Wanzhi Group is an expert in customized colour coated sheet solutions, providing OEM/ODM services for raw materials and finished products for applications such as roofing, wall cladding, exterior walls, garage doors and structural components, automotive body panels, trim and interior parts, containers, piping systems and agricultural structures, billboards and decorative panels.

Colour Coated Sheet for Sale

Colour coated sheet consists of a three-layer composite: base metal, pre-treatment layer, and coating layer. Each layer performs key functions: Base Metal: provides strength (e.g., galvanized sheet, aluminum sheet, etc.). Pre-treatment Layer: A chemical conversion coating (e.g., phosphate) enhances adhesion and corrosion resistance between the base metal and coating layer. Coating: A functional organic coating (e.g., PE/SMP/PVDF) provides color and long-lasting protection. Wanzhi Group offers full customization: base metal selection → metal layer treatment → paint formulation → surface finish → sheet structure design.

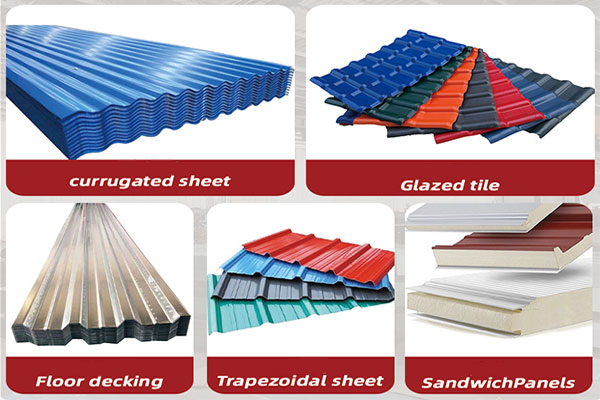

Classification by Sheet Type

- colour-coated plain sheets: Flat surface requirements (appliance panels, interior partitions)

- colour-coated profile sheets: Corrugated/ribbed/trapezoidal sheets (with peak structure for enhanced drainage and compressive strength)

Classification by Substrate Material

| Product | Abbreviation | Substrate | Features |

| Colour Coated Galvanized Sheet | PPGI | Galvanized Substrate | Economical rust prevention, suitable for general environments |

| Colour Coated Galvalume Sheet | PPGL | Galvalume Substrate | 2-6 times improved corrosion resistance (coastal/industrial areas) |

| Colour Coated Aluminum Sheet | PPAL | Aluminum Substrate | Lightweight + extremely high weather resistance (curtain walls/decorative) |

Classification by Coating

| Product | Coating | Durability | Cost | Applicable Scenarios |

| PE Coated Sheet | PE | General | Low | Temporary buildings/interior partitions |

| SMP Coated Sheet | SMP | Good | Medium | Residential roofs/walls |

| PVDF Coated Sheet | PVDF | Very Good | High | Landmark buildings/severe environments (20-year color retention) |

| HDP Coated Sheet | HDP | Very Good | Medium-High | Cost-effective alternative to PVDF |

| PU Coated Sheet | PU | Good | Medium-High | Cold chain warehouses (low temperature resistance, anti-condensation) |

Classification by Surface Effect

| Product | Effect | Features |

| Solid Color | Matte/ Pearlescent/ Glossy (Monochrome) | Diverse colors, gloss can be adjusted, customizable according to the application scenario |

| Texture | Wood Grain/ Brushed Metal/ Leather Embossed/ Metal Texture/ Orange Peel/ Grit Texture | Aesthetic, anti-slip, wear-resistant, scratch-resistant, real tactile feel |

| Printed | Brick Pattern/ Tile Pattern/ Marble/ Natural Scenery/ Flowers, Grass, Insects, Fish | Custom patterns, one-to-one reproduction of design drawings |

Classification by Application

| Product | Features | Application |

| Colour Coated Roofing Sheet | Wind pressure resistance, efficient drainage, thermal insulation, weather-resistant | Industrial factories, stadiums, residential roofs |

| Colour Coated Wall Sheet | Decorative texture, heat and sound insulation, quick installation | Commercial complexes, cold chain logistics centers |

| Colour Coated Home Appliance Panels | Food-grade safety, enhanced surface resistance, precision processing for adaptation | Appliance housings |

| Colour Coated Writing Board | Magnetic function, easy-to-wipe surface, fire safety | Smart classrooms in schools, corporate meeting rooms, medical consultation centers |

| Transportation Plates | Lightweight, vibration and fatigue resistance | Vehicle interior panels, car body |

Advantages of Color Coated Sheet

Colour coated sheet combines the mechanical properties of a metal substrate with the decorative and corrosion-resistant properties of an organic coating, offering both aesthetics and durability. It is a high-end material for applications in construction, home appliances, transportation, and other fields.

- Decorative Features: Color-coated steel can be customized with colors, simulated natural textures, and printed with various patterns to meet the visual needs of diverse residential, commercial, and industrial building applications.

- Corrosion Resistance: Available with dual protection options of galvanizing, galvanizing, or aluminum coating, it withstands salt spray tests of 1,000 to 3,000 hours, making it suitable for a variety of applications, including inland areas, dry outdoor environments, highly corrosive chemical zones, and coastal areas.

- Processability: It can be processed through a variety of processes, including stamping, bending, forming, welding, and cutting.

- Cost-Effectiveness: Highly cost-effective, the color coating not only enhances the steel’s aesthetics but also extends its service life, with a service life of 10 to 30 years.

- Wide Applications: It can be used in various applications, including exterior walls, roofs, interior decoration, home appliance panels, and transportation infrastructure.

Color Coated Sheet Processing and Installation

Color coated sheet is made from color coated steel coils through bending, profiling, and other processes. Wanzhi Group produces both prepainted steel and sheet metal processing services.

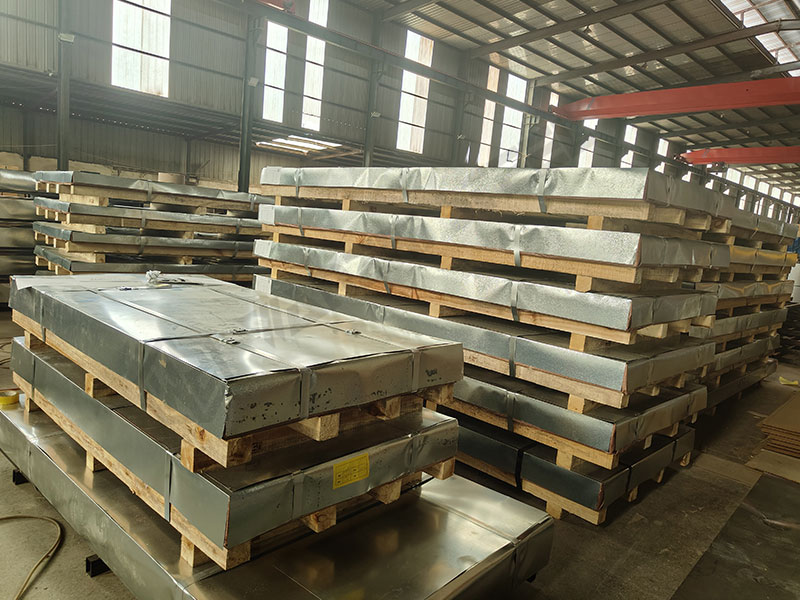

Raw Material Preparation

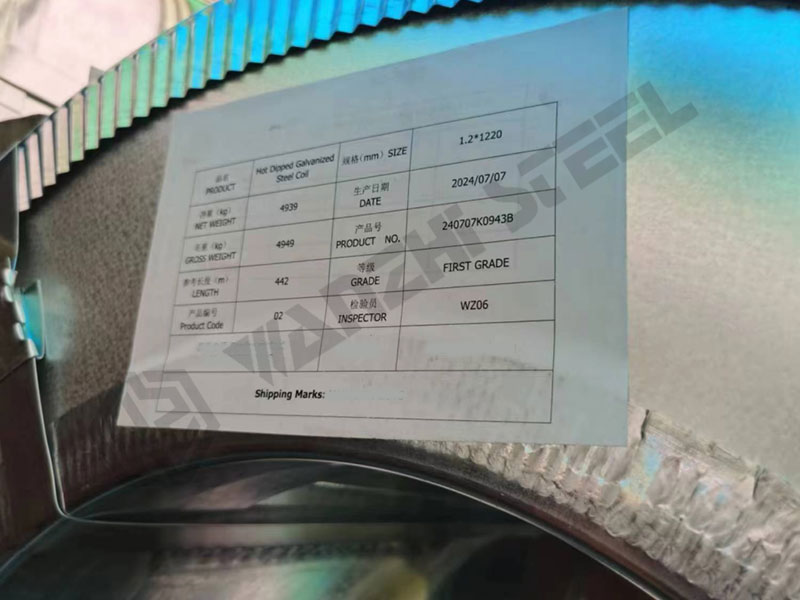

- Verify the coating thickness (≥ 20μm on both sides), the zinc coating weight on the substrate, and the presence of surface indentations/roller marks.

Cutting

- PPGI, PPGL, and PPAL coils are cut into the desired shape as required. Common processing methods include laser cutting, water jet cutting, and mechanical shearing.

Forming

- Color coated sheet is rolled into the desired shape through bending, roll forming, and hemming.

Connecting

- Common metal sheet joining methods include concealed locking, self-tapping screws, and structural adhesive bonding. The appropriate method can be selected based on the specific application requirements.

Acceptance

- Before delivery of color coated sheet, the sheet must be inspected for flatness, hemming, and coating adhesion.

Maintenance

- To extend the service life of the sheet materials, regularly clean the gutters, inspect the sheet joints, and clean the surface. If any scratches or dings are found, promptly repair them with paint.

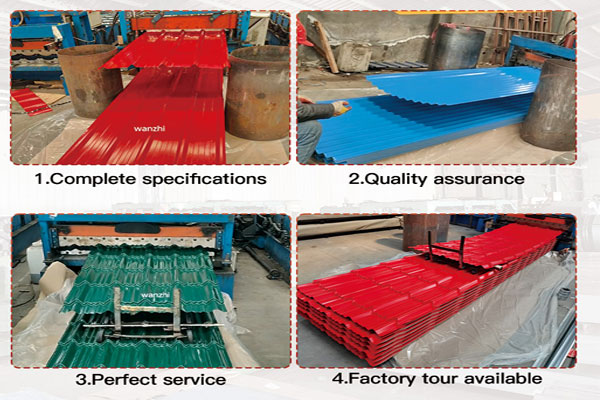

Wanzhi Group Customized Services

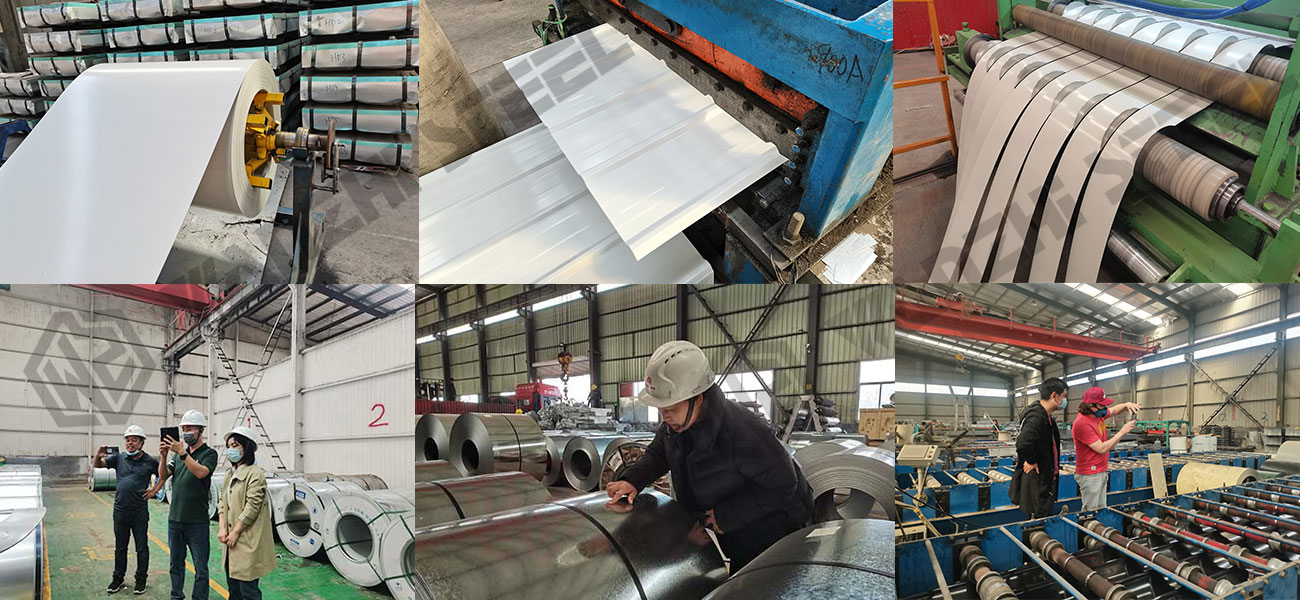

Wanzhi Group’s factory features production lines for baseboards (GI, GL, ZAM, PPGI, and PPGL steel), color-coated steel profiled sheet production lines, and sandwich panel production lines. We can provide color-coated sheet OEM or ODM services tailored to your project needs.

- Flexible substrate selection: Covering a full range of specifications from 0.12mm to 1.5mm.

- Coating application scenarios: Optimized formulas for acid rain, high-salt, and extreme cold environments.

- Quick prototyping: Physical samples are available within 3-5 business days (color matching supported).

- Delivery time: Production and delivery are completed within 5-45 business days.

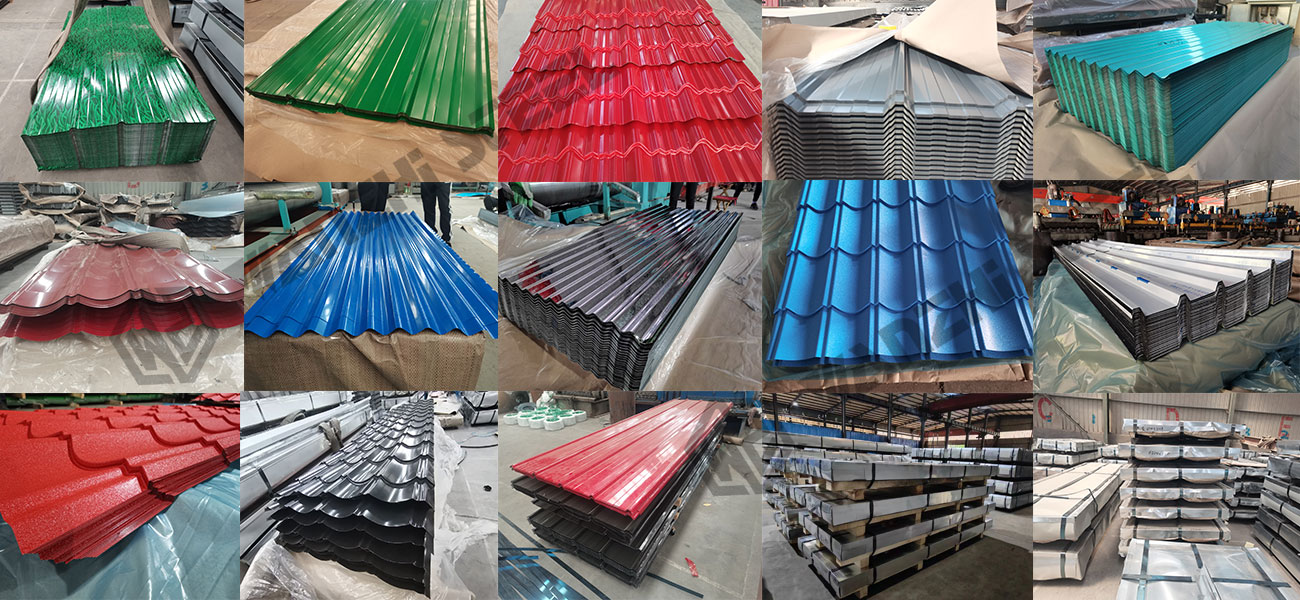

Wanzhi Color-Coated Sheet Project

To date, we not only provide PPGI and PPGL coil sheets as raw materials for roof and wall panels to customers in over 100 countries and regions worldwide, but also provide cost-effective color coating sheets, purlins, screws, and other accessories for commercial buildings, greenhouses, and other projects.

Wanzhi Steel – Agricultural Greenhouse Project in Turkmenistan

550 tons PPGI Steel Coil to Azerbaijan

100 tons of Galvanized Coils to Saudi Arabia

144 ton Steel Wire to Spanish

Project of PPGI Roofing en Libya

100 tons of GL and PPGL in Solomon Islands

Solutions to Common Problems

Q: How can I prevent scratches on the panels during transportation and installation?

A: The panels can be coated.

Q: Why does the seam of the color-coated roof panels leak?

A: The sealant is ineffective/not tightly bonded. Check the edge strength during inspection of the color-coated panels.

Q: How can I solve the problem of condensation accumulation?

A: Use thermally isolated purlin spacers or fill the gaps between the panels with polyurethane foam.

Q: How can I solve the problem of the coating becoming lighter or yellower, and the glossiness decreasing?

A: The coating is not resistant enough or the ambient UV rays are too strong. This can be solved with touch-up paint.

Q: Why does the coating on the color-coated panels peel, and how can I solve this problem?

A: Incomplete pre-treatment leads to poor coating adhesion. Improve the coating process during processing. If peeling occurs during use, spray the peeling area with the same color paint.

Wanzhi Group’s Color Coated Sheet is available in various sizes, including PPGI sheet, PPGL sheet, and PPAL sheet. Leave a message to tell us your needs and get a free quote!