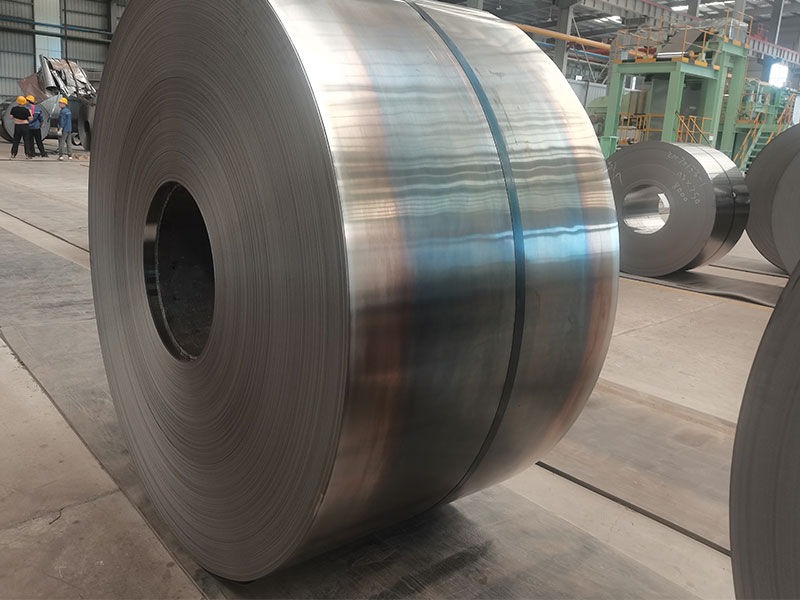

When manufacturing galvanized steel, galvanized aluminum-zinc steel, galvanized aluminum-magnesium-zinc steel, and color-coated steel sheets, the term “cold-rolled steel plate” is frequently mentioned. It refers to steel plates or steel strips produced through the cold-rolling process. Cold-rolled steel plates are produced by rolling hot-rolled steel plates, but they have superior surface quality, dimensional accuracy, and mechanical properties compared to hot-rolled steel plates, making them a high-quality low-carbon steel base material.

Core Characteristics

Production Process

International Standards

Chinese standards (GB/T)

| Grade | Meaning and Use | Performance Characteristics (Examples) |

| SPCC | Cold-rolled carbon steel for general stamping and bending purposes. | Average formability. Tensile strength: 270-410 MPa. |

| SPCD | Cold-rolled carbon steel for stamping. | Better formability than SPCC. |

| SPCE | Cold-rolled carbon steel for deep drawing. | Excellent formability. |

| SPCF | Cold-rolled carbon steel for extra deep drawing. | Better anti-aging and deep drawing performance than SPCE. |

European Standard (EN)

| Grade | Meaning and Use | Performance Characteristics and Correspondence |

| DC01 | General-purpose, equivalent to SPCC. | Basic level, lowest cost. |

| DC03 | For stamping, equivalent to SPCD. | Better formability than DC01. |

| DC04 | For deep drawing, equivalent to SPCE. | Good deep drawing performance. |

| DC05 | For extra deep drawing, equivalent to SPCF. | Excellent deep drawing performance. |

| DC06 | For ultra-deep drawing. | Higher performance than DC05. |

| S235JR, S355MC, etc. | High-strength steel grades. | High strength. Used for safety and structural components. |

American/ASTM Standard

| AISI Grade | Carbon Content (Approx.) | Use and Performance |

| 1006 | 0.06% | Very soft, excellent formability, used for deep drawing. |

| 1008 | 0.08% | Soft, good formability, very commonly used. |

| 1010 | 0.10% | Balanced strength and formability. |

| 1012 | 0.12% | Slightly higher strength, slightly worse formability. |

| 1015+ | >0.15% | Higher strength, used for structural components. |

Japan/JIS Standard

| Grade | Meaning and Use | Corresponding Relationship |

| SPCC | Exactly the same as the national standard SPCC. | General-purpose use |

| SPCD | Exactly the same as the national standard SPCD. | For stamping |

| SPCE | Exactly the same as the national standard SPCE. | For deep drawing |

| SPFC440, SPFC590 | High-strength steel grades | Equivalent to the European S-series, such as S35 |

Derivatives of Cold-rolled Steel Substrates

There are many derivatives of cold-rolled steel substrates as base materials, among which the most popular include galvanized steel, galvalume steel, ZAM steel, and color-coated steel, among others.

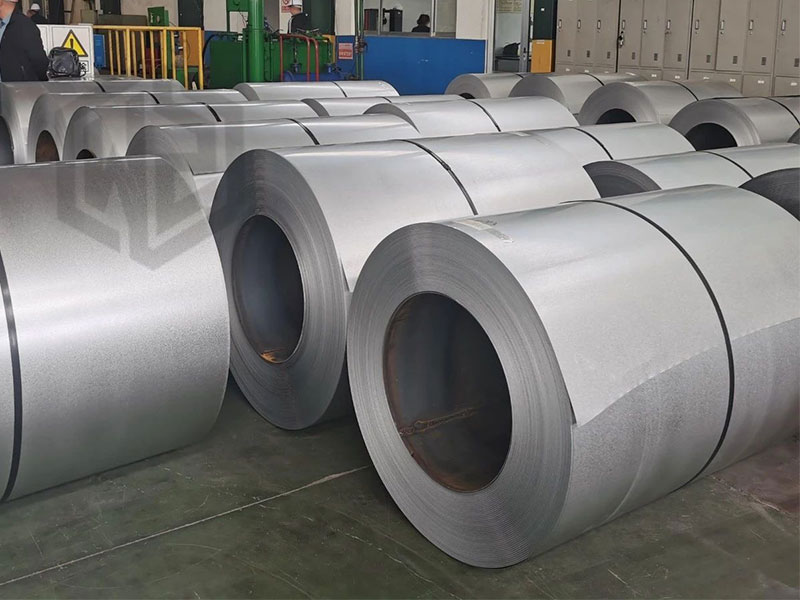

GI – Galvanized Steel

Coated with a pure zinc layer, it combines the mechanical properties of cold-rolled steel with the ductility, sacrificial anode protection, and edge protection of zinc.

- Main products: painted galvanized steel, galvanized structural components, pipe systems, automotive panels, roof and wall panels, etc.

AZ – Aluzinc Steel

A 55% aluminum-zinc alloy coating combined with cold-rolled steel, leveraging the advantages of aluminum and zinc elements, offering excellent wear resistance, corrosion resistance, and heat resistance (up to 315°C).

- Main products: color-coated aluzinc steel, aluzinc building roofs/walls, ovens, water heater liners, grain silos.

ZAM – Zn-Al-Mg Steel

Next-generation coating (Zn-Al-Mg), with corrosion resistance 10-20 times that of cold-rolled galvanized steel. Its standout advantage is strong self-healing capability at cut edges and excellent wear resistance.

- Main products: livestock farms, cold chain logistics, solar panel mounts, structural components in highly corrosive environments.

PPGI/PPGL – Pre-Painted Steel

Organic coatings (such as PE, SMP, PVDF, PU, HDP) are applied to galvanized/aluminum-zinc-coated substrates, combining the corrosion resistance of metal-coated steel with the decorative properties of coatings.

- Main products: building exterior wall panels, roof panels, appliance panels (such as refrigerators, washing machines), and interior decorative panels.

Wanzhi Group can provide all standard cold-rolled substrates and their derivatives, as well as professional technical selection support and customized solutions. For further information, please contact our sales engineers.