Color-coated steel sheet encompasses both painted steel sheets and laminated steel sheets. Due to its outstanding weather resistance (UV resistance), corrosion resistance, color durability, mechanical strength, formability, fingerprint resistance, scratch resistance, and high decorative appeal, it is widely used in construction, home appliances, engineering projects, and other fields.

Color-coated Steel Sheet Product Classification

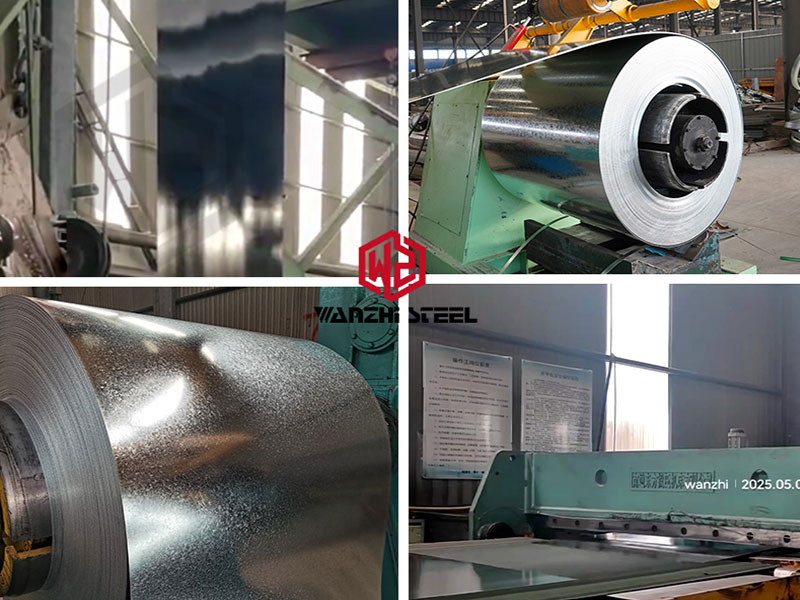

Color-coated steel sheet is a composite material manufactured by applying a coating or film to a substrate of cold-rolled steel, galvanized steel, or aluminum-zinc alloy steel after surface pretreatment (degreasing, chemical conversion treatment). Wanzhi Group offers a comprehensive range of color-coated sheet types and dimensions, with customization available based on application requirements.

Classification by Panel Type

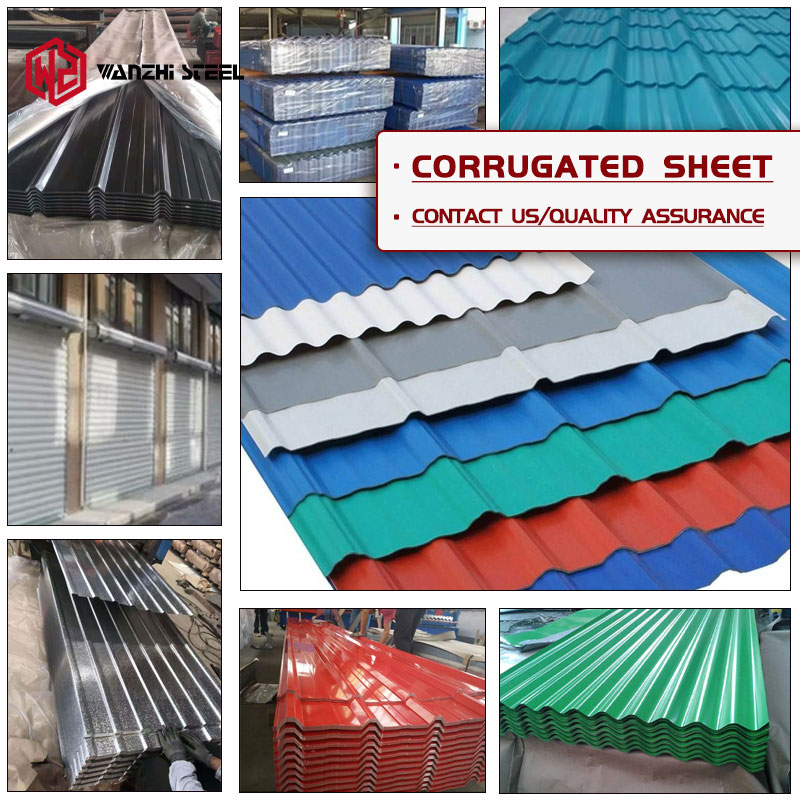

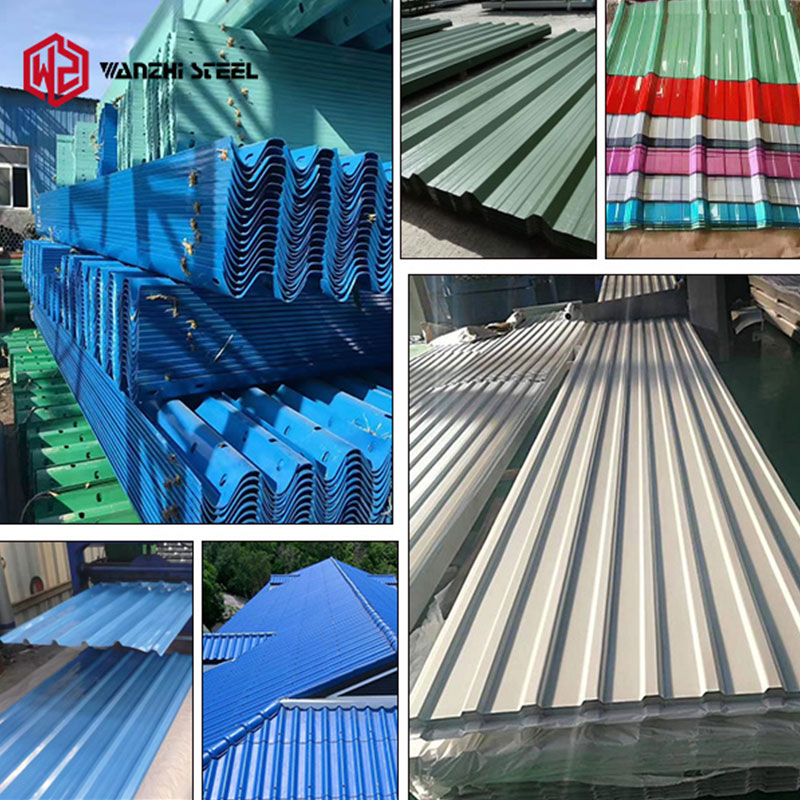

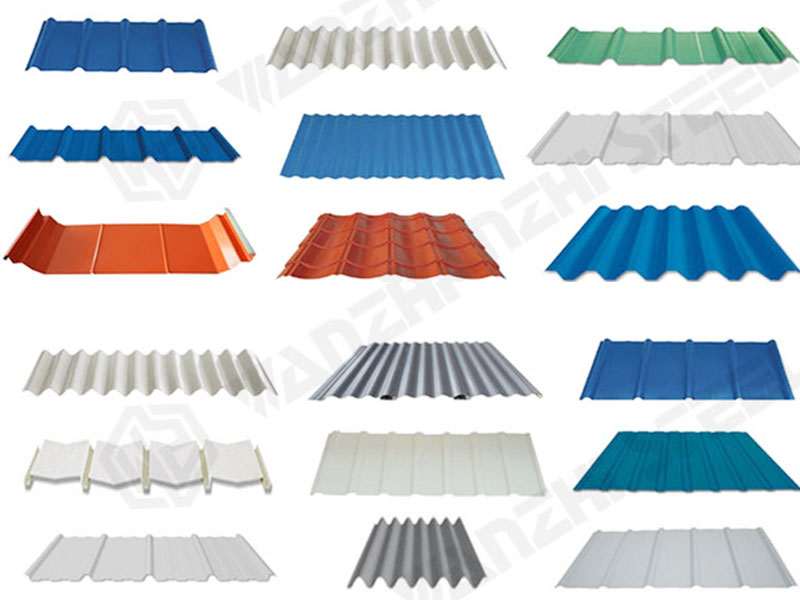

Profiled Sheets: Color-coated steel sheets are rolled into various corrugated profiles using forming machines, such as corrugated sheets, trapezoidal sheets, ribbed sheets, and floor decking.

Sandwich Panels: Consist of two outer layers of color-coated steel sheets with an insulating core material sandwiched between them, e.g., polyurethane sandwich panels, rock wool sandwich panels.

Classified by Base Material

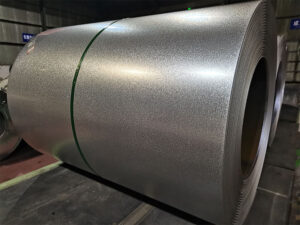

Color-coated Galvanized Steel: Uses 99% pure zinc-coated steel (GI steel) as the base material.

Color-coated Aluminum-Zinc Steel: Uses steel coated with an alloy of 55% aluminum, 43.4% zinc, and 1.6% silicon (GL steel) as the base material.

Color-coated aluminum-magnesium-manganese sheet: Features an aluminum-magnesium-manganese alloy substrate.

By Manufacturing Process

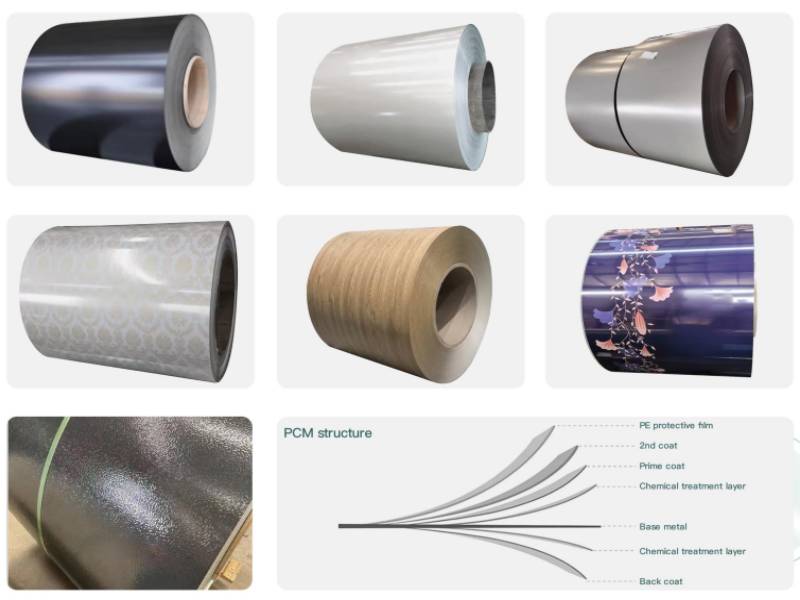

Painted Steel Sheets: The most popular type of color-coated steel, produced by uniformly applying polyester (PE)/silicon-modified polyester (SMP)/high-durability polyester (HDP)/polyvinylidene fluoride (PVDF) coatings to the substrate surface via roll coating.

Laminated sheet: A process where printed plastic film (PVC, PET, PETG, etc.) is bonded to the substrate using an appropriate adhesive.

Color-coated Steel Sheet Applications

Color-coated steel sheets are high-performance materials that integrate protection and decoration. Combining the superior physical properties, mechanical strength, and decorative qualities of steel and coatings, they have become indispensable metal materials in our daily lives and industrial production.

Construction Sector

Color-coated steel sheets for construction must exhibit excellent color retention, corrosion resistance, heat resistance, and mechanical strength. Roofing and exterior walls in high-temperature, high-humidity regions demand exceptional weather resistance (UV resistance) and superior durability.

Finished Forms:

- Profiled Sheets: Color-coated corrugated sheets, color-coated ribbed sheets, color-coated trapezoidal sheets, etc., primarily used as roofing panels, wall panels, and floor decking for industrial plants and commercial buildings.

- Sandwich Panels: Polyurethane (PU) sandwich panels, polystyrene (EPS) sandwich panels, rock wool sandwich panels, glass wool sandwich panels, aluminum honeycomb sandwich panels, etc. Primarily used in cold storage facilities, exterior walls of high-rise buildings, container houses, and similar applications.

- Other: Building accessories including downspouts, gutters, ductwork, door panels, etc.

Home Appliance Sector

Colored coated steel sheets for home appliances demand high standards in appearance (surface quality), functionality, and manufacturing processes. Appliance panels require exceptional decorative appeal, heat resistance, fingerprint resistance, scratch resistance, strong corrosion resistance, and workability, while also meeting product personalization and fashion trends.

Finished Forms:

- Appliance Housings: VCM sheets (capable of simulating stainless steel, glass, wood grain, and other special finishes) for side panels and doors of refrigerators, washing machines, air conditioners, and microwaves.

- Internal Structural Components: Pre-painted steel coil for internal partitions, bases, and other appliance frameworks.

Engineering Project Applications

Engineering-grade color-coated steel demands high standards for fire resistance, structural strength, and decorative appeal. Additionally, engineering projects impose the most stringent requirements on material performance and safety standards. High-quality rock wool sandwich panels, aluminum-magnesium-manganese panels, and laminated panels are the most popular choices.

Finished Forms:

- Public Facilities: Color-coated corrugated sheets and sandwich panels for roofing and wall systems in airport terminals, stadiums, and convention centers.

- Transportation: Color-coated anti-slip panels and perforated panels for ship interiors, RV bodies, and train car interior/exterior finishes.

- Home Furnishings: Color-coated profiled panels and laminated panels for office partitions, security doors, and cabinet facings.

Premium Product Showcase

Color-coated steel sheets have permeated every facet of modern industry and daily life thanks to their vibrant colors, excellent corrosion resistance, ease of processing, and extended service life. Selecting the appropriate substrate, coating, and sheet type is key to maximizing their performance.