Material: GI, GL, PPGI, PPGL,etc.

Usage: roofing, wall, ceiling, facade, decorative, etc.

Types of Metal Panel Materials

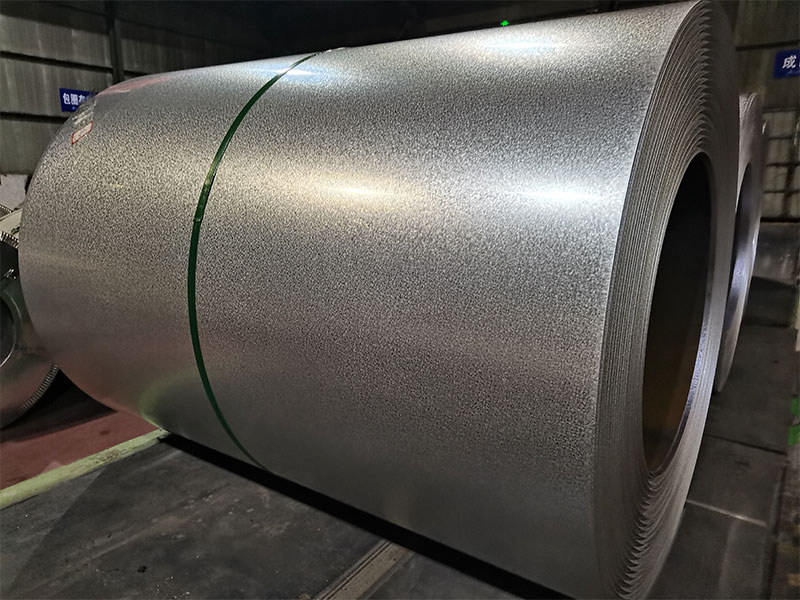

Wanzhi Group produces coated metal materials, alloy metal materials, and color-coated metal materials, providing not only finished metal panels, but also finished roofing and wall panels for construction projects. According to the material, Wanzhi’s panels are divided into 6 categories, galvanized panels, galvalume panels, prepainted galvanized panels, prepainted galvalume panels, stainless steel panels, prepainted aluminum panels.

- Galvanized: Galvanized steel has good toughness and plasticity, corrosion resistance, and low processing cost, is suitable for bending, and forming processes, and is popular for general outdoor construction materials.

- Aluminum: Zinc-aluminum alloy layer provides corrosion, weather, and heat resistance to the panel, which is commonly used for exterior walls, roofs, etc. in tropical, high-temperature, humid, and rainy areas.

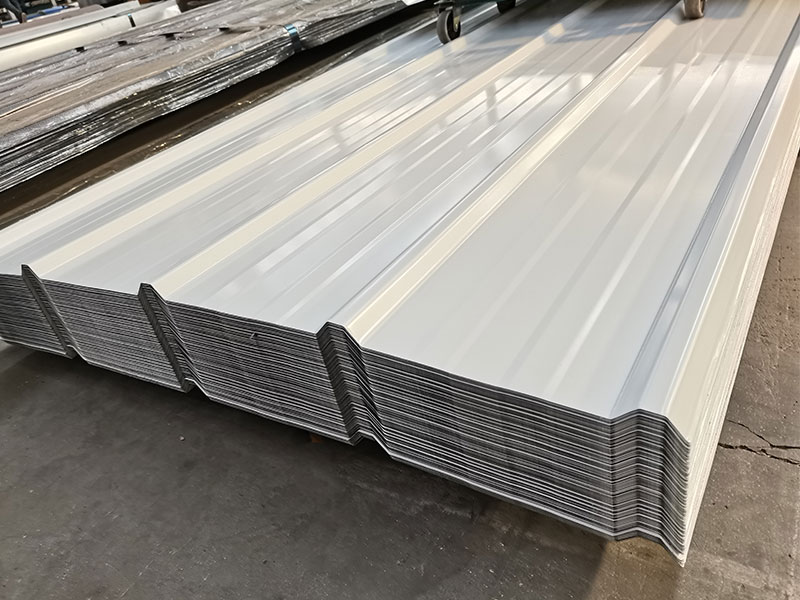

- Prepainted steel: Usually galvanized/aluzinc steel as the substrate, combining the advantages of steel, metal coating and paint layer, it is a popular roofing material.

- Stainless Steel: Stainless steel has average processability but excellent corrosion and temperature resistance and is often used in demanding environments such as medical, food, and aerospace.

- Colored Aluminum: Aluminum alloy has low density, light weight, and high thermal reflectivity, but high cost. Colored aluminum panels are generally used in high-grade commercial buildings for curtain walls, facade,s and airports, where material requirements are high.

Types of Structural Forms of Metal Panels

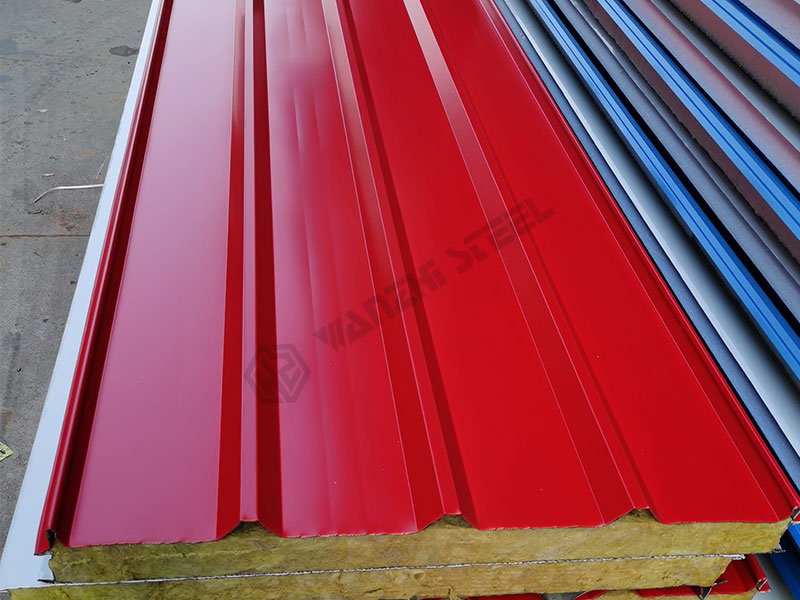

In addition to the material, metal panels can be categorized according to the surface structure, e.g. flat panels, sandwich panels, engraved panels, embossed panels, etc.

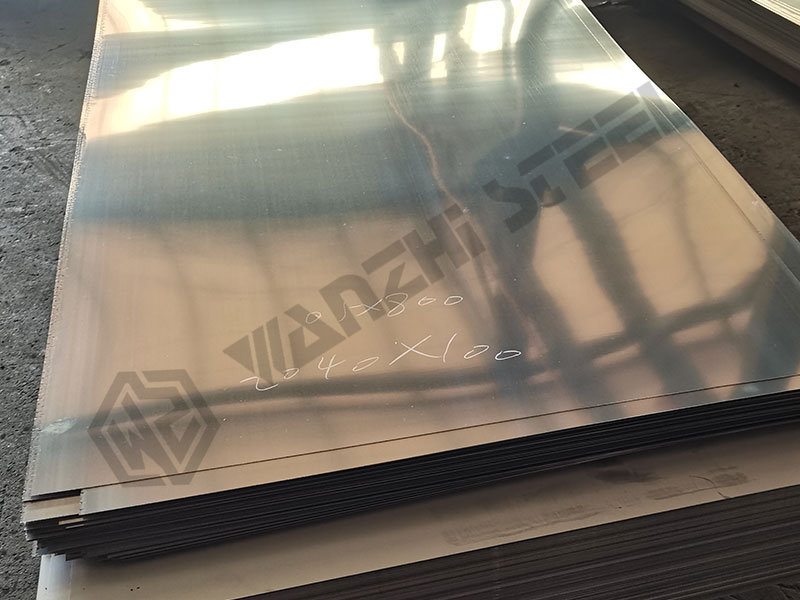

- Single-layer: galvanized/color-coated flat sheets, cut from steel coils, with a smooth and flat surface.

- Composite: galvanized/PPGI sandwich panels, metal profiled panels, etc. A sheet made from a combination of two layers of metal material and a core material, the surface structure is determined by the shape of the metal material.

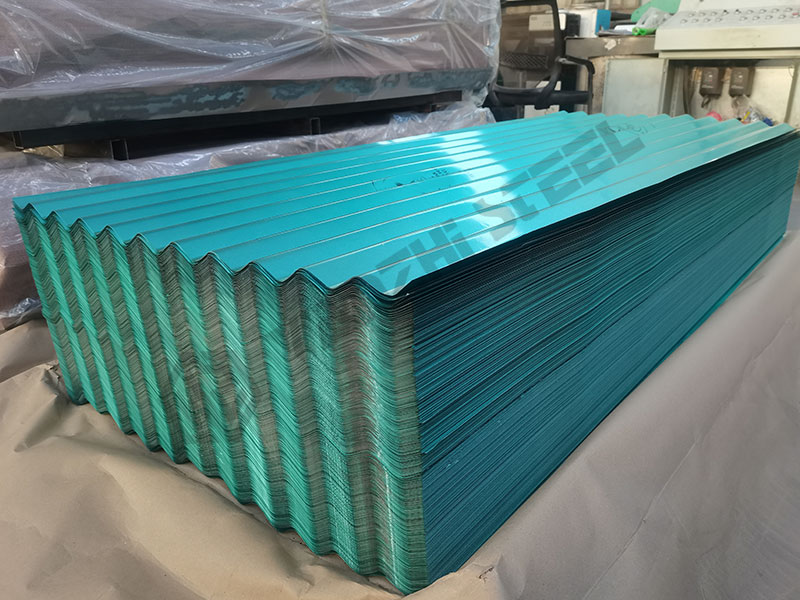

- Pressing: Galvanized/prepainted corrugated sheets, embossed sheets, ribbed sheets. Made from coils of various coated or alloy steel, after cutting, stamping, punching, bending, molding, and other further processing. The surface has a corrugated or raised structure.

Metal Panel Benefits and Applications

Metal panels are widely used in construction, decoration, industry, manufacturing, and other fields because of their durability, plasticity, and beauty.

Benefits

- Anti-corrosion, anti-oxidation, anti-weathering

- Fireproof, waterproof, soundproof

- Easy to transport, store, and install

- Low maintenance cost

- High strength

Applications

- Residential and commercial building exterior walls

- Building roof materials

- Interior decorative panels

- Billboards/advertising signs

- Insulation materials

- Soundproof walls

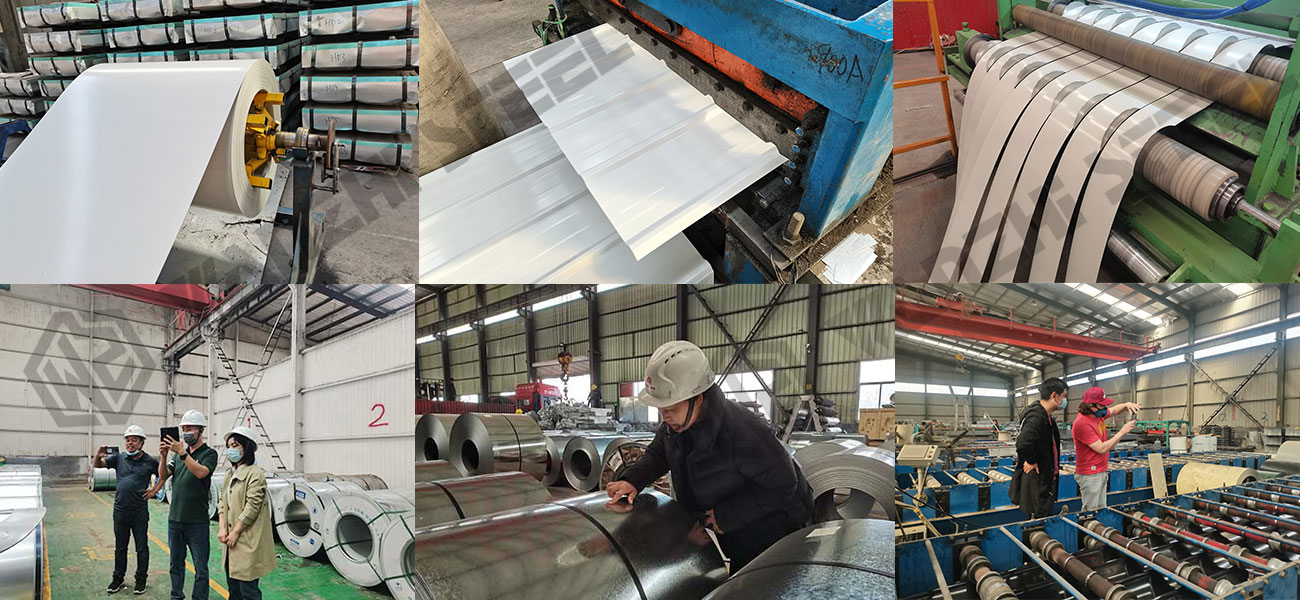

Manufacturing Process for Metal Panels

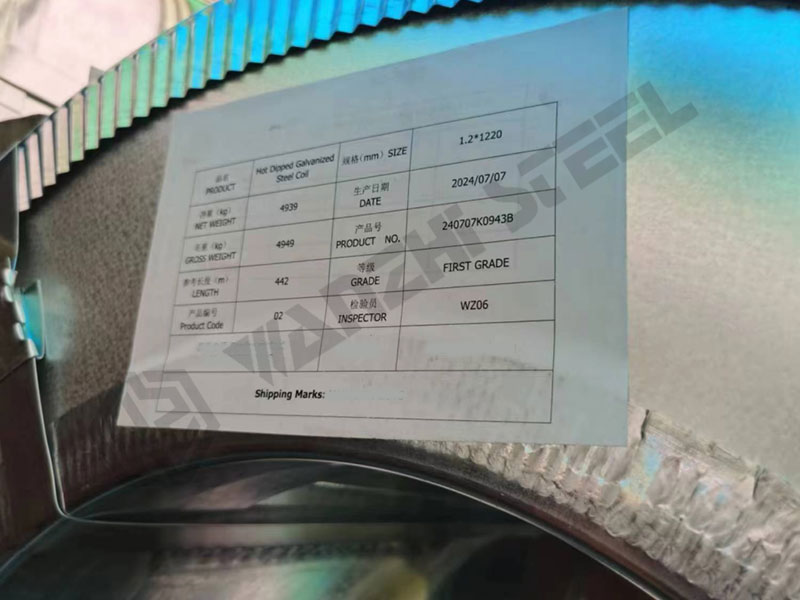

The manufacturing process of metal sheets is very simple. Wanzhi Group provides raw materials (galvanized steel coils, galvanized steel coils, PPGI coils, PPGL coils, stainless steel coils, etc.), as well as finished product processing (bending, cutting, stamping, forming, punching, shaping, etc.).

- Raw materials: Select materials according to the purpose, including aluminum, steel, stainless steel, etc.

- Metal sheet processing: Cut and stamp the raw materials.

- Surface treatment: Perform surface treatment such as lamination, polishing, and sandblasting to improve the appearance

- Further processing: After the surface treatment of the metal sheet, it will be further processed according to the actual use, such as curling, pressing, splicing, composite board (composite, hot pressing), etc.

- Shaping: After all the processing is completed, the metal panel will be finally cut and shaped according to the size requirements.

- Quality inspection: The appearance, physical, and chemical properties of the sheet need to be tested.

- Packaging: Wanzhi’s export packaging includes plastic film, moisture-proof paper, galvanized iron sheets, corner fixers, etc.

Metal Panel Factory and Manufacturer

Wanzhi Group has its raw material suppliers, galvanizing and color coating production lines, and deep processing equipment. Galvanized and color-coated metal panels of various sizes and specifications can be customized according to different application requirements. So far, our factory has received customers from more than 40 countries and provided metal sheet raw materials and finished products to customers in more than 100 countries.

Products of Wanzhi Metal Panel

- metal roof panels

- metal wall panels

- insulated panels

- corrugated panels

- decorative panels

- perforated panels

- metal ceiling panels

- Pressed panels

- box rib panel

- fluted panel

Factory

Wanzhi Factory is located in Binzhou, Shandong Province, China. It has 7 production lines with an annual output of 600,000 tons. In addition to the production lines, there are sample rooms and quality inspection rooms. Samples can be provided (welcome to contact us). Of course, we give you the metal materials we just produced, and then process them, strictly control production efficiency, and provide customers with the most competitive prices.

Cases and Project

We not only have all sizes and types of metal panels, but also design and produce according to the project requirements of customers, and provide one-stop service. Our products cover plates, coils, gutters, eaves panels, ridge tiles, galvanized wires, and other accessories, which can help you save time and cost.

Metal Panel Projects

The following are the construction projects in Liberia and Turkmenistan where we are involved in supplying steel!

Wanzhi Steel – Agricultural Greenhouse Project in Turkmenistan

550 tons PPGI Steel Coil to Azerbaijan

100 tons of Galvanized Coils to Saudi Arabia

144 ton Steel Wire to Spanish

Project of PPGI Roofing en Libya

100 tons of GL and PPGL in Solomon Islands

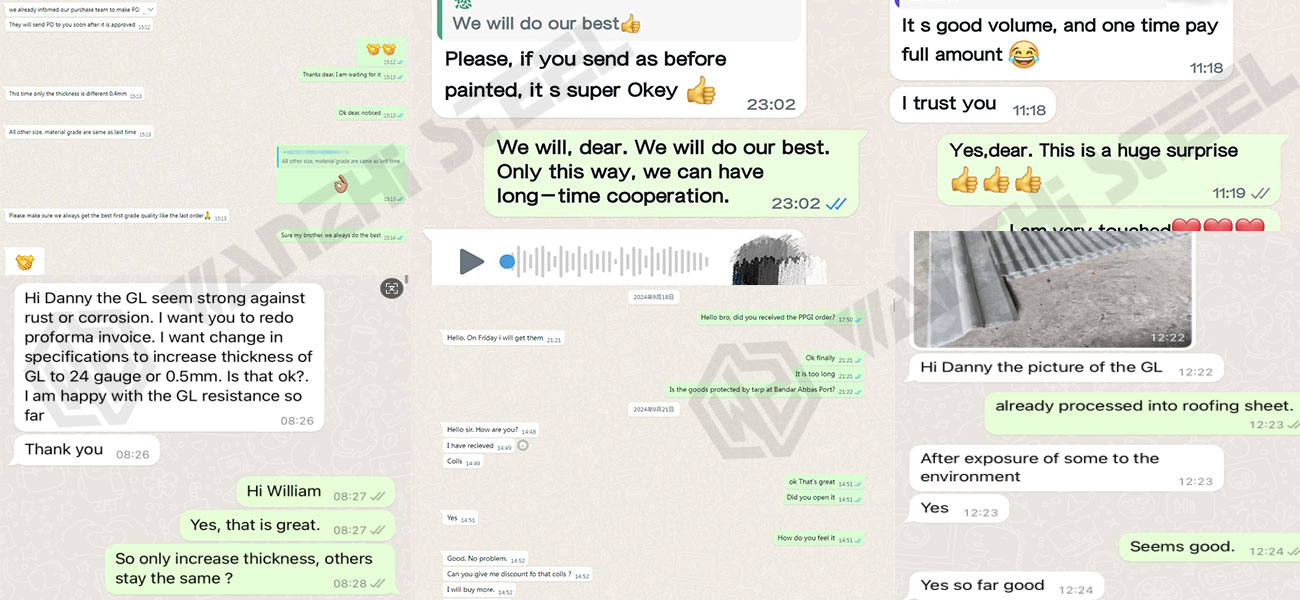

Feedback

Wanzhi Group provides galvanized and PPGI steel to customers of roofing panel processing plants. Customer feedback!

Do you want to design and produce metal panels with characteristics according to the local market, or do you want to buy steel coils as raw materials to produce metal roof panels/wall panels for local sale? No matter which demand you have, please leave a message, and we will provide you with premium steel and the most competitive price.