Established in 2011, Wanzhi steel materials is committed to providing professional coated steel solutions for global customers. We produce, sell and process prepainted steel preoducts including PPGI/PPGL/PPGF/PPAL coil, sheets, strips, corrugated, etc. We can do slitting, cutting, punching, punching, embossing, forming, profiling and other deep processing. Corrugated, etc. We can do slitting, cutting, punching, punching, embossing, molding, profiling and other deep processing.

Prepainted Steel Materials

Prepainted steel is a metal material made from mild steel or alloy steel with a galvanized and painted substrate, also known as prepainted metal, consisting of a base material, a chemical conversion layer, a primer and a topcoat.

Low Carbon Steel: Hot rolled and cold rolled steel with high strength and durability, coated with paint to improve corrosion resistance and aesthetics.

Galvanized: Hot-dipped galvanized steel and electro-galvanized steel, sacrificial anode protection + physical barrier to improve the corrosion resistance of the steel, as a substrate and then roll-coated with organic coatings to form a stronger protective layer.

Aluminum-zinc Steel: 55%Al-43.4%Zn-1.6%Si alloy coated aluminum-zinc plated steel, has better corrosion and high temperature resistance, as a substrate for paint treatment, can enhance the appearance and wear resistance.

Zinc-Aluminum-Magnesium (ZAM) steel: ZAM steel coated with Zn-6%Al-3%Mg alloy has good self-healing ability and is resistant to scratches and corrosion. Roller coating with functional coating enhances the performance of ZAM steel.

Aluminum alloy: Aluminum substrate itself has good corrosion resistance, weather resistance, the coating can provide additional protection.

Stainless steel: 04/316 austenitic stainless steel, with strong corrosion resistance, coated to enhance aesthetics.

Prepainted Steel Coatings

Pre-coated steel is usually coated with a thickness of 5-40 microns (5-20 microns for primer and 10-40 microns for topcoat), which enhances the corrosion resistance of the steel, improves weathering, aesthetics, machinability, abrasion resistance and fire resistance, and the coating’s service life is usually between 10 and 30 years.

Polyester coating: A common coating with low cost, good durability and a wide range of color options.

PVDF (Polyvinylidene Fluoride) coatings: super weather resistant, chemical resistant, self-cleaning.

HDP (Highly Weatherable) Coating: Improved version of PVDF, scratch resistant, stain resistant, better weatherability.

PVD (Physical Vapor Deposition) Coating: Provides a high gloss coating with excellent corrosion resistance.

Epoxy Coating (Epoxy): Provides good adhesion and corrosion resistance.

Silicon Modified Polyester (SMP) Coating: Provides enhanced weathering, chalking and UV resistance.

Antibacterial coating: inhibits bacterial growth.

Polyurethane coating (PU): with abrasion resistance, oil resistance, UV resistance, weather resistance.

Prepainted Steel Surface Effects

Prepainted steel surfaces can have a wide variety of visual and functional effects depending on the type of coating and the process. In different application scenarios such as outdoor construction advertising, roofing, home electronics, high-end decoration and packaging, you can choose from a wide range of colors, glossy effects, textures and functional surfaces to achieve decorative, corrosion-resistant, weather-resistant and other effects.

Prepainted Glossy Surface

Glossy surface ≥ 80% smooth, bright, with high reflectivity, giving a bright, fresh feeling. Commonly used in home appliances, decorative panels and other occasions that require visual aesthetics.

Prepainted Matte Surface

Surface gloss 10%~30%, presenting a soft visual effect, usually giving people a low-key, simple impression. Commonly used in construction materials, home decoration and other fields.

Prepainted Metallic Surface

By adding metal powder (aluminum, copper) to the coating, it creates a metallic surface effect. Suitable for applications requiring a metallic look, such as automotive housings and high-end home appliances.

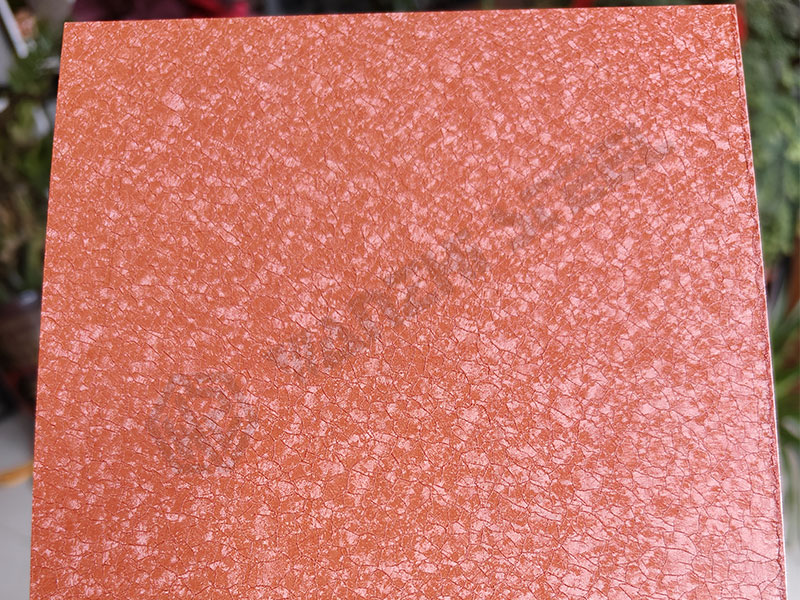

Prepainted Textured Surface

The surface of the coating has a certain texture, such as regular stripes, diamonds, waves, sand, grains, leather, etc. The textured surface effect adds a tactile feel. The textured surface effect increases the sense of touch and visual depth, commonly used in building facades, doors and windows.

Prepainted Woodgrain Effect

Coated to give the surface an imitation of oak, walnut and other natural texture texture effect, widely used in doors, windows, facades and other occasions that require a wood effect but also require weather resistance.

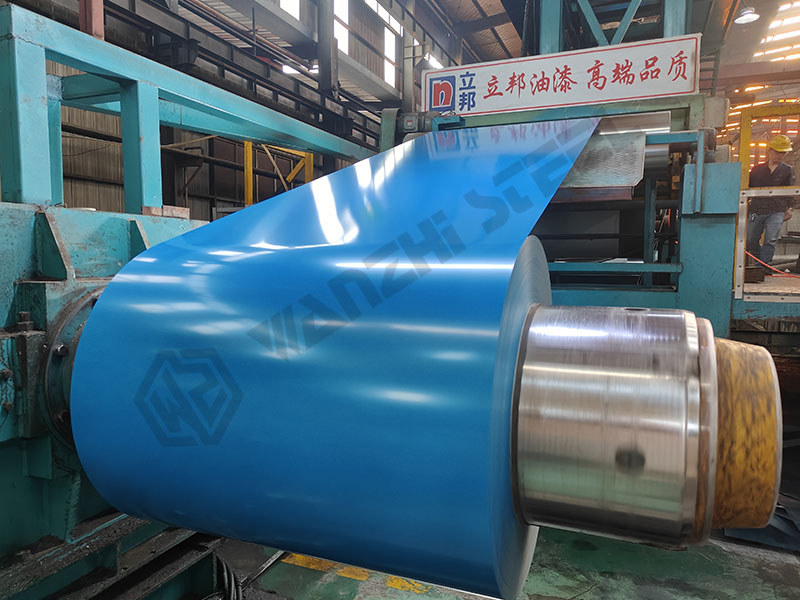

Prepainted Color Coated Surface

According to the demand, the coating can present various bright colors, providing diversified decorative effects, widely used in building facades, appliance shells, furniture and so on.

Prepainted Mirror Surface

The surface of the coating is extremely smooth and has a mirror reflection effect, giving people a modern and exquisite feeling. Commonly used in high-end decorative materials and design fields.

Prepainted Anti-fingerprint

Special coating treatment can make the surface anti-fingerprint and keep the surface clean. Suitable for cell phones, home appliances, office equipment and other surfaces that require frequent contact.

Prepainted Steel for Sale

Wanzhi Group is a professional factory manufacturer of pre painted metal with a wide range of products including pre painted galvalume, pre painted galvanized, prepainted aluminium, etc. We export prepainted steel to all over the world in compliance with ASTM A755, EN 10169, RoHS/REACH, etc. We are also a professional manufacturer and supplier of prepainted steel. EN 10169, RoHS/REACH, etc. We export prepainted steel to all over the world.

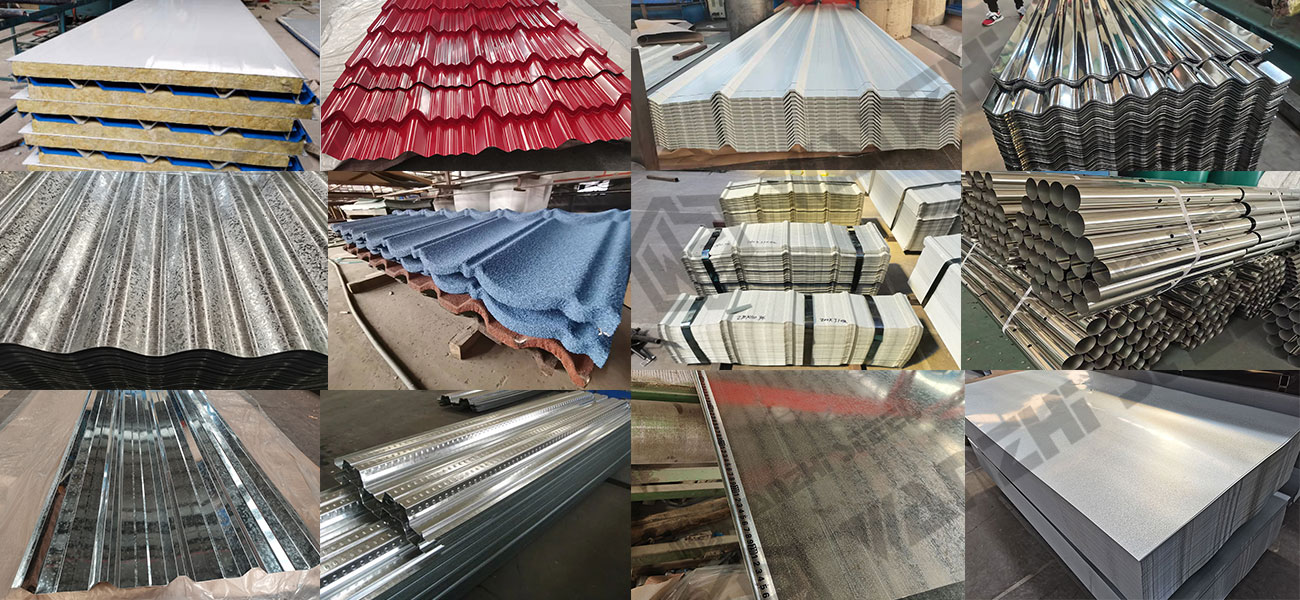

Hot Products

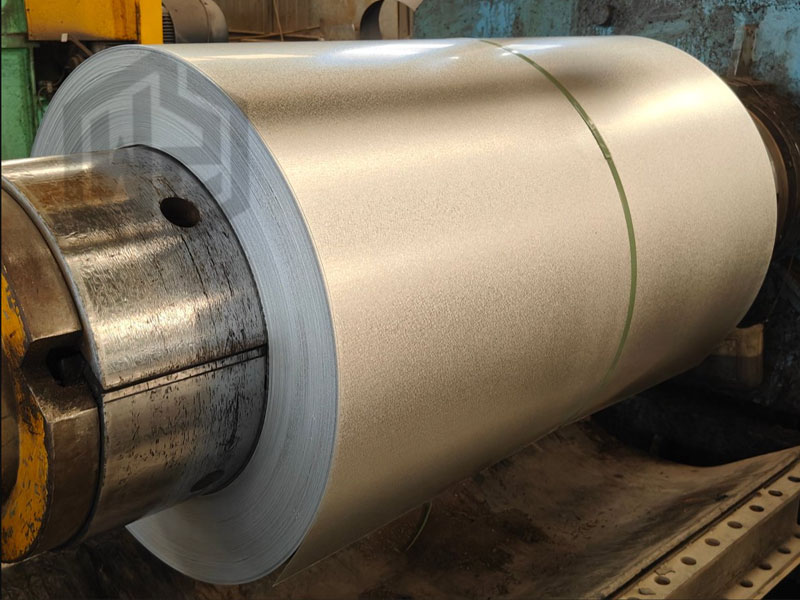

- prepainted galvanized steel coil

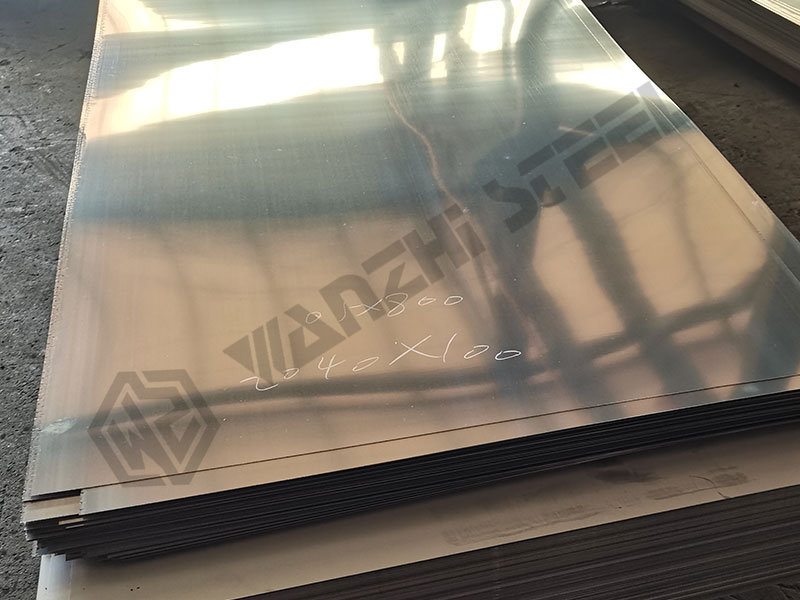

- prepainted galvanized steel sheet

- prepainted galvalume steel coil

- pre painted galvalume sheet

- pre painted plain sheet

- Prepainted corrugated

- Prepainted roofing

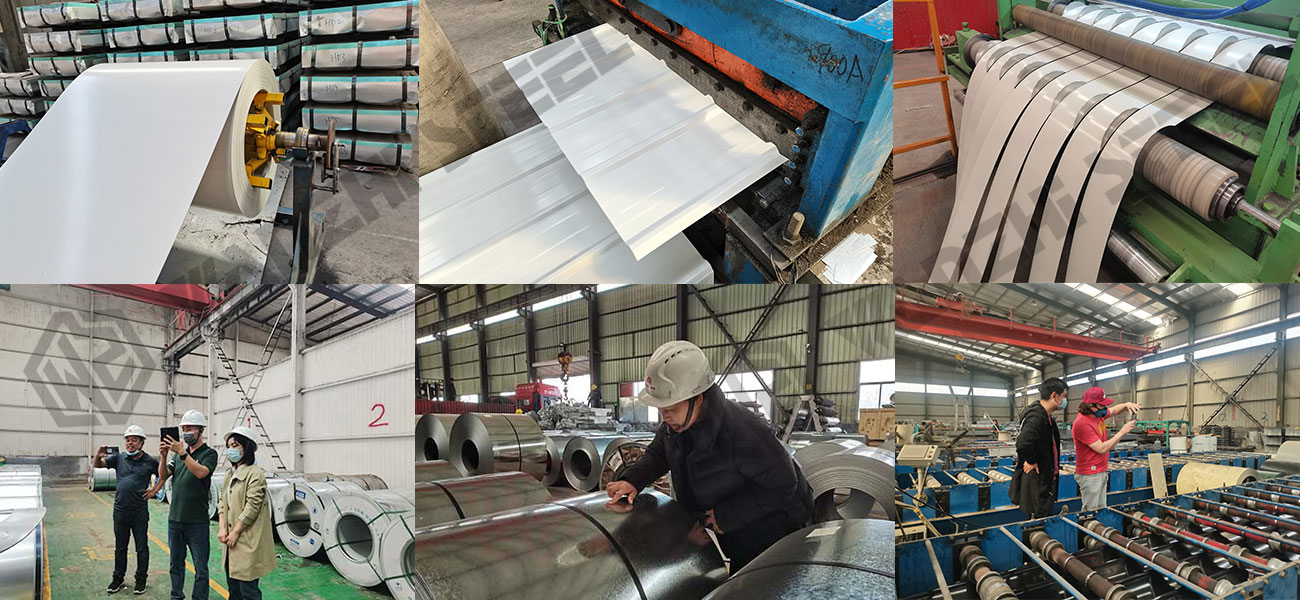

Production

Prepainted process: Uncoiling of substrate → Cleaning and degreasing → Surface passivation → Primer coating → Drying → Topcoat coating → Curing at high temperature → Cooling → Coiling / Cutting

Wanzhi Steel factory: There are three prepainted steel production lines, average monthly output of 10,000 tons, delivery time 5-45 days, samples can be provided.

Prepainted steel OEM ODM

1.Manufacture prepainted steel according to the specification and design provided by customers.

2.Design and production according to customer’s brand and application.

Service

One-stop service, Wanzhi Group provides a full range of comprehensive steel solutions including raw material sourcing, solution design, production and processing, transportation, and after-sales. By combining resources to realize cost savings, Wanzhi Group is able to offer the most competitive price of painted steel to customers with different needs.

The price of prepainted steel is affected by many factors such as material, paint film, coating, processing, etc. Leave a message to tell micron the specification and quantity you need and get a free quote!