PPGI Steel and PPGL Steel are not interchangeable in most application environments. In many industrial fields such as construction, home appliances, and automobiles, color-coated steel sheets are widely used due to their beautiful appearance and corrosion resistance. PPGI Steel (pre-coated galvanized steel sheet) and PPGL Steel (pre-coated aluminum-zinc steel sheet) are two common types of color-coated steel sheets. Because of their similar appearance but large price differences, they often cause discussions in the project material selection stage. Today, follow Wanzhi Group to have a deep understanding of PPGI and PPGL from multiple aspects such as composition, performance, and application scenarios.

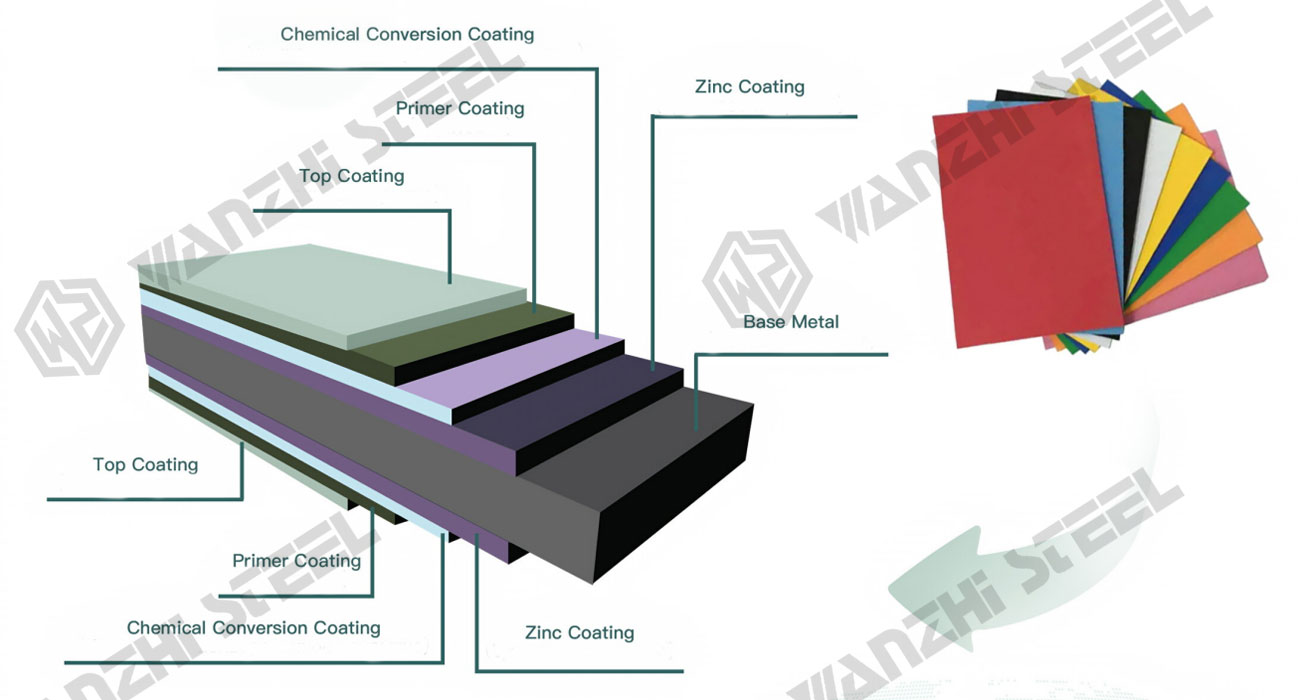

Differences in Composition and Structure

The structures of PPGI Steel and PPGL Steel are both cold-rolled substrate + metal coating + paint coating, but the substrate of PPGI is hot-dip coated with pure zinc metal coating, while the substrate of PPGL is hot-dip coated with aluminum-zinc alloy coating. The difference in the composition of the metal coating affects the service life and corrosion resistance of the plate.

PPGI Steel

PPGI Steel is based on cold-rolled steel sheet, and a layer of pure zinc alloy is hot-dip coated on its surface to form a galvanized layer before color coating. Zinc has good ductility and sacrificial anode protection. When the coating is damaged, zinc will corrode first, thereby protecting the substrate steel from corrosion.

PPGL Steel

PPGL Steel is also based on cold-rolled steel sheet, but the surface is hot-dip coated with aluminum-zinc alloy, usually with an aluminum content of about 55%, a zinc content of about 43.5%, and a small amount of silicon. The presence of aluminum forms a dense aluminum oxide protective film on the surface of the coating, which can effectively prevent corrosive media such as oxygen and moisture from contacting the substrate, while silicon plays a role in improving the adhesion between the coating and the substrate.

Performance Comparison

| Performance | PPGI Steel | PPGL Steel |

| Corrosion Resistance | Relies on the zinc coating for rust protection; corrosion resistance significantly decreases once the zinc layer is gone | Protected by both zinc and aluminum coating; lifespan is 2-3 times longer than pure zinc coating |

| Heat Resistance | Easily oxidizes and vaporizes at high temperatures, leading to reduced coating performance | Aluminum forms a stable oxide film at high temperatures, offering good heat resistance |

| Processing Performance | Good ductility; stamping, bending, etc.; coating is less prone to cracking or peeling | Poor ductility; more brittle than PPGI; requires more attention to processing parameters |

Processing Comparison

| Parameter | PPGI | PPGL |

| Substrate Hardness (HV) | 90-130 | 70-100 |

| Deep Drawing Limit (LDR) | ≤1.8 | ≤2.2 |

| Bending Radius (R/t) | ≥1.0 | ≥0.6 |

| Weldability | Good resistance welding rate >95% | Requires laser welding (zinc vapor contamination) |

Application Scenario Analysis

PPGI Steel is suitable for various complex molding processes. The ductility of PPGL Steel is weaker than that of PPGL, and the processing technology requirements are higher.

Scenarios Suitable for Using PPGI Steel

- Architecture: PPGI Steel can meet the aesthetic and durability requirements of interior wall panels of office buildings in inland cities, roofs of industrial plants, ceilings and facades of shopping malls. At the same time, its cost is relatively low and has certain economic advantages.

- Household appliance shell: The inner tank, shell, heat sink of household appliances are used in a relatively dry environment, and the corrosion resistance requirements are not extremely high. PPGI Steel can provide good appearance and certain protective performance, and the price is relatively affordable.

- Transportation: Inland highway guardrails, subway platform ceilings, urban bridge guardrails, PGI coating can achieve better decorative properties on complex textured surfaces.

Scenarios Suitable for Using PPGL Steel

- Industrial buildings such as chemical industry and power: exterior walls of landmark buildings in coastal cities, roofs of wind power towers, partition materials of hospital corridors, in environments with severe industrial pollution and strong corrosion, such as acid, alkali, salt spray, etc. PPGL Steel can effectively extend the service life of buildings and reduce maintenance costs with its excellent corrosion resistance.

- High-temperature equipment housing: In the manufacture of some equipment housings that need to withstand certain high temperatures, such as ovens, battery packs, etc., PPGL Steel’s heat resistance makes it a more suitable choice, which can ensure the long-term stable operation of the equipment in high-temperature environments.

- Transportation: Coastal road guardrails, rail transit fixtures, cross-sea bridge guardrails, etc. PPGL steel has low maintenance costs and can resist wind and sand wear.

Reasons why PPGI and PPGL are Not Interchangeable

- Fundamental difference in corrosion protection mechanism: Red rust appears at the scratch of PPGI steel sheet in 24 hours, and no red rust expands at the scratch of PPGL steel sheet in 500 hours.

- Processing formability limit: PPGI has a higher elongation and is suitable for processing processes that require large deformation. PPGL has slightly higher yield and tensile strengths and is suitable for scenarios that require higher load-bearing capacity.

- Life cycle cost: PPGI has a low initial cost, and PPGL has a high cost-effectiveness for long-term use.

The essential difference between PPGI PPGL Steel lies in the substrate-coating synergistic protection mechanism. Due to significant differences in composition, structure and performance, they cannot be simply used interchangeably. When selecting materials, comprehensive consideration should be given to factors such as specific application scenarios, usage environment, and requirements for material performance. For projects with high requirements for corrosion resistance and heat resistance, PPGL steel is selected; for projects that are more cost-sensitive and have a relatively mild use environment, PPGI Steel can meet basic needs. Wanzhi Group provides PPGI PPGL steel solutions in different fields, welcome to leave a message for consultation.