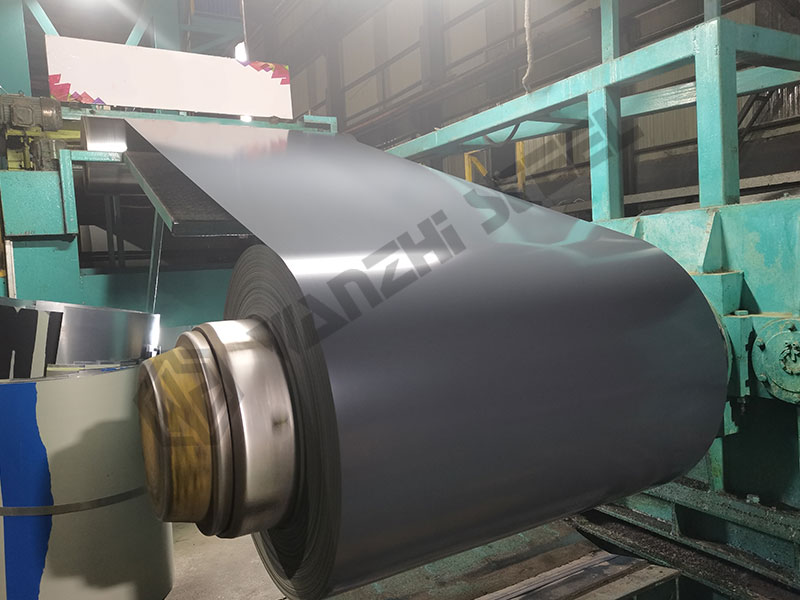

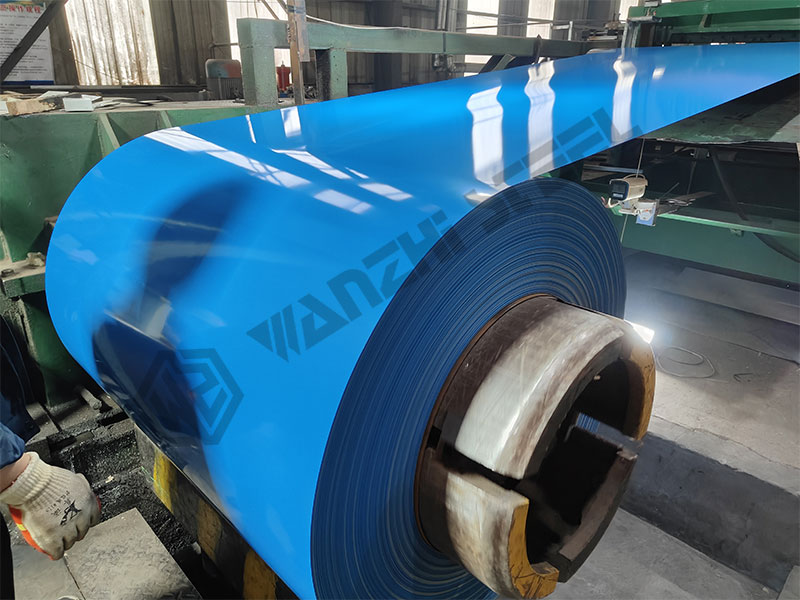

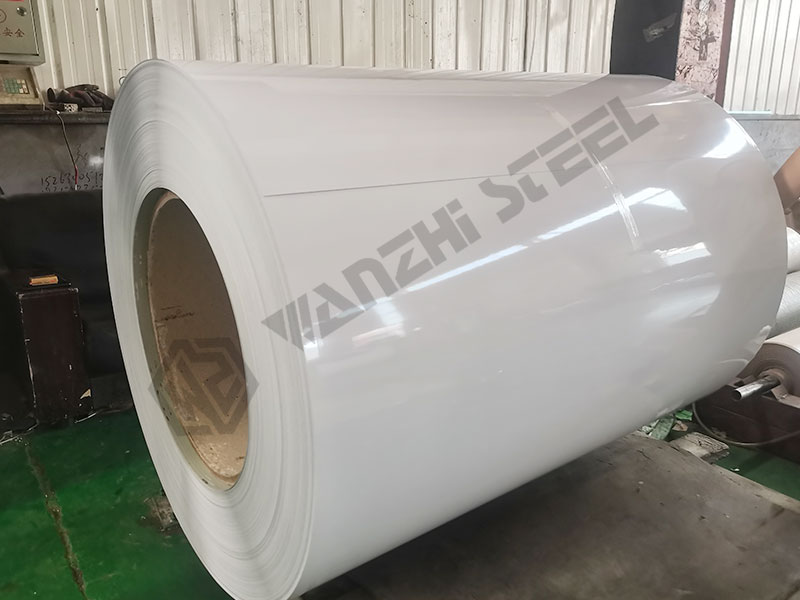

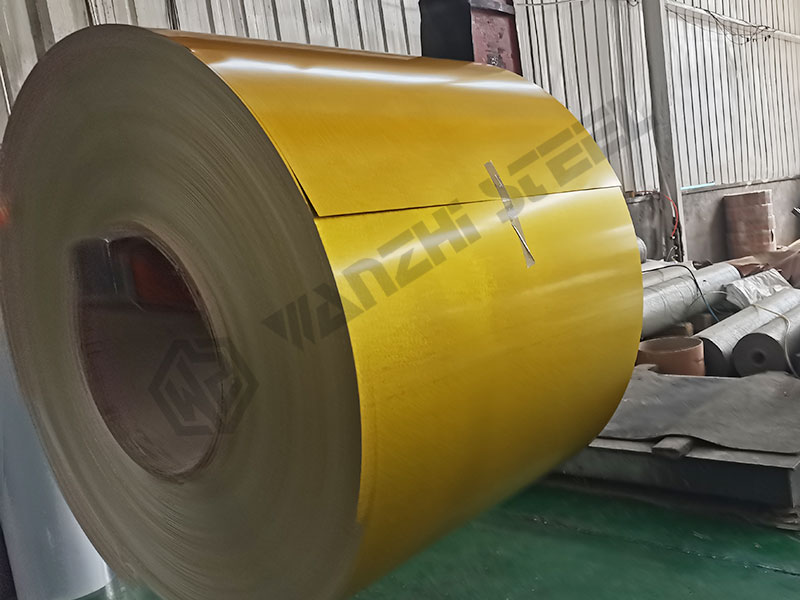

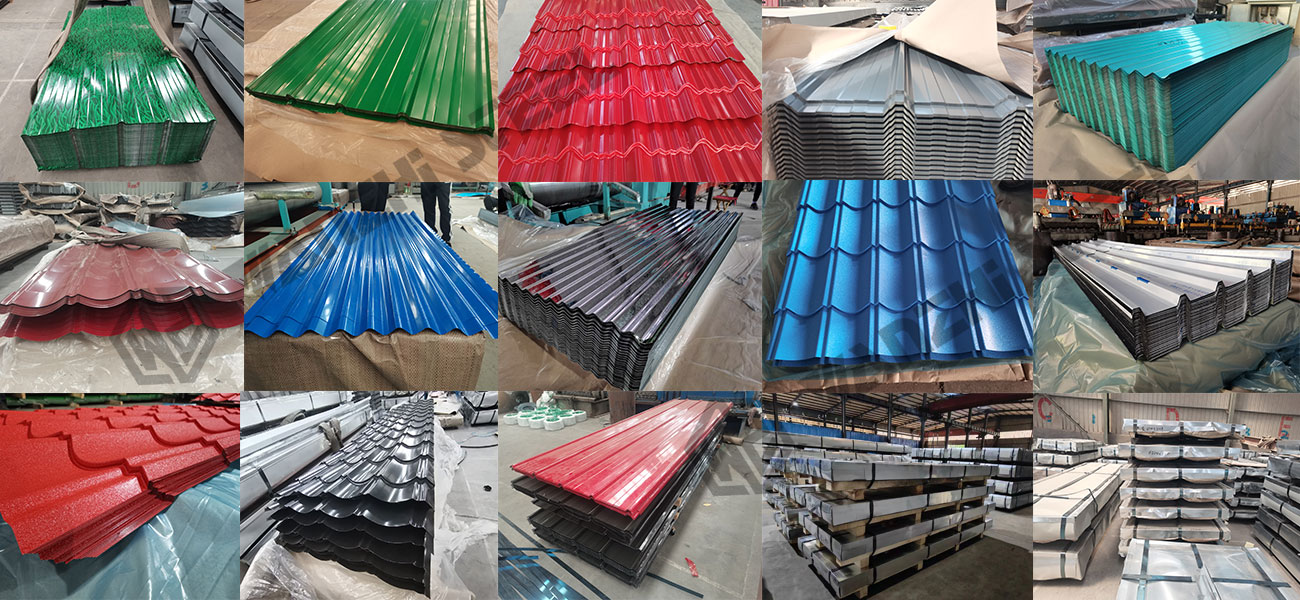

PPGI steel coil (Pre-Painted Galvanized Iron Coil) is a kind of Pre-Painted Galvanized Iron Coil, is a product formed after the coating process, with galvanized steel (GI) as the substrate, surface coating polyester/silicon modified polyester PVDF and other materials of the paint, through the curing of baking to make both corrosion resistance and aesthetic properties of the color coating. Steel coils are baked and cured to produce color-coated steel sheets that are both corrosion-resistant and aesthetic. In addition, PPGI coil can be used as raw material for roofing sheets, wall panels, office panels, clean panels, appliance panels, steel profiles, steel structures, etc.

How Much Does PPGI Steel Coil Cost Per Ton?

The market price of PPGI steel coil ranges from $500-$1000 per ton. The price of PPGI steel coil is affected by the application, cost of galvanized steel, price of coating material, size, thickness, color, finish, quantity purchased, and other factors. PPGI steel prices are lowest for general architectural and industrial applications, higher for high-end architectural and appliance applications, and customized PPGI steel with special specifications, colors, and properties. Discounts are available for bulk purchases, so leave us a message telling us what type of product you need and get a free quote!

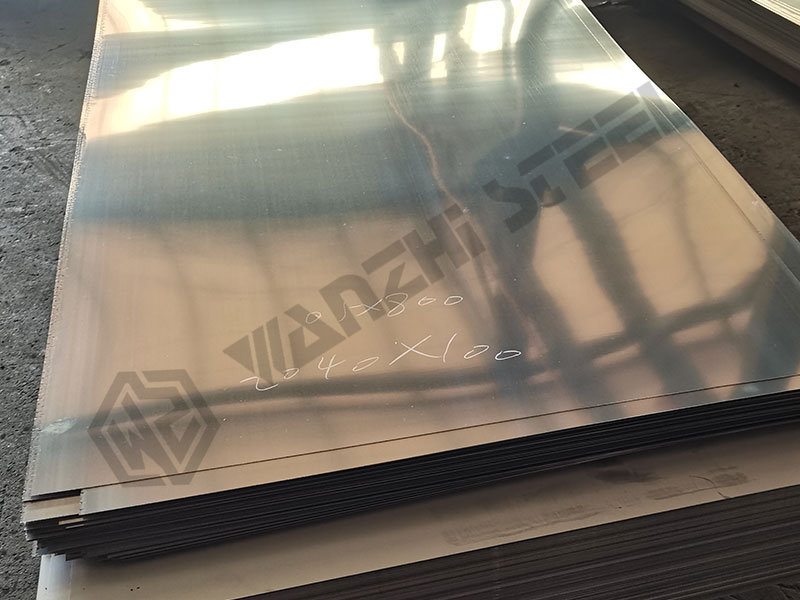

What are the Specifications of PPGI Steel Coils?

Wanzhi PPGI factory can produce both standard color-coated steel specifications and customized special specifications.

- Thickness: 0.12-1.5 mm

- Width: 600-1250mm

- Length: as per customer’s requirement

- Coil weight: 5 tons/customer specified

What Types of Coatings Are Available for PPGI Steel Coil?

The coatings on PPGI steel coils protect the substrate, increase the color diversity of the sheet, and improve the decorative, corrosion, and durability properties. The coating material can be selected according to the application scenario of the project.

Polyvinyl Chloride Plastisol (PVC): Tough, commonly used in outdoor environments.

Polyester (PET): good gloss and color stability, suitable for most applications.

Polyvinylidene Chloride (PVDF): Weather resistant, suitable for construction and decoration that requires long-term exposure to outdoor environments. Silicon Modified Polyester (SMP): abrasion resistance, good durability, suitable for applications requiring high durability.

Polyurethane (PU): Folding resistance. Good weathering and thermal insulation, suitable for applications requiring thermal insulation.

Highly Durable Polyester (HDP): Thermal insulation, excellent weather resistance, suitable for harsh environments and corrosive areas.

Where Can PPGI Steel Coil be Used?

PPGI steel coil, as a multi-functional, high-performance metal material, is widely used in construction, home appliances, transportation, industry, furniture, agriculture, and many other fields.

PPGI coil can be used for building roofs, walls, ceilings, partitions, outdoor canopies, awnings; refrigerators/washers/air conditioners/microwave ovens/dishwashers and other home appliances; automobile/ships decorative panels, door panels, compartments, roofs and so on; appliance cabinets, ventilation ducts, shelves; cupboards, bookcases; greenhouse greenhouses, fences; billboards, street signs; temporary housing; solar energy racks, etc.

What is the Corrosion Resistance of PPGI Steel Coil?

PPGI steel coil has excellent corrosion resistance, it has a double protective barrier of galvanized and color-coated to maintain long-term performance in different applications. Of course, you can also visualize the corrosion resistance of PPGI coil in different environments through tests such as salt spray test, acid salt spray test, damp heat test, and immersion test. (Up to now, Wanzhi Factory has complete testing equipment, welcome to visit our factory!)

How to Cut and Process PPGI Coil?

PPGI coil has very good mechanical properties, and it can be processed by bending, punching, punching, slitting, profiling, and so on.

Is PPGI Coil Environmentally Friendly?

PPGI coil is environmentally friendly. We use state-of-the-art manufacturing processes and equipment to reduce the generation of pollutants from the start of production. In addition, galvanizing and organic coating layers effectively isolate the coil from corrosive media, thus reducing the amount of waste generated by corrosion. If you need a third-party testing organization to certify the environmental performance of PPGI steel coils to meet your project’s environmental requirements or project standards, we can do that, too.

How to Choose Reliable PPGI Steel Coil Suppliers?

China is the largest producer of PPGI steel coils in the world, with a well-established industrial chain and advanced production technology. China PPGI steel suppliers can provide a wide range of PPGI products to meet the needs of various applications. Suppose you are planning to purchase prepared steel from China. In that case, you can select a reliable supplier by checking ISO9001 quality management system certification, CE certification, customer reviews, inventory and production capacity, etc. You can also request samples for testing and quality inspection.

What are the Quality Standards of PPGI Steel Coils?

The international standards for Pre-Painted Galvanized Iron Coil are ASTM A755/A755M, EN 10169, JIS G 3312, etc. The environmental protection standards for PPGI are RoHS Directive, REACH Regulation, etc. Other standards include coating performance, substrate performance, fire protection, and antimicrobial performance.

How Can the Service Life of PPGI Coils be Extended?

- Choose a high-quality galvanized or galvalume steel sheet as the substrate, and then select the appropriate coating according to the application environment.

- Avoid mechanical damage during installation and processing.

- Do not store in the open air and avoid prolonged exposure to humidity.

- Regularly clean the surface of PPGI steel and repair any scratches, damages, or corrosion on the surface.

What is the Difference Between PPGI and PPGL?

PPGI (pre-painted galvanized steel coil) and PPGL (pre-painted galvanized steel coil) are two common color-coated steel materials.

1. Material composition

PPGI: Galvanized steel, primer, top coat.

PPGL: Zinc-aluminum alloy steel and paint.

2. Properties

PPGI: excellent corrosion resistance, toughness, strength, rigidity, and impact resistance.

PPGL: excellent corrosion resistance, weathering, thermal stability, and tensile strength.

3. Application

PPGI: Gentle applications.

PPGL: High humidity, high salinity, high-temperature applications.

4. Costs

PPGI: The galvanized steel process is simple and the cost of PPGI is relatively low.

PPGL: Zinc-aluminum alloy layer is expensive to manufacture, PPGL cost is higher than PPGI.

Which is better, PPGI Steel Coil or Stainless Steel?

PPGI steel and stainless steel are two different types of metal materials, PPGI is a color-coated steel and stainless steel is an alloy steel, but both have excellent corrosion resistance, strength, and durability, especially in a few harsh environments to keep the performance stable, so they are popular solutions for many outdoor projects.

1. Material

PPGI steel: Coated steel consisting of galvanized steel coils, colorfully painted.

Stainless steel: Alloy steel made of chromium, nickel, and aluminum.

2. Properties

PPGI steel: corrosion-resistant, strong, available in a wide range of surface colors and styles.

Stainless steel: excellent corrosion resistance and durability, smooth surface, relatively monochromatic colors.

3. Application

PPGI steel: Construction, home appliances, automotive manufacturing, decorative applications.

Stainless steel: medical, food, chemical, aerospace, energy, and other applications requiring high strength and corrosion resistance.

4. Costs

PPGI steel: relatively low.

Stainless steel: Higher cost.

Can PPGI Steel Coil be Customized in Color?

Yes, it is possible. PPGI colors, patterns, and finishes can be customized according to the project.

PPGI colors: You can refer to the RAL color card, or mix the colors according to the sample.

PPGI patterns: Popular PPGI patterns include wood, brick, flower, grass, fish, tile, stripe, 3D, marble, and more. Customized patterns are also available based on samples.

PPGI Finish: Wanzhi PPGI steel Popular finishes include glossy, Matt, wrinkled, etc.

What is the Customization Process of PPGI Steel Coil?

- Leave a message to tell us your requirements, (zinc layer, color, paint film, thickness, width, weight, surface effect, etc.).

- Special specifications and special patterns need to provide samples or pictures.

- Provide you with cost-effective solutions according to your needs.

- Produce after sample confirmation.

- Support SGSM BV and other third-party testing organizations to come to Wanzhi Steel Factory for quality inspection.

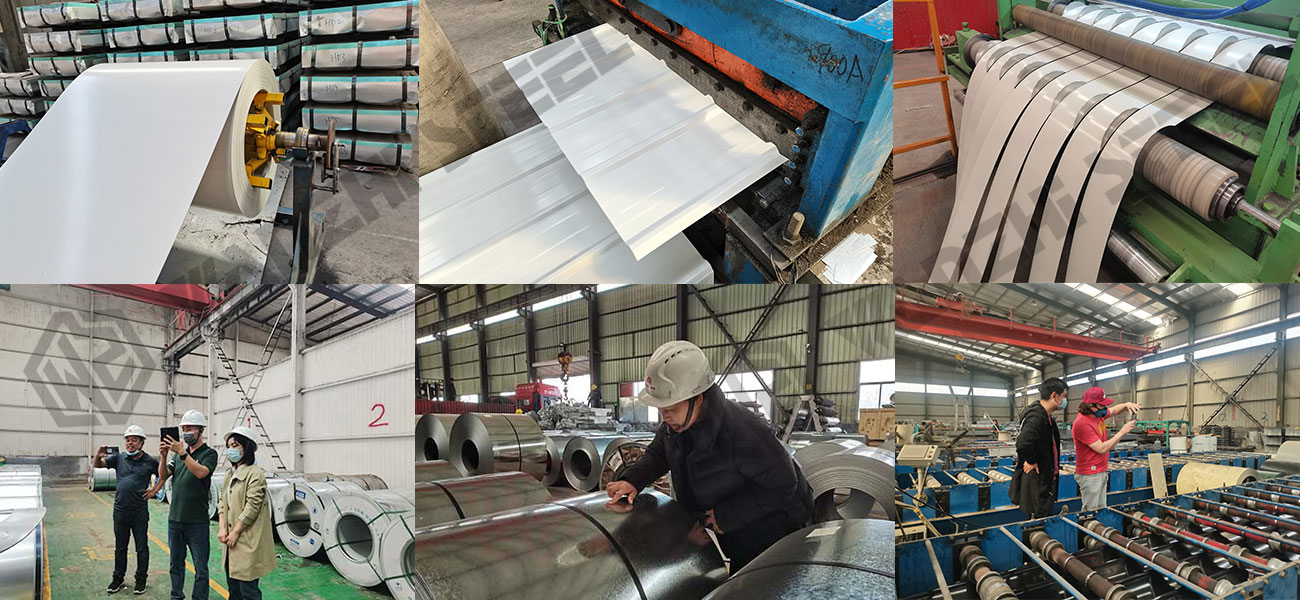

Wanzhi PPGI Supplier in China

Wanzhi Group is a steel supplier from China that can customize cost-effective solutions for construction, industrial, and manufacturing applications. Our prepainted steel factory-Wanzhi Steel Factory is located in Binzhou City, Shandong Province, China, with an annual production capacity of 600,000 tons, and a delivery time of 5–45 days, we can provide samples of various specifications of steel, welcome to contact us!