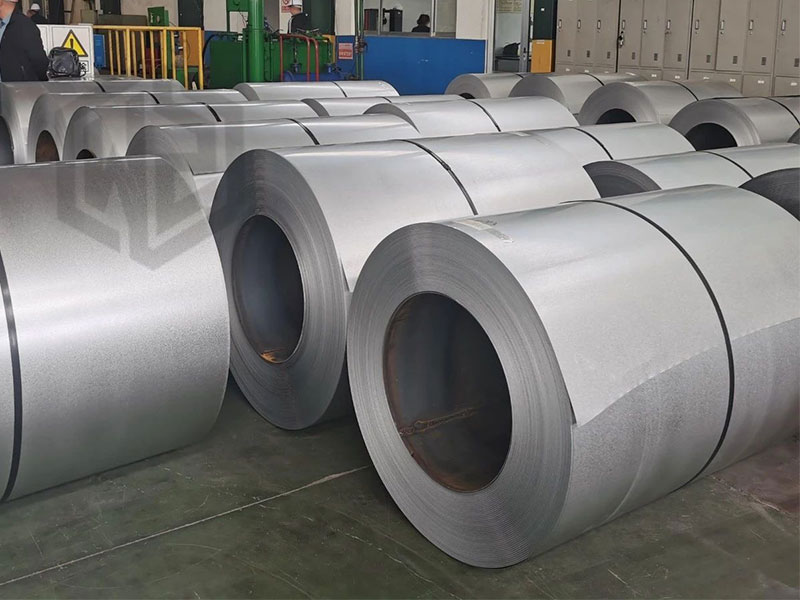

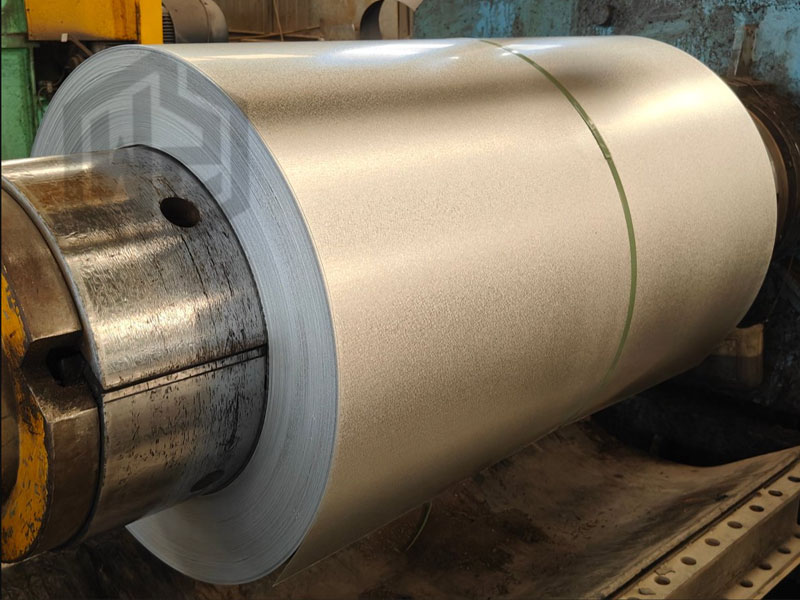

Aluzinc AZ30 galvanized steel coil is Wanzhi Group’s cost-effective coated steel product, featuring a total coating weight of 30g/m² on both sides with a “55% aluminum-zinc alloy coating.” Building upon pure zinc galvanized steel, it strikes a balance between corrosion resistance, formability, durability, and cost, making it widely applicable in mildly corrosive environments across various industries.

Product Specifications

| Product | Aluzinc AZ30 |

| Base Material | DX51D, DX52D, S220GD, etc. |

| Thickness | 0.12 – 6.0 mm |

| Width | 600 – 1500 mm |

| Plate Length | Customizable from 1 – 12 m |

| Mechanical Properties | Yield Strength: 140 – 300 MPa Tensile Strength: ≥ 270 MPa Elongation: ≥ 20% (varies slightly depending on the base material grade) Good bending, stamping, and welding performance |

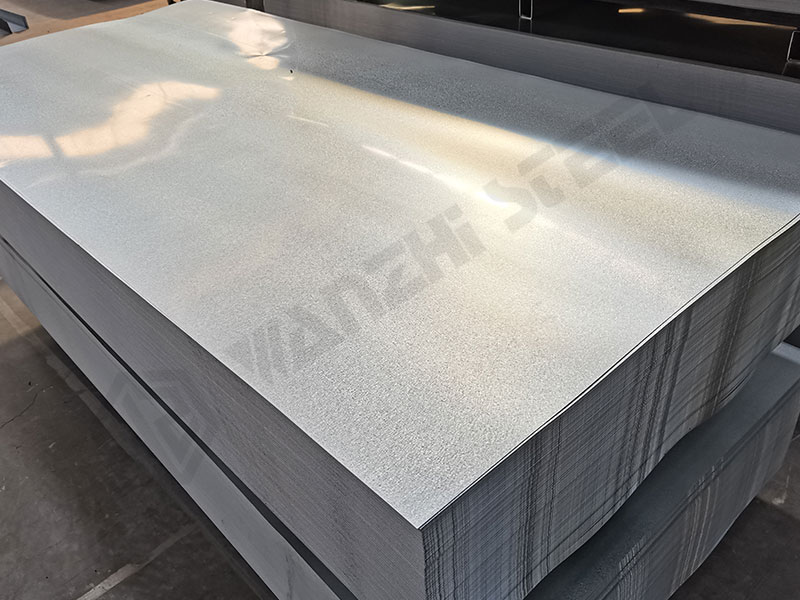

| Surface Characteristics | Silver-white surface with zinc crystal patterns |

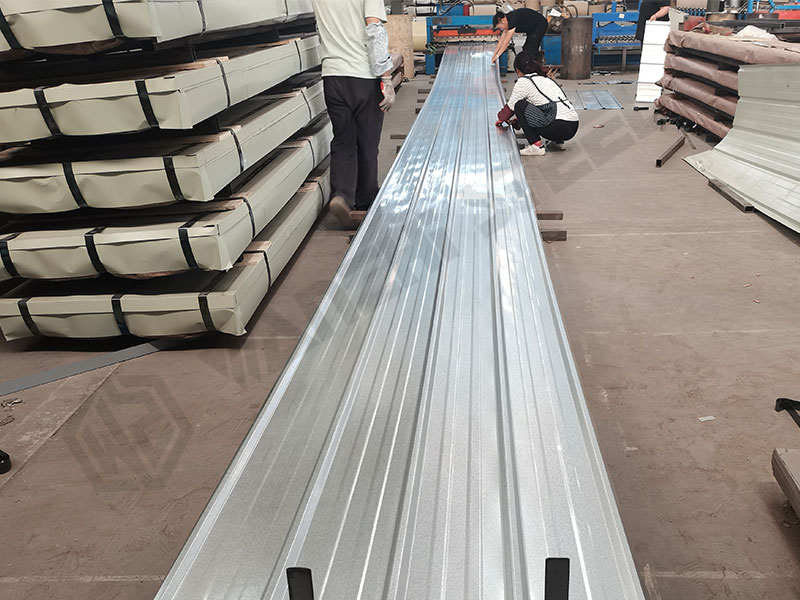

| Applications | Can be used directly or as the base plate for color-coated sheets (PPGL) |

Aluzinc AZ30 vs. Galvanized Steel (GI)

| Comparison Aspect | Aluzinc AZ30 (55% Al-Zn) | Galvanized Steel (GI) (Pure Zinc) |

| Coating Composition | An alloy coating consisting of 55% aluminum, 43.4% zinc, and 1.6% silicon | A coating of over 99% pure zinc |

| Corrosion Protection Principle | Synergistic protection of aluminum and zinc | Single zinc cathodic protection |

| Corrosion Resistance | Generally superior to GI steel in terms of oxidation resistance and heat oxidation resistance under the same coating weight | Sensitive to scratches and cuts; zinc is consumed rapidly, with a higher corrosion rate in humid or saline environments |

| Appearance | Silver-gray, more aesthetically pleasing | Gray-white with distinct zinc spangles; prone to white rust |

| Durability | Higher surface hardness, scratch-resistant; good heat resistance | Relatively soft surface, easily scratched; poor heat resistance |

| Processing and Coating | Good bending and stamping performance; can be used as a base plate for PPGL with strong adhesion | Excellent processing performance; can be used as a base plate for PPGI |

| Cost | Slightly higher than ordinary galvanized steel of the same grade | Lowest initial cost |

| Suitable Environments | Indoor dry environments, warehousing, well-ventilated light industrial plants, dry inland regions | Short-term rust prevention, non-exposed internal structural components, dry indoor environments |

Aluminum-Zinc AZ Series Coating Weight Comparison

| Comparison Aspect | AZ30 Aluzinc | AZ50 Aluzinc | AZ100 Aluzinc |

| Coating Weight | 30 g/㎡ (total for both sides) | 50 g/㎡ (total for both sides) | 100 g/㎡ (total for both sides) |

| Corrosion Resistance Grade | Mild corrosion protection | Moderate corrosion protection | Moderate-to-high corrosion protection |

| Suitable Environments | Indoor/dry storage, extremely dry inland areas | Dry/semi-humid inland areas, general industrial zones | Humid inland areas, mild coastal regions, areas with strong UV exposure |

| Cost | Economical choice | Cost-effective choice | Performance-oriented choice |

Aluzinc AZ30 Application Scenarios

Aluzinc AZ30 coil sheet features a uniform, silvery-white appearance, combining cost-effectiveness, fundamental corrosion resistance, heat tolerance, and excellent formability. It is suitable for various cost-sensitive applications with low corrosion exposure.

- Construction Sector: Interior light-gauge steel framing, ceiling systems, interior wall panels, dry-area fencing, cable trays, ventilation ducts, warehouse interior partitions, and non-load-bearing concealed structures.

- Home Appliances & Electronics: Appliance back panels, internal support brackets, refrigerator liners, non-exposed internal structural components in appliances, and electronic equipment enclosures.

- Agriculture & Livestock: Greenhouse internal frameworks, livestock sheds, storage facilities, and farm equipment sheds.

- Light Industry & Logistics: File cabinets, non-load-bearing parts of storage equipment, lighting fixture back panels, and metal furniture frames.

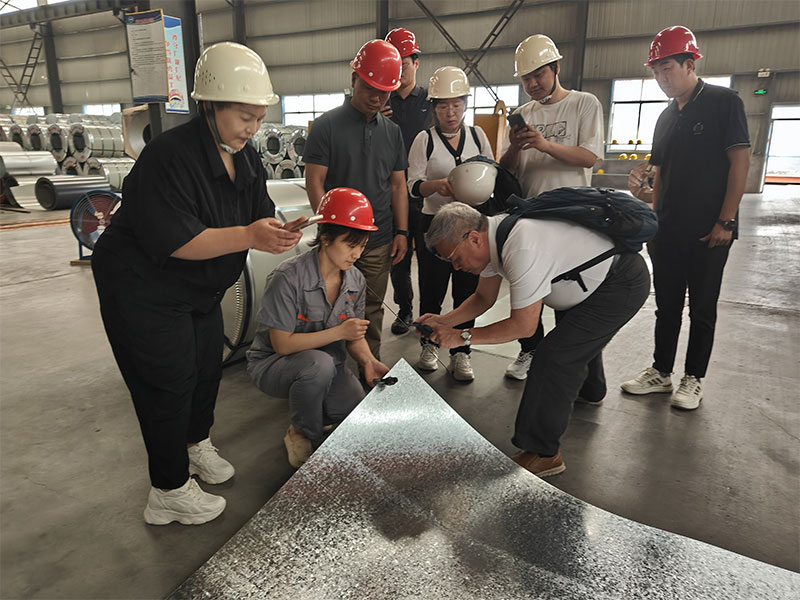

AZ30 Aluzinc Coated Steel Sheet Factory

Wanzhi Group, a specialized coated steel manufacturer, operates an ISO-certified facility with an annual production capacity of 600,000 tons, including 120,000 tons of aluzinc products. We accept custom orders for aluminized zinc coils, sheets, strips, color-coated aluminized zinc, and custom profiles in thicknesses ranging from 0.12 to 6.0 mm and widths from 600 to 1500 mm. Delivery cycles range from 5 to 45 working days. We provide SGS and BV third-party inspection reports and offer free samples.

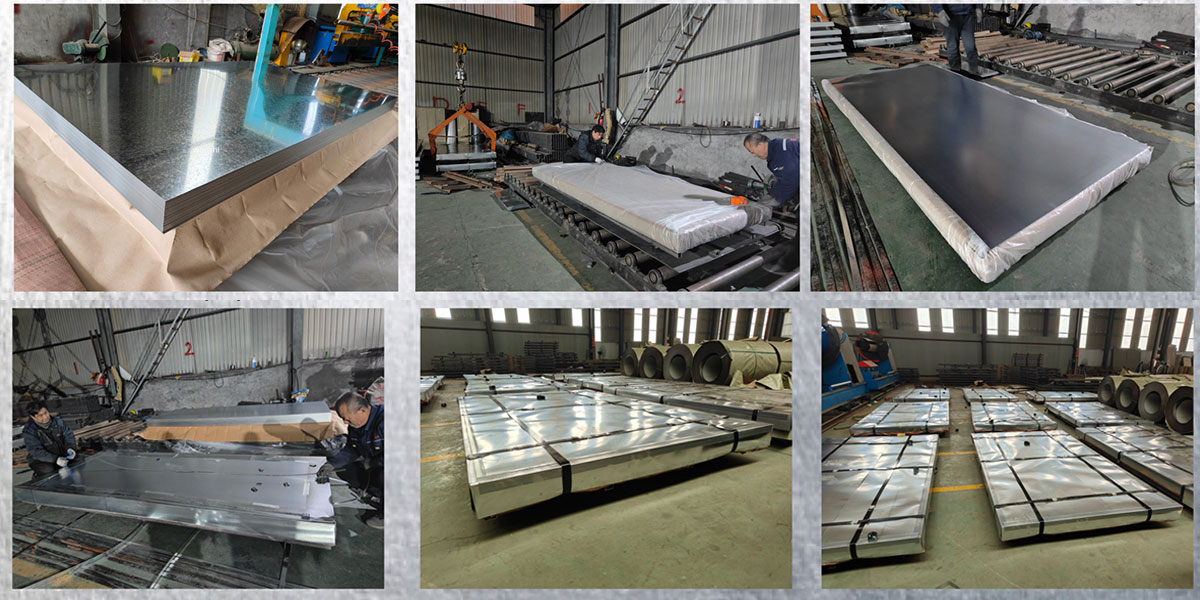

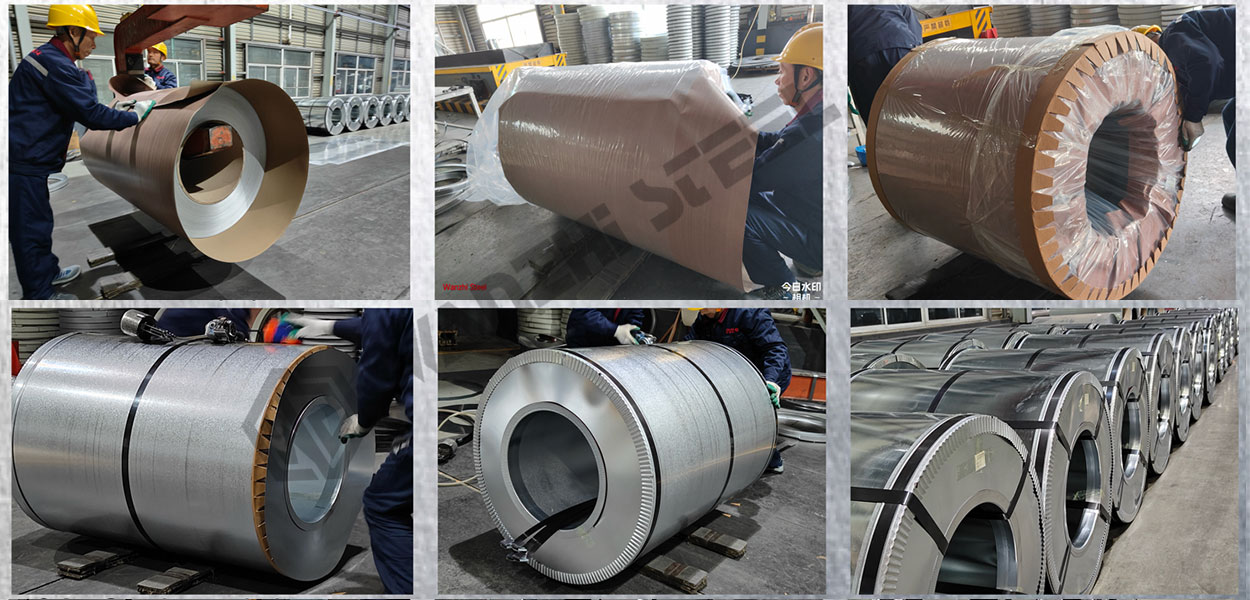

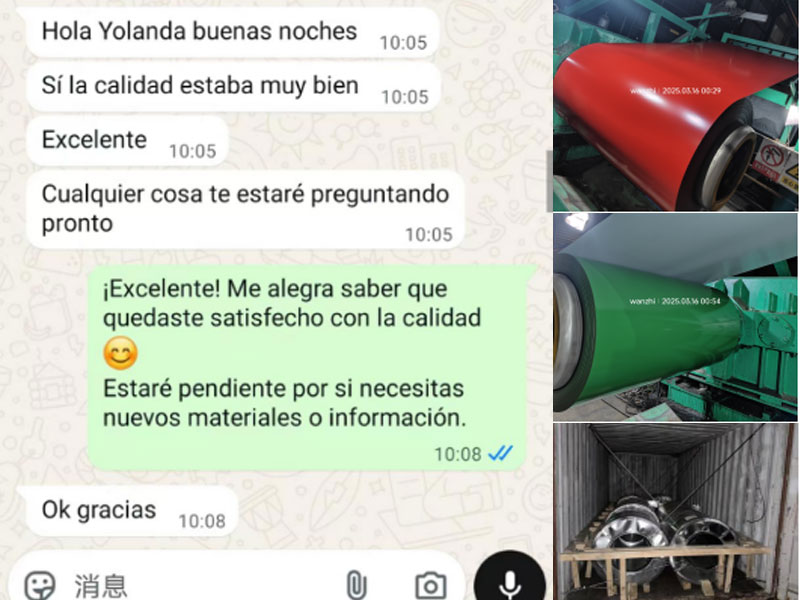

Packaging

All coated steel coils are packaged with export-grade rust-proof protection (plastic film + moisture-proof paper + galvanized iron sheet + wooden pallet) to ensure product integrity during long-distance sea and land transportation.

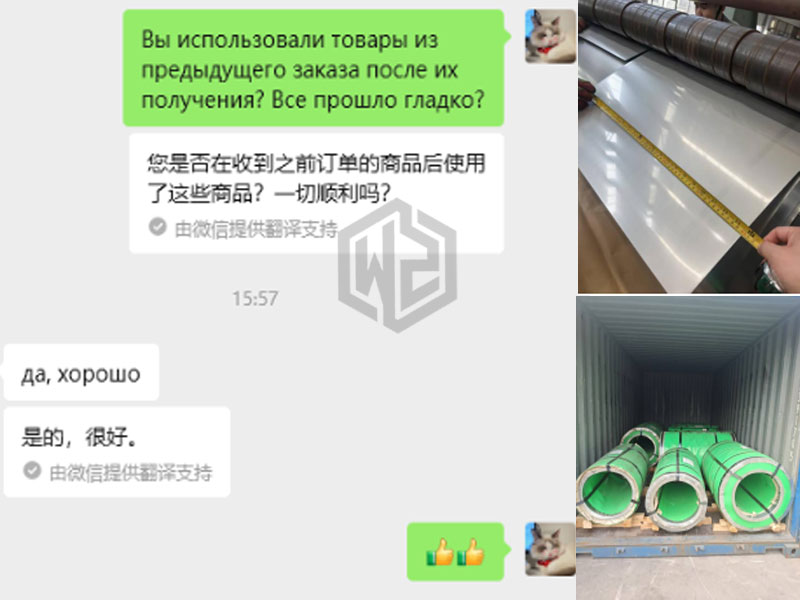

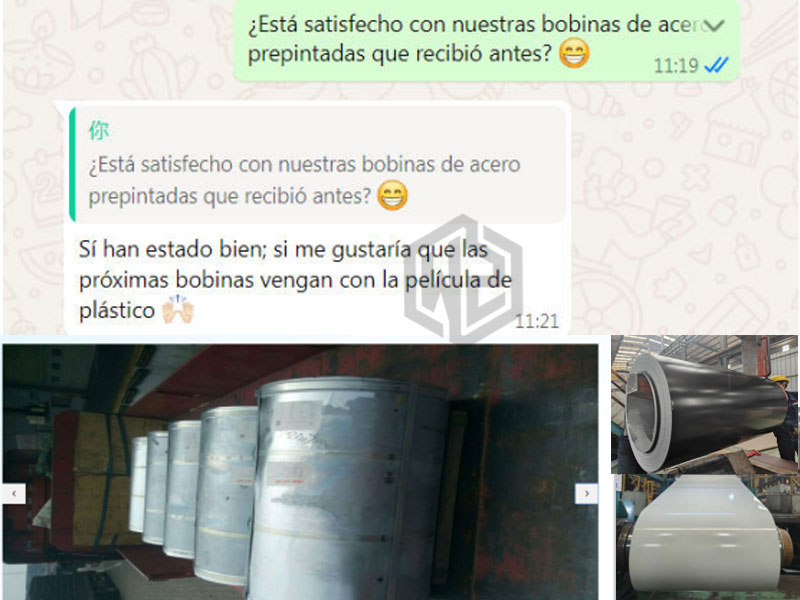

Customer Feedback

To date, Wanzhi Steel has received positive feedback from global clients across diverse applications including interior construction projects, home appliance factories, and storage facilities in arid regions.

Wanzhi Group manufactures and sells aluzinc AZ30-AZ150, as well as ultra-high-coating AZ200+ and other registered aluzinc coated materials. Please leave a message detailing your requirements or application environment to receive a free quote!