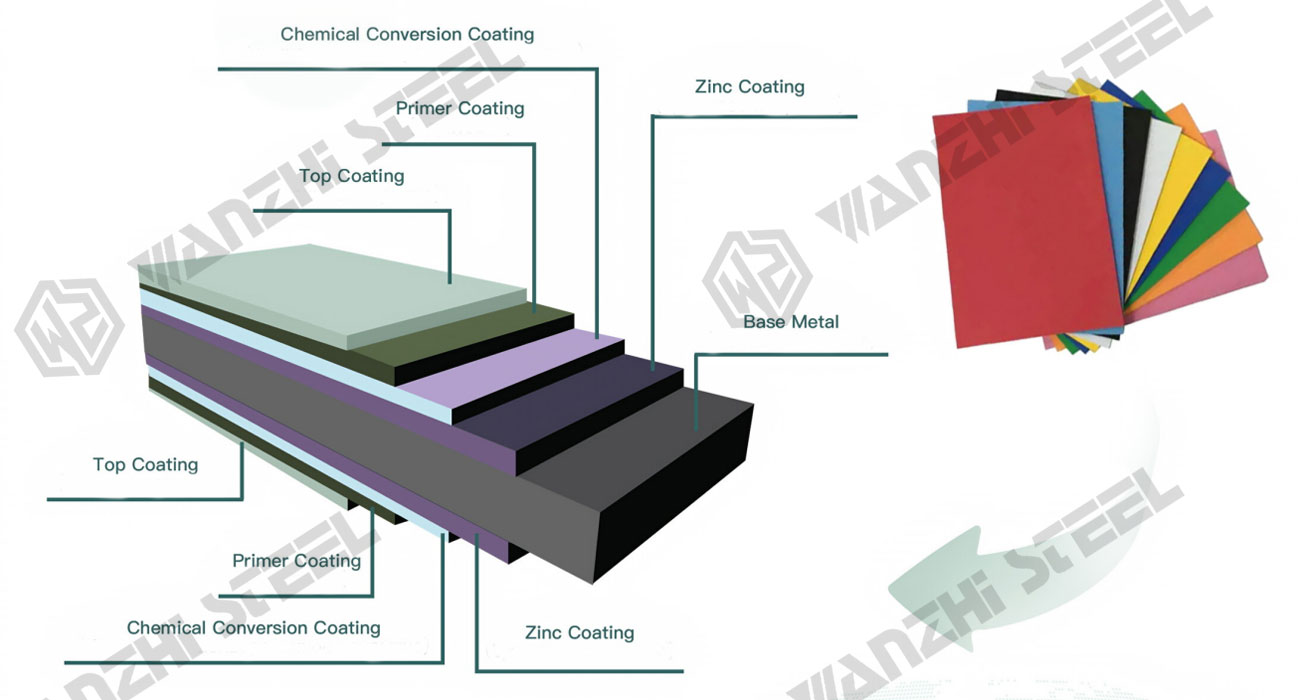

Color-coated steel has a service life of 8 to 30 years. Not only does the coating material play a crucial role, but its precise multi-layer coating structure is also the secret to the sheet’s longevity. The typical coating structure of color-coated steel consists of a pretreatment layer (passivation layer), primer, and topcoat. Together, they form a robust defense, ensuring the color stability of color-coated products across various application environments.

Pre-treatment Layer (Passivation Layer)

The pre-treatment layer of color-coated steel is typically a colorless or light-colored inorganic chemical conversion coating. It acts as a “bridge” between the metal substrate (such as galvanized steel or galvalume steel) and the organic coating. The passivation layer enhances coating adhesion. Although extremely thin, it remains an indispensable structural layer in pre-coated steel.

Functions

- Strengthens the bond between primer and galvanized/aluzinc steel substrates.

- Prevents electrolyte penetration to the substrate surface, thereby inhibiting substrate corrosion.

- Eliminates blistering issues during roller coating of organic coatings.

- Enhances the durability of color-coated steel.

Primer

Wanzhi Group color coated steel features a primer thickness of 5-20 microns. Typically composed of epoxy or polyester resins, the primer serves as an intermediate layer between the passivation layer and topcoat. It provides corrosion protection and facilitates superior color development for subsequent topcoats.

Functions

- Primer delivers corrosion protection to the substrate.

- Forms a strong bond with the pre-treatment layer while providing an optimal adhesion platform for the topcoat.

- Forms a physical barrier for color-coated steel.

Topcoat

The topcoat thickness for Wanzhi Group color-coated steel ranges from 10 to 40 microns. The topcoat determines the color, gloss, texture, and performance characteristics of the color-coated product. Our popular topcoat materials include Polyester (PE), Silicone Modified Polyester (SMP), High Durability Polyester (HDP), and Polyvinylidene Fluoride (PVDF). Colors are typically based on the RAL color chart, with gloss levels and surface effects specified by the customer.

Function

- The topcoat provides steel with rich colors, gloss levels (high-gloss, matte, etc.), and surface textures (smooth, orange peel, wood grain, crinkle, velvet, printed, etc.).

- It resists corrosion from UV rays, rainwater, acid rain, chemicals, pollutants, and other environmental factors.

Backcoat (Optional)

The backcoat typically refers to a paint layer applied to the reverse side of the color-coated sheet, positioned over the primer. Its color is simple and may be omitted in certain architectural and industrial applications.

Functions

- Prevents corrosion of the substrate from the reverse side of the finished color-coated product.

- Provides an aesthetic complement for applications like interior walls or ceilings.

- Enhances adhesion between the face sheet and core material during sandwich panel production.

The coating structure of color-coated steel forms an integrated system: the pretreatment layer determines coating adhesion, the primer provides core corrosion protection, and the topcoat delivers decoration and ultimate defense. Matching coating combinations to specific usage environments reduces costs while preventing material waste.