Color coated coil, or color-coated steel coil (PPGI/PPGL coil), is one of Wanzhi Group’s popular coated steel products. It offers corrosion resistance for approximately 10 to 30 years and can be used as roofing panels, appliance panels, exterior facades, signage, decorative materials, weather-resistant steel structural components, mechanical parts, and housings for construction and industrial production applications.

Color-Coated Coil Definition and Structure

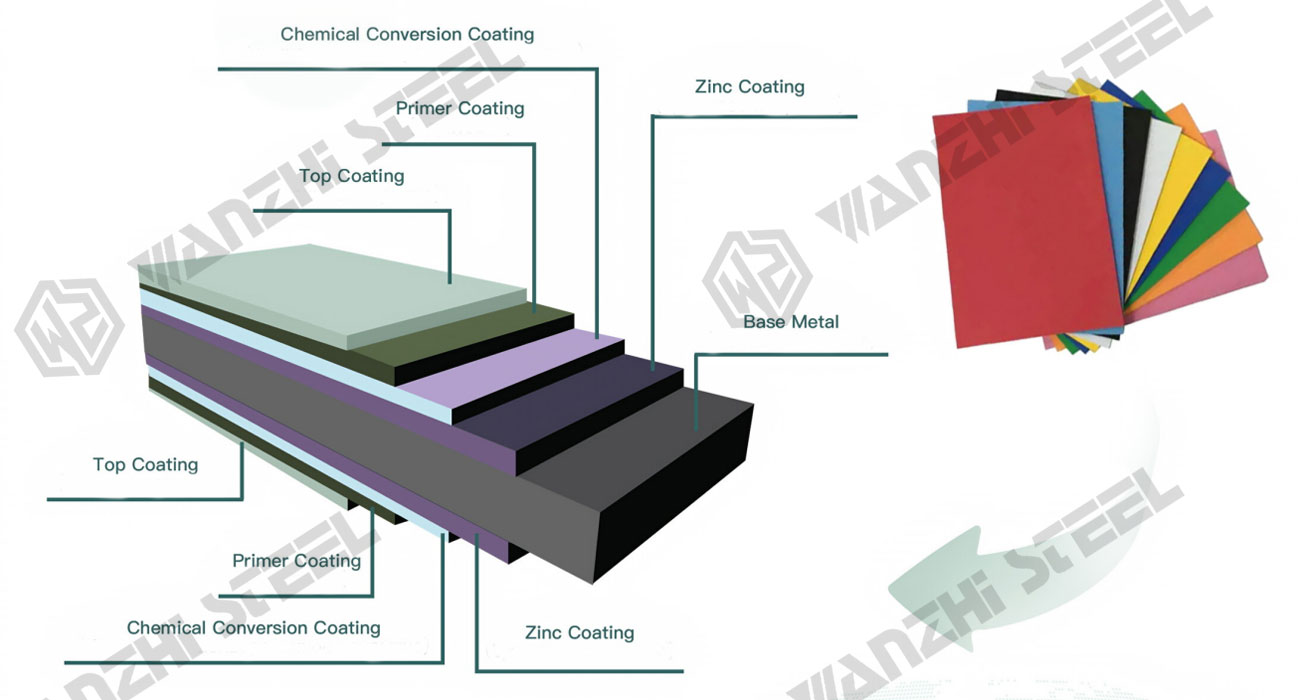

Wanzhi Group Color-Coated Coil is a pre-coated coil made from cold-rolled steel coil as the base material, undergoes pretreatment (cleaning, chemical conversion), coating (primer + topcoat + backcoat), and baking curing. Its names include Prepainted Galvanized/Galvalume Steel Coil (PPGI/PPGL) and Prepainted Steel Coil.

Structure:

- Base material: galvanized steel sheet (GI) or galvanized-aluminum steel sheet (GL), with a thickness typically ranging from 0.12 to 1.5 mm.

- Pre-treatment layer: chemical conversion coating to enhance coating adhesion.

- Primer: epoxy resin, polyester, or acrylic, with a thickness of 5–20 μm.

- Topcoat: Polyester (PE), silicone-modified polyester (SMP), fluorocarbon (PVDF), high-weatherability polyester (HDP), or plastic solvent (PVC), etc., with a thickness of 10–40 μm.

- Backcoat: Epoxy or polyester, protecting the back of the base material (backcoating can be selected according to application requirements).

Color-Coated Coil Classification and Material Selection

Color-coated coils are made of steel (cold-rolled, galvanized, or galvalume) and feature low cost and high strength. Depending on the coating, application, and surface finish, they can be categorized into various types. When selecting pre-coated steel, material selection should be based on environmental conditions, service life, application scenarios, and surface finish requirements.

Classification by Coating Type

- Polyester (PE) Coating: General-purpose, weather resistance of 5-10 years, low cost, suitable for indoor or low-corrosion environments.

- Silicone-modified Polyester (SMP) Coating: Weather resistance of 10-15 years, high cost-effectiveness, suitable for general buildings and appliances.

- Fluorocarbon (PVDF) coating: Weather resistance of 15-20 years, resistant to pollution and self-cleaning, suitable for high-end buildings and transportation.

- High-weatherability polyester (HDP) coating: Weather resistance of 10-15 years, UV-resistant, suitable for buildings and advertising.

Classification by Application

- Building-use color-coated coils: Roof panels, wall panels, etc., requiring corrosion resistance, weather resistance, and decorative properties, with a preference for PVDF or SMP coatings.

- Appliance-use color-coated coils: Appliance panels, etc., requiring scratch resistance, high-temperature resistance, and ease of cleaning, with a preference for polyester or high-gloss coatings.

- Transportation-use color-coated coils: automotive components, traffic signs, billboards, etc., requiring lightweight, UV resistance, resistance to rain corrosion, and vibration resistance, with a preference for PVDF coatings.

- Education-use color-coated coils: whiteboards, etc., requiring wear resistance, easy cleaning, and durability, with a preference for coatings such as polyurethane or fluorocarbon.

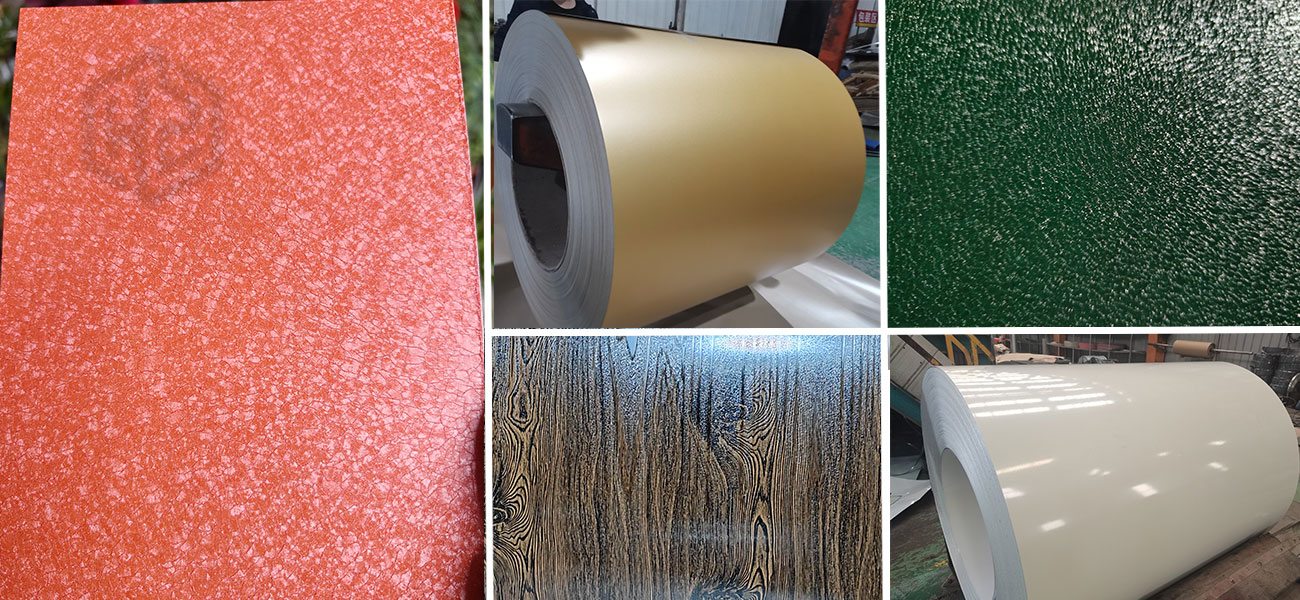

Classified by Surface Finish

- Smooth/Glossy

- Textured surfaces: Orange Peel, Woven Textured, Wood Grain, Metal/Leather Texture, Wrinkled, etc.

- Printed surfaces: Marble/Wood Grain/Flower/Grass/Brick/Sky/Bird/Stripe patterns, etc.

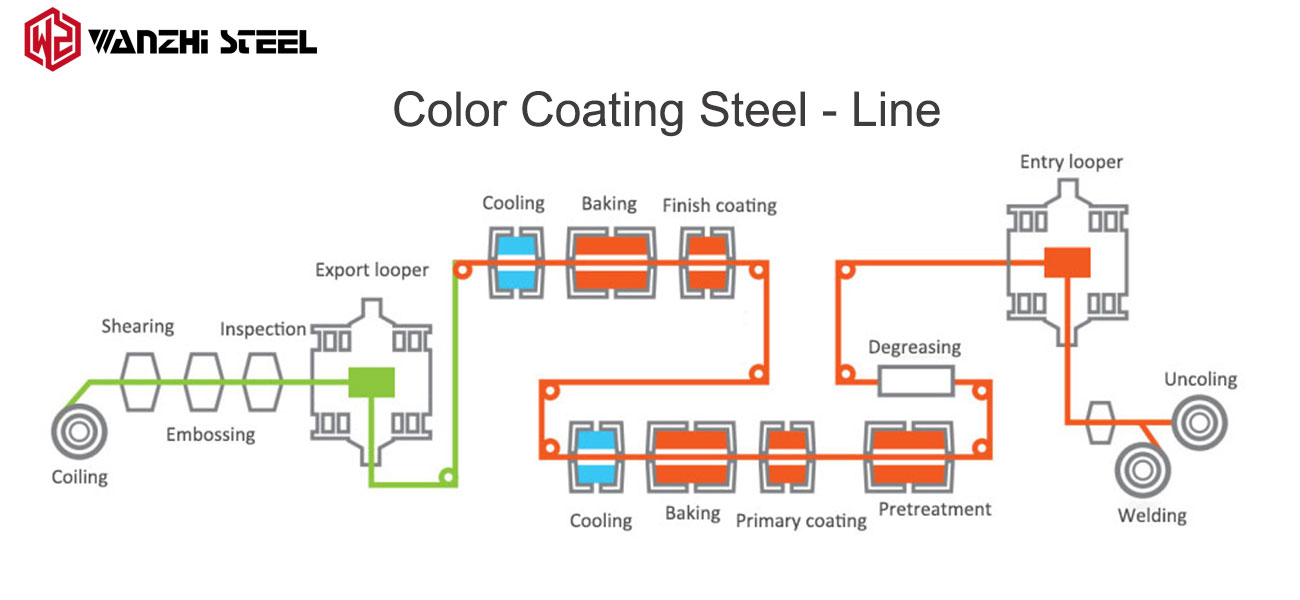

Color-Coated Coil Production Process

- Metal Substrate: Cold-rolled steel is used as the substrate, with a layer of pure zinc or zinc-aluminum alloy coating applied to the surface.

- Degreasing and Cleaning: Alkaline washing and water washing (spray + brush roll + electrolytic degreasing) are used to remove contaminants from the surface of the coated steel.

- Chemical Conversion: Passivation treatment forms a dense chemical conversion film on the surface of the steel.

- Primer Coating: Roll-coating with epoxy resin primer, followed by baking.

- Topcoat Application: Roll-coating with functional coatings.

- High-Temperature Curing: Heating to fully cure the resin in the topcoat, forming a protective layer.

- Cooling and Coiling: Rapid cooling of the cured coating via air cooling or water cooling, then coiling into finished coils for storage.

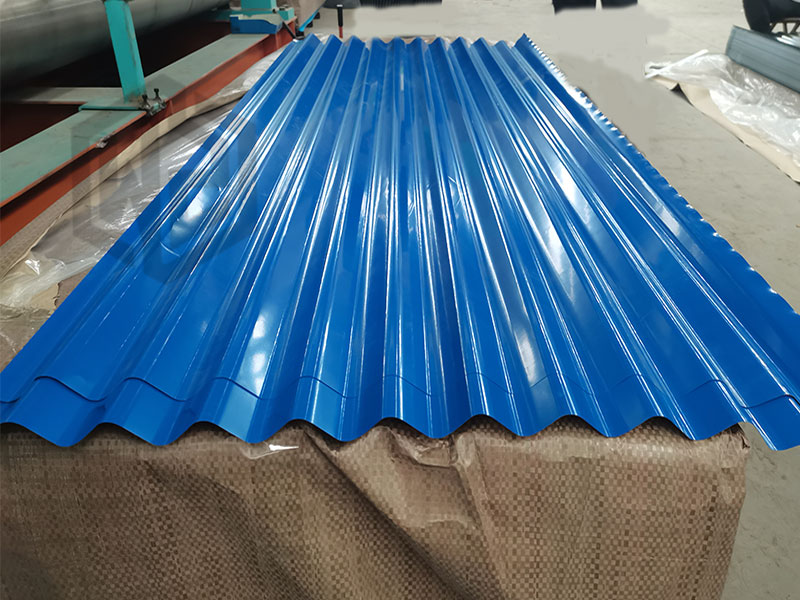

Color-Coated Coil Finished Product

Color-coated coils offer excellent processability and are easy to transport and store. They serve as raw materials for various color-coated finished materials. Wanzhi Group also provides value-added processing services for color-coated steel, including slitting, bending, forming, stamping, printing, and punching. Please contact us for a quote.

- Color-coated sheets: Directly slit after uncoiling, flatness ≤3mm/2m, color difference ΔE ≤1.0.

- Color-coated profiled sheets: Roll-formed (corrugated, trapezoidal, etc.), wave height 15-80mm, load-bearing capacity ≥1.5kN/m².

- Color-coated strip: Slitting and rewinding (without cutting), width tolerance ±0.5mm, inner diameter of the roll 508/610mm.

- Color-coated custom components: Laser cutting + bending, bending radius ≥4t (t is the plate thickness).

Color Coated Coil Performance Features

Color coated coil combines the advantages of metal-coated steel and colored functional coatings, offering excellent decorative properties, corrosion resistance, weather resistance, and processability.

- Rich colors and textures: Can simulate metal, stone, wood grain, orange peel, wrinkled effects, and can also be designed with various patterns such as flowers, plants, or fish to meet personalized needs.

- Gloss levels: High gloss (>80%), matte (<30%), glossy, or special effects.

- Synergistic protection of substrate and coating: Galvanized/aluminum-zinc-coated substrates provide basic corrosion protection, while the coating blocks water, oxygen, corrosive ions, and UV rays.

- Salt spray resistance: High-quality color-coated coils can withstand over 1,000 hours of salt spray testing.

- UV resistance: Fluorocarbon-coated PPGI/PPGL offers the best UV resistance, maintaining color and preventing chalking for over 20 years.

- High-temperature and low-temperature resistance: The coating remains intact without cracking or peeling in environments ranging from -40°C to 150°C.

- Formability: Can be stamped, bent, rolled, and slit to accommodate complex designs.

- Weldability: Color-coated steel coils are weldable (rust-proof paint must be applied to the welded areas).

Color Coated Coil Application Scenarios

Color coated coils are resistant to chemical corrosion, cost-effective, easy to process, and wear-resistant, making them a popular choice for steel solutions in the construction, home appliance, industrial, and transportation sectors.

- Roofs and walls: Galvanized color-coated steel coils (such as PPGL PPGL) are commonly used metal materials in commercial buildings, factories, warehouses, and villas.

- Decorative panels: Fluorocarbon color-coated steel coils are used for curtain walls, canopies, ceilings, and partition walls in high-end buildings.

- Outer shells and liners: Refrigerators, washing machines, and air conditioners (polyester coating).

- Control panels: High-gloss or metallic finish coatings.

- Equipment housings: Machine tools and instruments (epoxy coating).

- Warehouse facilities: Shelving and pallet outer panels (standard polyester coating).

- Containers: Pre-coated color-coated steel coils are used for the outer panels of dry cargo containers and refrigerated containers.

- Vehicle interiors: Interior panels for buses and trains (matte coating).

- Whiteboards: Schools, offices, etc.

- Cleanrooms: Hospitals, sterile/dust-free food processing facilities, etc.

Color Coated Coil Customization

If you are looking for a Color Coated Coil manufacturer to produce high-quality PPGI and PPGL steel coils for your project, Wanzhi Group is your ideal partner. First, we have our own factory, capable of producing metal-coated steel, color-coated processing, and even slitting and forming machines, ensuring product quality from raw materials to finished products. Secondly, we have been engaged in steel export business since 2011, with products exported overseas, and we have extensive export experience. Finally, we offer OEM/ODM services and can provide tailored solutions based on application requirements.

Wanzhi Steel Color Coated Factory

We have 7 production lines with an annual capacity of 600,000 tons. Delivery times for both stock and custom specifications range from 5 to 45 working days.

Our Projects and Certifications

We are certified under ISO 9001, ISO 14001, and ISO 45001, and support quality inspections by third-party institutions such as SGS and BV. To date, we have participated in projects including commercial hospitals, industrial warehouses, port construction, and roof panel processing.

Color coated coil can be customized with options for substrate material, zinc layer thickness, paint film, paint type, specifications, surface finish, surface structure, patterns, and more. Contact us for personalized customization and a free quote!