Photovoltaic mounting systems require long-term outdoor use and demand high corrosion resistance. Currently, commonly used corrosion-resistant metal materials include galvanized steel, galvanized aluminum-zinc steel, zinc-aluminum-magnesium alloys, aluminum alloys, and stainless steel. Among these, aluminum-zinc coated steel has gained prominence due to its exceptional cost-effectiveness. It is increasingly playing a vital role in components such as rails, beams, columns, foundation piles, and various connectors (e.g., clamps, bases, etc.).

Coating Thickness and Specification Selection

The thickness or weight of the aluminum-zinc coating is a key indicator for evaluating its corrosion resistance and service life. Thicker coatings offer superior corrosion resistance in outdoor environments.

Common Coating Thicknesses

- Aluminum-zinc coated steel sheets: AZ100 (100g/m²), AZ150 (150g/m²) , AZ185 (185 g/m²).

- Recommendation: For photovoltaic mounting systems, prioritize AZ150 galvanized steel sheets (total double-sided aluminum-zinc alloy coating weight of 150 g/m²), offering superior cost-effectiveness.

Base Material Thickness

- Common thickness range for photovoltaic mounting systems: 1.5–8.0 mm (hot-dip galvanized Q235 and Q335 materials).

- High-strength steel alternatives: S350GD, S420GD, etc., thickness 1.5-5.0mm.

- Recommendation: Select based on structural load requirements. Typically, 2.0-3.0mm for ground-mounted stations; 1.5-2.0mm for distributed rooftop projects.

International Standards

- Reference Standards: When procuring materials, ensure compliance with international standards such as ASTM A792/A792M (American standard) or EN 10346:2015 (European standard, grades S250GD+AZ or S350GD+AZ, etc.).

Aluzinc Steel Material Properties

Corrosion Resistance: Aluzinc steel is formed by solidifying 55% aluminum, 43.4% zinc, and 1.6% silicon at 600°C, creating a dense quaternary crystalline structure of aluminum, iron, silicon, and zinc. This process produces a robust corrosion-resistant barrier on the surface.

Processing Properties: Aluzinc steel exhibits excellent toughness, bending formability, superior unidirectional ductility, and weldability. It can be cold-formed, stamped, and welded into various shapes for photovoltaic mounting system components.

Mechanical Properties: Galvanized steel exhibits outstanding yield strength, tensile strength, and elongation, enabling superior resistance to natural elements like wind and rain. This ensures the stability and safety of photovoltaic mounting structures.

Thermal Stability: The presence of aluminum allows galvanized steel to withstand high-temperature conditions, making it suitable for industries and applications with elevated thermal requirements.

Advantages in Photovoltaic Installation Structures

Long Service Life: Under normal conditions, galvanized aluminum-zinc photovoltaic mounting systems can last over 25 years, reducing long-term maintenance and replacement costs.

High Adaptability: The high strength and stability of galvanized aluminum-zinc photovoltaic mounting systems suit diverse climatic and topographical conditions, including humid, rainy, and salt-fog environments, as well as regions with variable weather and strong winds.

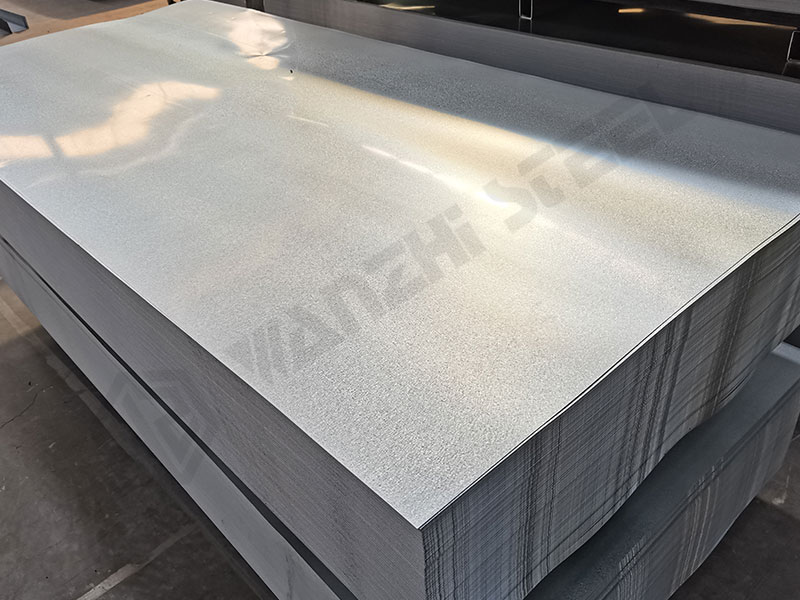

Aesthetic Appeal: The galvalume steel sheet features a distinctive smooth, flat surface with a lustrous star-like pattern and a silver-white base color. This enhances the visual appeal of the mounting structure, allowing it to harmonize with surrounding environments.

Eco-Friendly & Energy-Efficient: The high reflectivity of galvalume steel sheets further boosts the energy efficiency of photovoltaic systems.

Application Scenarios

Ground-Mounted PV Plants: Primary structural components for fixed and seasonally adjustable mounting systems in large-scale ground-mounted plants on flat terrain.

Industrial and Commercial Building Roofs: Most common application in distributed PV projects, serving as material for roof clamps, rails, and support components.

Agricultural PV Canopies: Structures requiring strength, durability, and resistance to environmental corrosion.

Special Projects: Photovoltaic installations in extreme environments such as high temperatures, high salinity, and high humidity.

Alternative Material Recommendations

- ZAM Mounting Structures: ZAM material exhibits red rust only after 4400 hours, offering lighter weight with higher strength and strong self-healing properties.

- Aluminum alloy brackets: Lightweight, corrosion-resistant, aesthetically pleasing, high strength-to-weight ratio.

- Carbon steel brackets: High strength, low cost.

- Stainless steel brackets: Superior corrosion resistance, extended service life.

- Weathering steel brackets: Excellent atmospheric corrosion resistance, relatively low cost, maintenance-free.

You may select based on the specific environmental corrosion level, design service life, and cost budget of the project location, or contact us for a cost-effective solution.