Wood Grain Aluminum Coil, a premium decorative metal material widely used across multiple fields including construction, furniture, home appliances, and interior decoration. Combining the lightweight, corrosion-resistant, and easy-to-process properties of aluminum alloy with the decorative effect and texture of natural wood, it is one of the popular wood grain coil series.

Wood Grain Aluminum Coil – for Sale

Wanzhi Group wood grain aluminum coils offer a wide variety of wood grain patterns, substrate options, and functional coatings. You may select the wood grain style and specifications that meet your requirements from our catalog, or email us the images of the patterns you need, and we will customize them according to your specifications.

Wood Grain Patterns

| Style | Pattern | Characteristics |

| Classic Natural Style | Oak grain, Walnut grain, Teak grain | Realistic texture, restoring the natural wood texture, versatile. |

| Rugged Primitive Style | Pine grain (with knots), Fir grain | Clear texture, with natural nodes and rugged texture. |

| Distressed Retro Style | Distressed Ash, Weathered Elm grain | Color is faded, with a worn and weathered look. |

| Modern Fashion Style | Brushed wood grain, Smoked wood grain, Mixed-color wood grain | Superimposed with processes such as brushing and dark dyeing on the basis of wood grain. |

| 3D Three-Dimensional Style | 3D relief oak, Hand-scraped grain | The surface has a concave-convex touch and a strong three-dimensional effect. |

Functional Features

Antibacterial Wood-Grain Aluminum Coil: Surface coating incorporates antibacterial agents, ideal for high-hygiene settings such as hospitals, schools, and kitchens.

Fire-Resistant Wood-Grain Aluminum Coil: Base material or coating meets specific fire-resistance ratings (e.g., Class A), used in public buildings with fire safety requirements.

Base Material

Series 3 Aluminum-Manganese Alloy Coil (e.g., 3003, 3005): Most commonly used aluminum substrate. Manganese addition enhances rust resistance and strength over Series 1.

5 Series Aluminum-Magnesium Alloy Coil (e.g., 5005): Incorporates magnesium for higher strength, good corrosion resistance, and excellent formability.

Wood Grain Aluminum Coil Processing Techniques

Pre-painted Coil: One of Wanzhi Group’s standard processes, applying wood grain patterns directly via high-definition roller coating printing technology.

Laminated/Film VCM Sheet: Another common process, achieving wood grain effects through film lamination. Film quality determines durability.

Wood Grain Heat Transfer Printed Aluminum Coil: A premium process transferring wood grain from transfer film onto aluminum substrate via heat transfer technology, ensuring lasting texture.

Wood Grain Printed Anodized Aluminum Coil: First anodized to create a protective layer, then printed with wood grain. High-grade with excellent weather resistance, but costly. (Less commonly used)

Applications and Advantages

Wanzhi Group’s wood grain aluminum coils feature strong adhesion, high realism, lightweight properties, corrosion resistance, and stable processing performance. They can replace premium natural wood in architectural decoration, furniture and appliance manufacturing, transportation, and other sectors while offering more competitive pricing.

Architectural Decoration: Exterior wall panels, ceiling tiles, door/window frames, curtain walls, partition walls, decorative moldings, canopies, column cladding, etc.

Furniture Manufacturing: Cabinet doors, wardrobe panels, table/chair frames, shelving units, kitchenware, etc.

Home Appliance Industry: Outer casings for refrigerators, washing machines, air conditioners, and decorative linings for microwave ovens and ovens.

Other Fields: Automotive interiors, marine decorative panels, public transportation cabin interiors; brand boutiques, exhibition halls, and other decorative settings; chemical processing equipment, etc.

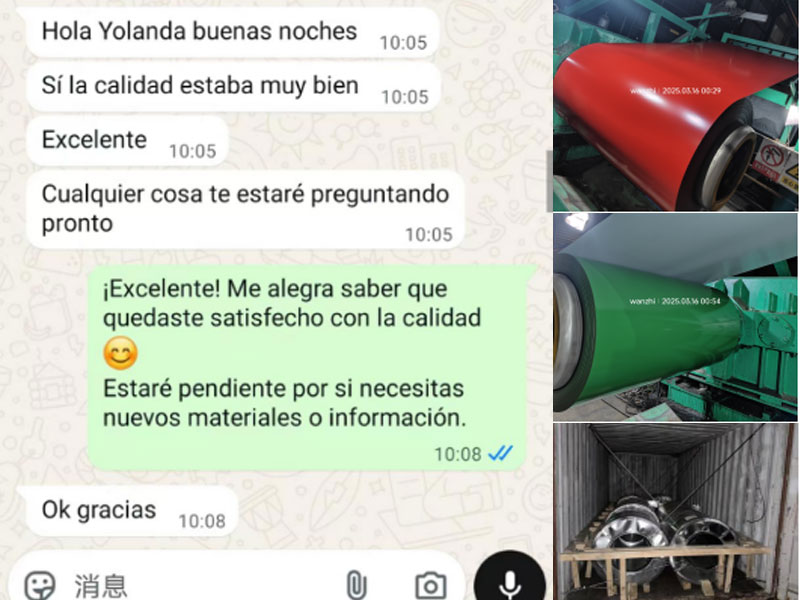

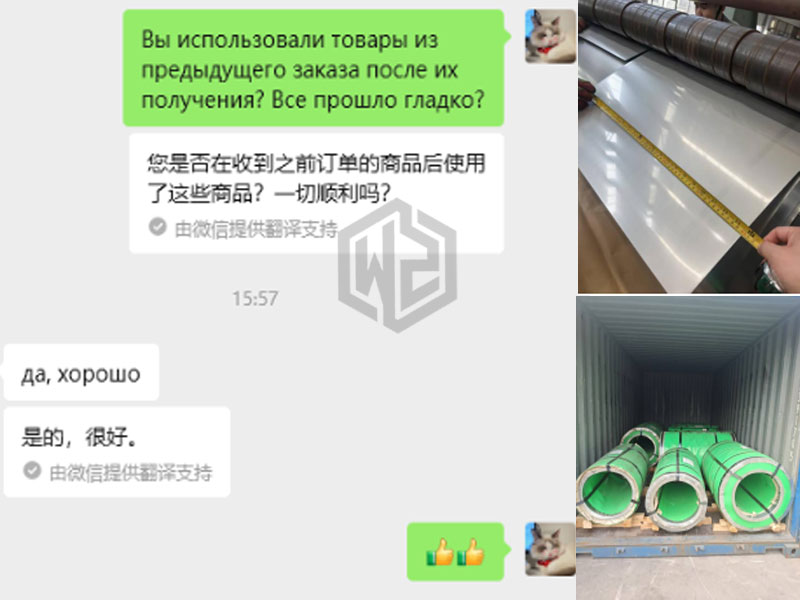

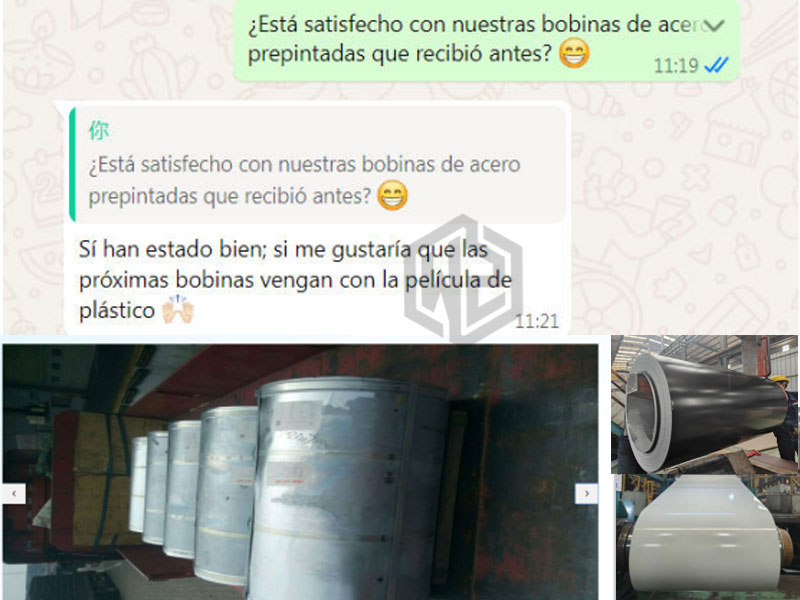

Factory and Case Studies – Wanzhi Group

Wanzhi Group is a manufacturer specializing in the production and sales of wood grain aluminum coils. The factory is equipped with advanced production lines and testing equipment, covering the entire production process from substrate selection and surface treatment to pattern processing. We strictly adhere to international quality standards, with products certified under the ISO9001 Quality Management System and ISO14001 Environmental Management System, ensuring consistent and reliable product quality.

Wood Grain Aluminum Coil Factory

Wanzhi Steel Factory boasts ample production capacity, with a monthly output of 10,000 tons prepainted aluminum. We flexibly accommodate orders of varying batch sizes, ensuring timely delivery within 5-45 business days. Additionally, we offer customized services, adjusting substrate material, thickness, width, wood grain patterns, and production processes according to specific client requirements.

Success Projects

With high-quality products and professional services, our Wood Grain Aluminum Coil has been exported to over 100 countries and regions worldwide. We have accumulated numerous successful applications in high-end residential projects, premium furniture, and appliance casing production, earning widespread recognition and trust from our customers.

If you’re seeking a high-quality decorative material that combines performance with aesthetics, Wanzhi Group‘s Wood Grain Aluminum Coil is your ideal choice. Contact us anytime to obtain detailed technical specifications, product samples, and a customized quote!