Wanzhi Group offers color-coated steel produced through three processing techniques: roll-coated color-coated steel, spray-coated color-coated steel, and VCM laminated steel. These products serve diverse applications spanning construction, interior decoration, industrial manufacturing, and high-end home appliances, balancing durability, aesthetics, and cost-effectiveness.

Roll Coating Process

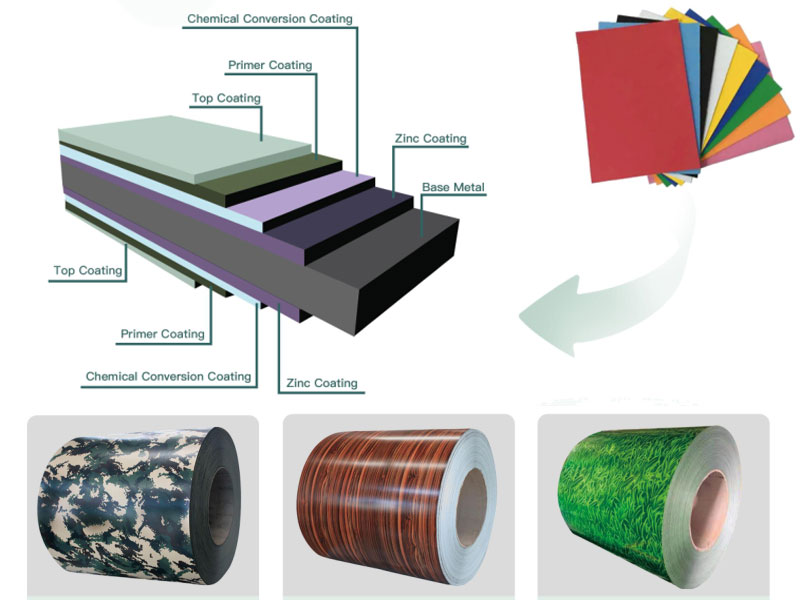

Pre-coated metal materials produced via roll coating, also known as PCM (Pre-Coated Metal), utilize continuous production lines. Liquid coatings are uniformly applied to steel sheet surfaces through roll coating equipment, then cured by baking to form the final coating. This represents the primary and most efficient method for manufacturing color-coated steel sheets.

Process

Substrate Pre-treatment: Cleaning and chemical conversion provide a clean, activated surface for coating. (Substrates: Galvanized steel, Galvalume steel)

Coating: Precisely controlled coating rolls uniformly transfer paint onto the substrate surface. (Common configurations: 2/1, 2/1M, 2/2, 3/3, etc.)

Baking Curing: Coated coils pass through high-temperature ovens where solvents evaporate and resins cross-link, forming a durable paint film. (Film thickness: Topcoat 10-40 microns, Primer 5-20 microns.)

Features

High Efficiency: Continuous production line with extremely fast speeds.

Uniform Coating: Smooth surface with excellent color and gloss consistency.

Low Cost: Mass production enables low manufacturing expenses.

Stable Performance: Adjustable coating types to meet diverse performance requirements.

Appearance: Rich color variety.

Finished Products

Color-coated steel coils/sheets for construction.

Standard color-coated panels for home appliances.

Color-coated products for general applications.

Laminating Process

Laminated color-coated steel uses cold-rolled steel or galvanized steel as the substrate. A pre-formed, printed, and embossed polyvinyl chloride (PVC)/PET film is bonded to the steel surface via a hot-pressing process, forming a composite material known as VCM sheet, which offers exceptional decorative properties.

Process

Substrate Preparation: Prepare cold-rolled steel coils or unpatterned galvanized steel coils with a smooth surface.

Lamination: Apply PVC/PET/ACM/PETG film pre-printed with patterns (wood grain, stone texture, brushed finish, pearlescent, etc.) and coated with adhesive. Through heating and pressure, the film is firmly bonded to the color-coated substrate.

Embossing: Typically performed concurrently with lamination to create a three-dimensional texture.

Features

Exceptional Decorative Appeal: Capable of producing specialized patterns like wood grain, leather grain, and stone textures.

Superior Tactile Feel: Offers diverse textural options.

Excellent Physical Properties: Highly scratch-resistant, fingerprint-resistant, and stain-resistant.

Good Flexibility: Can be bent and processed.

High Cost: Complex manufacturing process for plastic films and high material costs.

Applications

Premium appliance panels: High-end refrigerator, air conditioner, and washing machine doors.

Interior trim panels: Elevator cabs, metal cabinets, door panels.

Luxury furniture: Office furniture, display cabinets.

Spray Coating Process

Spray coating primarily applies post-production finishes to formed metal components. Compressed air atomizes paint into a fine mist that adheres to steel surfaces.

Process

Process the substrate into its final shape.

Atomize and spray the coating onto the workpiece surface.

Cure in a baking oven.

Characteristics

High Flexibility: Suitable for complex shapes and large-volume workpieces.

Cost: Low equipment investment.

Thick Coating: Typically thicker than roller coating, offering stronger protection.

Easy Color Change: Ideal for small-batch customization.

Disadvantages:

Low efficiency, higher paint waste, and inferior surface uniformity compared to roll coating.

Applications

Large steel structures.

Complex-shaped metal components.

On-site repairs or refurbishments.

The above outlines the three primary processing techniques for Wanzhi Group‘s color-coated metal materials. Among these, PCM sheets are most commonly used, while VCM sheets serve as the preferred material for high-end applications. Please share your specific application requirements with us to obtain the most cost-effective solution!