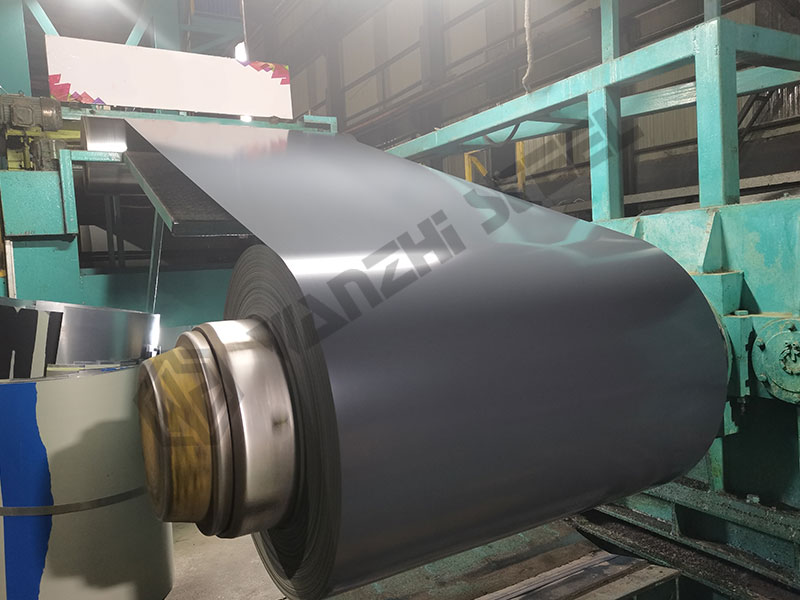

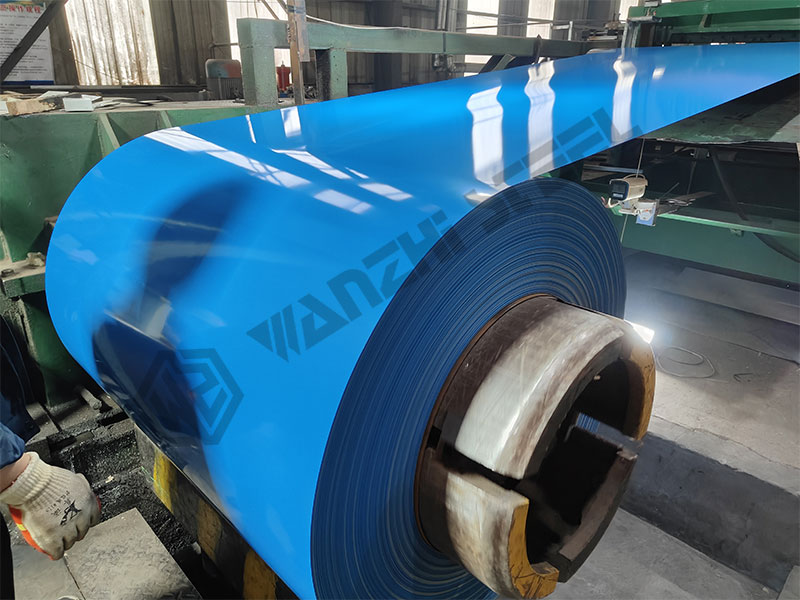

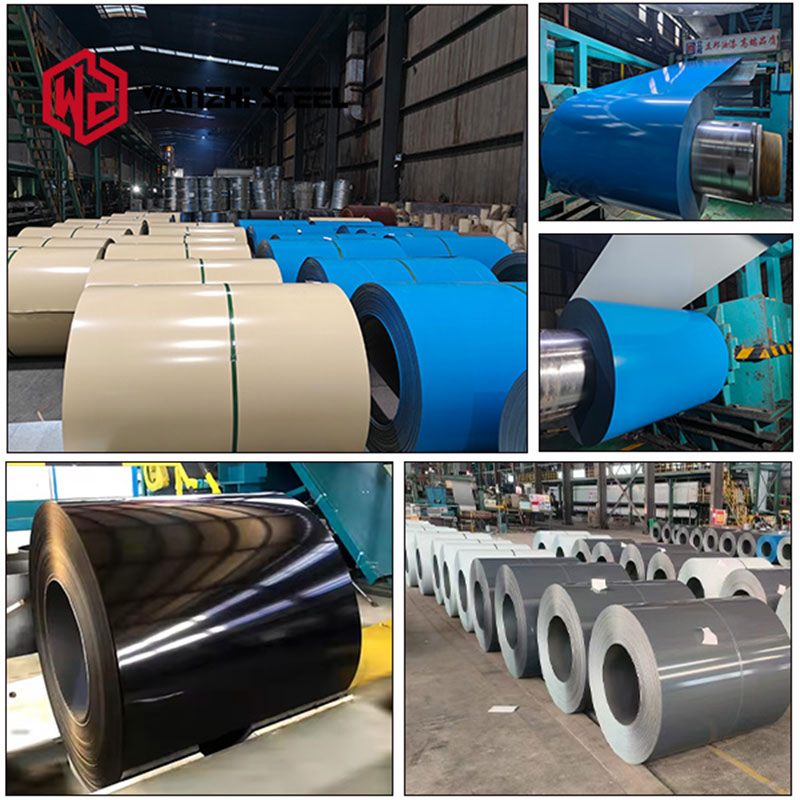

PPGI stands for Pre-painted Galvanized Iron, also known as Color-coated Galvanized Steel. PPGI coil is one of the most common forms of PPGI steel. Coils are widely favored across various processing sectors due to their ease of transportation and storage, as well as their flexible workability.

PPGI Coil Specification

| Specification | Details |

| Thickness | 0.12-1.5mm (Common: 0.12/0.14/0.16/0.18) |

| Width | 600-1250mm (Common: 1000/1200) |

| Coating | PE/SMP/PVDF/HDP/PU/PVC |

| Pattern | RAL color card / Special printing / 3D embossing |

| Substrate Type | GI/GL/SPCC/SPCD/SPCE/DC01-DC07/Q195, Q215, Q235 |

| Unit Weight | 5t |

| Packaging | Standard export packaging (Plastic film + Moisture-proof paper + Galvanized steel sheet) |

PPGI Price

PPGI Coil Structure

Base Material: Cold-rolled steel, hot-rolled steel (typical grades: DX51D, DX52D, DX53D, SECC, SGCC,etc.)

Chemical Conversion Layer: Phosphate conversion layer, chromate conversion layer, etc.

Primer: Thickness 5-20 microns

Topcoat: Thickness 10-40 microns

PPGI Coil Coating Structure

2/0: Double-layer topcoat, no backcoat.

2/1: Double-layer topcoat + single-layer backcoat

2/1M: Double-layer topcoat + single-layer backcoat (modified coating)

2/2: Double-layer topcoat + double-layer backcoat.

3/2: Triple-layer topcoat + double-layer backcoat.

3/3: Triple-layer topcoat + triple-layer backcoat.

PPGI Coil Colors

Wanzhi Group offers a variety of standard colors (such as white-gray, sea blue, brick red, etc.) and supports custom RAL color codes to meet diverse design requirements.

PPGI Coil Patterns

Beyond solid-color PPGI, Wanzhi PPGI coils can also feature decorative patterns including wood grain, stone texture, camouflage, floral, sky, stripes, marble, trees, and grass to enhance aesthetics. (Customization available based on samples.)

PPGI Coil Gloss Level

Gloss level is a critical aesthetic performance indicator for PPGI Coil (pre-painted galvanized steel coil), commonly denoted as GU. It influences the decorative appeal and application scope of PPGI products.

- High Gloss (≥85%)

- Semi-Gloss (40-60%)

- Matte (≤30%)

PPGI Coil Laminating

A secondary processing technique where a transparent or patterned (e.g., wood grain, brushed, printed) plastic film (such as PET, PE, PVC) is laminated onto the color-coated surface of PPGI coil. PPGI laminated sheets are primarily used in high-end home appliance manufacturing.

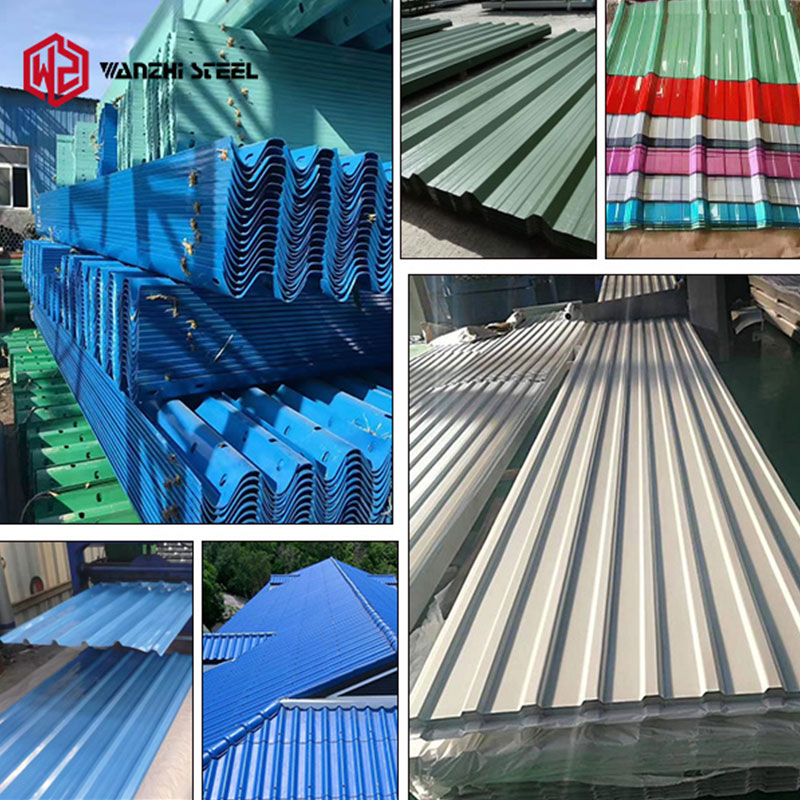

Characteristics of PPGI for Different Applications

Architectural PPGI Coil: Emphasizes weather resistance and UV protection. Commonly used for roofing, walls, ceilings, suspended ceilings, decorative walls, roller shutters, garage doors, and rainwater gutters.

Home Appliance PPGI Coil: Prioritizes surface flatness, corrosion resistance, and ease of cleaning. Suitable for refrigerator, washing machine, indoor/outdoor air conditioner units, water heater casings, microwave ovens, ovens, range hood exteriors, and interior liners.

Industrial Production PPGI Coil: Requires high strength, abrasion resistance, and chemical corrosion resistance. Commonly used in filing cabinets, office partitions, bookshelves, electrical cabinets, control boxes, industrial lighting housings, ductwork, cleanroom panels, food processing equipment panels, and advertising display board substrates.

Other Applications: Customized for specific uses such as transportation facilities, interior decoration, and greenhouse structures.

PPGI Coil Service Life

Typically 10-30 years, depending on coating type, usage environment (humidity, UV exposure, pollution levels), and maintenance conditions.

Differences in PPGI Coil Coatings

Primer:

- Epoxy Resin: Strong adhesion, excellent rust prevention, commonly used as the base layer for topcoats.

- Polyester: Wear-resistant, chemical-resistant, used for topcoat surfaces.

Topcoat:

- Polyester (PE): Low cost, moderate weather resistance, lifespan 8-10 years; suitable for indoor or short-term outdoor use.

- Silicone-modified polyester (SMP): Enhanced weather resistance, lifespan 10-15 years; suitable for moderate outdoor environments.

- High-weatherability polyester (HDP): UV resistance, anti-chalking, lifespan 10-15 years.

- Fluorocarbon (PVDF): Premium weather resistance, lifespan over 20 years, used in high-end architecture.

PPGI Coil Further Processing

Can undergo shearing, stamping, bending, roll forming, welding, etc., to produce finished products like roofing panels, wall panels, appliance housings, and ventilation ducts.

Shearing: The fundamental process of cutting PPGI coils to required dimensions, primarily involving two methods—slitting and cross-cutting—to produce PPGI sheets or strips.

Stamping: A process where PPGI material is deformed into specific shapes under press pressure, yielding open-ended hollow components.

Forming: Continuous plastic deformation produces finished products like roofing panels, wall panels, C-shaped steel, and floor decking.

Punching:Using molds under the action of a press, various hole patterns are formed on the surface of PPGI steel.

Which is Better: PPGI or PPGL?

PPGI and PPGL are popular prepainted steel options. Selecting material based on environmental factors like corrosion, temperature, and strength requirements can significantly reduce project costs!

PPGI: Features a galvanized iron substrate with high strength, suitable for structural components and buildings.

PPGL: Utilizes an aluminum-zinc coated substrate, offering superior heat resistance and corrosion resistance, ideal for high-temperature environments (e.g., ovens, chimneys).

PPGI Coil Customs Code

Common PPGI customs code: 72104900 (Galvanized steel sheet, width ≥600mm, coated)

Color-coated coil sheet customs code: 72107010.00 ( Painted or plastic-coated flat-rolled products of iron or non-alloy steel, width ≥600mm, thickness <1.5mm)

Color-coated coil/sheet customs code: 72124000.00 (Painted or plastic-coated narrow sheets of iron or non-alloy steel, width <600mm)

Color-coated coil sheet (appliance sheet) Customs code: 72109000.00 (Flat-rolled products of iron or non-alloy steel, coated or covered with other materials, of a width of 600 mm or more)

Whiteboard (writing board) Customs code: 96100000.00 (Slates, blackboards, and similar boards with writing or drawing surfaces, whether or not framed)

Wanzhi PPGI Coil Overseas Projects

Wanzhi Group‘s PPGI coil has been exported worldwide as raw material, playing a vital role in construction and industrial applications such as roof panel fabrication, greenhouse construction, ventilation duct and gutter production, home appliance manufacturing, and building structures.

Wanzhi Steel – Agricultural Greenhouse Project in Turkmenistan

550 tons PPGI Steel Coil to Azerbaijan

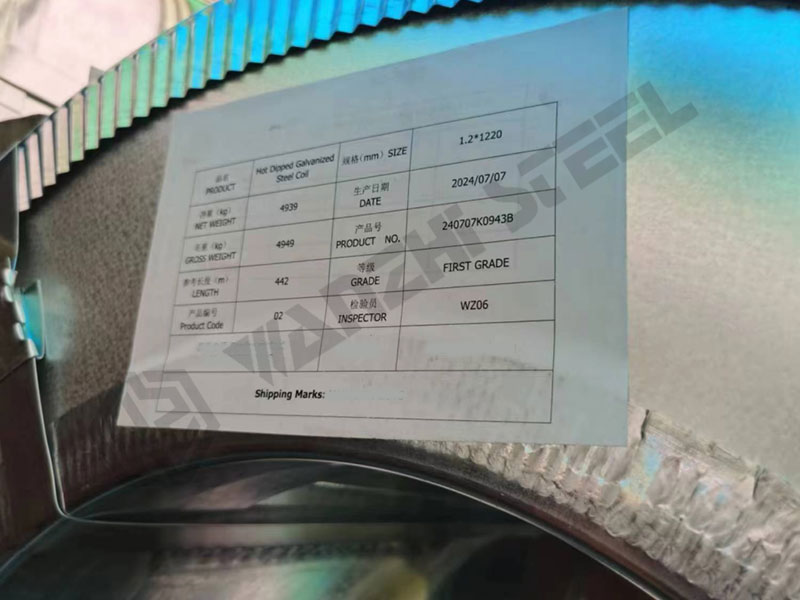

100 tons of Galvanized Coils to Saudi Arabia

144 ton Steel Wire to Spanish

Project of PPGI Roofing en Libya