Why Choose PPGI/PPGL for Automotive Parts?

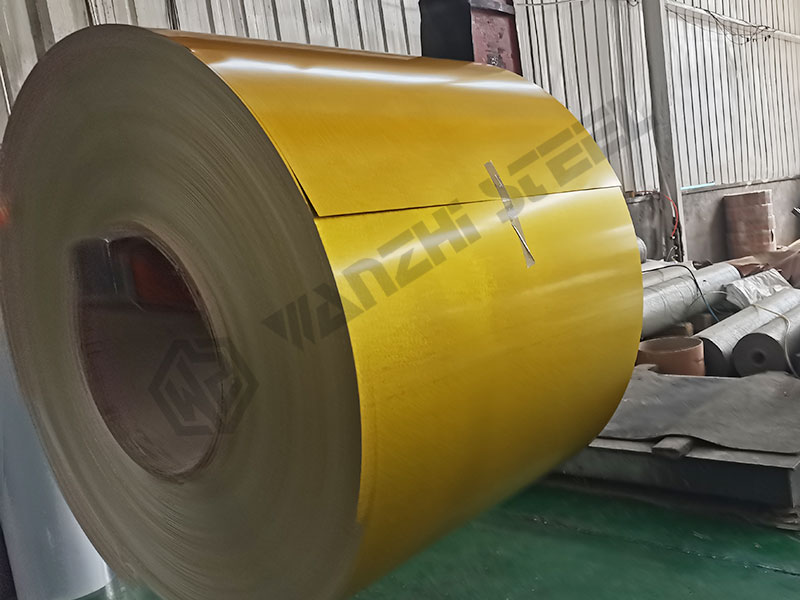

PPGI (Prepainted Galvanized Iron) is a coating material based on galvanized steel that offers the corrosion resistance of galvanized steel, as well as a better appearance and additional surface protection. PPGL (Prepainted Galvalume Steel), on the other hand, is a coating material based on zinc-aluminum-plated steel sheet, which provides better high-temperature resistance and corrosion resistance.PPGI PPGL Prepainted Steel used in automobile manufacturing can reduce the weight of the car, and has zero-rusting effect for more than 10 years.

Environmentally friendly: Hot-dip galvanizing and coating processes do not use hazardous substances, and the steel recycling rate is >90%, which is more friendly to the environment.

Application – Key Automotive Parts Made from PPGI/PPGL

PPGI and PPGL materials excel in areas such as exterior body panels, chassis, interior parts, or battery housings.

PPGI PPGL exterior parts

- Applications: door panels, hoods, roofs, wings, etc.

- Requirements: High weather resistance + color stability

PPGI PPGL Structural Parts

- Applications: chassis supports, seat frames\seat structures

- Requirements: high strength steel substrate (≥340MPa yield strength)

PPGI PPGL Interior Parts

- Applications: instrument panel brackets, door trim panels, mirror housings, window frames

- Requirements: matte texture + scratch resistance

PPGI PPGL Battery System

- Application: Battery pack housing for new energy vehicles

- Requirements: insulation + electrolyte corrosion resistance

PPGI PPGL Exhaust System

- Application: muffler housing, heat shield

- Requirements: high temperature resistance

PPGI PPGL Prepainted Steel for Automotive Parts – Buyer’s Guide

The specification and coating of PPGI PPGL Pre-painted steel affects the material’s performance and application. Selecting the right steel for the application scenario can effectively reduce the cost of ownership.

Coating Selection

The coating of the steel affects its corrosion resistance and the application environment, and the service life of different materials can range from 10 to 30 years.

- PVDF coating PPGI PPGL: High weather resistance, color stability (not easy to fade), chemical resistance.

- SMP/PE coated PPGI PPGL: anti-stoning, cost-effective, abrasion-resistant, heat-resistant, high temperature-resistant.

- HDP coated PPGI PPGL: Weather resistant, scratch resistant, UV resistant, not easy to photolysis and chalking.

Cautions

When selecting PPGI PPGL steel for automotive applications, it is important to pay attention to the strength, weight, ductility, durability, and corrosion resistance of the material to ensure that the selected material meets the production requirements and enhances the performance and longevity of automotive parts.

- Substrate material: SPCC, SGCC, DX51D, DX52D, DX53D

- Standard: GB/T 5224, ASTM A1011, etc.

- Thickness: 0.12-1.5mm

- Coating type and thickness: primer ≥ 5 microns, top coat ≥ 15 microns.

- Paint color and surface treatment: customized color, matte, glossy or metal finish surface, etc.

- Quality control: Coating adhesion test, corrosion resistance test and bending test meet the material standard.

Supplier Selection

When choosing a supplier, you should consider the budget, purchase quantity, customization requirements, and other factors. If customization or wholesale pricing is required, PPGI PPGL factory suppliers are usually chosen.

- Supply: production line, supply quantity, examine the factory’s production technology and product quality.

- Delivery time: production cycle, spot stock, examine the supplier’s ability to supply.

- Certificates: Suppliers must have ISO 9001 and other certificates, request salt spray test report and IATF 16949 certificate.

- Samples: Request samples for testing or small production runs to verify press formability.

If you are looking for a reliable supplier of prepared steel for your project, then Wanzhi Group will be your ideal partner, we have factories and rich experience in exporting, and we have provided many steel solutions for construction and industrial production, contact us for more cases, prices and solutions!