Wanzhi Group is a coated steel supplier and manufacturer, selling high-quality GI, GL, ZAM, PPGI, PPGL, PPAL, and other coated metal materials. PPGI, PPGL, PPAL are three common pre-painted metal materials used in construction, home appliance, automotive, education, energy, agriculture, and other industries. They can be customized with colors, sizes, finishes, and patterns according to the application environment and project, contact us to get your solution!

What are PPGI, PPGL, PPAL?

PPGI, PPGL, and PPAL are three common metal coating products. These are color-coated metal materials made of metal materials (GI, GL, AL) with organic coatings (PE, SMP, PVDF, HDP, PVC, PU, etc.) rolled on the substrate.

| Material | Full name | Substrate | Coating | Core features |

|---|---|---|---|---|

| PPGI | Pre-Painted Galvanized Iron | Galvanized Steel (GI) | Polyester (PE), Fluorocarbon (PVDF), etc. | Economical, versatile, suitable for general environments |

| PPGL | Pre-Painted Galvalume Steel | Galvalume Steel (GL, 55% Al-Zn) | Same as PPGI | Corrosion resistance 3–6 times higher than PPGI, high-temperature resistance 315°C |

| PPAL | Pre-Painted Aluminum | Aluminum alloy sheet (e.g. 3003/5052) | Same as PPGI | Lightweight (density 2.7 g/cm³), aesthetically appealing |

Comparison of PPGI, PPGL, PPAL

Production Process

| Material | Substrate Treatment | Coating Process |

|---|---|---|

| PPGI | Hot-dip galvanized steel sheet → Degreasing → Passivation (chromed/chrome-free) / Roller primer | Top coat (PE/PVDF/SMP/HDP) → Bake curing (200-250°C) |

| PPGL | Aluminium zinc-plated steel sheet → Degreasing → Passivation / Roller primer | Top coat (high-temperature-resistant topcoat) → Bake curing |

| PPAL | Aluminium alloy sheet → anodized / chemically converted → cleaned / primer rolled | Top coat → Bake curing at low temperature |

Comparison of components (substrate + coatings)

| Material | Substrate Type | Substrate Composition | Plating/Treatment | Coating Type |

|---|---|---|---|---|

| PPGI | Hot-dip galvanized steel sheet (GI) | Mild steel + zinc coating (30-275g/m²) | Chromated/chrome-free passivation | Polyester (PE), Fluorocarbon (PVDF), etc. |

| PPGL | Aluminized zinc-plated steel sheet (GL) | Mild steel + 55% Al-43.4% Zn-1.6% Si coating | Chromated/chrome-free passivation | Same as PPGI |

| PPAL | Aluminum alloy sheet (e.g. 3003/5052) | Aluminum (≥97%) + alloying elements such as Mg/Si/Cu, etc. | Anodic oxidation/chemical transformation | Same as PPGI |

Comparison of Mechanical Properties

| Performance Indicator | PPGI | PPGL | PPAL |

|---|---|---|---|

| Tensile strength (MPa) | 270-350 (base material DX51D) | 300-550 (base material S350GD) | 70-500 (depending on alloy type) |

| Yield strength (MPa) | ≥140 | ≥220 | 30-450 (e.g. 5052-H32 up to 195) |

| Elongation (A50, %) | ≥22 | ≥14 | 10-25 (pure aluminium higher) |

| Hardness (HV) | 70-130 | 100-160 | 20-150 |

| Density (g/cm³) | 7.85 | 7.85 | 2.7 |

| Salt spray resistance (hrs) | 500-1000 (PE coated) | 1500-3000 (PVDF coated) | 500-1500 (Dependent coating) |

Key Performance

| Performance | PPGI | PPGL | PPAL |

|---|---|---|---|

| Corrosion resistance | 500-1000 hours (salt spray) | 1500-3000 hours (salt spray) | 500-1500 hours (depending on the coating) |

| Heat resistance | ≤ 120°C (PE-coating) | ≤ 315°C | ≤ 150°C |

| Density | 7.85g/cm³ | 7.85g/cm³ | 2.7g/cm³ |

| Machinability | Easy to press, welding needs protection | Requires special tools for cutting | Very easy to bend / press (no rebound) |

| Costs | Low | Medium | High |

Applications

| Application Scenario | PPGI | PPGL | PPAL |

|---|---|---|---|

| Architecture | Lightweight Roofing, Temporary Fence | Coastal Factory, High-Temperature Workshop Roofing | Curtain Walls, Decorative Facades (e.g. Airports) |

| Household Appliances | Washer Shells, Air Conditioner | Liners, Oven Panels, Microwave Oven Shells | High-end Refrigerator Panels, LED Lamp Shades |

| Automotive | Truck Compartment Linings | Battery Cases for New Energy Vehicles | Decorative Strips for Vehicle Bodywork, Interior Trims |

| Electronics | Electrical Control Cabinets Shell | Photovoltaic Bracket (Weatherproof) | Cell Phone, Laptop Shell (Precision Processing) |

| Advertising | General Signage | Long-term Outdoor Billboards | Art Installations, Display Cabinets |

Advantages

| Materials | Core Advantages |

|---|---|

| PPGI | ✅ Cost-effective: lowest cost

✅ Versatile: suitable for common environments ✅ Easy to process: good stamping and bending performance |

| PPGL | ✅ Superior corrosion resistance: salt spray life 3–6 times longer than PPGI

✅ High-temperature resistance: long-term resistance to 315°C ✅ Thermal reflectivity: reflects 80% of the sun’s heat, energy saving |

| PPAL | ✅ Extreme lightness: density of only 2.7g/cm³ (1/3rd that of steel)

✅ Aesthetics Versatile: supports anodized colorful surfaces ✅ 100% recyclable: high environmental value |

How to Choose a Pre-painted Metal Material

PPGI is suitable for most application scenarios, PPGL has the best price/performance ratio in long-term use, PPAL is suitable for high-end projects where cost is not an issue.

Selection by environment

Normal dry environment → PPGI.

High corrosive/high-temperature environment → PPGL.

Lightweight + decorative → PPAL.

Selection by budget

Low cost: PPGI.

Long life: PPGL.

Special needs

Antimicrobial/self-cleaning: PPAL + Functional coatings.

Extreme weathering: PPGL + PVDF coating.

PPGI, PPGL, PPAL Paint Coating Type

| Paint Type | Main Ingredients | Weatherability | Applicable Substrate | Cost |

|---|---|---|---|---|

| Polyester (PE) | Polyester resin + pigment | Medium (5-8 years) | PPGI, PPGL | Low |

| Silicone-modified polyester (SMP) | Silicone-modified polyester resin | Medium-high (8-12 years) | PPGI, PPGL | Medium |

| Fluorocarbon (PVDF) | Polyvinylidene Fluoride (PVDF) resin | Extremely high (15–25 years) | PPGI, PPGL, PPAL | High |

| Acrylic | Acrylic resins | Low (3-5 years) | PPAL | Low |

| Nanoceramic Coatings | Silicon dioxide, titanium oxide nanoparticles | Extremely high (20+ years) | PPAL | Extremely high |

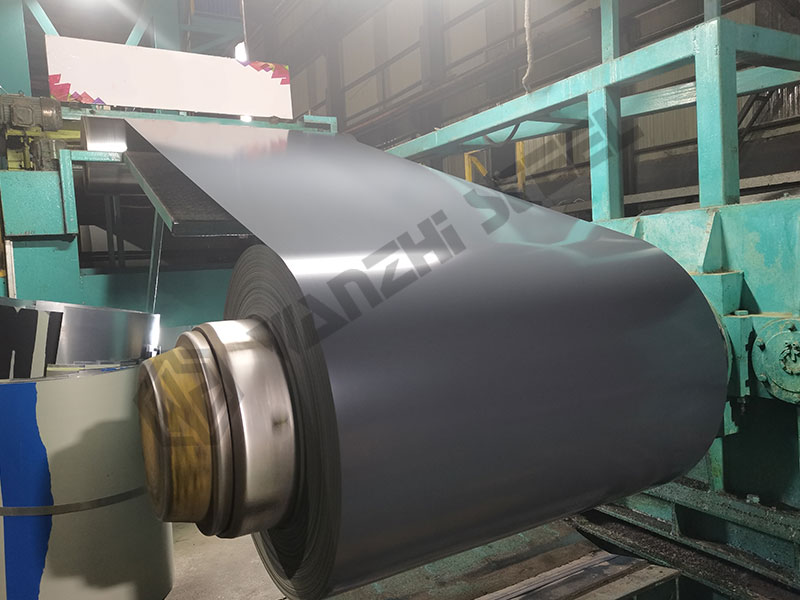

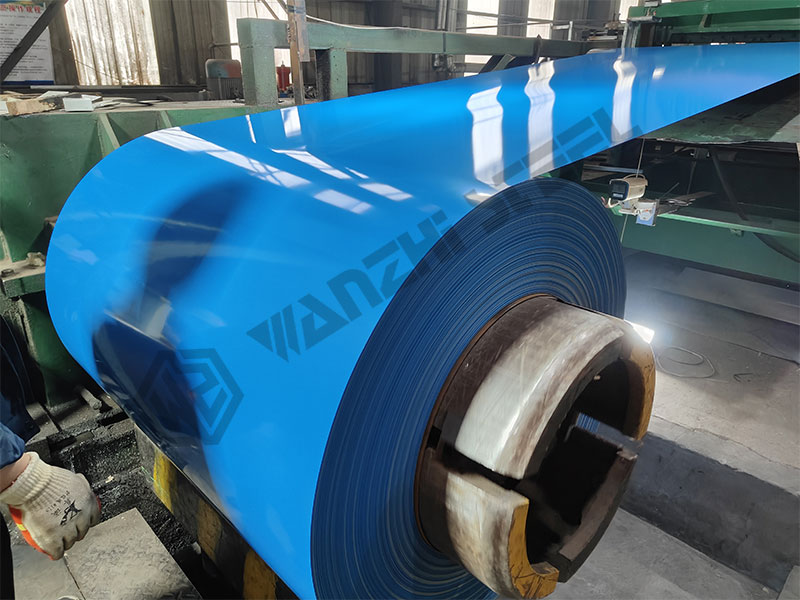

PPGI, PPGL, PPAL Manufacturer

Wanzhi Group produces high-quality pre-painted metal materials to specified thicknesses, widths, finishes, surface effects, and patterns, and can also provide customized solutions for project applications. We have 3 color-coated production lines in our painted steel factory, with an average monthly production of 10,000 tons and a delivery time of 5–45 days.

- Products: color-coated coils, color-coated panels, color-coated corrugated sheets, sandwich panels, sculpted panels, modular housing, etc.

- Customized: color, pattern, luster, paint film, paint material, surface effect, size, packing, etc.

- Further processing: bending, slitting, molding, stamping, printing, etc.

What kind of pre-painted metal materials are you looking for? Leave your request, and get a free quote from Wanzhi Group!