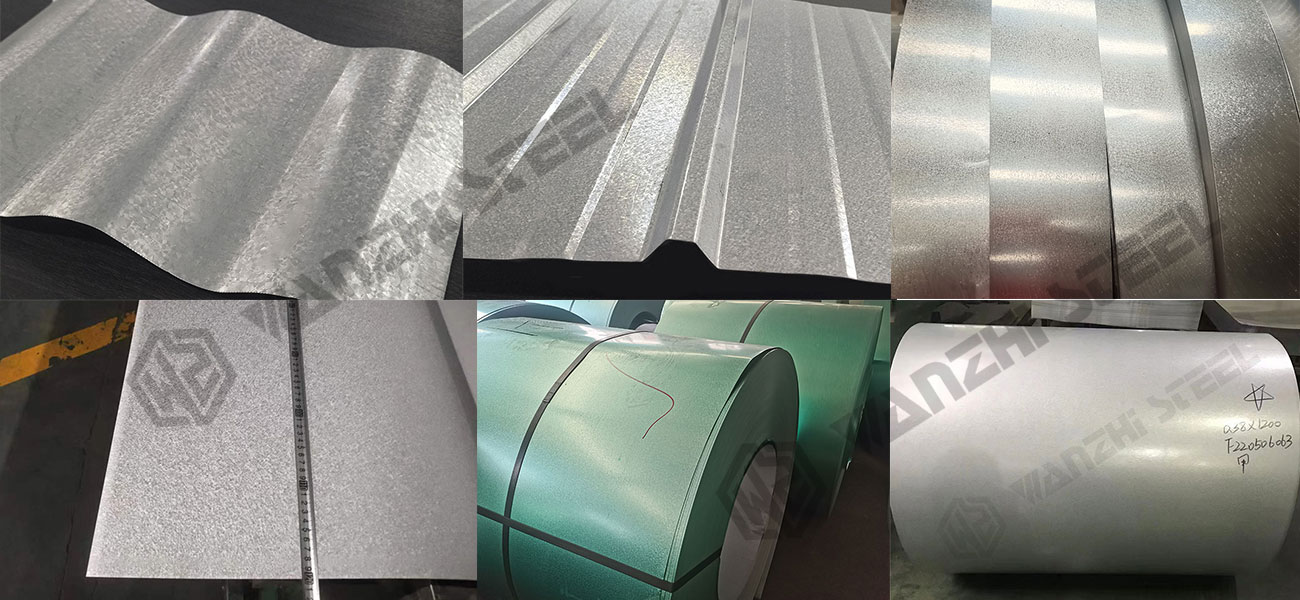

Fingerprint-resistant Aluzinc Steel is a passivated galvanized steel with a surface that exhibits very faint interference colors (such as extremely light blue, yellow, or iridescent hues) or appears colorless and transparent. It offers dual functionality: “fingerprint resistance + enhanced corrosion protection,” making it the preferred metal material for sectors demanding stringent surface cleanliness and durability, including home appliances, electronics, and high-end decoration.

Fingerprint-Resistant Aluzinc Steel: The Core Principle

The core of fingerprint-resistant aluzinc steel lies in coating the aluminum-zinc layer surface with an ultra-thin, dense, and transparent functional protective film. This addresses the common issues of ordinary aluzinc steel—fingerprint retention and difficult cleaning—while preserving the base material’s metallic texture and structural strength.

Processing Technology

- Substrate Preparation: High-quality cold-rolled steel coils are selected as the base material. They undergo rigorous cleaning and degreasing to ensure absolute surface cleanliness.

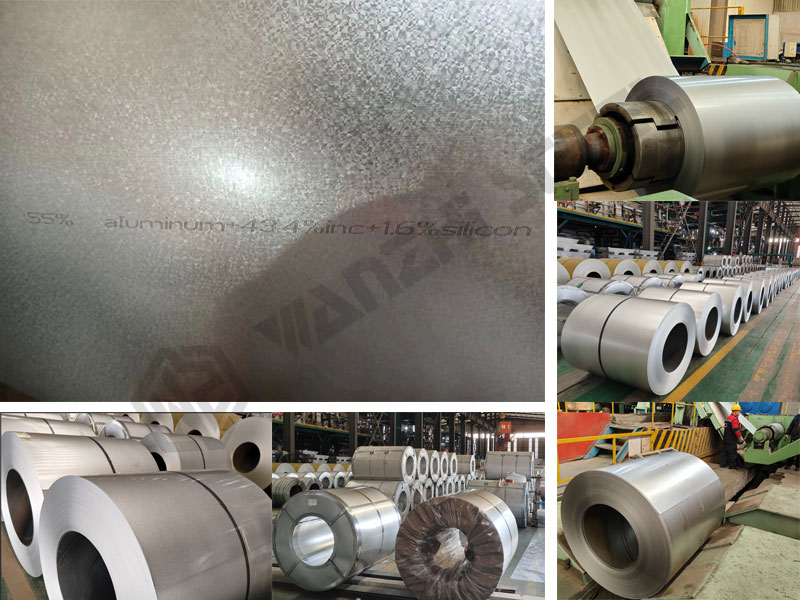

- Hot-Dip Aluzinc Coating: The clean steel strip is immersed in a molten alloy bath containing 55% aluminum, 43.4% zinc, and 1.6% silicon. An air knife controls the coating process, forming a firmly adhered, uniformly thick layer.

- Surface Pretreatment: Post-coating, essential chemical pretreatment (e.g., passivation) enhances coating adhesion.

- Precision Anti-Fingerprint Coating: A roller coating process evenly applies a specially formulated anti-fingerprint coating to the steel surface.

- Baking and Curing: The coated steel enters a curing oven. Following a specific temperature profile, solvents evaporate and the resin undergoes cross-linking, forming a robust, transparent functional film.

- Cooling and Post-Processing: After forced cooling, secondary processing such as online inspection, printing, or lamination may be performed as required.

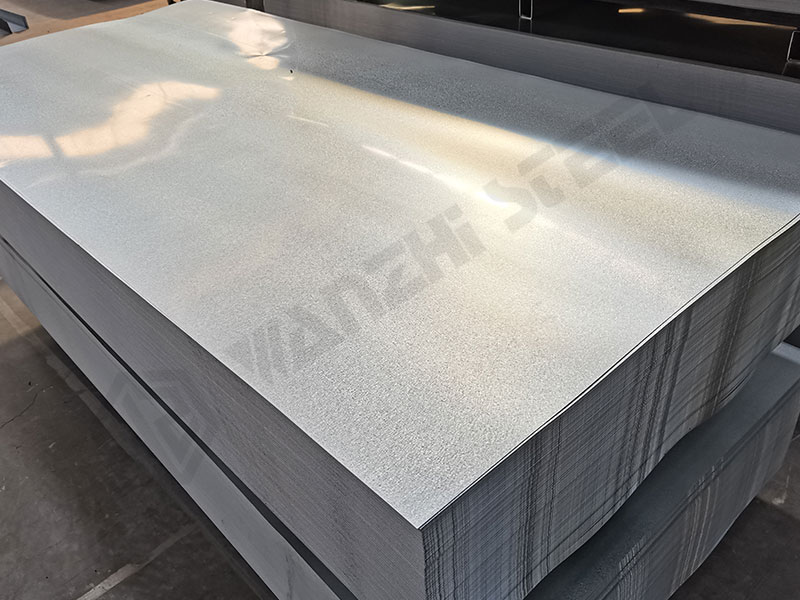

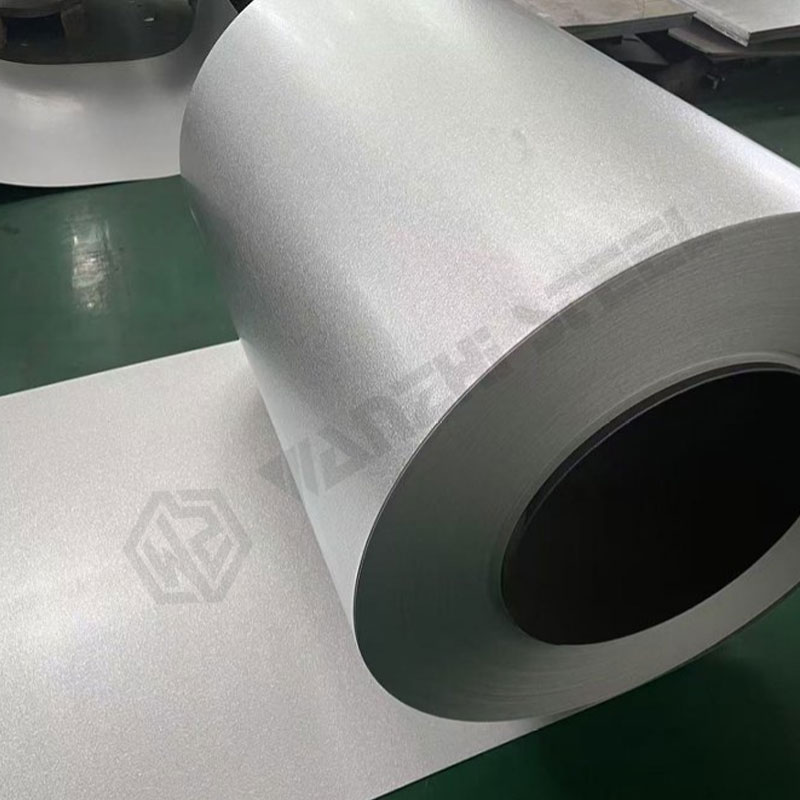

- Coiling and Packaging: The final product is packaged in protective, scratch-resistant materials as Aluzinc steel coils or slit Aluzinc sheets according to specifications.

Features and Performance

- Superior Fingerprint Resistance: High surface smoothness prevents easy adhesion of fingerprints, sweat marks, and grease.

- Easy Cleaning: Residual stains on the fingerprint-resistant aluzinc steel surface wipe away effortlessly, maintaining long-term surface cleanliness and aesthetics.

- Superior Surface Appearance and Texture: Offers various gloss options including bright and matte finishes. The smooth, refined tactile feel enhances the aesthetic value and premium quality of end products.

- Dense Physical Barrier: The coating forms a smooth, continuous, and non-porous barrier at the microscopic level.

- Enhanced Corrosion Resistance: The protective film and aluminum-zinc coating provide dual protection, effectively extending the service life of aluzinc steel.

- Superior chemical and weather resistance: Resists corrosion from various household chemicals and cleaners, maintaining stable performance indoors and outdoors without yellowing or chalking.

- High heat resistance and oxidation resistance: Withstands continuous temperatures up to 315°C (peak temperatures higher), outperforming galvanized steel.

- Outstanding process adaptability: Similar to the substrate, it can undergo conventional processing such as bending, stamping, and shearing.

- High environmental compliance: Meets international standards including RoHS and REACH, ensuring safe use in high-end applications like home appliances, electronics, and medical devices.

Fingerprint-Resistant Aluzinc Steel Applications

Fingerprint-resistant aluzinc steel is primarily suited for scenarios involving frequent touch, where surface cleanliness, corrosion resistance, and durability are essential. It meets diverse requirements including sterility, easy cleaning, corrosion prevention, enhanced decorative appeal, moisture resistance, aesthetic appeal, and fingerprint resistance, serving high-end manufacturing across multiple industries.

- Home Appliance Manufacturing: Outer shells and inner liners for refrigerators, washing machines, and air conditioners; cavity components for microwaves and ovens; water heater panels.

- Electronics & Electrical: Charging station housings; distribution box/panel enclosures; server cabinets; smart meter enclosures.

- Precision Manufacturing: Laboratory equipment; medical device housings; instrument enclosures; high-end computer cases; audio equipment shells; automation equipment control panels.

- High-end decoration: Cleanroom panels, elevator car panels, premium architectural metal cladding, smart home control panels.

- Transportation: Interior trim panels, luggage racks, partitions for buses, trains, and elevators.

- Office furniture & home goods: File cabinets, storage units, display racks, high-end lighting fixtures.

- Construction and interior decoration: Premium metal roofing, wall cladding, ceilings, and partition systems.

Differences from Standard Aluzinc Steel

| Characteristic Dimension | Aluzinc Steel | Fingerprint-Resistant Aluzinc Steel |

| Surface State | Bare metal coating, possibly with a passivation film. | A transparent functional organic/inorganic composite coating is applied on top of the coating layer. |

| Color | Silver-white | Silver-white, green, blue, gold, etc. |

| Fingerprint Resistance | Poor, with obvious fingerprint residue that is difficult to clean. | Excellent, with fingerprints easily wiped off and no residue. |

| Stain Resistance | None. | Extremely good. |

| Corrosion Resistance Mechanism | Electrochemical protection and physical barrier of the aluzinc coating layer. | Dual protection: aluzinc coating layer + physical isolation by the surface coating. |

| Appearance and Feel | Strong metallic luster, with a relatively rough touch. | Gloss level can be selected (glossy/matte), with a smoother and more delicate touch. |

| Processability | High friction coefficient, with easy damage to the coating during processing. | Low friction coefficient, with less mold wear and less likelihood of coating layer detachment. |

| Cost | Relatively low. | Higher cost. |

| Applicable Scenarios | Non-touch scenarios such as building envelopes and industrial supports. | Frequently touched scenarios such as home appliances, electronics, and high-end decorations. |

| Features | Excellent base corrosion resistance, heat resistance, and cost-effectiveness. | Enhances surface aesthetics, ease of cleaning, and protection against contact contamination based on the base properties, elevating product grade and user experience. |

Fingerprint-Resistant Aluzinc Steel Factory Supplier

When selecting a reliable Fingerprint-Resistant Aluzinc Steel supplier, prioritize evaluating production capabilities, quality control systems, environmental certifications, and service capacity. As a professional coated steel manufacturer, Wanzhi Group offers end-to-end supply chain solutions to precisely match procurement requirements.

Production Capabilities

Wanzhi Steel Factory operates multiple metal-coated steel production lines, including a high-precision fingerprint-resistant aluzinc coating line capable of customized production for coating thickness and surface texture. Base material utilizes premium 55% Al-Zinc alloy coated steel sheets with selectable coating weights from AZ30 to AZ150. Specifications cover 0.15-6mm (thickness) × 600-1250mm (width), accommodating diverse application requirements.

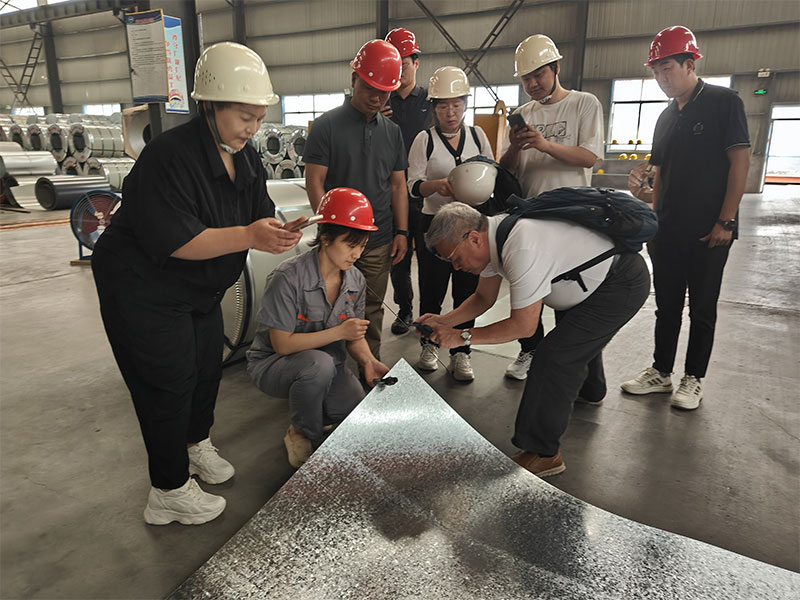

Stringent Quality Control System

Our factory holds ISO9001 Quality Management System and ISO14001 Environmental Management System certifications. We implement comprehensive quality control standards covering “raw material inspection – process monitoring – finished product testing,” utilizing high-precision thickness gauges, color difference meters, salt spray testers, and other equipment. Core metrics including coating thickness, adhesion, fingerprint resistance, and corrosion resistance are rigorously tested. Each batch comes with a certificate of conformity and third-party test reports, ensuring consistent quality.

Full-Chain Service Capabilities

Wanzhi offers one-stop services spanning product selection, parameter customization, small-batch sampling, mass production, packaging, and transportation. Our products reach over 100 countries and regions including Latin America, the Middle East, and Southeast Asia, delivering efficient and convenient procurement experiences.

Specifications

| Type | Galvalume Steel |

|---|---|

| Thickness | 0.15-6 mm |

| Width | 600-1250 mm |

| Packing Weight | 5-10t, customize |

| Aluzinc Coating | AZ20-AZ150 g/m2, 40-150 micron. |

| Surface Finish | oiled, chrome plated, anti-fingerprint, lacquered, etc. |

| Quality | SGS, ISO, support third-party organization testing |

Whether you are a bulk purchaser in the home appliance or electronics industry, or a client with customized requirements in high-end decoration, Wanzhi Group can provide suitable fingerprint-resistant aluzinc steel products and professional solutions. Contact us today to receive free samples, technical specification manuals, and a customized quote!