Material: cold rolled steel, hot rolled steel

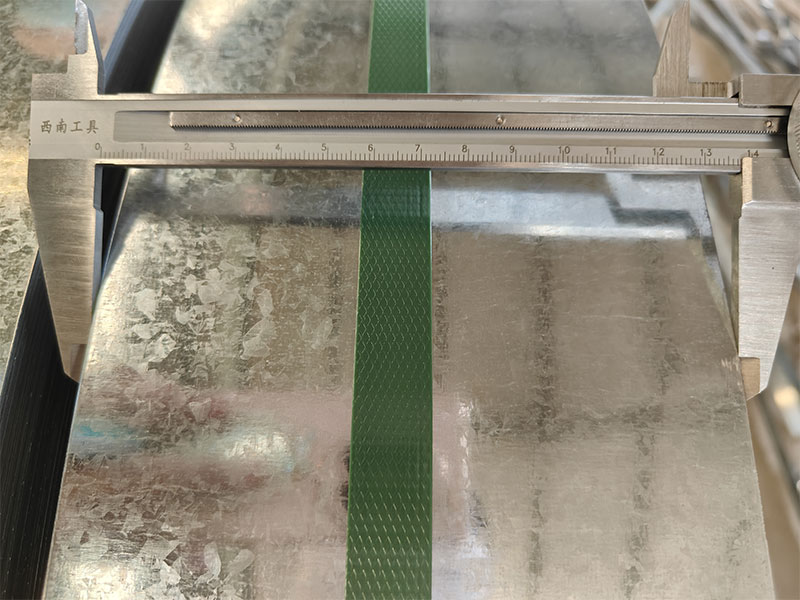

Width: less than 1300 mm

Category: Z/ZA/AZ/ZF

Delivery: 5–45 days

What is Galvanised Steel Strip?

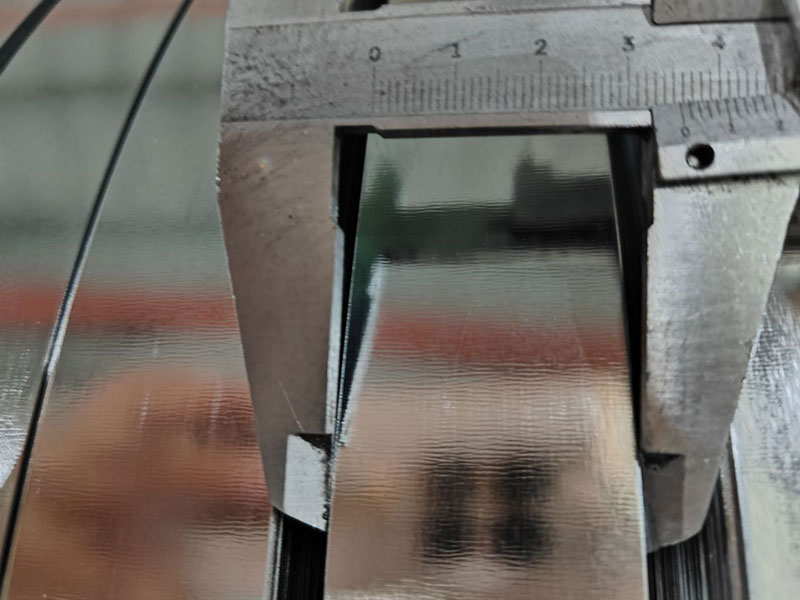

Galvanised steel strip is made from cold rolled or hot rolled steel sheets, which are hot dip galvanized or electro galvanised. Depending on the process, it can be divided into electro-galvanized and hot-dip galvanized strips. The thickness of the zinc layer can be adjusted according to the requirements, Wanzhi’s production line can produce galvanized steel with a zinc layer thickness of 30-350 g.

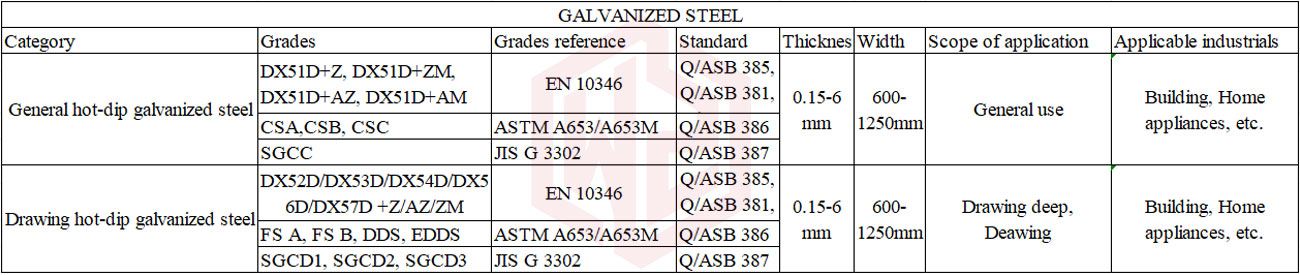

Specification

Surface

In addition to galvanizing, the surface of the strips can also be aluminized and sprayed with organic coatings, which improve the properties, service life, and range of application of the strips.

Why Use Galvanised Steel Strip?

Where to Buy Quality Galvanised Steel Strip?

The quality of galvanised steel strips can be carefully identified both at the factory and at the trading company. The quality of the product can be initially judged by the material grade, price, tolerances, quality of the zinc coating, the supplier’s qualifications, and the product certificates provided by the supplier. The authenticity of the product can then be judged by the testimonials and return orders from regular customers.

Galvanised Steel Strip Supplier

Wanzhi Group has its galvanising line, it is factory direct so we can provide customized service according to your application, and we have a reasonable production plan to control the cost, we can offer you a wholesale price. (Raw materials are in stock, so lead time is fast, 5–45 days depending on order quantity. )

Service of Wanzhi Group

As a factory and a trader with more than a decade of export experience, Wanzhi can offer galvanised steel strip services such as processing, quality inspection, customized packaging, tailor-made solutions, cost-effective pricing, prompt after-sales service, and more.

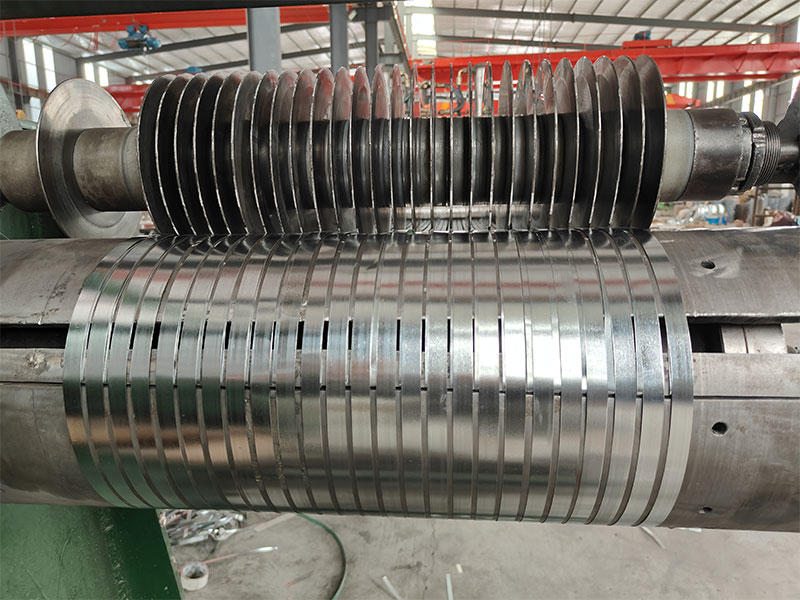

How is Galvanised Steel Strip Made?

If you are interested in the production of galvanised steel strips, you are welcome to visit Wanzhi’s factory.

- Raw material preparation: Welding several strip coils into long strips.

- Pre-treatment: The finished long strip is cleaned and degreased to remove surface impurities.

- Annealing: Annealing at a high temperature improves the physical and mechanical properties of the strip.

- Hot-dip galvanizing: The strip is galvanised by immersion in a hot zinc bath at 500 degrees Celsius.

- Post-treatment: Removal of excess zinc to improve the surface quality of the zinc layer.

- Leveling: Improvement of plate shape and dimensions.

- Cutting and packing: Cut and weighed according to requirements.

How to Improve the Rust Resistance of Galvanised Steel Strip?

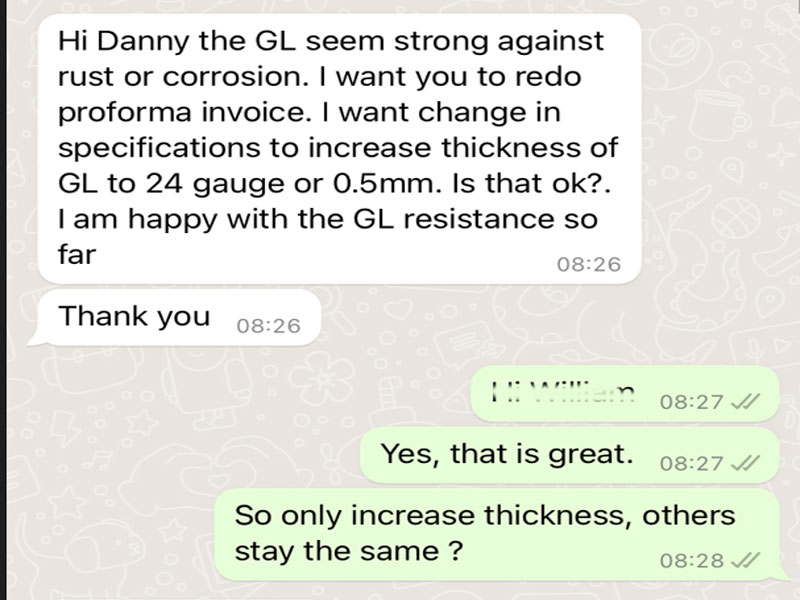

The corrosion resistance of galvanised steel strip varies in different environments, the thickness of the zinc layer is a key factor influencing the corrosion resistance, e.g. in heavy industry and in marine areas, z100, z140, z180, z275 have a service life of a few years to a few decades.

Effective methods to improve the corrosion resistance of galvanised products include passivation, pre-phosphating, oiling, and alloying. In addition, the application of corrosion-resistant coatings to galvanised steel can also be effective in extending its service life and other properties, such as weathering, heat resistance, and so on.

Uses of Galvanised Steel Strip

Maintenance and Care of Galvanised Steel Strip

Galvanised steel can rust over time, galvanised steel relies on a zinc layer to protect the steel from contact with other corrosive substances which can lead to rust, the thickness of the zinc layer determines its service life. The thickness of the zinc layer determines its service life. Therefore, attention should be paid to maintenance in the process of use.

- Regular cleaning, reduces dirt and dust.

- Prevent scratches to avoid damaging the zinc coating.

- If there are scratches, pits, rust, etc., repair and replace them in time.

If you are looking for good-priced, experienced galvanised steel strip suppliers, then Wanzhi Group will be your best partner!