Galvanized structural steel is ubiquitous in construction projects and industrial facilities. Leveraging its high strength for load-bearing and long-lasting corrosion resistance, it serves as the skeletal material providing structural support and decorative functions across various building components. Based on its role in construction, it can be categorized into four types: primary structural steel, secondary structural steel, secondary/auxiliary structural steel, and auxiliary structural/connecting components.

Primary Structural Steel

Galvanized structural steel that bears and transfers all primary loads (e.g., gravity, wind loads, seismic forces) within a building is classified as primary structural steel. Material selection for this tier prioritizes mechanical properties and demands the highest zinc coating standards, typically achieved through hot-dip galvanizing of hot-rolled base materials.

Products

- Galvanized H-Beams: Core structural members for beams and columns, offering exceptional load-bearing efficiency.

- Galvanized Box Columns: Welded from thick plates into rectangular hollow sections, offering outstanding compression and torsional resistance.

- Galvanized Heavy-Duty Welded Shapes: Used for large-span, non-standard main structural members with special geometries.

Function

- Bear core loads.

- Ensure overall structural stability.

- Resist corrosion from various substances.

Applications

- Main frame columns and roof girders in large industrial plants.

- Main girders for large-span spatial trusses or arched structures.

- Core columns in steel structures of high-rise buildings.

- Primary structural components for coastal bridges and buildings in highly corrosive environments like chemical industrial parks.

Secondary Structure Steel

Secondary structures are galvanized steel materials installed atop primary structures to supplement them. They bear localized loads from building walls and roofs, transferring them to the core structure. Secondary structural steel demands high material adaptability and installation flexibility, typically utilizing cold-formed thin-walled galvanized steel sections.

Products

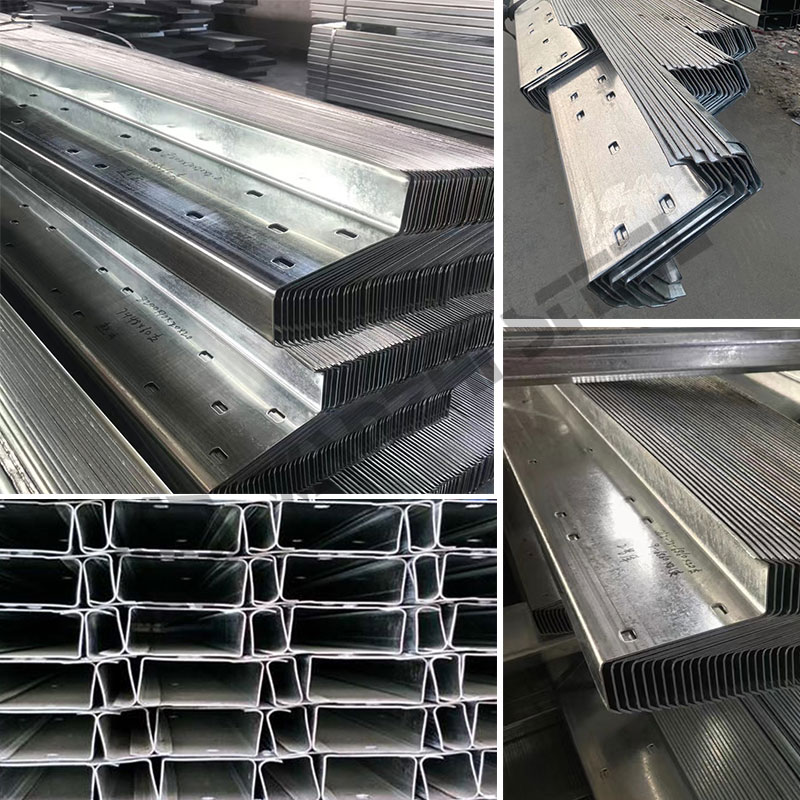

- Galvanized C-/Z-shaped purlins: Secondary load-bearing components for roofs and walls.

- Galvanized secondary beams/trusses: Used to support floor slabs or as secondary bracing between main beams.

- Galvanized Floor Decking: Profiled steel sheets serving as formwork, structural reinforcement, and permanent platforms.

Functions

- Directly support building envelope systems.

- Effectively transfer loads.

- Form the foundation for building envelopes.

Applications

- Roof purlins and wall beams in all steel structures.

- Secondary beams and floor girders in multi-story steel buildings.

- Walkway decking and supports for industrial platforms.

Secondary/Ancillary Structures

This category represents galvanized steel structures positioned between secondary structures and purely auxiliary elements. They do not directly bear primary loads but fulfill additional functions such as decoration and protection while providing support and spatial division. Requirements include lightweight materials, adaptable forms, and corrosion resistance.

Products

- Galvanized Square/Rectangular Tubing: The most versatile functional structural material, offering easy connection and assembly.

- Galvanized Round Pipe: Commonly used for railings and spatial trusses.

- Galvanized Cable Trays & Conduits: Dedicated electrical support systems.

Functions

- Reduce overall building load.

- Provide installation and support surfaces.

- Create additional architectural space.

- Integrate decorative and functional requirements.

Applications

- Staircases, railings, partitions, protective barriers, curtain wall framing, shelving systems.

- Equipment access platforms and heavy-duty storage racks in factories.

- Rails and supports for solar photovoltaic mounting systems.

- Pipe supports.

Ancillary Structures/Connectors

Connectors are critical components in construction, securely joining all structural elements. Though not bearing primary loads, they ensure tight connections and overall structural integrity.

Products

- Galvanized angle steel: The most versatile connection and support member.

- Galvanized steel plates, connection plates: Used for beam-column joints and splicing connections.

- Galvanized bolts, self-tapping screws: Standardized fasteners.

- Galvanized bracing (tie rods, diagonal braces): Auxiliary members providing structural stability.

Function

- Ensures precise, secure connections at all structural levels.

- Transfers internal forces including tension, compression, and shear.

- Guarantees stability and prevents structural deformation or buckling.

Applications

- Connecting plates and stiffeners at steel structure joints.

- Cross-braces and round steel tie rods for roofs and walls.

- Self-drilling screws for fixing color-coated steel sheets.

- Angle steel truss systems for transmission towers and communication towers.

Wanzhi Group operates galvanizing plants and steel deep-processing production lines, offering comprehensive galvanized structural steel manufacturing and customization services. We provide end-to-end solutions from material selection and specification customization to corrosion protection system design. Contact us for a complimentary quote.