What are the key data that we need to pay attention to during the acceptance inspection of PPGI coil and PPGI sheet to ensure that the product meets the international standards and our needs? Wanzhi Group has organized the PPGI quality inspection process, which mainly covers substrate quality inspection, coating performance inspection, appearance inspection, mechanical performance inspection, dimensions and packaging, etc. We hope it can help us select Premium PPGI materials.

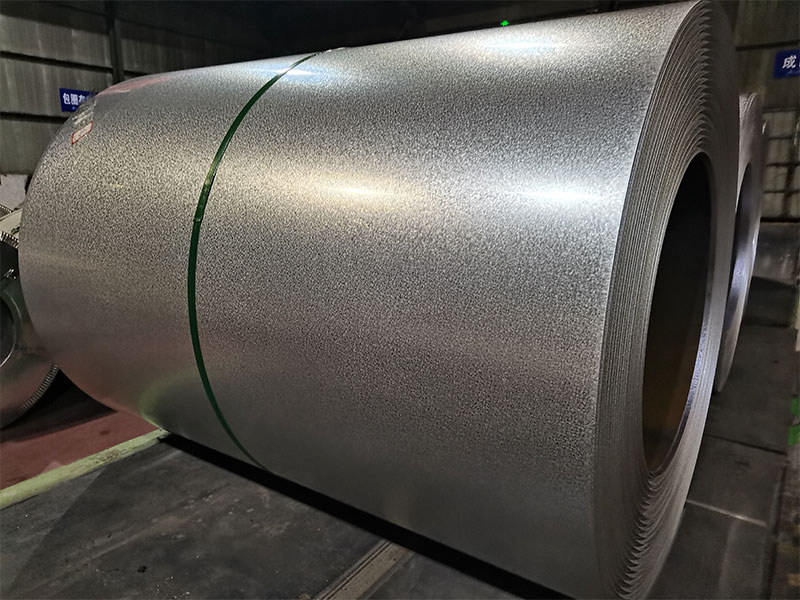

GI GL Substrate Quality Inspection

PPGI coil/prepainted galvanized steel coil is a color-coated steel made from GI (galvanized steel) substrate, and PPGL coil/prepainted galvalume steel coil is a painted metal made from GL (galvalume steel) substrate. PPGL coil/prepainted galvalume steel coil is a painted metal material made from GL (galvalume steel). The scope of the substrate inspection includes coating weight, thickness error, surface residue, etc.

Zinc/Aluminum-Zinc Coating Inspection

- Zinc layer weight: The weight of the zinc layer on both sides is checked for consistency with the required weight using the gravimetric method (ASTM A751).

- Uniformity: Ensure that the coating thickness error is ≤±5% by magnetic thickness gauge.

Surface cleanliness

- White glove test: wipe the surface without oil or oxide residue.

- Chemical residue test: pH test paper is used to verify whether the residue of the degreasing solution is qualified (neutral is competent).

PPGI PPGL Coil Coating Performance Testing

PPGI PPGL coil paint layer consists of a primer and a topcoat. The primer is usually epoxy resin or PE, and the topcoat is commonly PE/SMP/HDP/PVDFD coatings. Sometimes, it may also be used in PVC or PU coatings.

1. Coating thickness

- Total thickness of primer + topcoat: ≥20μm (ISO 2808 or ASTM D7091).

- Uniformity of single layer: multi-point measurement, deviation ≤±2μm.

2. Adhesion test

- Scratching method: 0~1 level (no flaking).

- T-bend test: 0T~2T (no crack).

3. Weathering and corrosion resistance

- Salt spray test: ≥500 hours without red rust (PVDF coating ≥1000 hours).

- UV aging test: simulate 10 years of outdoor exposure, color change ΔE≤1.5.

4. Color and gloss

- Color difference test: ΔE≤1.5 (compared with RAL/Pantone color card).

- Glossiness: measured at 60° angle, deviation ≤10%.

PPGI Coil Surface Treatment and Appearance Inspection

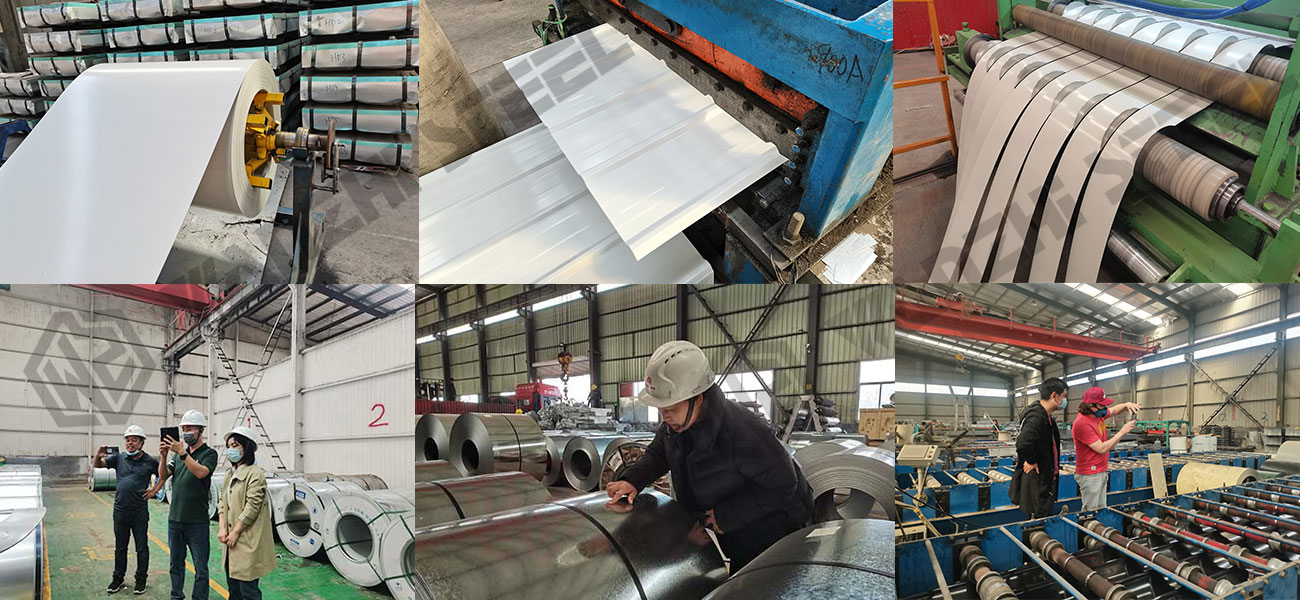

Prepainted steel coils are available in matte, high gloss, and textured finishes and can be customized with different patterns, such as wood grain, flower, marble, brick, and so on. PPGI‘s surface treatment and appearance inspection is essential in the quality control process, especially for embossed and painted products.

Surface effect

- Visual inspection: no broken grain, overlapping or blurred areas.

- Laser Profiler: Error in texture depth ≤ ±0.05mm (ISO 4287).

Surface defects

- Pinhole Inspection: High voltage EDM inspection to ensure that there are no missed coating spots.

- Scratches and bubbles: manual inspection or AI vision system identification.

PPGI Coil Mechanical Property Test

| Test item | Reference standard | Reference standard |

| Tensile strength | ASTM A370 | ≥270 MPa (according to the grade of substrate) |

| Yield strength | ASTM A370 | ≥140 MPa (mild steel base material) |

| Elongation (after break) | ASTM A370 | ASTM A370 |

| Bending performance | Bending performance | 180° bending without cracks (T-bend test 0T ~ 2T) |

| Hardness | ASTM D3363 | Pencil hardness ≥H (coated surface) |

| Coating adhesion | ASTM D3359 | Scribing method 0~1 grade (no flaking) |

International Standard Comparison

| Standard | Tensile strength requirement | Bending test method | Application area |

| ASTM A755 | ≥270 MPa | 180° bend (T-bend) | America, Middle East |

| JIS G3302 | ≥260 MPa | Reverse Bend (R=0t) | Japan, Southeast Asia |

| EN 10169 | ≥280 MPa | Cup punch test (Erichsen) | Europe |

Steel Coil Dimensional and Packaging Inspection

Specification Accuracy

- Thickness tolerance: ±0.02mm (e.g. 0.5mm thickness).

- Width/Length: Slitting error ≤±1mm, roll weight error ≤±3%.

Packaging Compliance

- Moisture-proof and rust-proof: VCI film sealing, foam-lined to prevent scuffing.

- Clear labeling: batch number, specification, coating type, production date.

Example of Wanzhi Group’s Quality Control Process

Our factory has PPGI production line and quality inspection equipment, and we also accept third-party organizations to come to our factory for quality and goods inspection.

- Factory self-inspection: Each roll is inspected online for coating thickness, color, and surface defects.

- Third-party sampling inspection: SGS, TÜV, and other organizations are commissioned to verify the salt spray, adhesion, and other key indicators.

- Customer Inspection: Pre-Shipment Inspection (PSI), sampling and testing according to contract standards.

Wanzhi Group‘s factory (Shandong Wanzhi Steel) has passed ISO9001, ISO14001, and other certificates and provides global customers with premium PPGI steel that meets international standards (ASTM/ISO/EN) and customer needs. If you have a purchasing plan, let us provide you with a free quote and samples! Let’s do it!