Prepainted metals typically refer to products that have one or more layers of organic coatings pre-coated on a metal surface (including pre-painted galvanized, pre-painted aluminized, pre-painted aluminum, etc.). These coatings provide corrosion and oxidation resistance, high temperature resistance, UV resistance, and decorative features. And remain stable in coastal/high humidity, industrial polluted areas, and food/medical applications, and are a popular metal material for building curtain walls, industrial roofing, coastal facilities, and hospital operating room walls.

Common Substrate Types

| Base Material Type | Composition | Process | International Standards |

|---|---|---|---|

| Hot-Dip Galvanized Steel (GI) | Steel base material with a zinc coating on the surface | The steel base is immersed in molten zinc to form a zinc-iron alloy layer with the steel surface. | ASTM A653, EN 10346 |

| Electrogalvanized Steel (EG) | Cold-rolled steel, surface electroplated with a layer of zinc | Zinc is electroplated onto the cold-rolled steel surface through an electrolytic process. | ASTM A879, JIS G3313 |

| Aluzinc Steel (AZ) | Steel base material, surface coated with a 55% Al-43.4% Zn-1.6% Si alloy layer | The aluminum-zinc alloy coating is applied to the steel surface via a hot-dip process. | ASTM A792, JIS G3321 |

| Cold-Rolled Coil (CRC) | Regular carbon steel (SPCC/DC01) | Hot-rolled sheet is heated to a certain temperature and then pressed into shape by rollers. | ASTM A1008, JIS G3141 |

| Stainless Steel (SUS) | Mainly composed of iron, chromium, nickel, etc., with at least 10.5% chromium | Produced through melting, casting, and cold working processes. | ASTM A240, JIS G4305 |

| Zinc-Aluminum-Magnesium Steel (ZAM) | Steel base material, surface coated with an alloy of zinc, aluminum, and magnesium (Zn-6%Al-3%Mg) | The zinc-aluminum-magnesium alloy coating is applied to the steel base material through a hot-dip process. | EN 10346, JIS G3323 |

| Aluminum Alloy (Al) | Mainly composed of aluminum with small amounts of other elements (such as silicon, copper, manganese, etc.), 5052/6061 aluminum alloy base material | Manufactured through casting or extrusion processes. | ASTM B209, EN 485 |

Characterization

| Product | Features | Performance |

|---|---|---|

| Hot-dip Galvanized Steel (GI) | Excellent corrosion resistance, low cost | – Salt spray resistance: 500~3000 hours

– Tensile strength: 270-450 MPa – Density: 7.85 (g/cm³) |

| Electrogalvanized Steel (EG) | Thinner zinc coating, smooth surface, moderate corrosion resistance, suitable for precision coating | – Salt spray resistance: 100~500 hours

– Tensile strength: 270-500 MPa – Density: 7.85 (g/cm³) |

| Aluzinc Steel (AZ) | Better corrosion resistance than galvanized, high-temperature resistance | – Salt spray resistance: 1500~6000 hours

– Tensile strength: 350-550 MPa – Density: 7.0-7.5 (g/cm³) |

| Cold-rolled Steel (CR) | Smooth surface, precise dimensions, high formability, suitable for deep drawing, lowest cost | – Tensile strength: 270~500 MPa

– Density: 7.85 (g/cm³) |

| Stainless Steel (SUS) | Excellent corrosion resistance and strength | – Tensile strength: 500~700 MPa

– Density: 7.75-8.1 (g/cm³) |

| Zinc-Aluminum-Magnesium Steel (ZAM) | Provides better corrosion resistance, self-healing, scratch resistance | – Salt spray resistance: 3000~6000+ hours

– Tensile strength: 350~600 MPa – Density: 7.2-7.5 (g/cm³) |

| Aluminum Alloy (Al) | Lightweight, high strength, corrosion-resistant, oxidation-resistant | – Salt spray resistance: 500~1000 hours

– Tensile strength: 100~500 MPa – Density: 2.7 (g/cm³) |

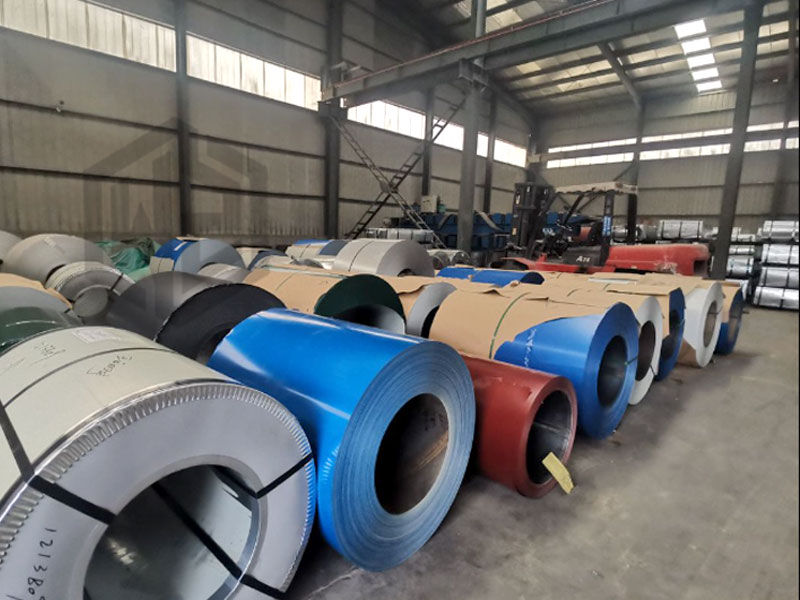

Typical Pre-Painted Metal Products

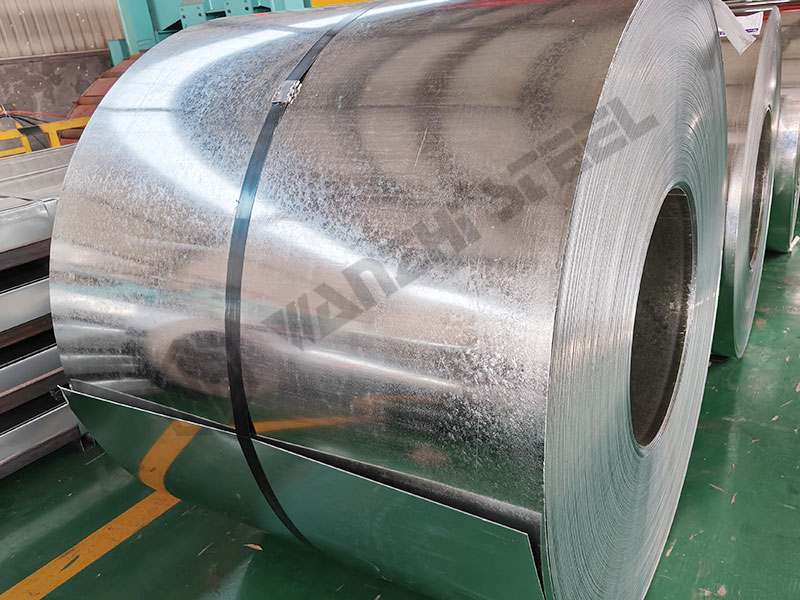

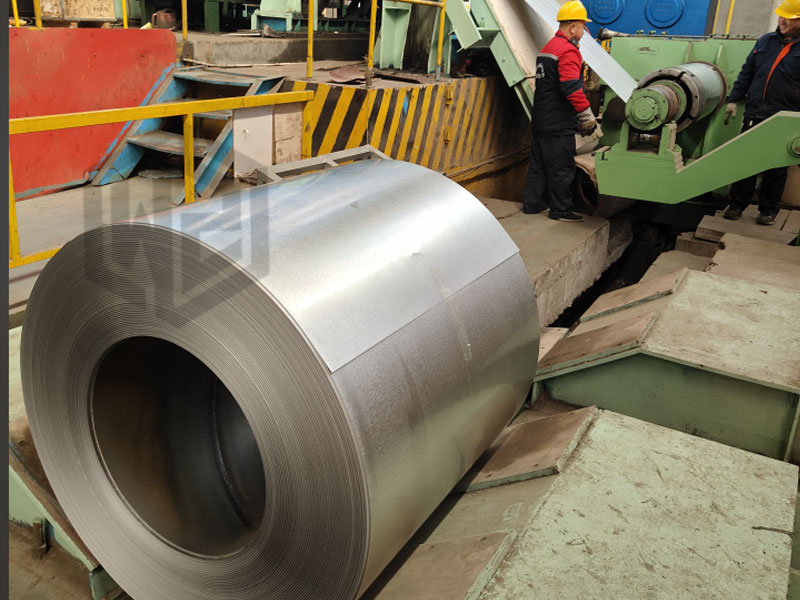

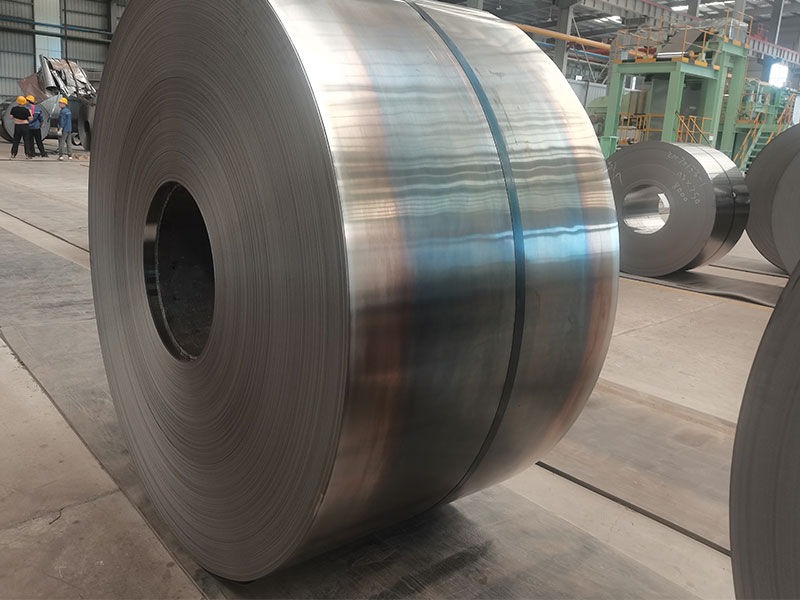

ZhengzhouWanzhi Steel Materials is a subsidiary of Wanzhi Gruop, specializing in the production of coated steel, with several galvanized and prepainted production lines, and certified to ISO9001, ISO14001, etc. We can customize premium prepainted metal to meet the application environment, mechanical requirements, project budgets, etc. in a cost-effective way. We can customize premium prepainted metal with economic benefits according to the application environment, mechanical requirements and project budget.

Hot Products

PPGI (pre-painted galvanized steel)

- Base material: hot dip galvanized steel

- Coating: PE/SMP/PVDF/HDP/PVC

- Application: color steel tiles, ventilation ducts, shelves.

PPGL (Pre-Painted Aluminum Zinc Steel Sheet)

- Substrate: Aluminum zinc plated steel (AZ100-AZ200)

- Coating: PVDF/HDP

- Applications: high temperature equipment housings, coastal building roofs.

PPAL (Color Coated Aluminum Sheet )

- Substrate: 5052/6061 aluminum alloy

- Coating: PE/PVDF + anodized

- Application: curtain wall, signage, aviation interiors.

Fireproof Pre-painted Panels

- Substrate: Galvanized steel or stainless steel

- Coating: fire retardant epoxy resin + mineral filler

- Application: fire doors, escape route decoration.

Self-cleaning Pre-painted Panels

- Substrate: Galvalume or ZAM

- Coating: PVDF + titanium dioxide nano-coating.

- Application: outdoor building facades, solar panel housings.

Application Examples

Architectural Facades

- Substrate: Galvanized steel (Z180 GI steel)

- Coating: PVDF fluorocarbon coating + brushed metal effect

- Advantage: Weather resistant for 20 years +, UV resistant

Roofs of Industrial Plants

- Substrate: Aluminum-zinc plated steel (AZ150)

- Coating: SMP coating

- Advantages: high temperature resistance, resistance to industrial exhaust gases

Photovoltaic Mounting Systems

- Base material: Zinc-aluminum-magnesium steel (ZAM100)

- Coating: Highly weather resistant (HDP) matte coating

- Advantages: 25 years maintenance-free, adapted to extreme desert/coastal environments, self-healing + self-cleaning.

Cold Chain Logistics Compartments

- Substrate: Aluminum-zinc plated steel (AZ150).

- Coating: Antimicrobial PE coating.

- Advantages: heat reflectivity, hygienic and safe, life expectancy of more than 10 years.

The choice of substrate for pre-painted steel has a direct impact on its corrosion resistance, strength, processability and cost. Selecting the substrate best suited to the project based on salt spray, humidity, chemical exposure levels, as well as tensile strength, ductility, and lightweighting needs creates greater economic value!