Cold-rolled stainless steel and hot-rolled stainless steel are the two primary processing methods for stainless steel sheets. The versatility of cold-rolled stainless steel is evident in various aspects, including surface types (2B/2D/BA/NO.4/Hairline, etc.). The surface type of stainless steel determines its “appearance, roughness, and subsequent processability,” making it suitable for applications such as decoration, anti-slip, and deep drawing. Today, let’s explore cold-rolled stainless steel from multiple angles, including surface finish, steel grade, international standards, and applications!

What is Cold-rolled Stainless Steel?

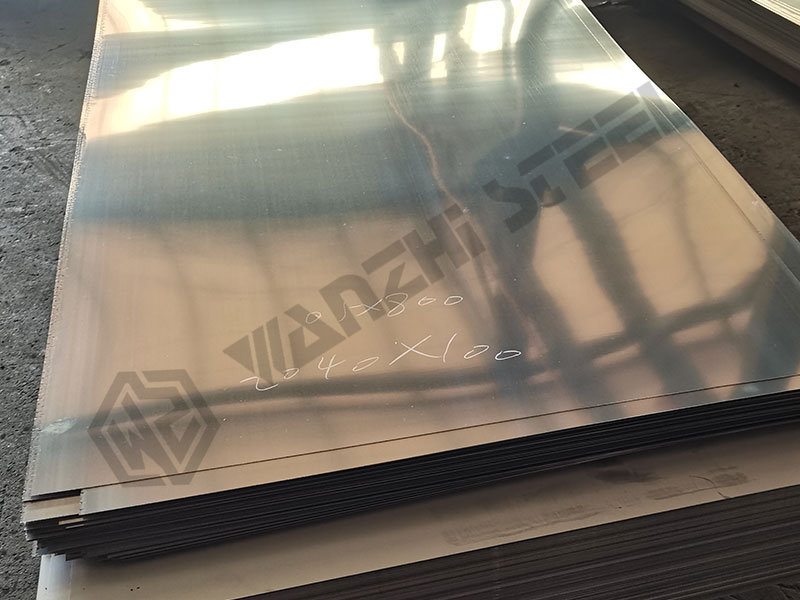

Cold-rolled stainless steel is stainless steel sheet or strip produced at room temperature through the cold-rolling process, with raw materials being hot-rolled sheets or cast-rolled sheets. After cold rolling, the stainless steel material has a smooth surface, high dimensional accuracy, and excellent mechanical properties, making it one of the most widely used types of stainless steel materials.

Process

Raw material preparation: Hot-rolled sheets or cast-rolled sheets

Acid washing: Remove oxide scale and clean the surface

Cold rolling: Multiple rolling passes to reduce thickness to the target thickness

Annealing: Eliminate work hardening and restore ductility

Post-processing: Surface finishing and functionalization

International Standards

| Standard | Description |

| ISO 6931-1~4 | Global standard for stainless steel cold-rolled plates and strips, covering chemical composition, mechanical properties, dimensional tolerances, and surface quality. |

| ASTM A240/A240M | US standard for stainless steel plates for pressure vessels, focusing on corrosion resistance and high-temperature performance (e.g., 304, 316). |

| ASTM A480/A480M | General requirements for stainless steel and heat-resistant steel thick plates, thin plates, and strips, used in conjunction with A240. |

| ASTM A666 | Cold working standard for austenitic stainless steel cold-rolled strips, thin plates, sheets, and flats. |

| EN 10088-2 | European standard for stainless steel cold-rolled plates and strips, specifying chemical composition, mechanical properties, and surface treatment (e.g., 2B, BA, NO.4). |

| EN 10088-3 | European standard for stainless steel – Part 3: Delivery technical conditions for semi-finished products, bars, wire, and sections for general corrosion-resistant steel. |

| EN 10051 | European standard for continuous hot-rolled non-alloy steel and alloy steel strips and thin plates – tolerances and dimensions. |

| JIS G4304/4305 | Japanese standard for stainless steel cold-rolled plates and strips, regulating chemical composition, mechanical properties, and dimensional tolerances. |

| GB/T 3280 | Chinese standard for stainless steel cold-rolled steel plates and strips. |

Cold Rolled Stainless Steel Grades

| Steel Type | Representative Grades | Core Features |

| Austenitic | 304, 304L, 316, 316L | Excellent uniform corrosion resistance, non-magnetic, superior workability/weldability |

| Ferritic | 430, 443 | Low cost, resistance to chloride corrosion, magnetic, less workability than austenitic |

| Martensitic | 410, 420, 440C | High strength, high hardness, wear resistance, corrosion resistance weaker than austenitic |

| Duplex Stainless Steel | 2205, 2507 | Corrosion resistance, high strength, resistance to chloride stress corrosion, more expensive than austenitic |

Cold Rolled Stainless Steel Surface Type

| Surface Type | Process Core | Features |

| 2D | Cold Rolling → Annealing → Pickling (No Flattening) | Rough surface Ra: 0.5 – 0.9, non-glossy (matte-like), high work-hardening, good deep drawing properties |

| 2B | Cold Rolling → Annealing → Pickling → Flattening | Matte, high flatness, moderate roughness (Ra: 0.3 – 0.5), strong corrosion resistance, basic stainless steel material |

| BA | Cold Rolling → Bright Annealing (Annealed in protective atmosphere to avoid oxidation) → Flattening | Mirror-like high gloss (reflectivity > 80%), very low roughness (Ra < 0.15), excellent corrosion resistance |

| No. 3 | Continuous Grinding Marks, Matte Surface | Coarse grinding, roughness (Ra: 0.5 – 1.5) |

| No. 4 | Cold Rolling → Annealing → Pickling → Polishing (Abrasive Belt/Wheel) | Matte brushed texture, even pattern, strong decorative appearance, good fingerprint resistance, Ra: 0.2 – 0.5 |

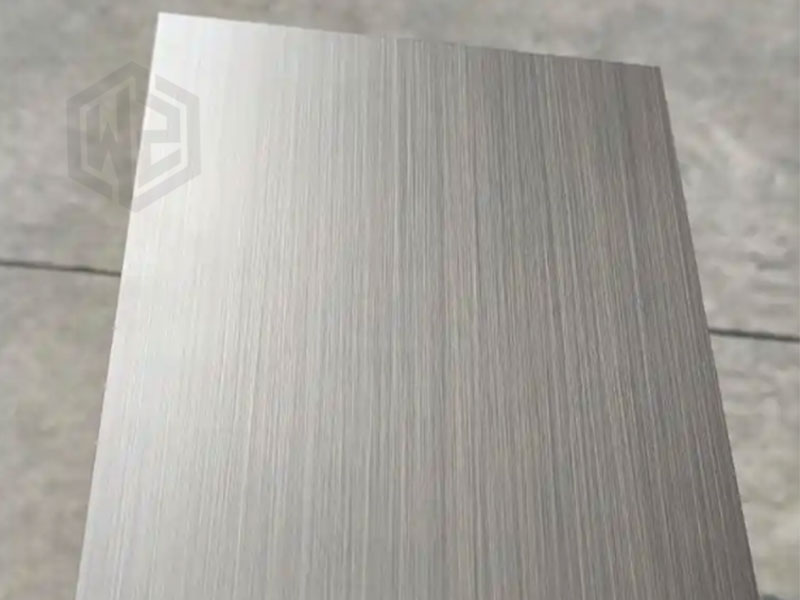

| HL (Hairline) | Cold Rolling → Annealing → Pickling → Polishing (Finer Abrasive Belt) | Fine brushed texture, gloss lower than No. 4, delicate touch, Ra: ~ 0.2 – 0.5 |

| SB | Cold Rolling → Annealing → Pickling → Sandblasting (Abrasive/Steel Shot) | Even rough surface, non-glossy, anti-slip/anti-fingerprint properties |

Main Applications

- Industrial equipment, structural components

- Deep drawing, chemical containers, industrial parts

- Food equipment, building interiors, home appliances, pharmaceuticals

- Electrical panels, elevator cabins, decorative parts, reflectors

- Kitchen equipment, dairy processing equipment

- Restaurant equipment, kitchen countertops, building decoration

- High-end electrical panels, interior decoration, signage

- High-end decoration, mirror sculptures, precision instruments

Wanzhi Group offers production and processing services for cold-rolled stainless steel coils, sheets, strips, tubes, and other products, as well as stainless steel OEM and ODM services. Please leave a message to request a free quote.