Galvanized steel (GI), the most widely used metal-coated steel worldwide (>90% market share), is the first choice for basic protection due to its proven process and cost advantages. Zinc-aluminum-magnesium coated steel (ZAM) is a revolutionary breakthrough in corrosion protection by introducing aluminum (Al) and magnesium (Mg) into the coating to form a ternary alloy phase (MgZn₂/MgZn₁₁), which provides a triple jump in corrosion resistance, wear resistance and heat resistance. Today we together from the composition, performance, application, processing and other aspects of a comprehensive understanding of these two metal materials!

ZAM GI Steel General Specification

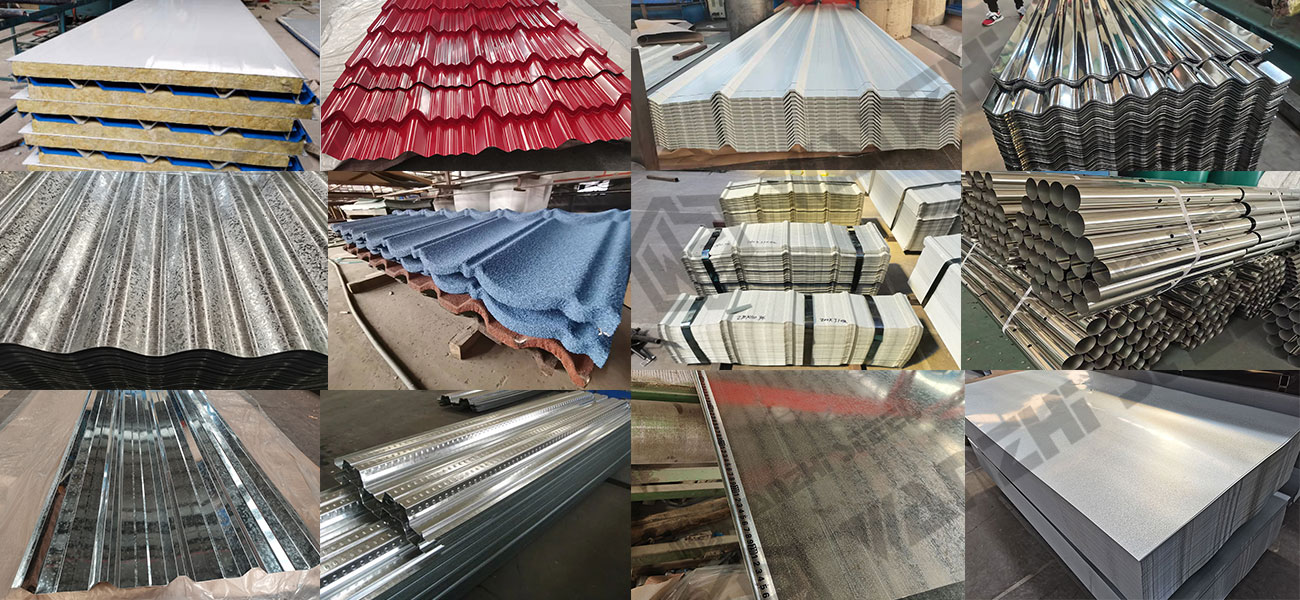

Wanzhi Group produces coated steel materials in accordance with international standards such as ASTM, JIS, GB, EN, ISO, etc., including zinc-plated steel, zinc-aluminum-zinc-plated steel, zinc-aluminum-magnesium-zinc coating steel, and so on.

| Parameter | Typical Specifications for ZAM | Typical Specifications for GI |

| Coating Weight | ZAM60/120/180 (g/m²) | Z60/120/180/275 (g/m²) |

| Substrate Strength | DX51D~S550GD+ZAM | DC01/DX51D~S550GD+Z |

| Surface Treatment | Chromium-free Passivation + Fingerprint Resistance (Standard) | Chromic Acid Passivation (Requires additional environmental treatment) |

| Tolerance Accuracy | Thickness ±0.03mm (<1mm sheet) | ±0.05mm |

ZAM GI Steel Composition

GI steel is a pure zinc coated steel, ZAM steel is a Zn-Al-Mg ternary coated steel, as ZAM is a surface protection upgrade program.

| Parameter | Zinc-Aluminum-Magnesium Steel (ZAM) | Galvanized Steel (GI) |

| Coating Composition | Zn-6~11%Al-1~3%Mg-Si | Zn≥99% |

| Coating Structure | MgZn₂/MgZn₁₁ Eutectic + Al-rich Dendrites | Pure Zn layer (η phase) |

| Coating Density | 3.75 g/cm³ (thinner, more material-efficient) | 7.14 g/cm³ |

| Protection | 1. Al₂O₃ Barrier

2. Zn/Mg Sacrificial Anode 3. MgO Self-healing |

Single Sacrificial Anode (Zn) |

ZAM GI Steel Mechanical Properties Differences

The mechanical properties of coated steels are affected by a number of factors relating to the substrate grade and the coating, with ZAM having superior ductility and double the fatigue life for the same strength grade.

| Performance | ZAM350 | GI S350GD | Advantage |

| Yield Strength (MPa) | 350 ± 30 | 350 | → |

| Tensile Strength (MPa) | 420 ± 40 | 420 | → |

| Elongation (%) | 22 (A80mm) | 18 (A80mm) | +22% |

| Fatigue Limit (MPa) | 260 | 190 | +37% |

| Hardness (HV) | 180 | 150 | +20% |

ZAM GI Steel Physical Properties

The physical properties of ZAM Zinc-Aluminum-Magnesium and GI galvanized steel are mainly influenced by the chemical composition, the coating process, the heat treatment process, and other aspects.

| Property | ZAM | GI | Impact |

| Thermal Conductivity (W/m·K) | 60 | 50 | Faster heat dissipation by 10% |

| Resistivity (μΩ·cm) | 15 | 6 | Requires higher welding current |

| Coefficient of Thermal Expansion (×10⁻⁶/K) | 13.5 | 12.0 | Differences in high-temperature deformation |

| Reflectivity (%) | 75~80 | 40~50 | 30% energy-saving in cooling |

ZAM GI Steel Processing and Manufacturing Adaptation

Process

| Process | ZAM Process | GI Process |

| Substrate Cleaning | Substrate cleaning | Substrate cleaning |

| Heating | Heating | Heating |

| Coating Process | Zn-Al-Mg bath immersion | Hot-dip galvanizing |

| Thickness Control | Air knife thickness control | Air knife thickness control |

| Oxidation Inhibition | Mg oxidation inhibition | – |

| Passivation | Chromium-free passivation | – |

Hot Treatment

| Process | ZAM Process | GI Process |

| Solution Treatment | Solid solution treatment (enhance substrate strength) | – |

| Aging Treatment | Aging treatment (further enhance coating hardness) | – |

| Annealing Process | Annealing process (improves processing performance) | No special heat treatment, excessive annealing may cause coating-substrate interface embrittlement |

Molding Process

| Process | ZAM Key Points | GI Key Points |

| Bending | Minimum radius = 0.5t (controlled speed to prevent cracking) | Must be ≥1t |

| Deep Drawing | LDR = 2.3 (DC04 substrate) | LDR = 2.0 |

| Punching | Burr height < 20μm | 50~80μm (requires secondary grinding) |

Welding Process

| Method | ZAM Parameters | GI Parameters |

| Resistance Spot Welding | Current +15%, Time -10% | Standard parameters |

| Laser Welding | Power density ≥ 5×10⁶ W/cm² | 4×10⁶ W/cm² |

| MIG Welding | Must use Al-Mg welding wire (ER5356) | Standard welding wire |

ZAM GI Steel International Standard System

Core International Standard for Galvanized Steel (GI)

| Standard | Key Parameter Requirements |

| ASTM A653/A653M (US) | – Coating designation: G60/G90/G115 (oz/ft²)

– Salt spray requirement: G90 ≥ 720h, red rust ≤ 5% |

| EN 10346:2015 (EU) | – Coating designation: Z100/Z180/Z275 (g/m²)

– Mechanical properties: S250GD-S550GD (strength grade) |

| JIS G 3302 (Japan) | – Coating designation: Z12/Z18/Z22 (g/m²)

– Surface treatment: C (chromic acid passivation)/N (untreated) |

| GB/T 2518-2019 (China) | – Coating designation: Z60/Z80/Z180 (g/m²)

– Surface structure: N (normal zinc flower)/M (small zinc spangle) |

Core International Standard for Zinc-Aluminum-Magnesium (ZAM) Steel Sheets

| Standard Number | Key Parameters |

| EN 10346:2020 (EU) | – ZMA180: Al 6-11% + Mg 1-3%

– Salt spray requirement: ≥1500h (red rust ≤ 5%) |

| ASTM A1079 (US) | – Coating designation: ZM50/ZM100 (g/m²)

– Composition: Al 1-22% + Mg 0.01-10% |

| JIS G 3323:2022 (Japan) | – DX1 (low aluminum): Al 1-3.5% + Mg 0.1-1%

– DX2 (medium aluminum): Al 3.5-9% + Mg 1-3% – DX3 (high aluminum): Al 9-13% + Mg 1-4% |

| GB/T 14978-2023 (China) | – ZAM150: Al 4-15% + Mg 1-3%

– Edge protection: ≥1mm (after 480h salt spray) |

Applicable Scenario Differences

ZAM Zinc Aluminum Magnesium Applicable Scenarios

- Extreme corrosive environments: seaside buildings, port facilities, shipbuilding, chemical plants, refineries, etc.

- High-demand processing scenarios: manufacture of automobile bodies, chassis and other components, transmission towers, substations, etc.

- Scenarios that require long term stability: highway guardrails, outdoor billboards

- Scenarios with high environmental protection requirements: solar panel brackets, wind power towers, green buildings

Galvanized Steel GI Applicable Scenarios

- General anticorrosive demand scenarios: steel structure factory buildings, warehouses, park benches, garbage cans, etc.

- Cost-sensitive scenes: shells of refrigerators, washing machines, etc., greenhouse greenhouses, livestock and poultry houses, etc.

- Short-term or temporary scenarios: temporary booths, movable scaffolding, construction hoardings at building construction sites

- Scenarios that do not require high material performance: drainage pipes, ventilation pipes, machinery manufacturing, etc.

Scenario Selection Suggestions

ZAM Zinc Aluminum Magnesium can maintain structural integrity and aesthetic appearance and excellent corrosion resistance in long-term exposure to outdoor environments. Therefore, ZAM Zinc Aluminum Magnesium may be preferred for long-term projects in extreme or harsh corrosive environments where high demands are made on material durability, processability, or environmental friendliness.

Galvanized steel provides basic corrosion protection at a lower cost, so ZAM steel GI is preferred in applications where corrosion environments are relatively benign, where material costs are sensitive, where there is a need to control the initial investment, or where material performance is not critical.

ZAM steel dominates in highly corrosive environments such as coasts, chemical plants, high temperature >300°C, and areas prone to wear and tear, while GI is popular for cost-effective applications such as dry indoor environments with humidity <60% RH, short-term projects with <10 years of service life, and cost-sensitive applications. Which metal material are you planning to choose for your project? Leave a comment and let Wanzhi Group know for a free quote!