Wanzhi Group – Your Trusted Partner for Printed PPGI Steel! We offer customised services for printed PPGI coils and sheets, featuring excellent visual appeal, high pattern flexibility, and a smooth, easy-to-clean surface, tailored for applications in wall cladding, decorative panels, home appliances, furniture, and more.

Printed PPGI Steel Customisation

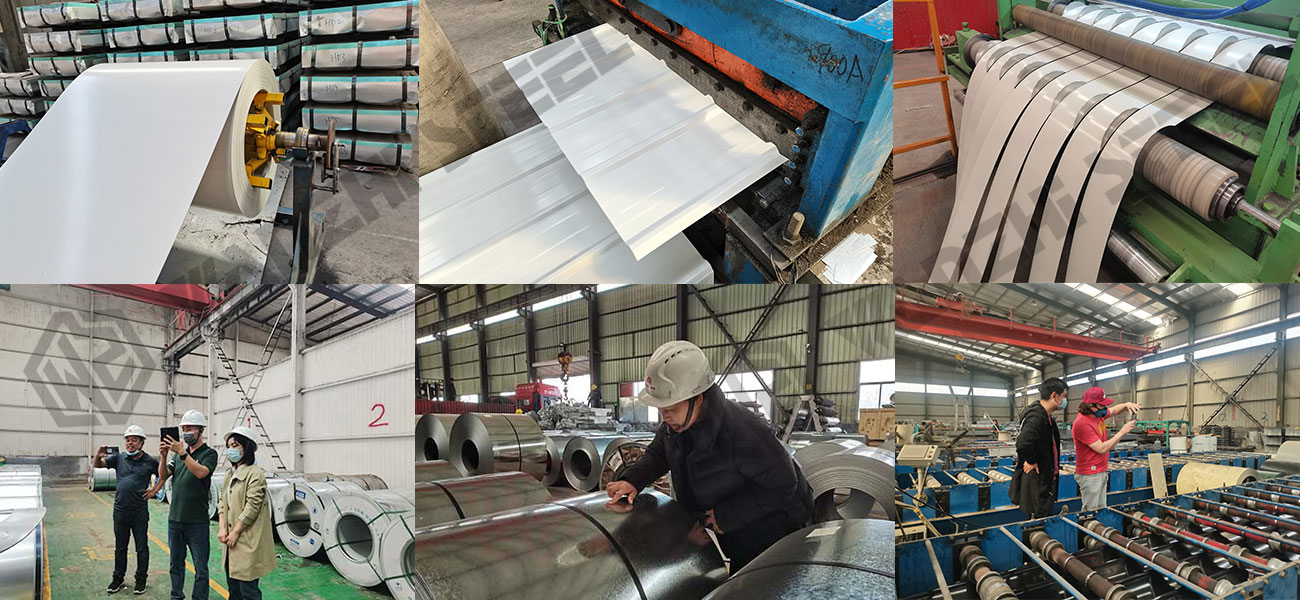

Wanzhi Group provides PPGI OEM ODM services. We use high-precision roller coating technology and premium galvanized steel or galvalume steel produced in our factory as the substrate to ensure that the steel has good corrosion resistance and that the surface patterns are clear, the colours are rich, and the adhesion is strong.

Pattern Selection

Marble Texture: Marble, granite, or slate cracks and granular texture / concrete texture / Carrara white / deep brown net cracks

Wood Texture Series: Oak / walnut / bamboo texture / smoked oak / walnut growth rings

Geometric Art: Memphis-style colour blocks / fluid gradients

Cultural Elements: Dunhuang Flying Apsaras Pattern/Islamic Geometric Tiling/Forbidden City Patterns

Antique: Copper Patina/Rust Oxidation Effect/Fabric Texture

Plants: Plant Vines, Flowers, Baroque Scrollwork, Tropical Leaves

Special Patterns: Corporate Logo, Gradient Blending, Architectural Projection Real-Scene Transfer

Coating Options

PE (Polyester): Rich colours, cost-effective.

SMP (Silicone-Modified Polyester): Excellent heat resistance (>120°C), good colour retention.

PVDF (Fluorocarbon): Ultra-weather resistant, self-cleaning, corrosion-resistant, premium choice.

HDP (High-Performance Polyester): Balanced cost-effectiveness and performance, scratch-resistant.

PU (Polyurethane): High elasticity, wear-resistant, low-temperature resistant (-40°C).

Colour and Surface

Wanzhi Group PPGI Steel colours are primarily matched according to the RAL colour chart, and can also be customised based on customer-provided samples. In addition to colour, our printed PPGI steel surfaces can be specified with various finishes such as matte, glossy, and textured.

Advantages and Applications of Printed PPGI Steel

Printed PPGI Steel combines the mechanical properties of cold-rolled steel, the corrosion resistance of the coating, the weather resistance and heat resistance of organic coatings, and the decorative properties of printed patterns. It supports customised patterns and is suitable for a wide range of applications, from interior decoration to outdoor construction.

Advantages

- Decorative: High-definition images, complex patterns, flexible colours, and high realism (wood, stone, fabric, metal brushing),

- Weather resistance: Functional coatings provide high-temperature resistance, UV resistance, and other functions.

- Processability: Printed PPGI coils and sheets support continuous stamping and roll forming.

- Post-processing compatibility: Can undergo secondary processing such as lamination and adhesive application.

- Cost-effectiveness:

- Low moulding costs: The cost of gravure/flexographic printing cylinders is spread across large-scale production, resulting in a lower cost per tonne compared to embossing (especially for complex patterns).

- Material savings: Can replace natural wood/stone, reducing raw material and transportation costs.

- Easy maintenance: Smooth and flat surface, stains do not linger, and easy to wipe clean.

Application scenarios

Construction field:

- Exterior wall decoration: Imitation natural stone, wood grain, and artistic patterns for the exterior walls and curtain walls of commercial centres or hotels.

- Interior walls: Elevator cabins, background walls, partitions, interior ceilings, door panels, etc. in public spaces such as hotels and shopping malls.

- Brand commercial spaces: Customised brand patterns for shopfronts, interior decoration, advertising signs, etc.

- Refrigerator, oven, range hood, washing machine, and other appliance shells feature imitation metal brushed finishes, solid matte colours, micro-textures, or artistic patterns, combining aesthetics with fingerprint resistance and scratch resistance.

Appliance Industry:

- Shell decoration: imitation metal brushed finishes, solid matte colours, micro-textures, or artistic patterns for refrigerators and washing machines.

Furniture Manufacturing:

- Cabinet bodies/door panels: Wood grain printed panels (e.g., dark wood grain) replace solid wood for kitchen cabinets, wardrobes, and office furniture panels.

- Desktops/countertops: Marble grain printed panels are used for office desks and coffee tables.

Transportation Equipment:

- Train interiors: Wood grain printed panels are used for high-speed rail and metro seat back panels, etc.

Printed PPGI Steel Process

Printed PPGI Steel achieves high-fidelity patterns through chemical printing. The process can be divided into several stages: galvanised steel treatment, coating, printing, and post-treatment. (Each stage can be adjusted to produce unique color-coated steel.)

- Pre-treatment: Galvanised steel is cleaned and passivated to enhance coating adhesion and corrosion resistance.

- Coating system: Primer (epoxy resin, 5–20 μm) + topcoat (polyester/high-weatherability polyester/fluorocarbon, 10–40 μm), providing basic corrosion protection and weather resistance.

- Printing process: A copper roller engraved with a pattern transfers ink onto the coating surface.

- Post-processing: After printing, the material undergoes hot air/UV curing to ensure complete adhesion between the ink and coating.

- Coiling: After production and quality inspection, the material is coiled into rolls for storage.

Why Choose Wanzhi Group Printed PPGI Steel?

If you need premium PPGI steel, diverse customisation options, competitive pricing, a one-stop solution, and free samples, then Wanzhi Group is your ideal partner!

- Advanced Manufacturing: The Shandong Boxing factory is equipped with professional GI and PPGI production lines and printing equipment, and is certified to ISO 9001/14001/45001 standards.

- Professional Customisation: From the base material of printed PPGI steel, specifications (thickness 0.12–1.5 mm, width 600–1,250 mm), coating type/thickness to your customised pattern design, we offer a one-stop customisation service.

- Strict Quality Control: We maintain rigorous quality control throughout the entire process, including cleaning, passivation, primer coating, top coating, printing, curing, and quality inspection, to ensure that the coating adhesion, colour difference, and weather resistance meet standards.

- Global Service: Our products are exported to over 100 countries and regions worldwide. We offer free samples, third-party testing support, and OEM/ODM services.

Printed PPGI vs. Solid-Colour PPGI

| Comparison | Printed PPGI | Plain/Solid Color PPGI |

| Appearance | Can display any high-definition image such as wood grain, stone texture, geometric patterns, natural landscapes, etc. | Surface is a single, uniform color like white-gray, porcelain blue, or crimson. |

| Process | More complex: After the standard coating process, an additional printing roller coating step transfers the pattern onto the coating. | Standard process: After cleaning, passivation, primer and topcoat application, and baking, it becomes a finished product. |

| Customization | Almost unlimited patterns and color combinations | Color and gloss options (high gloss, matte, satin, etc.) |

| Cost | Higher | Lower |

| Cleaning & Maintenance | Moderate | Very easy |

| Applications | – Architecture: High-end commercial curtain walls, indoor decorative walls, brand store decorations.

– Appliances: High-end appliance panels. – Furniture: Alternative to real wood veneer or stone. |

– Architecture: Industrial factory roofs/walls, warehouse logistics centers, simple mobile homes.

– Appliance interiors. – General: Any scenario needing corrosion protection with low aesthetic requirements. |

Printed PPGI steel, wood grain, brick pattern, metal pattern, etc. Pre-painted steel factory supplier. Contact us for a quote on your desired steel!