Galvanized steel profiles, renowned for their exceptional corrosion resistance and high strength, have become essential materials in construction, industrial manufacturing, and other sectors. Today, Wanzhi Group will provide a detailed explanation of hot-rolled galvanized sections and galvanized profiles: How can they support your projects? What are their respective advantages and applications?

Comparison of Hot-Rolled Galvanized Sections and Cold-Formed Galvanized Profiles

| Characteristic | Hot-Rolled Galvanized Sections | Cold-Formed Galvanized Sections |

| Process | Hot-rolled into shape first, then galvanized as a whole | Cold-formed using galvanized steel sheets/coils |

| Thickness | Relatively thick, usually ≥ 3mm | Relatively thin, commonly ranging from 0.8mm to 3.0mm |

| Cross-Sectional Shape | Standard (I, channel, angle, H), with large R-angles | Highly flexible (C, Z, U, special shapes), with small R-angles |

| Strength Source | Material itself and section moment of inertia | Cold work hardening and cross-sectional shape design |

| Load-Bearing Capacity | Extremely high, suitable for main load-bearing components | High, suitable for secondary structures and enclosures |

| Weight | High unit weight | Lightweight |

| Economy | Relatively high material cost | Often lower overall cost |

| Size and Customization | Standard specifications, with fixed lengths usually | Length can be flexibly customized, and cross-sections can be deeply developed |

| Applicable Fields | Heavy-duty structures, key load-bearing parts | Lightweight structures, enclosure systems, efficient manufacturing |

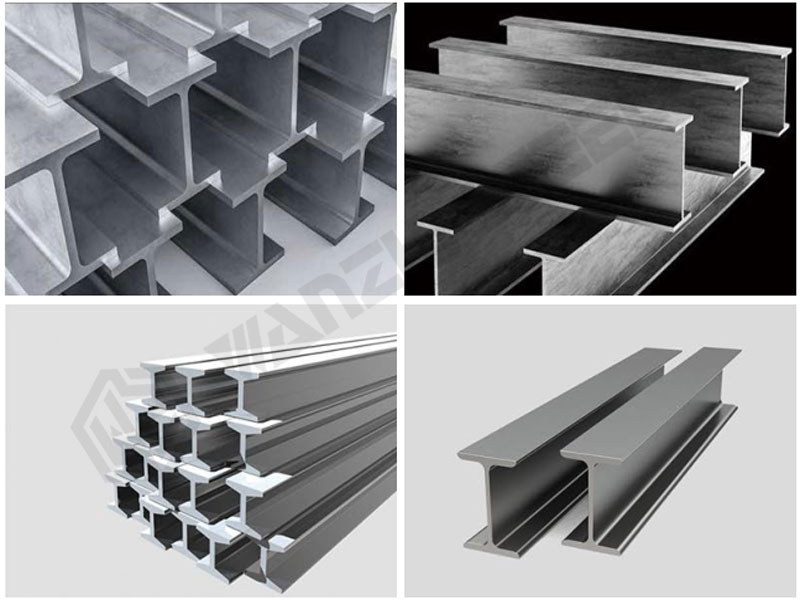

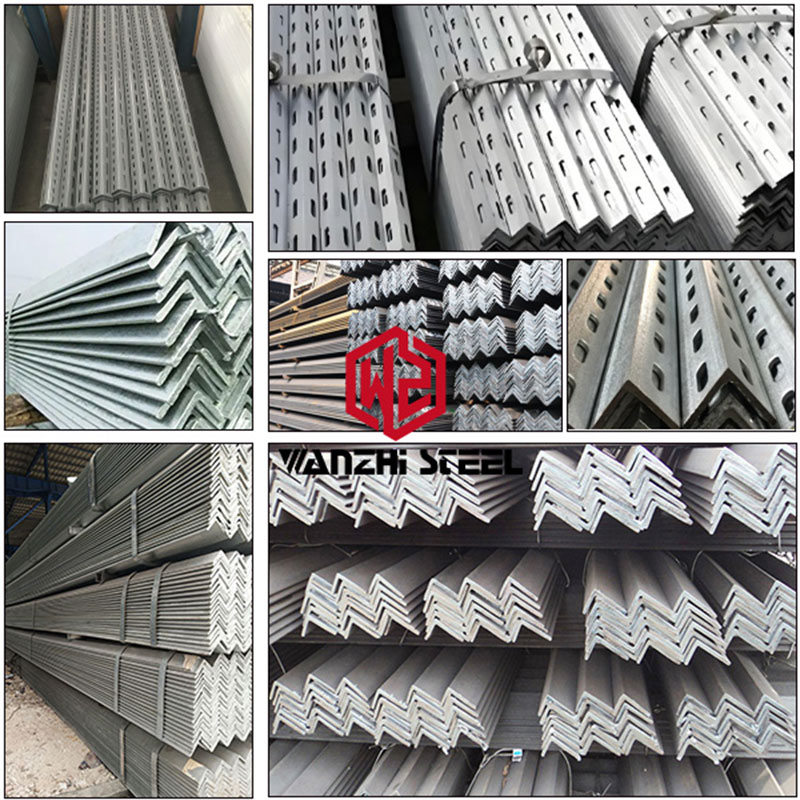

Hot-Rolled Galvanized Sections

Hot-rolled galvanized sections combine “hot-rolled profiles with galvanization,” making them the preferred material for heavy-duty, primary structural, and permanent applications.

Process

- Steel billets are directly rolled into specific cross-sectional shapes (such as classic I-beams and channel sections) at high temperatures (approximately 1200°C). After forming, the surfaces undergo hot-dip galvanizing to create a robust zinc-iron alloy protective layer.

Characteristics

- Material: Typically low-alloy high-strength steel with substantial thickness and dense structure.

- Strength: Yield strength and tensile strength determined by steel grade and hot-rolling process.

- Cross-section: Standardized shapes (compliant with GB, ASTM, etc.) with comprehensive dimensions. Larger radii optimize stress distribution.

- Galvanizing Effect: Formed before galvanizing allows zinc coating thickness up to 600g/m², uniformly covering complex cross-sections.

Advantages

- High strength

- Large load-bearing capacity

- Excellent stability

- Standardized specifications

- Comprehensive corrosion protection

Applications

- Primary load-bearing structures

- Heavy infrastructure

- Critical areas requiring extreme stability and safety factors.

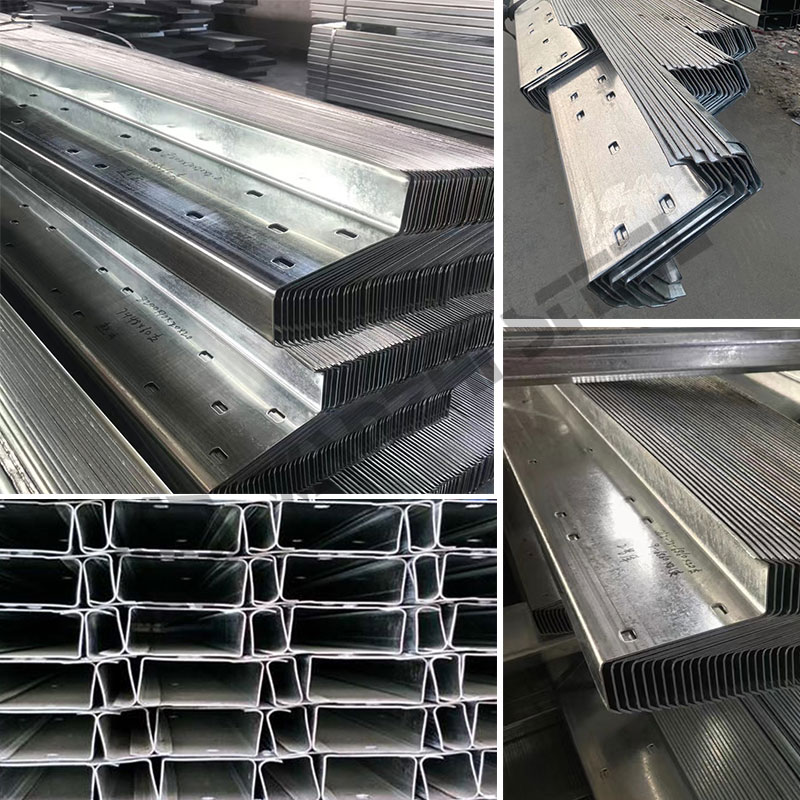

Cold-Formed Galvanized Profiles

Cold-formed galvanized profiles combine “galvanized coil/sheet + cold forming,” serving as a popular metal material for light loads, secondary structures, or decorative applications.

Process

- Steel sheets or strips undergo cold rolling and hot-dip galvanizing to produce galvanized coils or sheets. These are then formed through a series of precision rollers at room temperature.

Characteristics

- Material: Base material is galvanized steel sheet (e.g., SGCC, DX51D), featuring relatively thin and uniform thickness.

- Strength: Determined by material properties, processing techniques, and cross-sectional design.

- Cross-Section: Features complex, versatile shapes with small radii (R corners) for sharp, defined edges.

- Galvanization: Pre-galvanized substrate. Though zinc coating may undergo compression and stretching during forming, premium GI steel profiles maintain stable corrosion resistance.

Advantages

- Design flexibility

- High material utilization

- Lightweight

- Cost-effective

- High dimensional accuracy

- Customizable production lengths

Applications

- Lightweight steel structures

- Building envelope systems

- Warehouse shelving, supermarket shelving

- Automotive manufacturing, furniture, enclosures

- Non-load-bearing auxiliary structural components