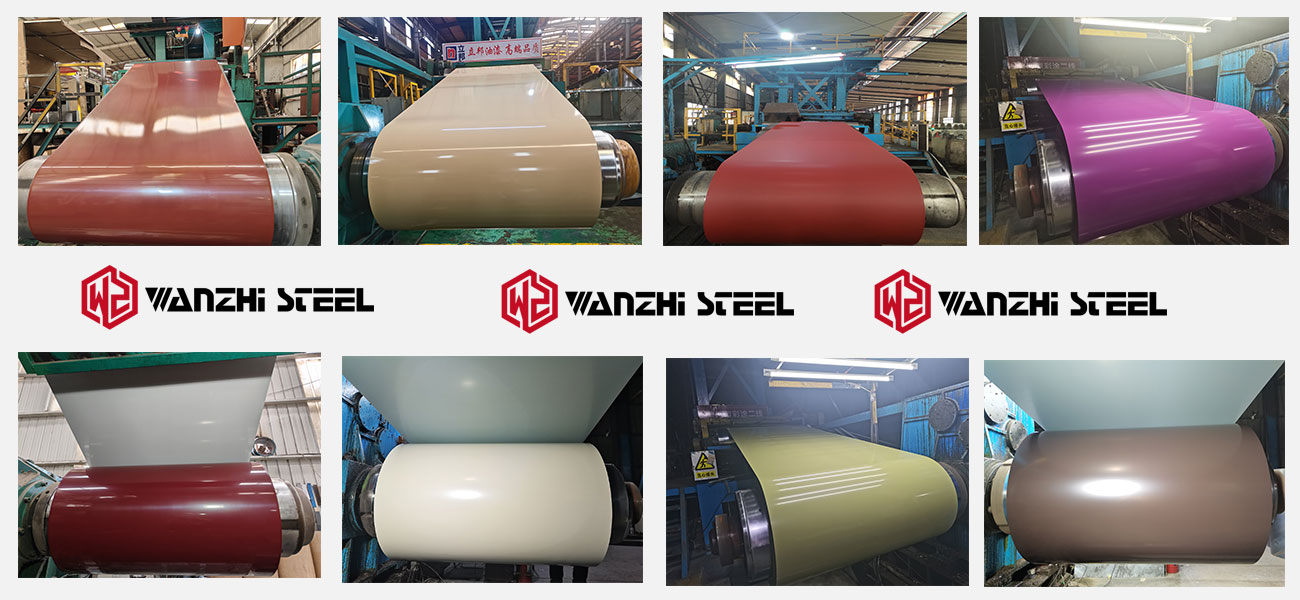

The flexibility of pre-painted metal (PPGI, PPGL, and PPAL) impacts product performance, lifespan, and end-use applications. The flexibility of color-coated aluminum alloys and color-coated steel is influenced by multiple factors, including the substrate and the surface coating system. Today, we will compare four mainstream coatings: PE (polyester), PVDF (polyvinylidene fluoride), HDP (high-weather-resistant polyester), and SMP (silicon-modified polyester), and explore the optimal coating solutions for different applications.

The Importance of Flexibility

Coating flexibility is a key indicator for evaluating the processing performance of color coated steel materials, directly determining their suitability for processes such as bending, stretching, stamping, and deep drawing. Good flexibility prevents the coating from cracking or peeling during deformation, thereby ensuring the finished product’s aesthetic quality and long-term durability.

In applications such as building curtain walls, metal roofing, and interior decoration, insufficient coating flexibility can easily lead to cracking during processing. This not only affects the visual appearance but also compromises the coating’s integrity, exposing the substrate, accelerating corrosion, and significantly shortening the overall structure’s service life.

The industry generally uses the T-Bend test to quantitatively assess coating flexibility. Results are expressed as T values (e.g., T0, T1, T2, T3). Lower T values indicate superior flexibility.

- T = 0: After the specimen is bent 180°, the two walls are completely in contact, achieving a zero-radius bend, the highest requirement.

- T = 1: The inner bend radius is equal to the material thickness (1 × T);

- T = 2: The inner bend radius is twice the material thickness (2 × T), with no damage to the coating.

- T = 3: The inner bend radius is three times the material thickness (3 × T), with no damage to the coating.

Four Major Coating Flexibility Factors

PE (Polyester Coating)

Polyester-coated metal materials are the best choice for parts requiring deep drawing and complex forming. Their molecular chain structure provides excellent elasticity and ductility, typically achieving T1-T2 bending levels with ease.

- Flexibility: Excellent

- Chemical Properties: Flexible molecular chains and good elasticity

- Advantages: Optimal formability and cost-effectiveness.

- Applications: Projects requiring processing and forming, such as appliance housings, air conditioning ducts, and metal furniture.

- Disadvantages: Average hardness and scratch resistance, making the surface more susceptible to scratching.

HDP (High Durability Polyester Coating)

HDP is an upgraded formulation of traditional PE, offering flexibility very close to PE. While maintaining excellent flexibility, it significantly improves durability through molecular optimization, typically achieving T2-T3 levels.

- Flexibility: Good

- Chemical Properties: Optimized polyester with balanced properties

- Advantages: The ultimate in balanced properties

- Applications: An ideal alternative to PE for outdoor applications such as residential roofing, exterior siding, and outdoor components requiring molding.

SMP (Silicon-Modified Polyester Coating)

SMP coatings incorporate silicone into the polyester resin, enhancing the coating’s hardness, heat resistance, and weather resistance at the expense of flexibility. Its flexibility is typically T3-T4, capable of withstanding only moderate bending.

- Flexibility: Good

- Chemical Properties: Silicone-incorporated, resulting in high hardness and rigidity

- Advantages: High hardness, excellent weather resistance, anti-powdering, and durability.

- Applications: Large-scale, simple-to-process outdoor structures, such as industrial plants and warehouse gates.

PVDF (Polyvinylidene Fluoride)

PVDF coating offers exceptional weather resistance, UV resistance, and self-cleaning properties, making it a standard feature of high-end buildings. It has the lowest flexibility of the four coating types, typically rated T4-T5.

- Flexibility: Average

- Chemical Properties: Fluorocarbon resin, extremely hard and inert

- Advantages: Extremely weather-resistant, longest lifespan

- Applications: Suitable for flat or slightly curved curtain walls, roofs, and other surfaces.

- Disadvantages: Unsuitable for parts requiring molding and prone to cracking at low temperatures.

Summarize

| Coating Type | Flexibility | T-Bend Value | Recommended Processing Methods |

| PE | ⭐⭐⭐⭐⭐ | T1-T2 | Deep drawing, stretching, complex bending |

| HDP | ⭐⭐⭐⭐☆ | T2-T3 | Bending, light forming |

| SMP | ⭐⭐⭐☆☆ | T3-T4 | Simple bending, rolling |

| PVDF | ⭐⭐☆☆☆ | T4-T5 | Avoid forming, mainly flat installation |

PE, PVDF, HDP, and SMP Coating Recommendations

Price comparison of different coating materials: PVDF > HDP > SMP > PE; Corrosion resistance comparison: PVDF > HDP > SMP > PE. However, in actual applications, cost is more important than price. Choosing a coating based on its characteristics can maximize the coating’s performance and save project costs.

- Designed for Processing: If your component requires complex forming, PE-coated painted steel or aluminum is the safest and most economical choice.

- Striving for Balance: If you require excellent formability and your product is intended for outdoor use, HDP coating offers an incredibly optimal balance.

- Sacrificing Durability: If your project features simple flat or curved designs without complex forming requirements, PVDF or SMP coatings are the best choices.

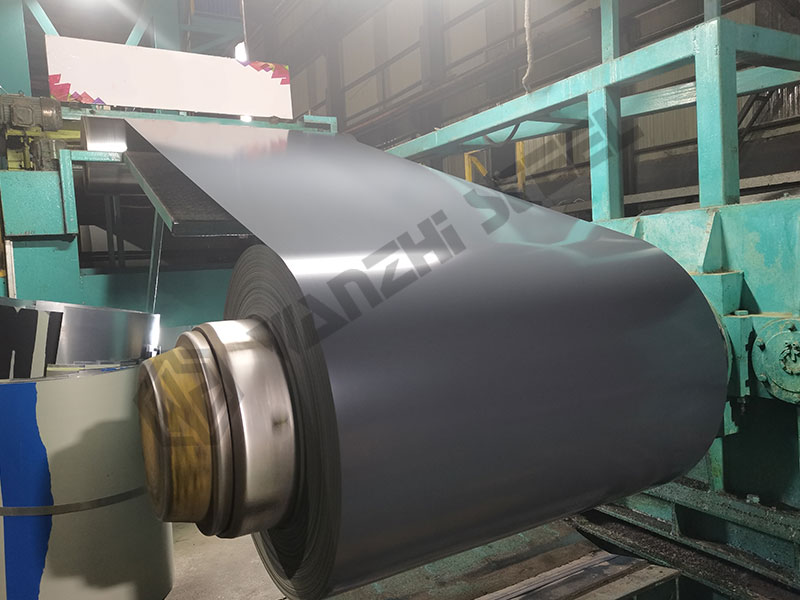

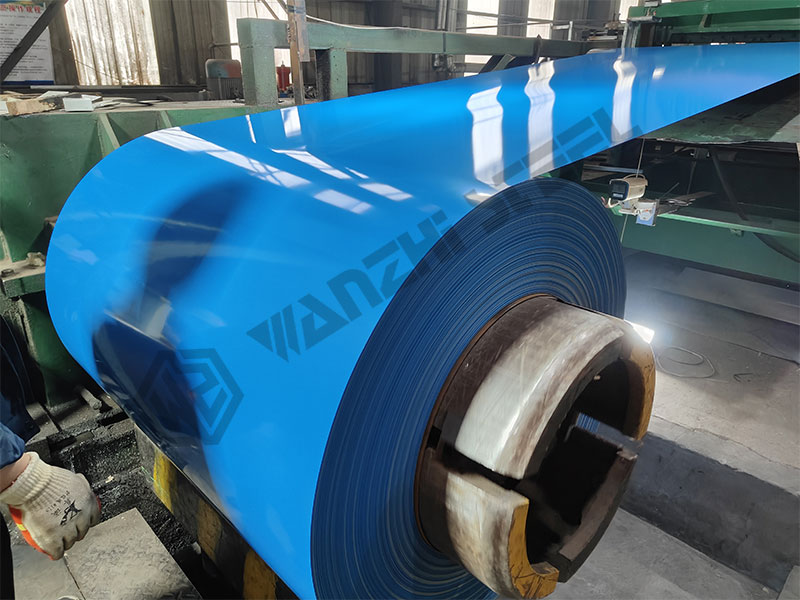

Wanzhi PE SMP PVDF HDP Coating PPGI

We hope this introduction to the differences in flexibility between different coatings will be helpful for your project. If you still have questions, please leave a message. Wanzhi Group will customize a solution based on material properties, coating structure and process, quantitative test data, environmental compatibility, and application scenario matching.