PPGI and PPGL are two popular pre-painted galvanized steel sheets used in a wide range of applications in the construction, appliance, and automotive industries. The main objective of choosing a PPGI PPGL solution for a project is to find a balance between corrosion risk, processing requirements, and budgetary constraints to reduce project costs. We’ve compiled data on galvanizing composition, structure, and performance to help you buy the right color-coated metal.

Comparison of PPGI and PPGL Galvanizing Composition and Structure

PPGI and PPGL are made up of a coating + chemical conversion film + primer + topcoat, in which zinc acts as a preferential corrosion protection for the substrate (sacrificial anode effect) in the damaged areas of the coating, while aluminum acts as a dense oxide film (Al₂O₃) to protect the substrate from water and oxygen.

| Parameters | PPGI | PPGL |

| Composition | Zn≥99% | 55%Al, 43.4%Zn, 1.6%Si |

| Structure | Uniform zinc layer | Multilayer composite (zinc-aluminum alloy) |

| Weight | z30-z275g/m² | az30-az275g/m² |

Comparison of PPGI PPGL Properties

PPGI and PPGL are mainly used for building roofs, walls, doors, windows, ceilings, suspended ceilings, fences, industrial chimney linings, oven housings, solar backsheets, etc., in inland dry climates/industrial acid rain zones/coastal areas with high humidity and salt. A performance analysis will allow you to select the best prepainted steel material for your project.

| Properties | PPGI | PPGL |

| Corrosion resistance (ASTM B117) | 3-20 years | 8-25 years |

| High temperature resistance | ≤120℃ | ≤315℃ |

| Elongation(ASTM E8) | ≥18% | ≥12% |

| Arc welding spatter rate | high | low |

| Laser welding compatibility | poor | excellent |

| Coating adhesion | grade 0 | grade 1 |

| Long-term cost | high | low |

| Carbon emissions | 1.8-2.2CO₂ | 1.2-1.5CO₂/ton |

| Recycling rate | low | high |

PPGI PPGL Buying Advice

PPGI and PPGL are both high-quality building materials and are two popular types of prepared steel. According to the environmental corrosion class Wanzhi suggests PPGI for corrosion class C3 and below, and PPGL for C3/C4 and above; according to the environmental stability suggests PPGL steel for applications where the ambient temperature exceeds 80℃ continuously; according to the application suggests PPGI materials for roofing panels and other applications that require deep drawing/multiple bending. Of course, if the project budget is limited or if the project is short-term, PPGI steel is the best choice.

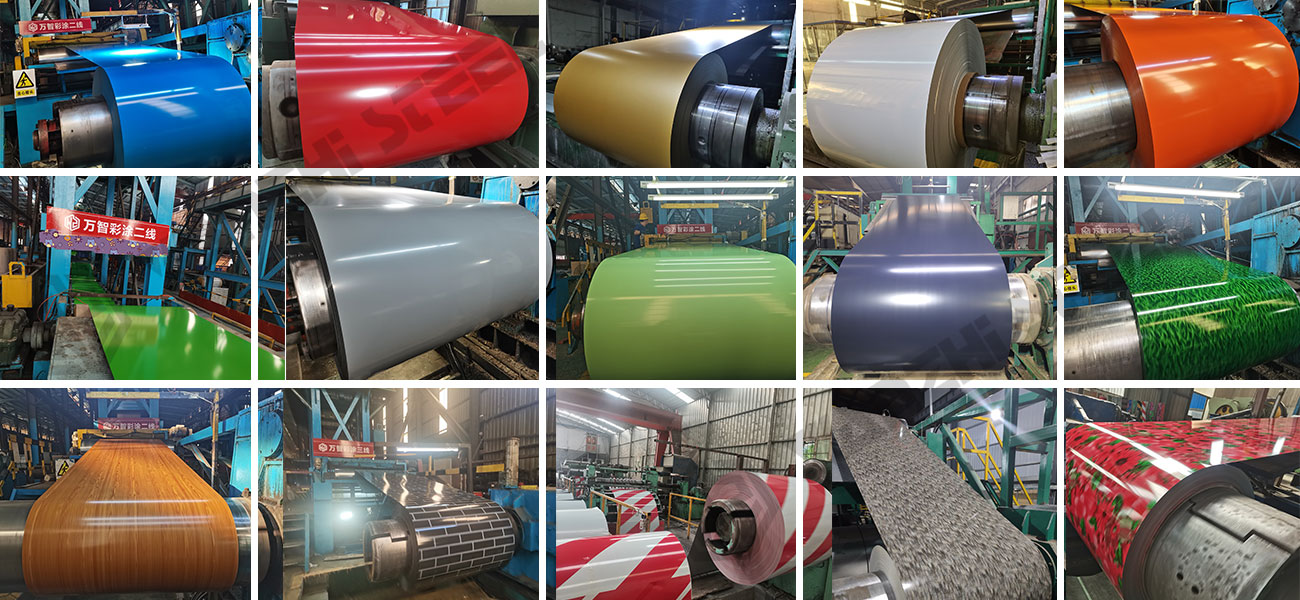

Wanzhi PPGI PPGL Solutions

So far, Wanzhi Group has provided PPGI PPGL solutions for hotel and commercial building roofs/exterior walls, factory floor partitions, airport suspended ceilings, photovoltaic power plant racking systems, and greenhouse roofs and steel structures. We can produce PPGL in different sizes, thicknesses, coatings, and finishes according to project requirements, as well as provide design and production services according to the application. If you need to purchase premium PPGI PPGL steel, please contact us!