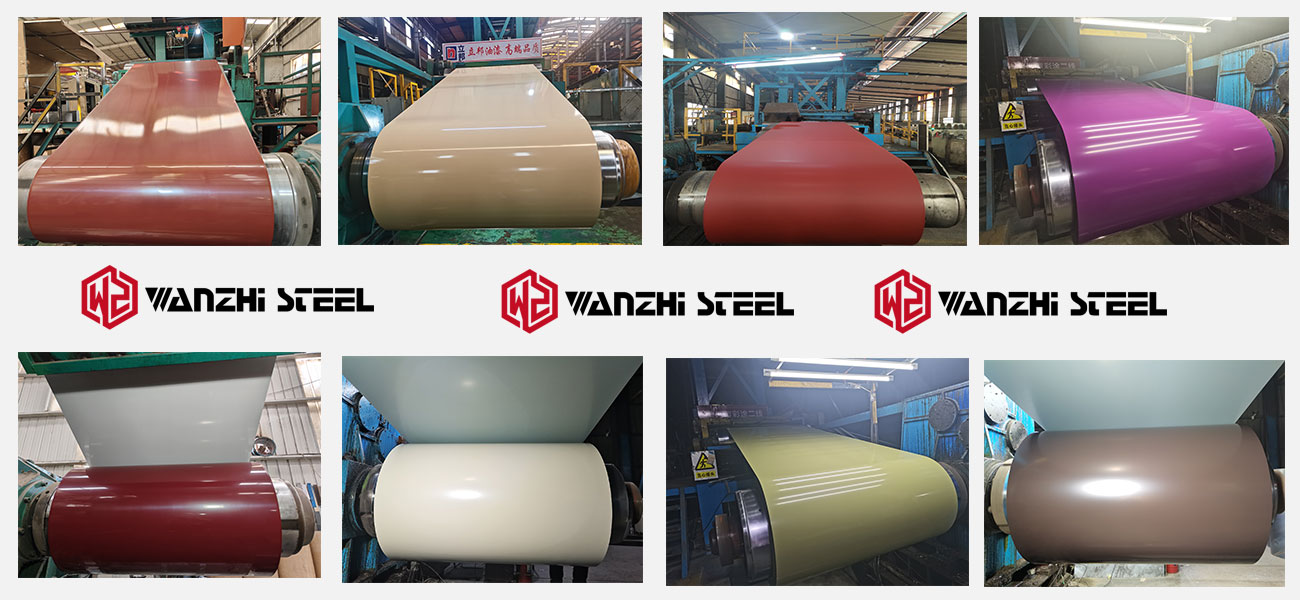

Wanzhi Steel Factory produces PPGI sheets in various grades, materials, and specifications, providing cost-effective prepainted sheet solutions for construction and industrial applications. We also provide various types of premium prepainted galvanized steel coil and sheet customization, including cutting, bending, stamping, punching, forming, painting, and other deep processing services.

What is PPGI Sheet?

PPGI (Pre-Painted Galvanized Iron Sheet) is a composite material made by applying an organic coating to galvanized steel (GI) or aluminized zinc (GL), which combines the corrosion resistance of galvanized steel with the decorative qualities of a coating.PPGI sheet is a sheet that has been coated with paint and then cut according to the requirements of high-quality roofing, appliances, steel structures, piping systems, and other raw materials.

Structure of PPGI Steel Sheets

The structure of a color-coated sheet consists of a substrate, a chemical conversion film, a primer, and a topcoat.

- Substrate: Hot-dip galvanized steel sheet (zinc layer weight 60-275 g/m²) or aluminized zinc sheet (55% Al-Zn alloy).

- Coating: Polyester (PE), Silicon Modified Polyester (SMP), Fluorocarbon (PVDF), etc., thickness 15-25 μm.

Production Process of PPGI Sheet

PPGI is made of hot-dip galvanized steel, with the organic coating applied by rollers.

- Substrate treatment: degreasing, pickling to remove surface impurities, phosphating/passivation to enhance adhesion.

- Coating process: primer (epoxy resin) + top coat (PE/SMP/PVDF) roller coating, baking curing (220-250 ℃).

- Post-treatment: embossing (optional), cooling, winding.

Standard Sizes of PPGI Sheet – Wanzhi

| Grades | GI/GL/SPCC/SPCD/SPCE/DC01-DC07/Q195、Q215、Q235 |

|---|---|

| Colors | Top/Back:RAL,Painted steel,3D Painted steel, etc(can be customized) |

| Thickness | 0.12-1.5 mm |

| Width | 600-1250mm/ customized |

| Coil Weight | 3-6 tons/ customized |

| Substrate Type | Hot dip galvanized, Galvalume, Zinc alloy, Cold rolled steel, Aluminum-zinc plated steel,Zimalium |

| Zinc Coating Thickness | Z30-275g/ ㎡,AZ30-150g/ ㎡ |

| Introduction to Coating | PVDF、HDP、SMP、PE |

| Coating Thickness | Top :10-40 um,Back:5-20 um |

| Inside diameter | 508/610mm |

| Package | Standard export package or as per your requirements |

| Certificates | SGS, ISO 9001,CE |

| Date of Delivery | 5-45 days |

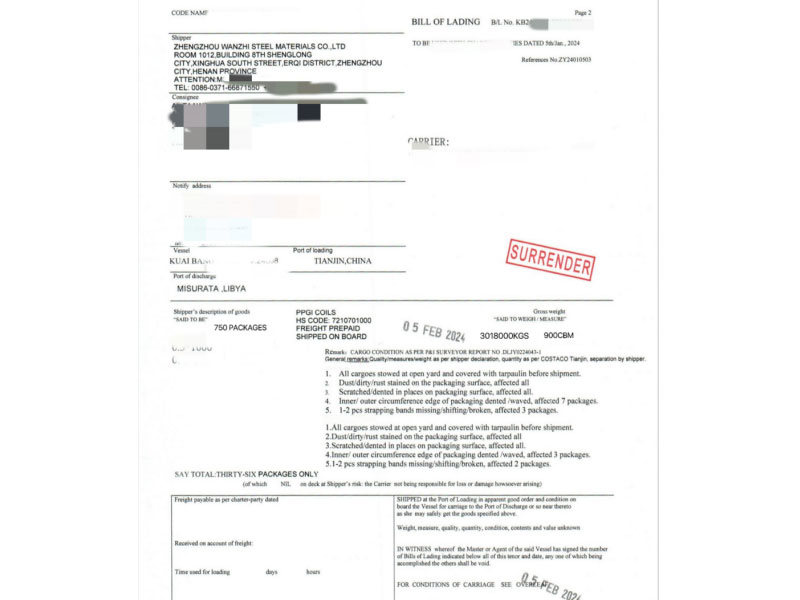

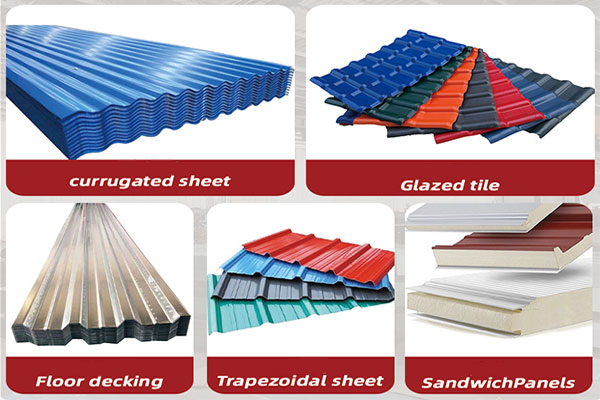

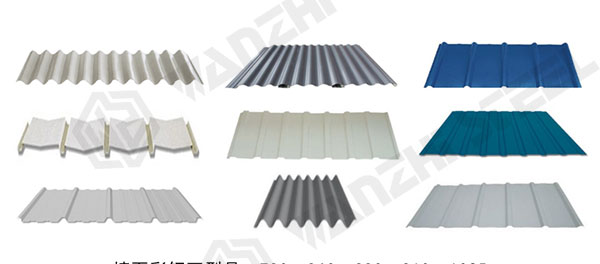

Type of PPGI Prepainted Galvanized Sheet

What types of PPGI sheets are available? Which type is more suitable for your project? Wanzhi Popular sheet types include plain sheets, PPGI corrugated sheets, printed sheets, and PPGI sandwich panels.

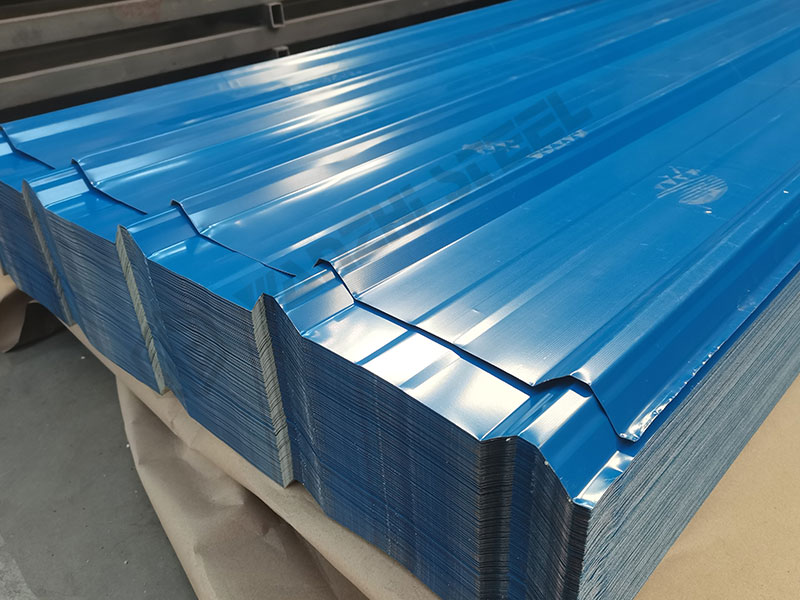

- PPGI corrugated sheet: Commonly used as roofing and wall covering materials, due to the corrugated shape of the sheet’s surface increases its strength and bending resistance, as a building material can enhance the structural strength of the building.

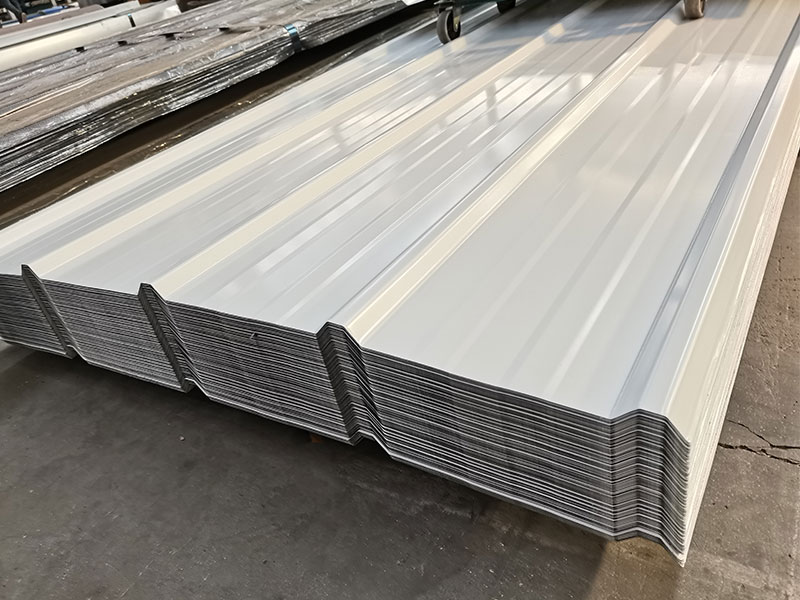

- PPGI plain sheet: Often used for roofing, exterior wall covering, and home appliance production, PPGI plain sheet has a smooth and flat surface, which is aesthetically pleasing and easy to clean in large flat surface applications.

- PPGI patterned sheet: often used for anti-slip and exterior decoration, e.g., floors and stair treads. The dimpled surface of the PPGI steel plate increases the friction and anti-slip effect.

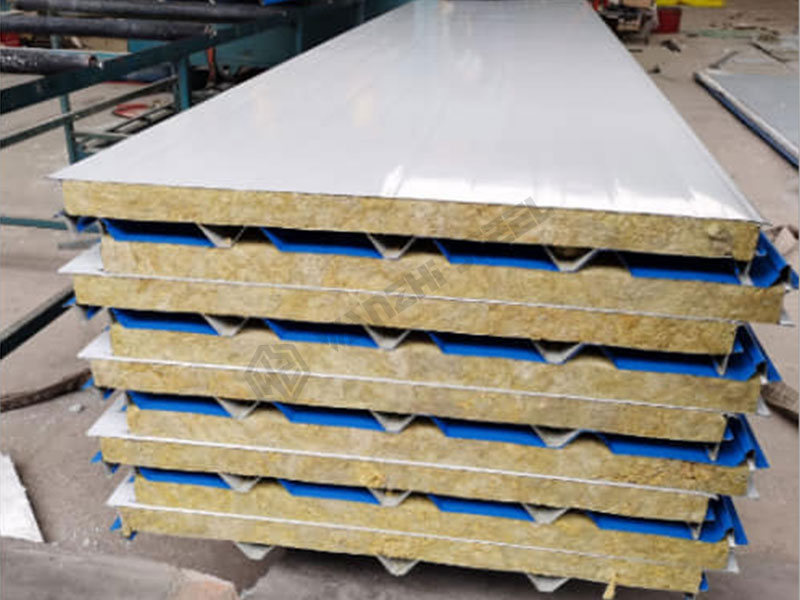

- PPGI sandwich panels: High-quality roofing and partitioning material for buildings, consisting of two color-coated sheets and a core material, which not only looks good but also provides thermal insulation and heat preservation.

What are the Features of PPGI Sheet?

What are the Usages of PPGI Prepainted Galvanized Steel Sheet?

PPGI sheet is widely used in various industries because of its excellent anti-corrosion and mechanical properties, especially in the fields of construction, decoration, home appliance manufacturing, and other fields. It is used in indoor and outdoor decoration of houses, roof and wall construction, and various electrical appliance side panels. PPGI color-coated sheet can be seen in the outer casing and the blackboard used for teaching.

- PPGI Roofing sheet: Roofs of residential and commercial buildings, industrial plants.

- PPGI wall sheet: Building walls, ceilings, suspended ceilings, partitions, etc.

- PPGI home appliance sheets: Refrigerators, washing machines, air conditioners, microwave ovens, televisions, etc.

- PPGI furniture sheets: Bookshelves, shelves, dining tables, etc.

- PPGI solar panels: Solar panel frames, brackets.

- PPGI power cables: Power equipment, brackets, accessories.

- PPGI agricultural sheets: Greenhouses, warehouse sheds, etc.

- PPGI sandwich panels: Firewalls, insulation buildings, sound insulation walls, etc.

Where to Buy PPGI Coil and Sheet?

PPGI steel is mainly produced in the United States, Japan, and China. At present, China’s PPGI sheet production capacity has exceeded 20 million tons per year, China PPGI steel suppliers have advanced production technology, high-quality products, and competitive prices, occupying an important position in the international market.

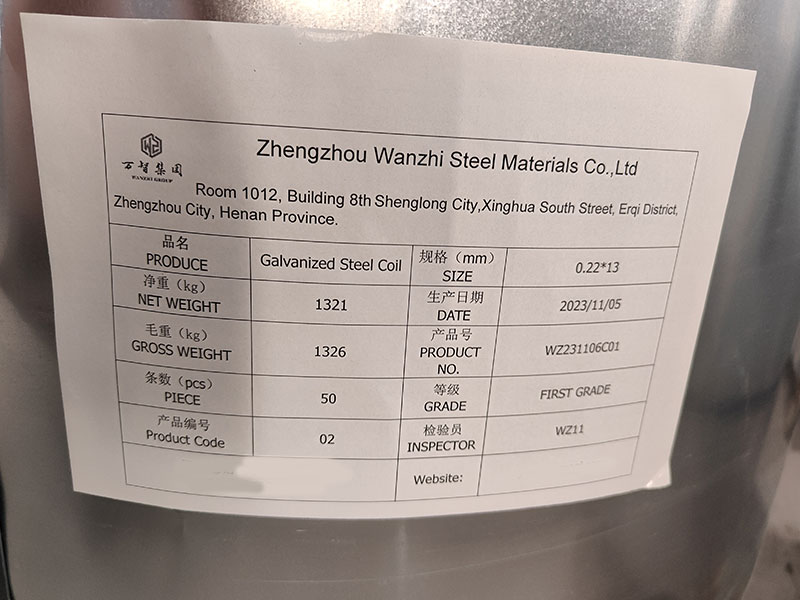

PPGI Steel Sheets Manufacturer – Wanzhi

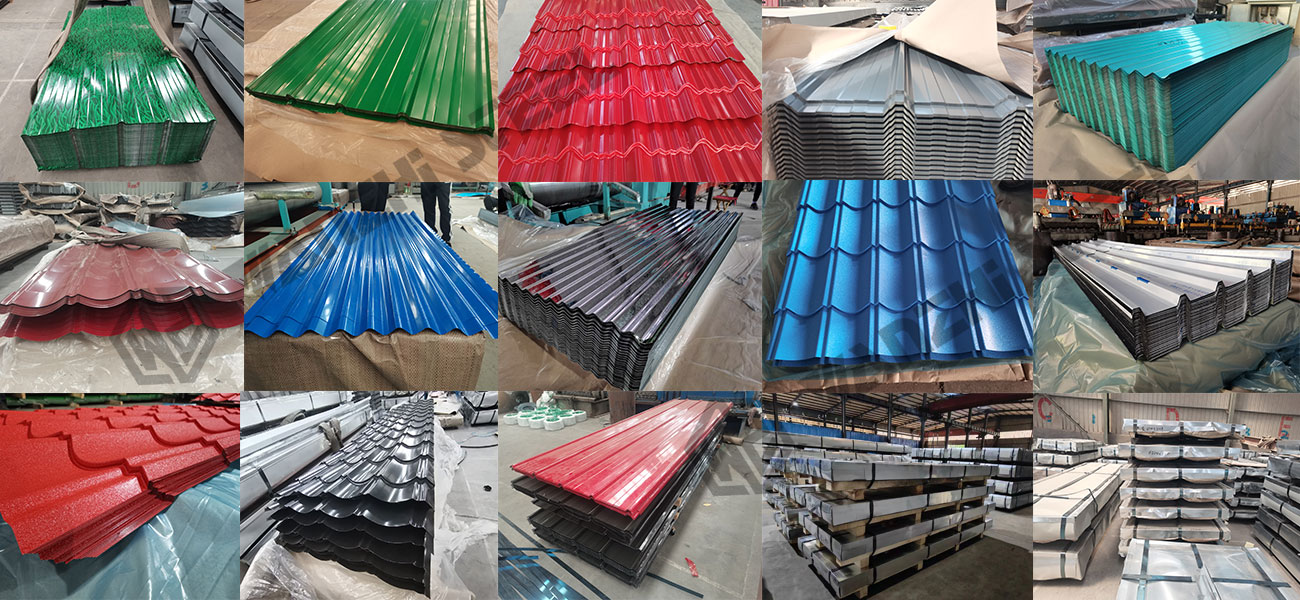

As a professional supplier engaged in the production and sales of color-coated steel sheets for more than 10 years, Wanzhi Group can provide competitive prices and premium color-coated steel sheets with international standard dimensions.

Production Line of PPGI

Packaging and Shipping

Case – Wanzhi Group

OEM/ODM PPGI Sheet

Wanzhi Group offers painted panels for architectural, industrial, and other applications by international standards such as ASTM A755, JIS G3312, EN 10169, etc. In addition, we also offer customized production and solutions. The delivery time is 5–45 days, and we accept SGS, TUV, and other third-party organizations to inspect the goods before shipment. Of course, you are welcome to contact us if you need samples for quality control before cooperation.

Custom PPGI Steel Sheets

PPGI steel sheet consists of two coating layers, galvanized and painted. At Wanzhi, we can customize the thickness of the galvanized coating, the paint material of the paint layer, the thickness of the paint film, the pattern, etc.

Galvanized coating: The thickness of the zinc layer is 40–150 microns. (z30-z350g)

Painted: Primer film thickness 5–20 microns, top coat film thickness 10–40 microns, paint material: PE, SMP, PVDF, HDP, PVC, etc.

Surface: glossy, wrinkled, matte, wood grain, brick pattern, flower, grass, fish, imitation tile.

Plate type: corrugated sheet, trapezoidal sheet, sandwich sheet, etc.

PPGI Prepainted Galvanized Iron Sheets Price

How to get the wholesale price of a PPGI sheet? Before buying, know the thickness, width, color, coating, and quantity of the steel used in your project. Get prices from local suppliers and overseas suppliers to understand the market condition. Currently, the price of galvanized steel is around 600-900 USD per ton, and the price of PPGI steel is around 635-685 USD per ton. You can leave your requirements or project information, and Wanzhi Group can provide you with a free quote.

Comparison with Other Materials

| Comparison | PPGI Sheet | Galvanized sheet | Stainless steel sheet |

| Corrosion resistance | High | Medium | High |

| Cost | Medium | Low | High |

| Decorative | Multi-color optional, the surface can be customized texture | Silver-white zinc flowers, uncoated | Metal original color or brushed effect |

| Scenarios | Architecture, home appliances, decorative fields | Temporary structures, industrial storage | High-end construction, medical equipment |

How to Choose Between PPGI and PPGL Sheets?

PPGI and PPGL sheets are two popular types of painted metal materials. PPGI is economical and practical for general corrosion resistance needs with excellent workability, while PPGL is high-end and weather resistant for harsh environments with long life but higher cost. We can choose the most suitable type of pre-painted steel sheet according to the specific project requirements, environmental conditions, and budget.

PPGI VS PPGL

| Item | PPGI Sheet (Pre-Painted Galvanized Steel Sheet) | PPGL Sheet (Pre-Painted Aluminum Zinc Steel Sheet) |

| Coating | Composition Pure Zinc (Zn) | Aluminum (55%), Zinc (43.4%), Silicon (1.6%) Alloy |

| Corrosion resistance | Sacrificial anode protection of zinc, suitable for general environment | Passivation film of aluminum + sacrificial protection of zinc, better salt spray resistance |

| High temperature resistance | Low, melting point of zinc (419°C), which makes it easy to oxidize at high temperatures | High melting point of aluminum (660°C), suitable for high temperature environments (≤315°C) |

| Processability | Soft zinc plating, excellent stamping and bending performance | Harder zinc plating requires special tools and slightly inferior deep-drawing performance. |

| Heat reflectivity | Low | High |

| Recyclability | Zinc recycling rate of about 95% | The aluminum recycling rate is more than 98%, which is more environmentally friendly. |

Recommendations

Is the environment high humidity/high temperature/high salt spray?

├─ Yes → Select PPGL

└─ No → Is the budget tight?

├─ Yes → Select PPGI

└─ No → Select according to processing complexity (PPGI or PPGL)