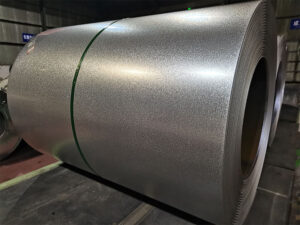

Wanzhi Group is a Chinese supplier of coated steel. Electrogalvanised steel is one of our most popular products. We provide steel solutions for various forming grades for different applications, such as commercial grade, deep drawing grade, ultra-deep drawing grade galvanised steel, etc. In addition to galvanised steel coils and sheets, we also provide special surface treatments such as fingerprint-resistant, passivated, phosphated, chromate-free, and UV-resistant coatings, as well as value-added services including bending, forming, stamping, and painting.

What is JIS G 3313 SECC、SECD、SECE?

SECC, SECD, and SECE are the grades of electro-galvanised steel sheets specified in JIS G3313. SECC is general-purpose galvanised steel, SECD is deep-drawing grade galvanised steel, and SECE is ultra-deep-drawing grade galvanised steel. These three grades of electro-galvanised steel sheets differ in carbon content, formability, application scenarios, and surface quality.

| Model | Formability Grade | Applicable Scenarios |

| SECC | Regular Formability | Simple stamping (e.g., appliance housings, enclosures) |

| SECD | Deep Draw (Draw Quality) | Complex stamping (e.g., automotive parts) |

| SECE | Extra Deep Draw | High-complexity stamping (e.g., pipe fittings) |

JIS G 3313 Electrogalvanised Steel Performance Comparison

The core difference between different types of electrogalvanised steel lies in their formability. SECC, SECD, and SECE electrogalvanised steel have similar mechanical properties, zinc coating uniformity, and surface quality.

Mechanical Performance

| Parameter | SECC | SECD | SECE |

| Tensile Strength (MPa) | 270–410 | 270–370 | 270–370 |

| Yield Strength (MPa) | ≥140 | ≥140 | ≥140 |

| Hardness (HRB) | 40–70 | 40–65 | 35–60 |

Formability

| Parameter | SECC | SECD | SECE |

| Plastic Strain Ratio (r value) | 0.8–1.2 | 1.0–1.6 | 1.4–2.2 |

| Strain Hardening Index (n value) | 0.16–0.20 | 0.18–0.22 | 0.20–0.25 |

| Elongation (%) | ≥28 (t ≤ 0.4mm) | ≥34 (t ≤ 0.4mm) | ≥38 (t ≤ 0.4mm) |

| Limiting Drawing Ratio (LDR) | 1.8–2.0 | 2.0–2.2 | 2.2–2.5 |

Uniformity of Zinc Layer

| Parameter | SECC | SECD | SECE |

| Coating Process | Electro-galvanizing (EG) | Electro-galvanizing (EG) | Electro-galvanizing + Grain Refinement |

| Coating Deviation | ±15% (JIS H 0401) | ±15% | ±10% |

| Coating Adhesion | Grade 3 (Cross-hatch method) | Grade 2 | Grade 1 (No peeling) |

| Salt Spray Test | 96h White rust | 120h White rust | 144h White rust |

Surface Quality

| Parameter | SECC | SECD | SECE |

| Surface Roughness Ra | 0.4–0.8 μm | 0.3–0.6 μm | 0.15–0.4 μm |

| Surface Treatment | Ordinary chromate | Fingerprint-resistant chromate treatment | Chromium-free environmentally-friendly passivation |

| Defect Control | Slight roller marks allowed | No roller marks/zinc particles | Zero defects (AA grade) |

| Coating Adhesion | 4B (Cross-hatch method) | 5B | 5B |

Application Comparison

JIS G 3313 SECC, SECD, and SECE galvanised steel are suitable for stamping processes ranging from simple bending to highly complex stamping. Applications cover multiple fields, including home appliances, automobiles, electronics, and construction.

SECC Galvanised Steel (Standard Grade)

- Home appliance field: Refrigerator, washing machine, and air conditioner shells, replacing plastic parts.

- Electronics industry: server enclosures and housings.

- Construction industry: construction scaffolding, interior ceilings, partitions.

SECD galvanised steel (deep-drawing grade)

- Automotive industry: door inner panels, fuel tank lids, seat frames, interior panels.

- Lighting industry: streetlight housings, advertising light boxes.

- Industrial industry: toolboxes, control cabinets, home appliance touch panels.

SECE Galvanised Steel (Ultra-Deep Drawing Grade)

- Automotive Industry: Engine hoods, fenders, chassis components.

- Home Appliance Industry: Microwave oven interiors, oven housings.

- Precision Industry: Electronic component housings, medical device components, battery casings, laptop computer housings.

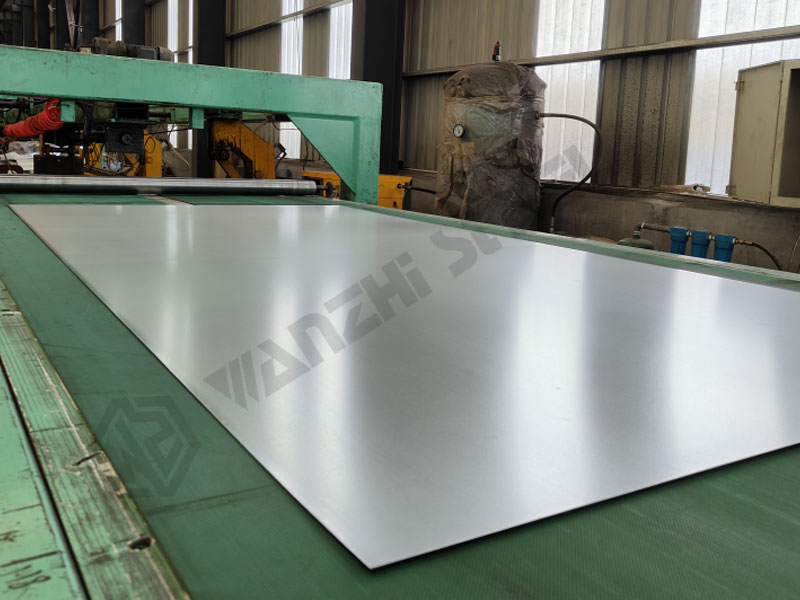

Galvanised Steel Manufacturing Plant

Wanzhi Group‘s factory has three galvanised steel production lines, providing electrogalvanised steel, hot-dip galvanised steel, aluminium-zinc-coated steel, and painted steel solutions for applications in construction, industry, automotive, energy, and other fields. Our factory is certified to ISO 9001, ISO 14001, ISO 45001 certifications, and our products comply with international standards such as JIS, EN, GB, and ASTM. We support inspections by third-party institutions such as SGS, BV, and TUV. Leave us a message with the information you wish to inquire about or the specifications you plan to purchase to receive a free quote and detailed answers!