PPGI Steel Sheet (Pre-Painted Galvanized Iron), also known as pre-painted galvanized steel sheet, is available in various forms, including flat, corrugated, trapezoidal, and ribbed steel. It is a composite material made from galvanized steel sheet, which undergoes surface pretreatment, is coated with multiple layers of organic coatings, and then cured by baking. It offers excellent strength, corrosion resistance, a variety of colors, and weather resistance, making it a high-performance material widely used in construction, home appliances, industry, and transportation.

PPGI Steel Sheet – Specifications

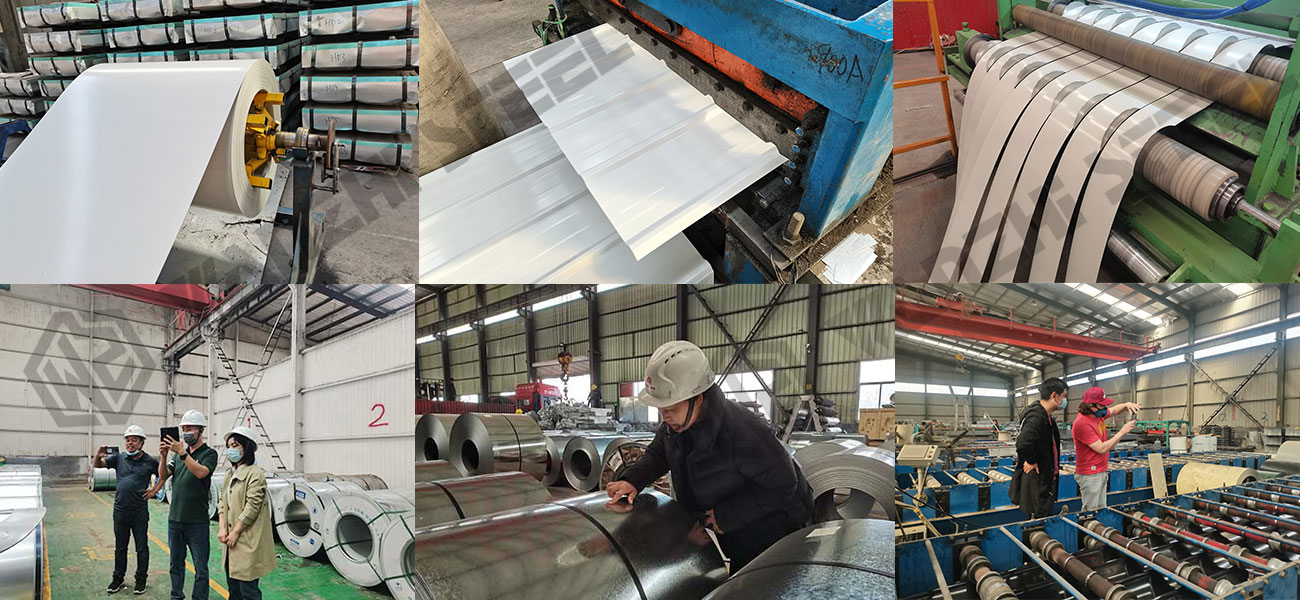

Wanzhi Group, a leading coated steel manufacturer in China, produces and exports a wide range of PPGI steel sheets. We offer a comprehensive range of specifications and support customization. We also provide free samples and material certificates to meet diverse application needs.

| Substrate Material | Low Carbon Steel, High Strength Low Alloy Steel, etc. |

| Standard Thickness | 0.12mm – 1.5mm (customizable for thicker specifications) |

| Common Width | 600mm – 1250mm (standard coil width) |

| Coating System | One layer of primer on the front + two layers of topcoat on both sides, one layer of back coat (adjustable based on requirements) |

| Coating Types | Polyester (PE), Silicon-modified Polyester (SMP), High Durability Polyvinylidene Fluoride (PVDF), etc. |

| Color Options | Standard color chart available, also supports Pantone, RAL, and other custom color options |

| Standards | Complies with GB/T, ASTM A755, EN 10169, and other international standards |

| Packaging | Standard international export packaging (moisture-proof paper, plastic film, steel banding, wooden pallet optional) |

| Minimum Order Quantity | 10 tons |

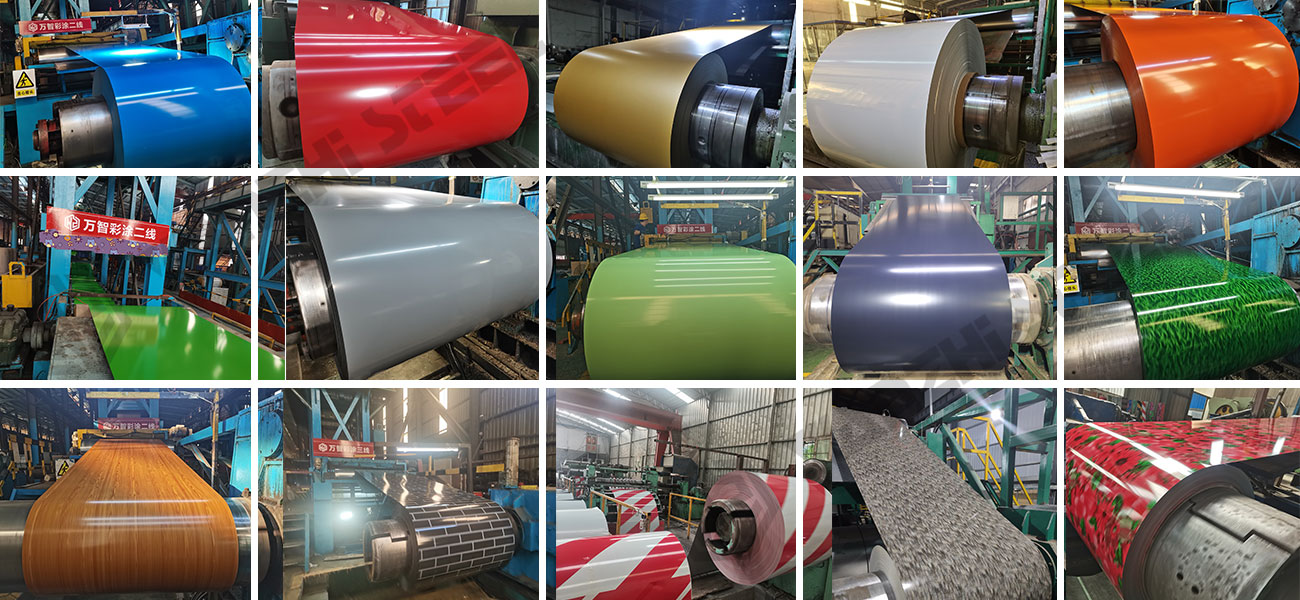

PPGI Steel Sheet – Product Types

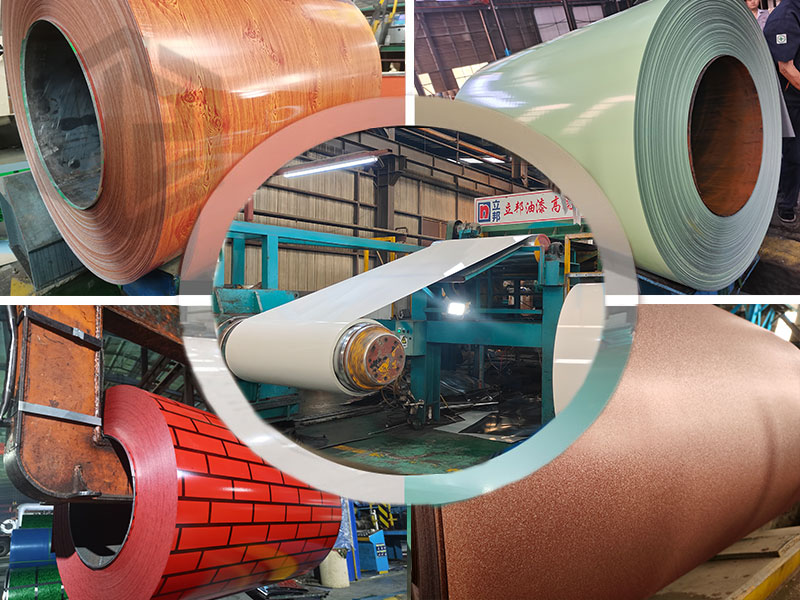

We offer PPGI steel sheets in a variety of finishes and appearances, including solid colors, prints, textures, and varying gloss levels to suit diverse visual and functional needs.

- Solid Color Panels: Based on the RAL color palette, over hundreds of colors are available.

- Printed Panels: Customizable patterns include wood grain, brick patterns, natural landscapes, and cultural landscapes.

- High Gloss Panels: Smooth surface, vibrant colors, and high reflectivity.

- Matt Panels: Understated, soft, and scratch-resistant.

- Textured Panels: Imitation wood, stone, and leather grains enhance aesthetics and feel.

- Embossed Panels: Surfaces feature a three-dimensional pattern.

PPGI Steel Sheet – Coil Sheet

PPGI coil sheet forms the foundation for all subsequent PPGI plain sheet and formed products. We offer heavy-duty, PPGI coil, providing the most efficient raw material for high-volume production and continuous processing.

- Product Features: Easy to store and transport, suitable for automated continuous production lines, and suitable for roll forming, slitting, and other processes.

- Main Applications: As raw material, we supply to large-scale engineering projects, corrugated sheet manufacturers, and home appliance manufacturers.

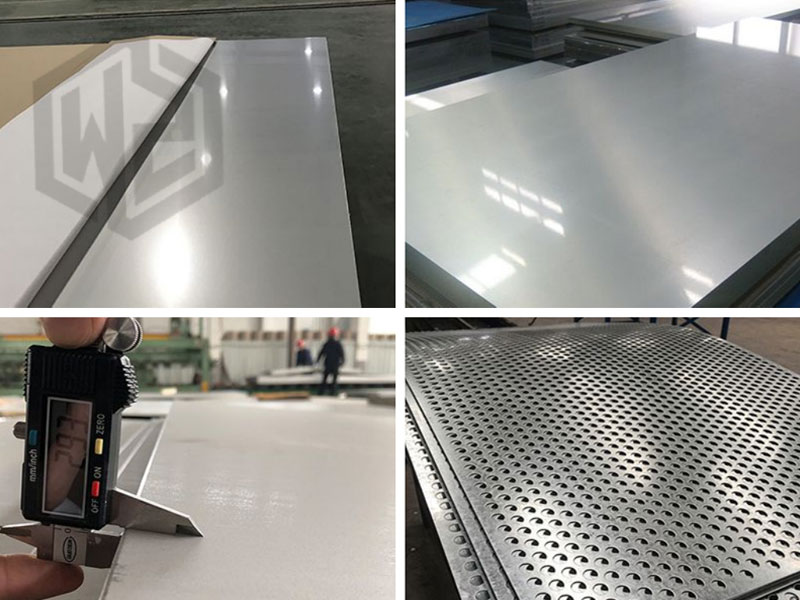

PPGI Steel Sheet – Plain Sheet

PPGI plain sheet is made from PPGI coils that are flattened and cut to size. It features precise dimensions and a smooth surface, making it ready for processing or installation. Custom lengths can also be cut.

- Product Features: Dimensionally stable, easy to cut, with a uniform and vibrant surface color, ready for immediate use.

- Main Applications: Appliance housings (such as refrigerator and washing machine panels), office furniture, electrical enclosures, and interior decorative partitions.

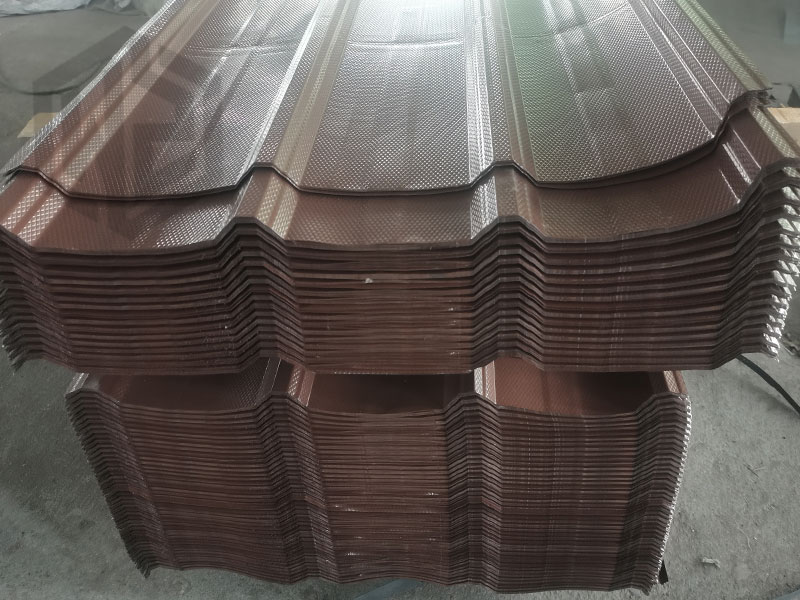

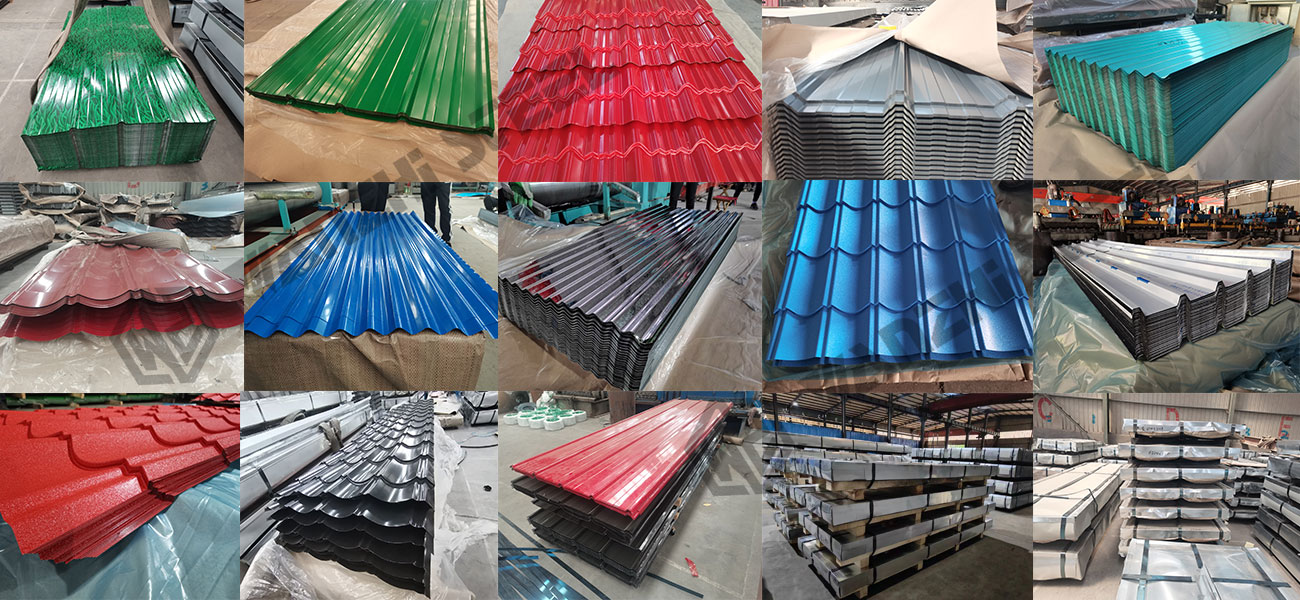

PPGI Steel Sheet – Profiled Sheet

Leveraging PPGI steel’s excellent formability, we use advanced roll-forming equipment to process PPGI steel sheet into a variety of structural sheet shapes to meet the specific needs of building envelope systems.

- PPGI Corrugated Sheet/Wave Sheet: Features a classic wave-shaped design and excellent drainage.

- Concealed Gusset: Provides a clean, modern appearance with concealed fasteners.

- PPGI Decking: Also known as composite slabs, these serve as permanent formwork in steel structures, working in conjunction with concrete to bear loads.

PPGI Steel Sheet – Stamping/Punching Sheets

Wanzhi Group also provides PPGI steel sheet stamping and punching services, perfectly combining functionality and decorative features.

- Punching Sheets: We can process a variety of hole shapes and patterns, including round, square, hexagonal, and plum blossom holes, providing excellent air permeability, light transmission, filtration, and decorative effects.

- Stamping Sheets: We use molds to stamp out three-dimensional textures such as simulated wood grain, diamonds, and dots, enhancing visual appeal and scratch resistance.

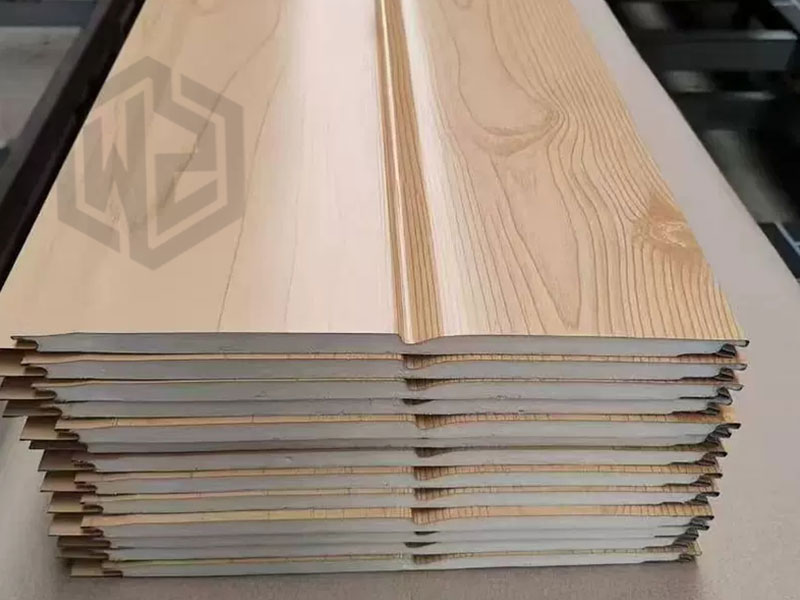

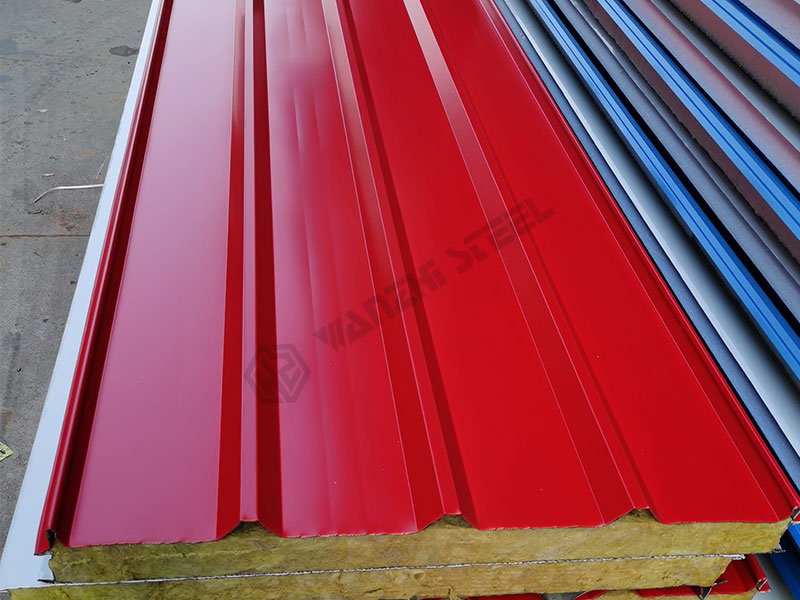

PPGI Steel Sheet – Sandwich Panels

PPGI sandwich panels are highly efficient and energy-saving building materials made by combining PPGI steel sheets with core materials. They offer multiple functions, including thermal insulation, heat insulation, and sound insulation.

- Product Structure: The upper and lower panels are PPGI color-coated steel sheets (flat, corrugated, or trapezoidal), with a core material such as polystyrene (EPS), rock wool, or polyurethane (PU) filling the middle.

- Features: Lightweight, high strength, excellent thermal and sound insulation, quick installation, and an aesthetically pleasing overall appearance.

PPGI Steel Sheet – Customization

Wanzhi Group boasts strong production capabilities and a strong technical team, offering a comprehensive range of PPGI customization services, with delivery within 5-45 business days. You can select specifications, paint, film finish, surface treatment, and surface structure based on your project needs.

Factory

Our color coating factory is located in Boxing County, Binzhou City, Shandong Province, China. It houses both galvanized steel and color coating lines. ISO-certified, we accept third-party quality inspections such as SGS and BV, and we can provide free samples.

OEM/ODM Services

- Custom Sizes: We offer custom thicknesses, widths, and cut-to-length options to meet specific project requirements.

- Coating and Color Customization:

- Coating Types: We recommend PE, SMP, PVDF, and other coatings depending on the application environment.

- Color and Gloss: We offer Pantone and RAL color palettes, and can customize gloss levels, including high gloss and matte.

- Performance Customization: We offer substrates with varying strength and corrosion resistance levels.

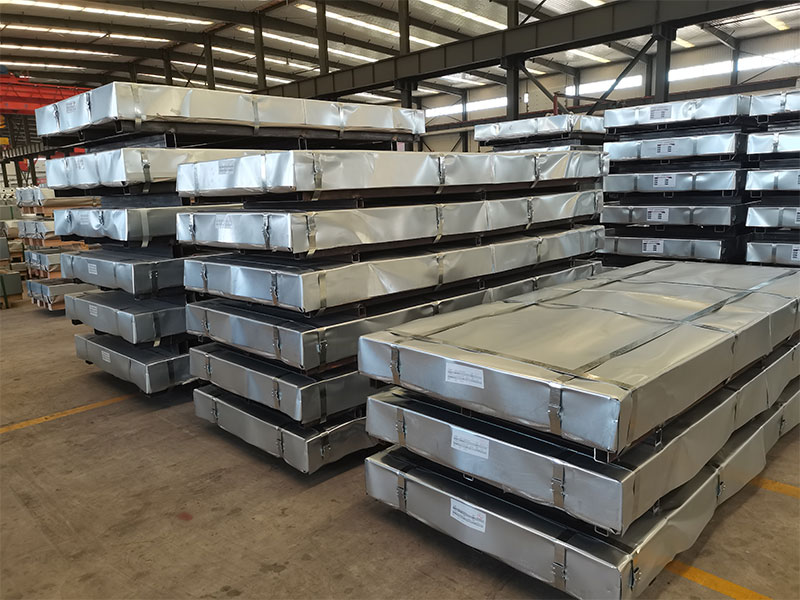

Packaging

To prevent PPGI steel sheet from damage due to scratches, moisture, and rust during long-distance transportation (land and sea) and storage, we use tight, moisture-proof packaging, including plastic film, moisture-proof paper, galvanized iron sheets, steel strapping, and wooden pallets.

Quality Inspection

- Coating properties: including color difference, gloss, film thickness, adhesion (cross-cut test), and hardness (pencil hardness).

- Weathering tests: UV aging test, salt spray test, and damp heat test.

- Mechanical properties: Bend test and impact test to ensure the coating does not crack or peel.

PPGI steel sheet (pre-coated color steel coil) is a construction and industrial material that combines aesthetics, corrosion resistance, and ease of processing. It plays an important role in roofing, wall cladding, awnings, partitions, home appliances, vehicle interiors, partitions, container housing, ceilings, countertops, display racks, and other applications. Leave a message to tell Wanzhi Group the type of sheet material you need or the application you need to get a free quote!