Outdoor Steel Requirements

Outdoor Steel Classification

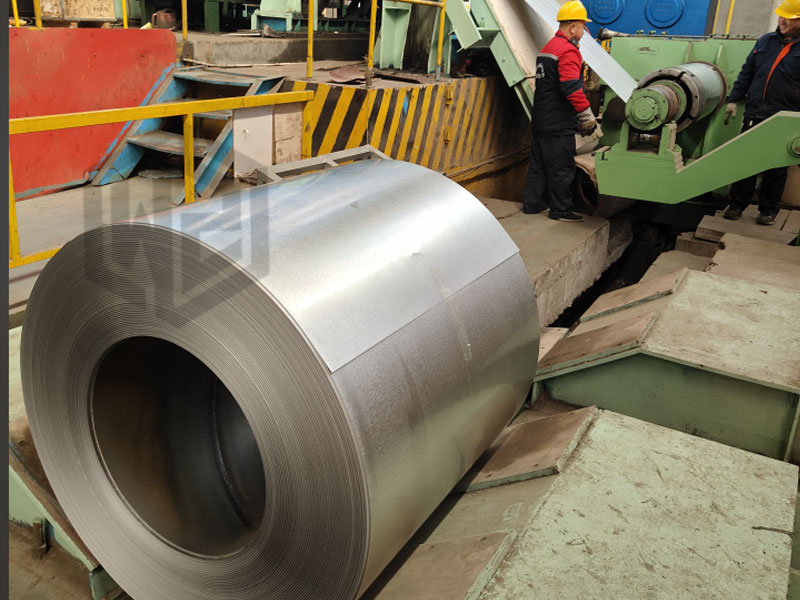

Hot-dip galvanized steel

Hot-dip galvanized steel is steel that has excellent corrosion resistance by forming a zinc layer by dipping the steel into a molten zinc solution. Highly zinc-coated galvanized steel can be used in outdoor environments, especially in wet or rainy areas.

Application Scenarios:

- Building structures

- Outdoor billboards and signs

- Fences, grids and power towers

- Road and railroad bridges

Aluzinc Steel

Aluzinc Steel is an aluminum-zinc alloy coating applied to the surface of steel with the addition of the element aluminum, which has stronger corrosion and heat resistance than hot-dip galvanized steel, and is particularly suitable for high temperature and strong acid and alkali environments.

Application Scenario:

- Buildings and roofs in high temperature environments

- Agricultural facilities

- Solar panel frames

- Outdoor electric facilities

Stainless Steel

Stainless steel is a steel that contains at least 10.5% chromium and has excellent corrosion resistance for outdoor projects that are budget friendly and in very harsh environments, such as applications in marine and chemical environments.

Application Scenario:

- Marine facilities

- Urban furniture

- Outdoor architectural decoration

- Food industry equipment

High Strength Low Alloy Steel (HSLA Steel)

High Strength Low Alloy Steel is a material that improves the strength of steel by adding a small amount of alloying elements. It has better weathering and corrosion resistance, and is widely used in large outdoor structures.

Application Scenarios:

- Heavy machinery and equipment

- Bridges and transportation facilities

- Building frames

- Aerospace and military installations

Carbon Steel

Carbon steel is a steel made up of iron and carbon and is used in outdoor environments where low corrosion resistance is required.

Application Scenario:

- Building structures

- Industrial facilities

- Roads and bridges

- Outdoor furniture (need to be painted to prevent rust)

Structural Steel

Structural steel offers high strength, weldability and corrosion resistance for large structural projects.

Application Scenarios:

- High-rise buildings

- Bridge construction

- Oil platforms

- Railroad and highway bridges

Prestressed Steel

Prestressed steel undergoes a special treatment during the manufacturing process that enhances the steel’s load-carrying capacity, making it suitable for structures that are subjected to great tensions.

Application Scenario:

- Highway and railroad bridges

- Elevated buildings

- Water utilities

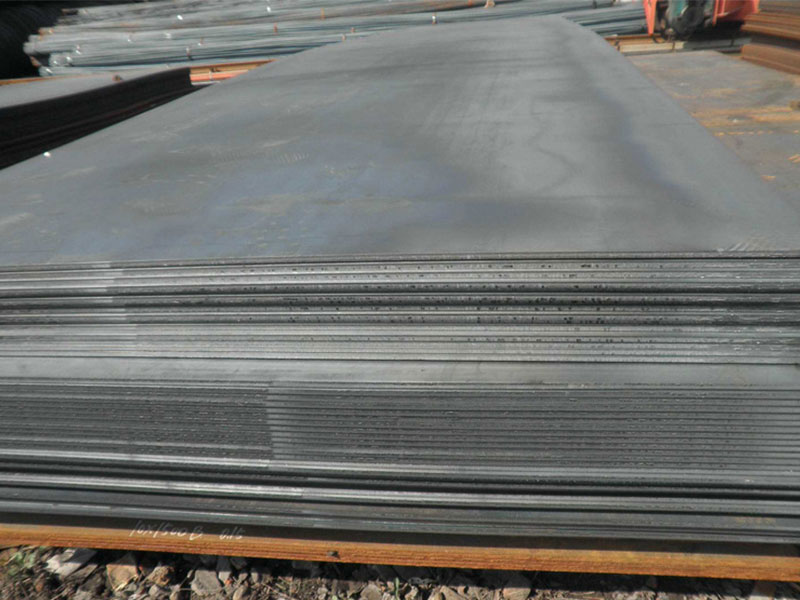

Hot Rolled Steel

Hot rolled steel is low steel processed at high temperatures with good formability for structures that require large areas to be processed.

Application Scenario:

- Building structures

- Steel plates and tubes

- Large mechanical structures

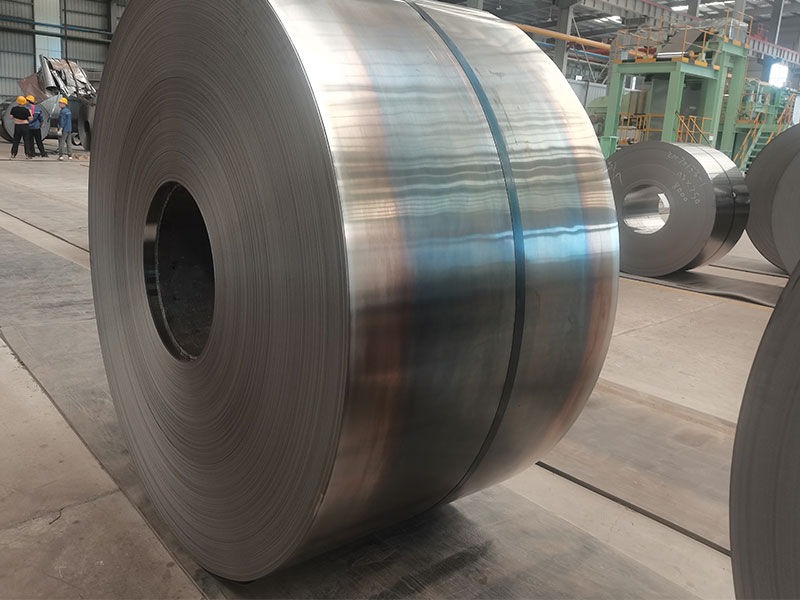

Cold Rolled Steel

Cold rolled steel is steel obtained by rolling at room temperature with a smooth surface, suitable for precision machined parts.

Application Scenario:

- Household appliance housings

- Automotive components

- Frames and brackets

Aluminum Steel

Aluminum steel combines aluminum with other metals such as copper and magnesium for lighter weight and better corrosion resistance. Commonly used for outdoor projects where weight reduction is required.

Application Scenarios:

- Aerospace industry

- High-speed trains and automobiles

- High-rise building facade decoration

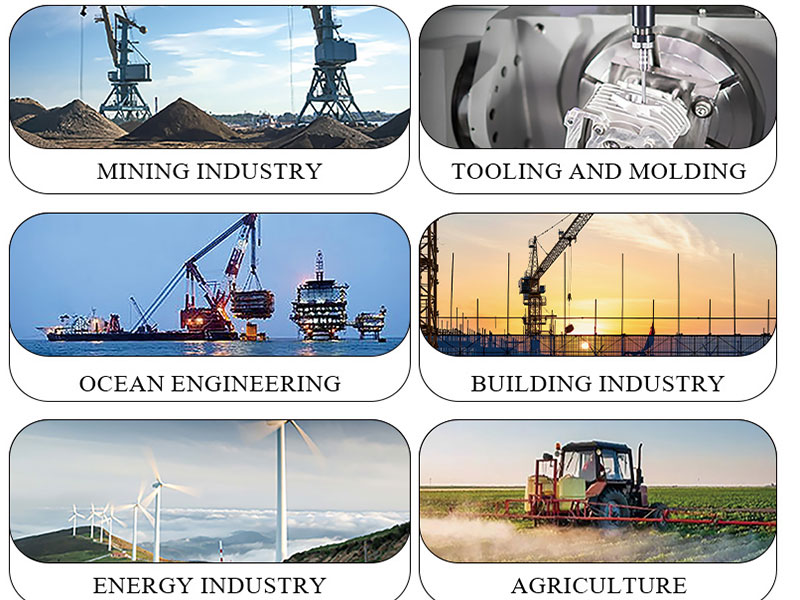

Wanzhi Group provides customized solutions to meet the needs of the project environment by combining the steel’s corrosion resistance, strength, toughness, oxidation resistance and aesthetics. In addition to these zinc coated, alloy coated, alloy steel, carbon steel, we also have color coated steel, colored stainless steel, colored aluminum and other solutions, contact us for more information!