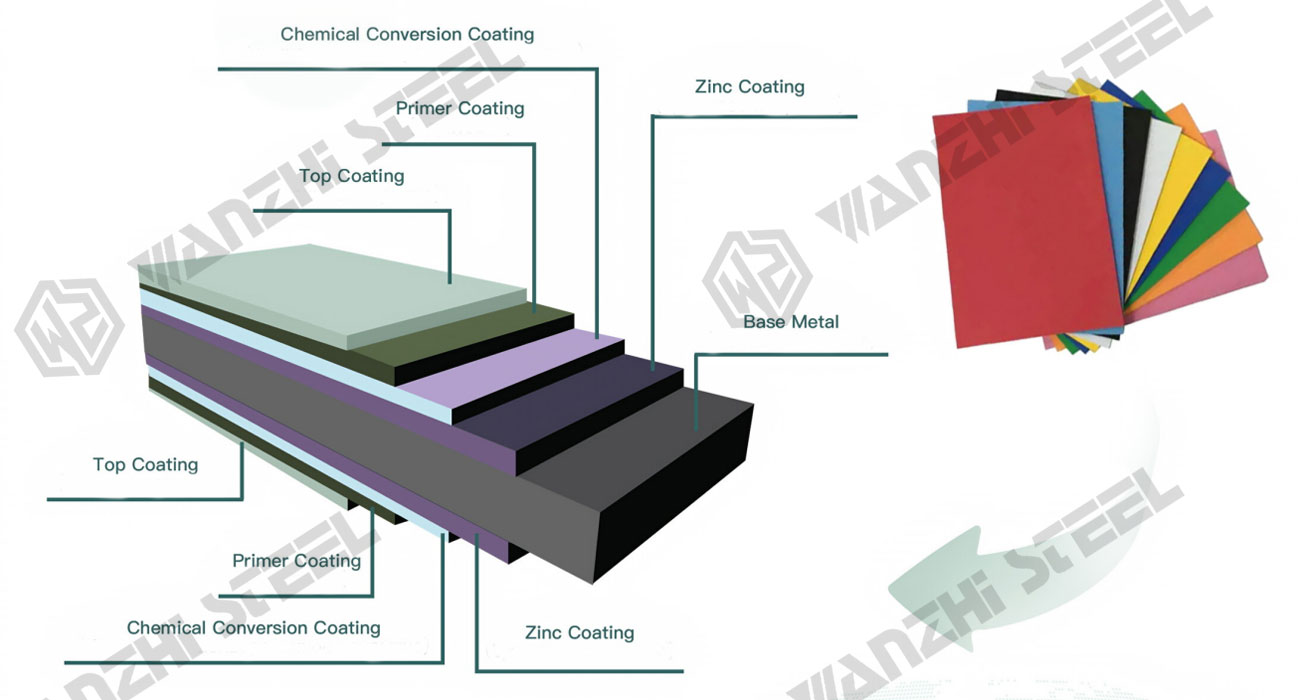

Structure

PPGI consists of a substrate, a chemical conversion layer, a primer and a topcoat.

- The substrate is mainly galvanized steel or galvalume steel.

- The chemical conversion layer is a primary chemical conversion film formed on the surface of GI/GLsteel by passivation, phosphatization, etc. The primer is a 5-20 micron coating.

- The primer is a 5-20 micron epoxy resin.

- The top coat is an organic coating of 10-40 microns.

Mechanical Property Parameters

| Item | Typical Value |

|---|---|

| Tensile Strength | 270 MPa ~ 550 MPa |

| Elongation | 15% ~ 30% (e.g., DX53D substrate elongation ≥ 20%, suitable for deep-drawing) |

| Pencil Hardness | 2H ~ 3H |

| Bending Performance | 0T ~ 2T |

Corrosion and Weathering Resistance Parameters

| Item | Test Standards and Results |

|---|---|

| Salt Spray Test | – Normal Environment: ≥ 500 hours (Neutral Salt Spray, ASTM B117) – Severe Environment: ≥ 1000 hours (PVDF coating) |

| Moisture and Heat Resistance | 1000 hours without blistering (temperature 40℃, humidity 95%, GB/T 1740) |

| UV Aging | 2000 hours QUV test (gloss retention ≥ 80%, ASTM G154) |

PPGI Specification and Parameter

We sell all regular size PPGI steel: coil, sheet, roofing, etc. We provide special specification, coating, surface effect, printed prepainted galvanized steel customized, and we can provide free samples.

Specification

| Item | Typical Specification |

|---|---|

| Material | Galvanized substrate (hot dip galvanized GI or electro galvanized EG) |

| Thickness | 0.12mm ~ 1.5mm |

| Width | 600mm ~ 1250mm (slit size can be customized) |

| Length | Coil: Continuous length (e.g., 1000m/coil) (can be customized) |

| Substrate Grade | Classified according to standard (DX51D, DC01, Q195, S220GD, SECC, SGCD, SGHC, FS Type A/B/C, etc.) |

Zinc Coating Parameters

| Item | Specification |

|---|---|

| Galvanizing Amount | Range of galvanizing amount on both sides: 60g/m² ~ 275g/m² (common grades: Z60, Z120, Z180, Z275) |

| Zinc Layer Structure | Pure zinc layer (GI) or zinc-iron alloy layer (GA, for better corrosion resistance) |

| Surface Treatment | Chromated (conventional) or chrome-free (environmentally friendly, e.g. zirconium and titanium systems) |

Coating Parameters

| Item | Parameter Range |

|---|---|

| Coating Type | – Polyester (PE): General-purpose, cost-effective – Silicone-modified Polyester (SMP): Improved weather resistance – Fluorocarbon (PVDF): Super weather-resistant (outdoor 20+ years) – High Durability (HDP): UV resistance enhanced |

| Coating Thickness | Single-side coating: 5μm ~ 25μm Total double-side thickness: 10μm ~ 50μm |

| Coating Structure | Primer + Topcoat + Back coating (optional) |

| Color and Gloss | – Color: RAL, Pantone, and other standard color charts, customizable – Glossiness: 10% ~ 90% (Matte ~ High Gloss) |

Common Standards

| Standard Type | Standard No. |

|---|---|

| Substrate Standard | JIS G3302, EN 10346 |

| Coating Standard | ASTM A755, GB/T 12754 |

| Environmental Standard | GB 30981, EU Ecolabel |

PPGI Materials and Coating

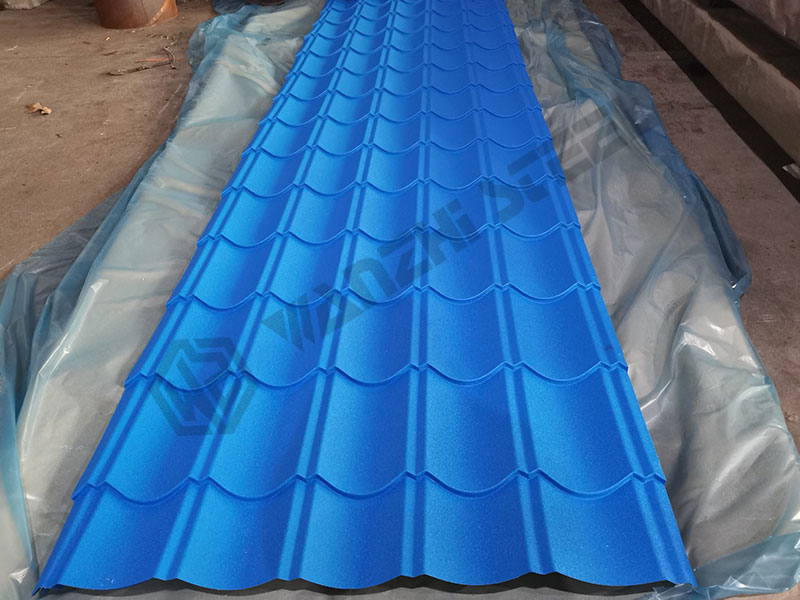

PPGI Colors and Surface Effects

PPGI colors and surface effects can be customized according to customer’s requirements, common colors are: white, blue, red, yellow, grey, green, refer to RAL color card or samples for color selection. Surface effects include glossy, matte, textured, etc. Printed coatings with special effects such as wood, stone, brick, flowers, etc. can also be selected.

PPGI Benefits

PPGI has a salt spray resistance of 500-1000 hours, high strength and hardness, good formability and adhesion, rich colors and patterns, and a service life of 10-20 years for different coating materials in the outdoor area, which makes it a high quality colorful metal coating material for indoor and outdoor use.

Excellent corrosion resistance: galvanized substrate (zinc sacrificial anode protection) + PE/SMP/PVDF/HDP organic coating double protection, stable performance in humidity, high temperature, salt spray and other marine and chemical environments.

Easy to process: the continuation of the mechanical properties of carbon steel, can be stamping, bending, curling, slitting, molding and other processing.

Cost-effective: The low cost of hot-dip galvanizing and the pre-painting process extends the service life and reduces maintenance costs.

Aesthetics: Wanzhi PPGI coil and sheet is available in a wide range of colors, textures, patterns, shapes, and glosses to meet different application requirements.

Weatherability and durability: Functional paints, such as fluorocarbon, Silicone Modified Polyester, High Durability Polyester, etc., have excellent resistance to high temperatures, ultraviolet rays, and temperature differences.

Fire Resistance: Flame retardant coatings (Class A2 non-combustible) are suitable for fire-resistant places.

PPGI Applications

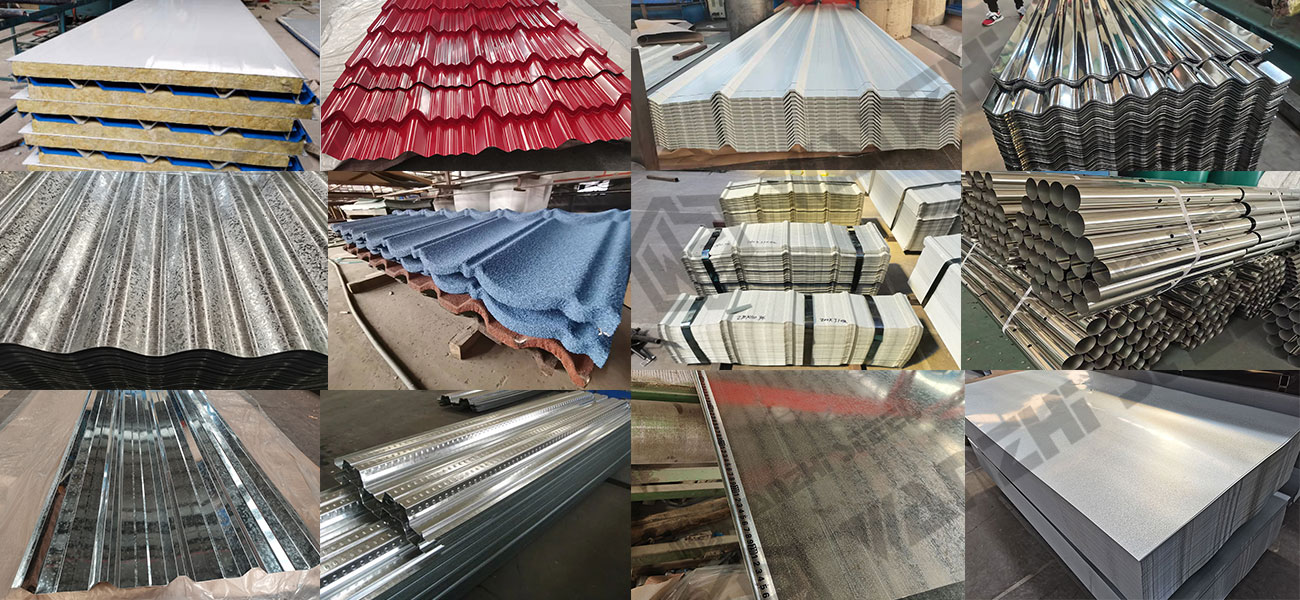

PPGI steel is widely used as a building material and industrial raw material for roofing/walls/decorating, household appliances, education, transportation, energy, advertising and other industries. When selected with different functional surface coatings, it can be used in environments with large temperature differences, in environments that require long-term exposure to sunlight, in marine and industrial environments.

Construction

- Roofing and walling (corrugated sheet, ribbed sheet, sandwich panels, color steel tiles, curtain wall panels)

- Interior decoration (elevator interiors, ceilings, clean panels, sculptured panels, partition walls)

- Public facilities (noise barriers, bus stops, airport roofs, fences)

Appliance Manufacturing

- Refrigerator/air conditioner housings and structural components

- Oven and microwave oven interior components

Transportation

- Automotive components (van compartments, high-speed rail interior panels, cargo panels, acoustic enclosures)

- Marine cabin bulkheads

- Containers and containers

Industrial equipment

- Ventilation ducts

- Warehousing systems

Other fields

- Agricultural facilities (greenhouses, farm roofs)

- Furniture and advertising (customized display cabinets, billboards)

- Writing panels

- Drainage gutters

PPGI Supplier

PPGI’s supplier types include two kinds of ODM and OEM, ODM is Original Design Manufacturer, providing one-stop service from design to production, while OEM is Original Equipment Manufacturer, producing products according to customer’s design and requirements. Wanzhi Group is a coated steel manufacturer from China, currently we can provide a variety of services such as design and production and OEM according to customers’ needs.

ODM PPGI

Customer’s requirement → manufacturer provides solution library (material, coating, specification) → customer chooses the solution → OEM production → delivery

OEM PPGI

Customer provides design drawings/parameters → technical feasibility assessment → sampling and testing → mass production → quality control → delivery

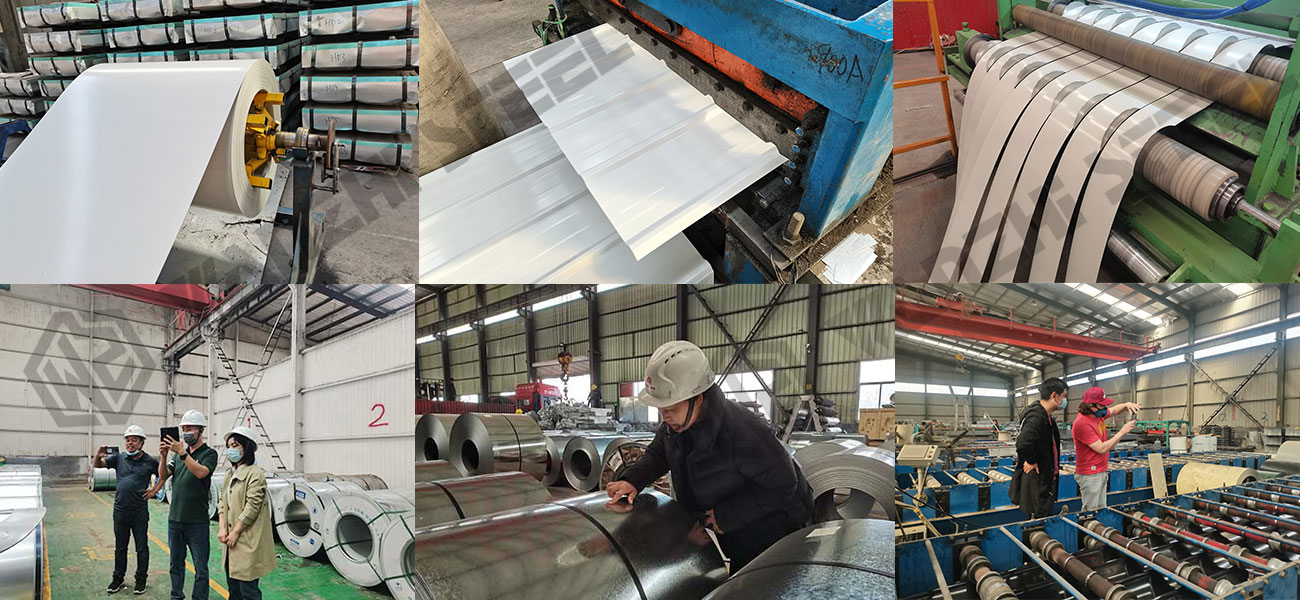

Wanzhi Factory

Our factory has prepainted steel production line, quality control equipment and sample room, production capacity of 600,000 tons per year, cold rolled coils, hot rolled coils and popular models, colors PPGI PPGL in stock, delivery time is 5-45 days.

Wanzhi PPGI Solution

Until now, we have provided design and production of color coated steel for commercial hospitals, greenhouse greenhouses, and roofing sheet processing plants, home appliance manufacturing plants, and infrastructure projects according to customers’ requirements.

PPGI Products

- PPGI coil

- PPGI sheet

- PPGI strips

- PPGI Roof

PPGI Price

The price of PPGI coil is 600-800USD per ton, the price of pre-painted steel with high performance coating and special surface effect will be higher, and the price of galvanized steel with low zinc layer + PE coating will be lower. The price of color coated steel is mainly determined by the substrate, coating, surface effect and processing technology, you can leave a message to tell us what kind of steel you need and get a free quote.

PPGI Manufacturing Process

PPGI (Pre-Painted Galvanized Iron) is pre-coated galvanized steel, which is a product with a protective coating (usually polyester, fluorocarbon, or acrylic coating) on the surface of galvanized steel, with better corrosion resistance and decorative properties.PPGI is commonly used in the fields of construction, home appliances, automobiles, and furniture.

Substrate Manufacturing Process

- Material Selection: Ultra Deep Draw Grade: SPCF > DC05> SPCE > DDS, Deep Draw Grade: DC04 /SPCD/ CS Type C, Ordinary Grade: SPCC/ DC01 /CS Type A

- Cleaning: Removal of oxidized skin, oil, rust and other impurities from the steel surface

- Galvanizing: Hot-dip galvanizing/electro-galvanizing process to complete the galvanizing, the thickness of the zinc layer is determined by the application environment.

- Cooling and curing: Water/air cooling to bond the coating to the steel.

Coating Manufacturing Process

- Pre-treatment: The galvanized steel sheet is cleaned to remove oil, oxidation and impurities from the surface of the steel sheet to ensure adhesion of the coating.

- Surface treatment: Surface treatment such as pickling, phosphating or chromating is carried out to form a chemically converted layer on the surface of the galvanized steel.

- Coating process: One or more layers of a predetermined coating are applied to the surface of the galvanized steel using the roll coating technique.

- Curing process: The coating is cured by baking to form a hard protective film on the surface of the PPGI.

- Cooling and Shearing: After the coating has cured, it is cooled down and finally sheared to shape the pre-painted steel product to meet the specifications of the application.

Deep Processing

Our factory not only has mature color coated production line, but also has various slitting instruments and forming machines, which can complete the deep processing of steel, such as slitting, bending, punching, punching, forming, etc. We not only supply pre-painted steel coil, sheet, but also roofing sheet, corrugated sheet, wall panel, fence panel, section steel, strip steel, pipe, etc.

PPGI Quality Certification and Testing Standards

The quality certification standards for PPGI materials are ISO 9001, ISO 14001, CE certification, ASTM standard, JIS standard, GB national standard, RoHS, and so on. To ensure the performance and quality of coated steel, you can ask the supplier to provide certificates and test results before purchasing. (Wanzhi Group supports SGS, TÜV, Intertek, CTC, CISRI, etc. for quality control of our products.)

Substrate and Galvanized Layer Testing

| Testing Item | Qualification Index |

|---|---|

| Substrate Thickness | Tolerance ±0.02mm |

| Galvanized Amount | Double-sided zinc layer ≥60g/m², high anti-corrosion scenarios need to be ≥180g/m² |

| Zinc Layer Adhesion | 4B or above (no flaking of the coating) |

Coating Performance Testing

| Testing Item | Qualification Index |

|---|---|

| Coating Thickness | Single-side ≥15μm (for building use), total thickness of both sides ≥25μm (for harsh environments) |

| Adhesion Scratch Test | After the coating peeling area < 5% (grade 0 optimal) |

| Salt Spray Resistance | 500 hours without red rust (ordinary environment), 1000 hours without red rust (PVDF coating) |

| Weather Resistance | 2000 hours gloss retention rate ≥ 80%, color difference ΔE ≤ 2.0 (no obvious change by visual inspection) |

| Pencil Hardness | ≥ 2H (ordinary coatings), ≥ 3H (high-hardness coatings) |

Projects and Cases

Wanzhi Group has supplied PPGI and PPGL steel to more than 100 countries from Turkmenistan, Tajikistan, Georgia, Turkey, Kazakhstan, Azerbaijan, UAE, Saudi Arabia, Indonesia, Colombia, Peru, Chile, Libya, etc. Premium coated steel materials have been supplied for agricultural projects, commercial buildings, residences, infrastructures, factories and processing.

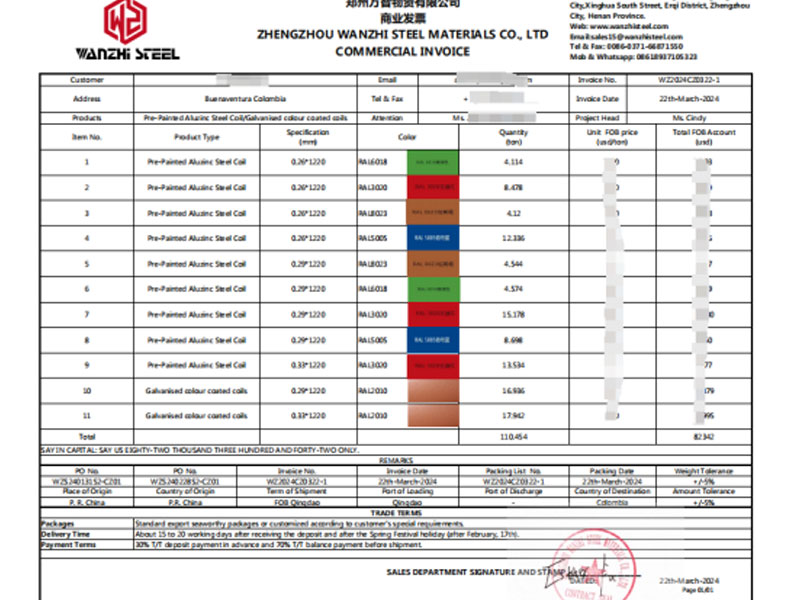

110 tons of PPGI and PPGL in Colombia

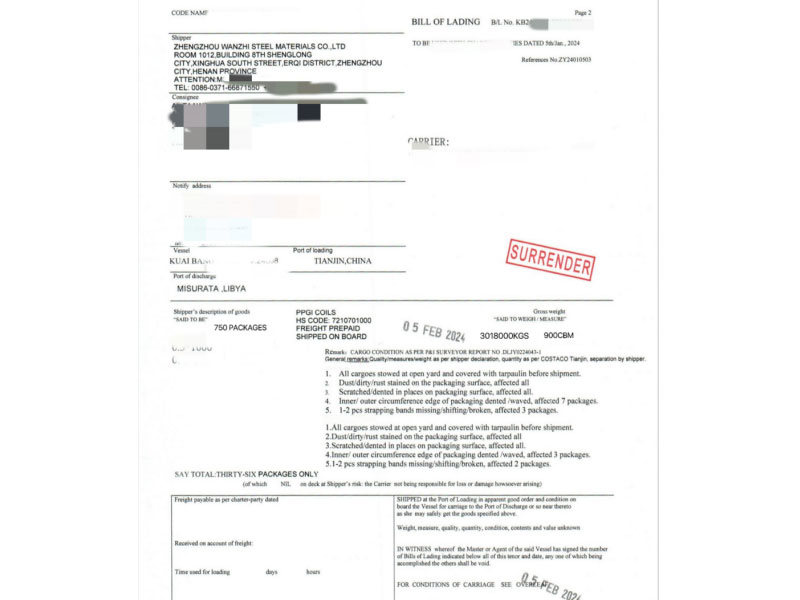

3000 Tonnes of PPGI Coil to Libya

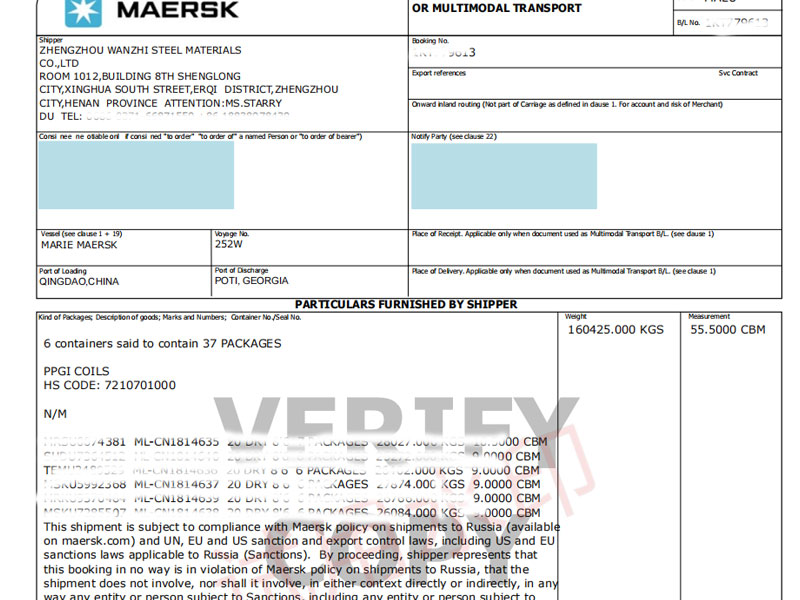

280 Tons of PPGI Coils Shipped to Georgia

Wanzhi Group Support and After-sales Service

We have a sample room in our factory (Boxing County, Binzhou City, Shandong Province, China) and marketing center (Zhengzhou City, Henan Province, China) with samples of regular specification galvanized steel, aluminized zinc coated steel, ZAM steel, painted galvanized steel, painted aluminized zinc coated steel, 3D printed galvanized steel, stainless steel, and so on, and we are able to provide free samples and sample testing service.

GI PPGI PPGL PPAL Stainless Steel Comparison

PPGI vs Conventional Galvanized Sheet (GI)

| Dimension | PPGI (Pre-painted Galvanized Iron) | Conventional Galvanized Sheet (GI) |

|---|---|---|

| Material Construction | Galvanized Substrate + Organic Coating | Galvanized Substrate only (uncoated) |

| Corrosion Resistance | Salt Spray Resistance 500~1000 hrs | Salt Spray Resistance 100~300 hrs |

| Appearance & Colors | Customized colors, textures, and patterns available, Surface effect | Single silver grey zinc finish, (optional, zinc size and no zinc) |

| Processing Performance | Coating flexibility, not easy to crack after bending/stamping | Zinc layer is easy to peel off, need to be sprayed to prevent rusting after processing |

| Cost | Higher | Lower (especially hot-dip galvanized) |

| Application Scenarios | Aesthetics + Weathering Requirements | Low Decorative Requirements |

PPGI vs PPGL (Pre-Painted Galvanized Aluminum)

| Dimension | PPGI (Pre-painted Galvanized Iron) | PPGL (Pre-painted Galvalume) |

|---|---|---|

| Substrate Characteristics | GI steel, high strength but heavier | GL steel, lightweight but low strength |

| Corrosion Resistance | Zinc + coating protection but may rust in acidic environments | Aluminum is naturally resistant to oxidation, + coating protection for better resistance to acids and alkalis |

| Thermal Conductivity/Electrically Conductive | Thermal conductivity is low, electrical conductivity is high (insulation required) | Thermal conductivity / high conductivity, suitable for heat dissipation scenarios (e.g., electronic housings) |

| Costs | Lower (steel substrates are about 1/3 the price of aluminum) | Higher (aluminum substrates are more expensive) |

| Application Scenarios | Roofing of buildings, automotive components (need to be load-bearing) | Lightweight façades, marine interiors (need to be lightweight + salt spray resistant) |

PPGI vs PPAL( color coated aluminum )

| Dimension | PPGI (Steel Substrate + Coating) | Color Coated Aluminum (PPAL) |

|---|---|---|

| Strength and Hardness | 270~550MPa | 70~150MPa |

| Weathering Resistance | Fluorocarbon coating weathering 20+ | Aluminum substrate + coating weathering 30+ |

| Weight | Heavier | Extremely lightweight |

| Fire Protection | Flame retardant coating up to class A2 (non-combustible) | Aluminum substrate has low melting point (660°C), but superior flame retardant properties |

| Cost | Relatively low | High |

| Application Scenarios | Cost-effective priority | Lightweight + high weather resistance |

PPGI vs Stainless Steel

| Dimension | PPGI | Stainless Steel (e.g., 304, 316) |

|---|---|---|

| Corrosion Resistance | Dependent on coating protection, life 10~30 years | Excellent, life 50 years or more (especially 316 grade salt spray resistant) |

| Strength & Hardness | Strength 270~550MPa, surface hardness 2H~3H | Higher 500~800MPa, surface hardness up to 5H |

| Processing Difficulty | Easy to press/bend | High processing cost |

| Appearance Maintenance | Regular cleaning is required to avoid aging of the coating | Surface can be polished to a mirror finish, simple maintenance |

| Cost | Low | Very high |

| Application Scenarios | Budget sensitive | Extreme corrosive environments |

Pre-painted steel Frequently Asked Quality Questions

Why does the coating on pre-painted steel peel off?

A: Inadequate coating adhesion can lead to peeling of the coating, caused by improper substrate handling and curing of the coating.

Why is there red rust in the salt spray test?

A: The main causes of red rust on PPGI PPGL are insufficient zinc coating and the coating material does not match the application environment, so you can choose the right coating material according to the application environment.

What causes cracks in pre-painted steel during processing?

A: The ductility of the sheet determines its processing performance. If multiple processing is required, a highly ductile substrate can be selected.

PPGI is a cost-effective, colourful, easy-to-process, colour-coated steel suitable for general corrosive environments, and can be used in construction, appliance housings, automotive exteriors, etc. It has excellent corrosion resistance, strong decorative properties, long service life, light weight, and is easy to process, etc. If you are looking for a cost-effective, color-coated steel, you can choose a highly ductile substrate. If you are looking for cost-effective and beautiful coated steel, then prepainted galvanised steel is the ideal choice for you.