Wanzhi GroupWanzhi Group is a coated steel supplier, produces and sells a wide range of DX51D coated steel with different types of coatings, such as DX51D+Z (pure zinc), DX51D+ZF (zinc-iron alloy), DX51D+AZ (aluminum-zinc alloy), DX51D+ZN (zinc-nickel alloy), providing cost-effective coated steel solutions for the construction, industrial, automotive, home appliance, energy, transportation and other industries.

What are dx51d + Z / ZF/ AZ/ ZN?

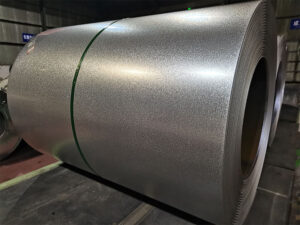

DX51D+Z (hot-dip galvanized)

Hot-dip zinc plating, zinc layer with 100% Zn, zinc pattern visible on the surface (regular spangle, large spangle, small spangle, etc.). Advantage: low cost, easy to process.

- Advantages: low cost, easy to process, suitable for a general environment.

- Applications: industrial plants, agricultural greenhouses, ventilation ducts.

DX51D+ZF (Zinc-iron alloy)

DX51D+ZF Zinc-iron alloy, coating with iron and zinc alloy (Γ phase, δ phase).

- Advantages: strong adhesion of the alloy layer, fingerprint resistant after passivation.

- Applications: automobile brackets, electronic cabinets, export plates.

DX51D+AZ (Aluminum-Zinc Alloy)

DX51D+AZ Aluminum-Zinc Alloy, coated with 55% Al, 43.4% Zn, 1.6% Si, corrosion resistance 2-6 times higher than that of pure zinc, silvery-grey fish scale effect on the surface, resistant to oxidation at high temperature.

- Advantages: extremely strong corrosion resistance, long life (25-50 years).

- Applications: coastal buildings, chemical plant roofs, solar racks.

DX51D+ZN (Zinc Aluminum Alloy)

DX51D+ZN Zinc-Nickel Alloy, nickel plated (10-15% Ni), excellent corrosion resistance, due to the extremely high cost and difficult processing, is commonly used in the military or marine, and other special projects.

- Advantage: Superior corrosion resistance, resistant to acid, alkali, and seawater erosion.

- Applications: nuclear power plants, deep-sea equipment, military facilities.

dx51d + Z / dx51d+ZF/ dx51d +AZ/ dx51d +ZN Chemical Composition

DX51D Substrate Chemical Composition

| Element | C | Mn | Si | P | S |

|---|---|---|---|---|---|

| Content | 0.08% | 0.50% | 0.10% | 0.020% | 0.015% |

Coating Chemistry

| Type of Coating | Composition (%) |

|---|---|

| Pure Zinc (Z) | Zn ≥99.9 |

| Zinc-Ferrous (ZF) | Zn 85-90, Fe 43.4, Si 1.6 |

| Zinc-Nickel (ZN) | Zn 85-90, Ni 10-15, Fe 10-15 |

| Aluminum-zinc alloy (AZ) | Al 55, Zn 43.4, Si 1.6 |

| Zinc-nickel alloy (ZN) | Zn 85-90, Ni 10-15 |

Comparison of the properties of dx51d + Z / dx51d ZF / dx51d AZ / dx51d ZN

| Indicator | DX51D+Z | DX51D+ZF | DX51D+AZ | DX51D+ZAM (Zn-Al, Zn-Al-Mg) | DX51D+ZN |

|---|---|---|---|---|---|

| Salt Mist Resistance (Hour) | 200-400 | 300-600 | 600-1500 | 1500-3000 | 3000-5000 |

| High Temperature Resistance (°C) | ≤120 | ≤120 | ≤150 | ≤150 | ≤200 |

| Hardness of Coating (HV) | 70-150 | 150-250 | 200-300 | 250-350 | 300-450 |

| Processing Ductility | Excellent | Good | Medium | Medium | Poor (high hardness) |

International Standard Comparison for Coated Steels

| Type of Coating | Chinese Standard | European Standard | American Standard | Special Approvals |

|---|---|---|---|---|

| Hot-Dip Pure Zinc (Z) | GB/T 2518 | EN 10346 | ASTM A653 | – |

| Aluminum-Zinc Alloy (AZ) | GB/T 14978 | EN 10346 | ASTM A792 | Galvalume® Patent |

| Zinc-Nickel Alloy (ZN) | None | None | MIL-DTL-23271C | Military Standard (e.g. NORSOK M501) |

More products

In addition to metal-coated steel, alloy-coated steel, Wanzhi Group also produces color-coated steel (PPGI, PPGL, PPAL, etc.) that meets international standards such as AST, JIS, GB, EN, etc. If you are selecting metal materials or suppliers for your project, leave your requirements and get a free quote!